Laser beam machining, or what is laser beam machining, is different from CNC milling. It uses a strong laser to cut things very accurately. When you learn about what is laser beam machining, you see it makes smooth edges. It works well on thin materials and tricky shapes. This is important in factories. You have to pick the best way to make your parts. What is laser beam machining is particularly good for detailed designs. CNC milling is better for making lots of things and many shapes. Think about how exact you need to be, what materials you use, how fast you need it, and the price before you choose.

| Machining Process | Key Features | Suitable Applications |

|---|---|---|

| Laser Beam Machining | Very accurate, little heat damage, cuts tricky shapes | Thin materials, detailed designs |

| CNC Milling | Can do many jobs, saves money for big orders | Many shapes, making lots of parts |

Key Takeaways

- Laser beam machining uses a strong laser to cut things. It does not touch the material. This makes the edges smooth and very exact.

- CNC milling uses a tool that cuts by touching the material. It works well for thick parts and tricky shapes.

- Pick laser beam machining for small details and thin pieces. CNC milling is better for big and strong parts.

- Laser cutting is quicker and makes less waste. This helps save time and materials when making things.

- CNC milling can work with many materials. But it needs more care and skilled workers.

- Think about how exact you need your project to be. Also, think about what materials you use and how much you need to make.

- You can use both methods together for the best results. This way, you get the good parts of each process.

- Laser beam machining costs more at first. But it can cost less to run over time.

Table of Contents

What Is Laser Beam Machining

Process Overview

To learn about what is laser beam machining, start with the basics. This process uses a strong beam of light. The beam puts energy on a tiny spot. The laser heats the material very fast. The heat melts or turns the material into vapor. You do not need to touch the material with a tool. This makes it different from old cutting methods. Old methods use a tool that touches and cuts the material. With what is laser beam machining, you do not touch the material. The strong beam gives a clean and exact cut.

Tip: The laser does not touch the material, so you do not worry about tool damage or marks on your parts.

Here is a simple comparison to show the difference:

| Feature | Laser Beam Machining | Traditional Machining |

|---|---|---|

| Process Type | Non-contact | Contact-based |

| Material Interaction | Melts, burns, or vaporizes material | Cuts through physical contact |

| Tool Wear | Minimal due to no physical contact | Significant due to tool wear |

| Precision | High precision on various materials | Varies based on tool and technique |

| Applications | Effective for metals, plastics, wood, etc. | Common in general manufacturing |

Key Features

There are many key features of what is laser beam machining. First, it uses a strong beam to melt, burn, or vaporize material. This heat method works well for thin or delicate parts. You can make tricky shapes that are hard with other tools. Laser cutting gives smooth edges and tight fits. You can get fits within ±0.01 mm. This is hard to do with other cutting ways.

- Laser cutting is up to 10 times faster than old cutting.

- You can save 30-40% on costs with this process.

- Waste drops by up to 80% because the cuts are exact.

You do not need to switch tools for new shapes. The laser can follow any path you set. This makes what is laser beam machining a good choice for many jobs.

Laser Cutting Applications

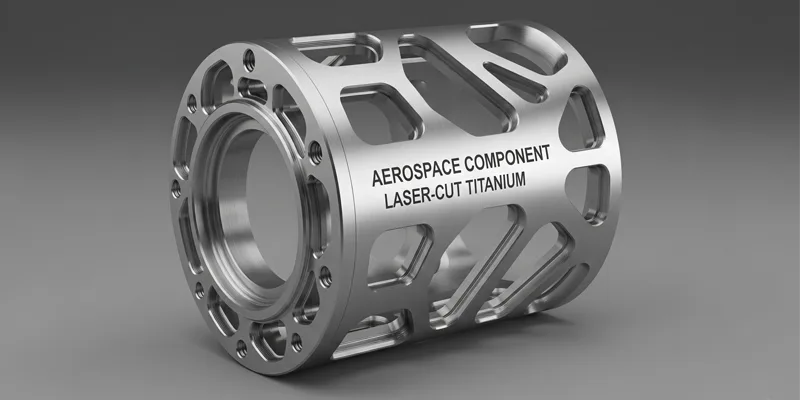

Laser cutting is used in many fields. In aerospace, you can cut titanium parts with high accuracy. Medical makers use laser cutting for tools and implants. In cars, you can cut body panels and small parts. Electronics companies use laser cutting for circuit boards and micro-welding. It also works for plastics, wood, and some fabrics.

- Aerospace: Cutting titanium and other metals with precision.

- Medical: Making surgical tools and implants.

- Automotive: Cutting body panels and small parts.

- Electronics: Making circuit boards and micro-welds.

If you need to work with thin materials or tricky shapes, what is laser beam machining gives you control and quality. You can also compare it to electron beam machining. That uses a beam of electrons instead of light. Both ways are very exact, but laser cutting is used more in many fields.

CNC Milling Basics

Process Overview

To start CNC milling, you make a 3D model of your part. This model shows all the details and sizes. When the design is ready, special software changes it into a computer program. The program tells the CNC machine how to move the cutting tool and the material. The machine follows these steps one at a time.

CNC milling is a subtractive process. You begin with a solid block of material. The machine cuts away small pieces until the part is done. Other ways to make parts are different. Additive manufacturing, like 3D printing, builds parts layer by layer. Formative processes, such as casting or injection molding, use molds to shape materials. CNC milling is special because it removes material very accurately.

Tip: CNC milling works on metals, plastics, and wood. You can use it for many different projects.

Here are the main steps in CNC milling:

- Make a 3D CAD model of your part.

- Change the model into a computer program for the CNC machine.

- Put the material block into the machine.

- Start the machine and let it follow the program.

- Check the finished part to see if it is correct.

Key Features

CNC milling has features that make it different from other ways to cut parts. It uses advanced CNC technology to control every move. The machines can work with three, four, or five axes. This lets you make hard shapes and tight fits.

You get high precision with CNC milling. The machine takes away material in small, careful steps. You can make parts with tiny slots and exact holes. Some other ways cannot make parts with this much detail.

Here is a table that shows how CNC milling compares to other machining:

| Feature | CNC Milling | Other Machining Processes |

|---|---|---|

| Technology | Advanced CNC technology | Manual or less advanced methods |

| Axis Capabilities | Multi-axis (3, 4, 5-axis) | Typically 1 or 2-axis |

| Precision | High precision material removal | Varies, often less precise |

| Material Removal Technique | Controlled, incremental removal | Varies, may not be controlled |

| Application | Complex geometries, tight tolerances | Simpler shapes, less complexity |

| Finishing Capability | Precision-drilled holes, intricate slots | Limited finishing capabilities |

You can use CNC milling for parts with hard shapes and smooth surfaces. It is good for making one part or many parts. You get the same good results each time.

Note: CNC milling needs careful setup and programming. Skilled workers are needed to get the best results.

CNC milling is a top choice for many industries. It gives you accuracy, flexibility, and the same results every time.

Technology Overview

Laser Cutting

Laser cutting is used when you need very exact cuts. It gives smooth edges on many materials. A focused laser beam melts, burns, or turns material into vapor. In the last ten years, laser cutting has gotten much better. Now you can cut metals, plastics, ceramics, composites, and even some organic things. Automation helps a lot. Robots and CNC controls make the process steady and easy.

Today, you get help from real-time data and artificial intelligence. These tools let you change things fast and work better. New fiber lasers use less power and make less pollution. Safety is better now with strong machine covers and live monitoring. Small laser cutters are now available for small shops and hobbies. If you need to cut tricky 3D shapes, 3D laser cutting can do it. Special lasers like nanosecond and femtosecond lasers are used for tiny, detailed work.

Tip: Modern laser cutting lets you work with more materials and shapes than ever before.

- You can cut metals, plastics, ceramics, and more.

- Robots and automation help stop mistakes and make better parts.

- Industry 4.0 lets you watch and control your work as it happens.

- Fiber lasers save energy and help the environment.

- Small machines make laser cutting easy for everyone.

Different Types of Laser Cutting Machines

There are different kinds of laser cutting machines. Each type has good points and bad points. The table below shows how they compare:

| Type of Laser Cutting Machine | Advantages | Disadvantages |

|---|---|---|

| CO2 Lasers | Good for non-metal materials and metals that do not reflect light; 25-100 watts; 10.6 micron wavelength | Only works well with non-metals and metals that do not reflect light |

| Fiber Lasers | Cuts shiny metals; very exact; lasts a long time (over 25,000 hours) | Costs more at first than CO2 lasers |

| Nd:YAG Lasers | Very exact for marking and engraving; cuts metals and some non-metals | Costs more and does not work with as many materials as CO2 and fiber lasers |

When you pick a machine, think about what you need to cut. Also think about how much detail you want. Fiber lasers are best for metals. CO2 lasers work well for plastics and wood. Nd:YAG lasers are good for marking and engraving.

CNC Milling Machines

CNC milling machines give you great control and the same results every time. You can make parts with very tight fits, as close as +/- 0.0005 inches. That is much smaller than a human hair. This is important for making hard parts for planes, cars, or medical tools.

There are many kinds of CNC milling machines. Some have three axes. Others have four or five axes. More axes let you make harder shapes. You can use these machines with metals, plastics, or wood. Advanced controls help stop mistakes and keep your work the same, even if you make lots of parts.

| Feature | Description |

|---|---|

| Design | Changes based on what you need and how hard the job is |

| Number of Axes | More axes mean more movement and better fits |

| Material Compatibility | Works with metals, plastics, and wood |

| Precision | Fits as close as +/- 0.0005 inches |

| Applications | Used for hard shapes in planes, cars, and medical tools |

- CNC milling works for simple and hard designs.

- The machines make sure every part is made just right.

Core Differences

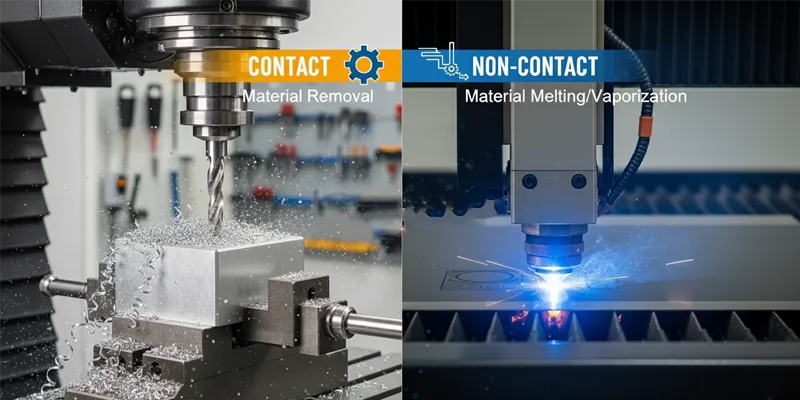

Contact vs Non-Contact

CNC milling and laser cutting work in different ways. CNC milling uses a tool that touches the material. The tool pushes against the part and cuts it. Laser cutting does not touch the material at all. The laser beam shines on a small spot. It melts or turns the material into vapor. There is no physical contact.

- CNC milling needs the tool to touch the part.

- Laser cutting uses a beam, so the tool does not wear out.

- Laser cutting does not leave marks or damage soft parts.

- CNC milling works with many types of materials. Laser cutting is best for thin materials.

Tip: If you want no tool marks or damage, use laser cutting because it does not touch the part.

Precision and Accuracy

Laser beam machining is very precise. CNC milling and laser cutting both give good accuracy. The results depend on the process and the material.

| Metric | Laser Processing | CNC Machining |

|---|---|---|

| Tolerance (mm) | ±0.05 | ±0.01 to ±0.002 |

| Surface Roughness (Ra, µm) | 0.8–1.6 | 0.4–0.8 |

| Cutting Speed (IPM) | Up to 114 | Up to 70 |

| Material Thickness (mm) | Effective up to 20 | Effective for >20 |

| Repeatability | High (CNC-controlled) | Very High (CNC-controlled) |

| Heat-Affected Zone | 0.1–0.5 mm | None |

Laser cutting is great for thin parts and small details. You can get very tight fits with laser cutting. CNC milling is better for thick parts and hard shapes. Both use CNC controls, so you get the same results every time. CNC milling makes smoother surfaces. Laser cutting gives clean edges and needs little finishing.

Note: If you need very tight fits and high precision, laser beam machining is the best choice.

Speed and Efficiency

Speed and efficiency are important when making parts fast. Laser cutting is very quick. It does not need tool changes or worry about tool wear. You can finish parts faster and waste less material.

| Feature | Laser Cutting | CNC Milling |

|---|---|---|

| Speed | High speed, no tool wear | Slower, tool wear and setup needed |

| Efficiency | Minimal material loss, fast setup | More waste, tool changes required |

| Precision | Unmatched for fine details | Good for 3D shapes, rougher edges |

| Material Stress | No stress on workpiece | High stress from vibration/heat |

Laser cutting saves material and sets up quickly. CNC milling takes more time for tool changes and setup. CNC milling can waste more material. Laser cutting puts less stress on the part. This helps keep small features safe and stops warping.

Tip: If you want to make parts fast and save material, laser cutting is a smart choice.

Material Compatibility

When you pick a machining process, you should know what materials work best. Laser beam machining and CNC milling are good for different things.

Laser beam machining works well with:

- Metals like steel, aluminum, and titanium

- Wood

- Acrylic

- Leather

- Glass

Laser cutting can be used on many materials, but not all. Some materials do not work well with the heat or light from the laser. You should not use laser cutting on:

- PVC (polyvinyl chloride)

- Vinyl and other chlorinated materials

- Polycarbonate and polystyrene

- Foam and Styrofoam

- Highly reflective materials

These materials can make dangerous gases or bounce the laser back. This can hurt the machine or cause safety problems.

CNC milling gives you more choices for metals and plastics:

- Aluminum, steel, stainless steel, titanium, copper

- Plastics like acrylic, polypropylene, polycarbonate, ABS, acetal, and nylon

CNC milling works for hard and soft materials. It can cut thick metals and tough plastics. You get strong and exact parts from many kinds of materials.

Tip: If you need to work with metals or tough plastics, CNC milling gives you more choices. For thin, non-metal materials or detailed designs, laser beam machining is a strong option.

Environmental Impact

You should think about the environment when you choose a machining process. Laser beam machining and CNC milling use energy and make waste in different ways.

Laser beam machining, especially with fiber lasers, uses less energy:

- Fiber lasers need only 2 to 4 kilowatts of power.

- CO2 lasers use more, between 7 and 15 kilowatts.

- Fiber lasers turn 50% of electrical energy into laser energy. CO2 lasers only reach 10% to 20%.

- Using fiber lasers can lower your energy costs by up to 40%.

Laser cutting helps you use more of your material. You can use up to 85% to 90% of your material, so there is less waste.

CNC milling makes more waste and uses more energy:

- CNC milling cuts away extra material, so you get more scrap.

- This means you need more raw materials and can run out of resources.

- CNC milling uses a lot of energy, which adds to your carbon footprint.

Note: If you want to save energy and make less waste, laser beam machining is better for the environment. CNC milling works well for many jobs, but it makes more waste and uses more power.

Design Flexibility

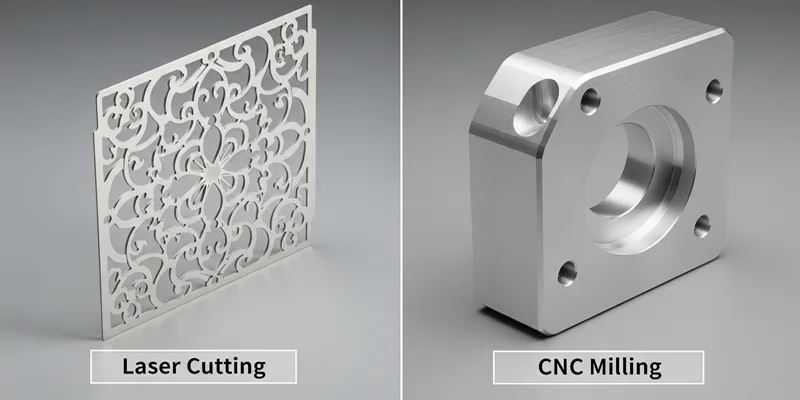

Intricate Details

When you need small details, your machining choice matters a lot. Laser beam machining is great for being very exact. The laser can cut lines that are super thin. This is important for projects with tricky patterns or tiny features. You see this in electronics, jewelry, and custom signs.

Laser cutting works best on thin materials. You can use it for party decorations, stencils, or metal art. The laser does not touch the material at all. This means you do not get scratches or marks like with other tools. If your material is sensitive to heat or pressure, laser cutting keeps it safe.

- Laser cutting is best for thin materials like event decor and signs.

- You can use it on materials that do not like heat or pressure.

- The laser does not touch the part, so there are no tool marks.

CNC milling is also very exact, but it is better for bigger shapes. The cutting tool in a CNC mill has a size limit. This makes it hard to get tiny details like a laser can. If you need small holes or sharp corners, laser beam machining gives you more control.

Tip: If you need very exact and detailed designs, laser beam machining is usually the best choice.

Geometric Complexity

Sometimes you need to make parts with hard shapes. Both laser beam machining and CNC milling can help, but they work differently.

Laser beam machining lets you make tricky shapes without special tools. You can cut detailed shapes and even tiny holes in thin metal. This saves time and money, especially for samples or custom parts.

- Laser beam machining lets you make hard shapes without special tools.

- It is good for cutting detailed shapes and small holes in thin materials.

CNC milling is good for many different shapes. Multi-axis CNC mills can make tricky designs and tight fits. You can use CNC milling for simple or hard parts, from flat plates to 3D shapes.

- CNC mills can make lots of different shapes.

- Multi-axis machines help you make parts with tight fits and tricky features.

If you need both small details and hard shapes, you might use both methods. Laser beam machining gives you sharp, detailed cuts. CNC milling shapes thicker or more complicated parts.

Note: Think about your part’s shape and detail before you pick a machining process. Laser beam machining is best for small details and tricky shapes. CNC milling is strong and works for many shapes.

Operational Requirements

Equipment Needs

You should think about the equipment before you choose. Laser beam machining uses a laser source, mirrors, and a computer. There are not many moving parts in these machines. The laser beam does the cutting work. You do not need to change tools often. You can switch jobs fast by changing the program.

CNC milling machines have lots of moving parts. They use motors, spindles, and tool holders. The machine moves the cutting tool in different directions. You must change tools for new shapes or materials. This setup takes more time and space. You also need extra tools and spare parts nearby.

Tip: Laser beam machines save space and set up faster. CNC mills let you make more shapes and use more materials.

Operator Skill

You need to think about the skills needed for each job. Laser beam machining needs advanced training. You must learn laser safety and how to program the machine. You also need to know how to change settings for different materials. Many companies want you to get certified before using a laser machine. You must keep the process safe and working well.

CNC milling operators need Skill Level 2. You learn basic machine skills and follow instructions. You do not need as much training as laser operators. You can start with easy jobs and move to harder ones as you learn more.

Here is a table to help you compare:

| Process | Skill Level Required | Training Focus |

|---|---|---|

| Laser Beam Machining | Advanced | Learning better ways to work safely and efficiently |

| CNC Milling | Skill Level 2 | Basic machine skills and handling |

- Laser cutting operators need advanced training and certification.

- CNC machine operators are Skill Level 2.

Note: If you want to use laser beam machining, you must train your team more.

Maintenance

You need to plan for maintenance with both machines. CNC milling machines have many moving parts. You must check for tool wear and replace parts. You also need to keep everything oiled. This means you spend more time and money on upkeep. Yearly costs for CNC milling maintenance are $2,000 to $5,000.

Laser beam machining systems have fewer moving parts. You do not worry about tool wear. You need to clean the optics and refill gases sometimes. Maintenance costs are lower, usually $1,000 to $3,000 each year.

| Machine Type | Maintenance Needs | Annual Costs |

|---|---|---|

| CNC Milling Machines | Needs lots of care because of many moving parts. You must check for tool wear, replace parts, and keep things oiled. | $2,000 to $5,000 |

| Laser Beam Machining Systems | Fewer moving parts, lower costs, but you need to clean optics and refill gases sometimes. | $1,000 to $3,000 |

Tip: Laser beam machines help you save money and reduce downtime. CNC milling machines need more care to keep working well.

Cost Factors

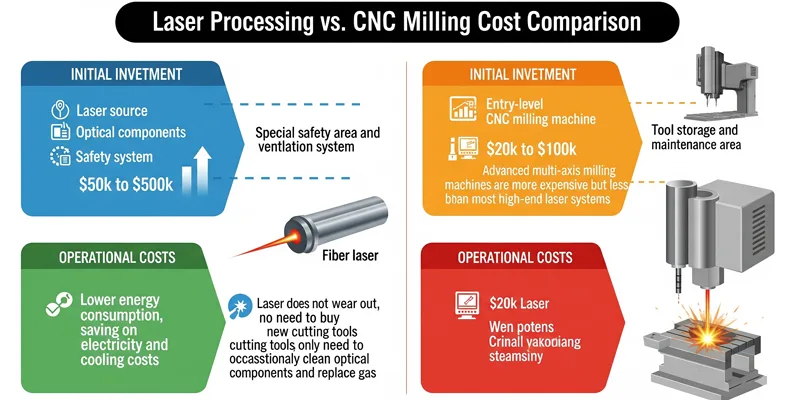

Initial Investment

When you choose between laser beam machining and CNC milling, you need to look at the initial investment. Laser beam machines often cost more at the start. You pay for the laser source, optics, and safety systems. These machines can range from $50,000 to over $500,000, depending on the power and features. CNC milling machines usually have a lower starting price. You can find entry-level CNC mills for $20,000 to $100,000. Advanced multi-axis mills cost more, but the price still stays below most high-end laser systems.

You also need to think about the space and setup. Laser machines need special safety zones and ventilation. CNC mills need less safety gear, but you must plan for tool storage and maintenance areas.

Tip: If you want to start with a lower budget, CNC milling gives you more options. Laser beam machining pays off when you need high precision and fast production.

Operating Costs

Operating costs play a big role in your decision. Laser beam machining uses less energy, especially with fiber lasers. You save on electricity and cooling. You do not need to buy new cutting tools often because the laser does not wear out. You only need to clean optics and replace gases sometimes. This keeps your ongoing costs low.

CNC milling uses more power and needs regular tool changes. You must buy new cutting tools and pay for more maintenance. Tool wear adds to your costs. You also spend more on lubricants and coolants. Labor costs can be higher because CNC milling needs more hands-on work and setup.

| Cost Type | Laser Beam Machining | CNC Milling |

|---|---|---|

| Energy Use | Low (fiber lasers) | Moderate to high |

| Tool Wear | Minimal | High |

| Maintenance | Low (clean optics, gases) | High (tool, spindle care) |

| Labor | Lower (automation) | Higher (manual setup) |

Note: Laser beam machining helps you save on energy and tool costs. CNC milling costs more to run over time.

Cost per Part

You need to know how much each part will cost you. The cost per part depends on the number of parts, material, and machine time. Laser beam machining shines in large production runs. You pay more at the start, but the cost per part drops as you make more parts.

- For a run of 1,000 parts, you might see:

- Material costs of $4 per unit, totaling $4,000

- Setup and programming at $150 (fixed)

- Machine time of 40 hours at $75 per hour, totaling $3,000

- Labor for a CNC operator at $35 per hour for 40 hours, totaling $1,400

- Tooling at $500

- Total cost for 1,000 parts: $9,050

- Per-part cost: $9.05

- For a medical device company making 5,000 precision titanium parts, the initial setup might be $1,000 or more. The per-part cost could drop to $5 to $10 or even lower.

Laser beam machining gives you the best value when you need many parts with tight tolerances. CNC milling works well for small batches or when you need to change designs often. You should always compare the total cost for your project size before you choose.

Tip: If you plan to make thousands of parts, laser beam machining can lower your cost per part and boost your profits.

Pros and Cons

Laser Beam Machining

Laser beam machining is known for being very exact and useful. You can cut many materials, like metals and plastics, with high accuracy. The laser does the cutting, so you do not touch the part. This means there is no tool wear, and the edges are smooth. Many industries, like aerospace and electronics, use laser cutting for detailed jobs.

Here is a quick list of the good and bad points:

| Advantages | Disadvantages |

|---|---|

| High precision and accuracy | High initial costs |

| Increased speed and productivity | Maintenance and operational costs |

| Versatility across materials | Complexity of setup and operation |

Laser cutting is fast and works well for making lots of parts. It is great for thin materials and tricky shapes. You can change jobs quickly by updating the program. This helps factories stay flexible. But, laser machines cost a lot at first. You also need to learn how to set them up. Maintenance can cost more, and you need skilled workers. If you look at electron beam machining, both are very exact. But laser cutting is used more in factories.

Tip: If you want top precision and fast cutting, laser beam machining is a good choice. Just remember, it costs more and needs special training.

CNC Milling

CNC milling is a trusted way to make many different parts. You use it to remove material from metals and plastics. It shapes parts with high accuracy. CNC milling machines can cut thick pieces and make 3D shapes. You get the same results every time, which helps keep quality high.

Pros of CNC Milling:

- Makes very exact parts, with tolerances as small as 0.0001 inches. You can count on the accuracy for good parts.

- Works efficiently. The machine runs all the time, so you make parts faster and waste less.

- Is flexible. You can use many materials and make hard shapes.

- Saves money over time. The first cost is high, but you spend less on workers and fixing mistakes later.

Cons of CNC Milling:

- Needs a lot of money to start, which can be tough for small shops.

- Needs skilled people to run and program the machines.

- Needs regular care to keep working well, which takes time.

- Can become old as new machines come out.

You can trust CNC milling for strong cutting and steady results. It fits many factory jobs, but you must think about the need for skilled workers and regular care.

Note: CNC milling gives you control and flexibility for cutting, but you need to plan for costs and training.

Choosing the Right Process

Application Suitability

You should pick the best machining process for your project. Laser beam machining and CNC milling are both good for different jobs. If you want very exact cuts and tiny designs, laser beam machining is great. It makes smooth edges and fine details, especially on thin materials. CNC milling is better for making hard shapes and tight fits. You can use CNC milling for thick parts and many types of materials.

Here is a table to help you compare:

| Criteria | Laser Beam Machining | CNC Milling |

|---|---|---|

| Precision and Accuracy | Best for tiny designs and fine details | Great for hard shapes and tight fits |

| Speed and Production Efficiency | Cuts thin materials quickly | Good for making lots of parts |

| Material Compatibility and Versatility | Works with many materials, but not shiny metals | Works with metals and other materials |

| Cost Considerations | Costs more to set up and keep running | Needs money to start, but tools cost less |

Tip: If you want to make thin, detailed parts fast, laser beam machining is smart. For big batches and tough materials, CNC milling gives you more choices.

Industry Examples

Many industries use both laser beam machining and CNC milling. In aerospace, laser cutting is used for engine parts and other important pieces. It gives the exact cuts needed for safety. CNC milling is also used in aerospace for landing gear and strong parts.

Car companies use both methods. Laser cutting helps make exact engine parts. CNC milling makes strong car parts with tight fits.

Farm equipment makers use CNC milling for things like seed drills and plows. Laser cutting helps make small, detailed parts for harvesters.

Medical companies need very exact work. Laser beam machining makes implants and surgical tools with smooth edges. CNC milling shapes prosthetics and other medical tools to fit just right.

| Industry | Application Description |

|---|---|

| Aerospace | Makes important airplane parts like engines and landing gear |

| Automotive | Makes exact engine and transmission parts for cars |

| Agriculture | Makes farm tools like seed drills and plows |

| Medical | Makes implants and surgical tools with high accuracy |

Note: Many factories use both laser beam machining and CNC milling together. Each one helps with different steps in making things.

Selection Checklist

You can use a checklist to help you pick the right process. Ask yourself these questions before you choose:

- How exact do your parts need to be?

- Are your designs tiny or do they need hard shapes?

- What materials will you use? Are they thin, thick, or shiny?

- How many parts do you want to make? Is making lots important?

- Do you need fast cutting for quick jobs?

- What is your budget for setup and care?

- Do you have skilled workers for special machines?

- Will you need to change designs or batch sizes often?

If you want very exact cuts and smooth edges for thin materials, laser beam machining is best. For strong, hard parts and making lots of them, CNC milling works better. You can also look at older ways of cutting metal if they fit your project.

Tip: Check your list before you start making things. Picking the right process saves you time, money, and helps you get the exact parts you need.

When you pick between laser beam machining and CNC milling, there are big differences. Laser machining uses heat to cut and does not touch the material. CNC milling uses tools that touch and cut the material. The table below shows how they are different:

| Aspect | CNC Machining | Laser Machining |

|---|---|---|

| Material Removal | Mechanical | Thermal |

| Contact | Physical | Non-contact |

| Tool Wear | High | Minimal |

| Setup | Complex | Simple |

- Laser cutting is great for thin parts and detailed designs. It also works well when you need to make many pieces.

- CNC milling is good for thick materials and making hard 3D shapes.

To get the best outcome, think about how exact you need to be, what materials you use, how fast you want your parts, and how much you want to spend before you choose.

FAQ

Laser beam machining can cut metals, plastics, wood, and some ceramics. Do not use it on PVC or shiny metals. Always check if your material is safe before you start.

CNC milling uses a spinning tool that touches the material and removes it. Laser cutting uses a strong light beam to melt or turn material into vapor. The laser does not touch the material. Each process gives different results and looks.

Laser beam machining is safe if you follow all safety rules. You must wear safety gear and make sure the room has good air flow. Always train your team and follow the machine’s rules to stay safe.

Laser beam machining is very good for thin and detailed parts. CNC milling is great for thick and tricky shapes. Pick the one that fits your project best.

Yes, you can use both methods together. Many factories use laser cutting for small details and CNC milling for thick parts. Using both gives you more ways to make your parts.

Laser machines need you to clean the optics and check the gas. CNC mills need you to change old tools and add oil to moving parts. Doing regular care helps both machines work well.

Think about your part’s size, shape, material, and how exact it must be. Also think about your budget and how many parts you need. Use laser cutting for thin, detailed parts. Pick CNC milling for thick or tricky shapes.

Laser cutting costs more at first. But you save money later because you do not need new tools as often and use less energy. CNC milling costs less to start but needs more money for tools and care over time.