Milling is a way to cut material off a workpiece. This helps make exact shapes. CNC milling uses computers to control the process. The operator sets up the CNC machine. The machine moves the cutting tool very accurately. CNC milling is good for making hard parts. It gives the same results each time. Many industries use CNC milling. It is reliable and works fast. Computer-numeric control lets people make special parts. CNC milling services help with quick samples and big jobs.

Key Takeaways

- Milling removes material from a solid block. Spinning tools help make exact shapes.

- CNC milling uses computers to run machines. This makes parts very accurate and the same every time.

- There are various CNC machines designed for different tasks. Vertical, horizontal, 3-axis, and 4-axis machines work with many materials.

- Some common milling jobs are face milling, peripheral milling, slotting, drilling, and contour milling.

- CNC milling is very precise. It works with many materials and makes things fast.

- Repeatability means every part looks the same. This helps cut down on waste and saves money.

- CNC milling costs more at first. But it saves money when making lots of parts.

- Keeping machines in good shape helps CNC milling stay reliable. It also keeps parts of high quality.

Table of Contents

Milling Basics

Definition

Milling is a way to take away material from a solid block. This helps make a certain shape. A spinning cutting tool moves over the workpiece. The tool cuts off pieces to form the object you want. CNC milling uses computer code to move the cutting tool. The computer tells the tool where to go with great accuracy. This makes the process quick and exact.

CNC milling does not need someone to guide it by hand all the time. The machine follows instructions from the software. This makes CNC milling more exact and automatic than old-style milling. CNC milling is one part of CNC machining. Other parts are turning, drilling, and routing. All these use computers to shape materials.

Key Features

Milling has special features that make it different. The process uses a spinning tool with many teeth. This tool cuts away material from a still workpiece. The tool usually comes down straight onto the workpiece. Milling can make shapes, holes, and curves.

CNC milling machines can work on flat or curved surfaces. They can also work on many sides of a part. This is easier with 3-axis, 4-axis, or 5-axis machines.

CNC milling is great for making engine housings and aerospace brackets. It works with things like aluminum, stainless steel, and plastics. CNC milling machines are made to be fast and exact. They follow rules to stop shaking and tool noise. This keeps the work accurate and the surface smooth. CNC milling can reach very small tolerances with good machines. The finish depends on the tool, the path, and the speed. Ball-nose end mills and flat end mills can both make smooth surfaces if used correctly.

Tip: CNC milling often uses coolant to keep things cool and lower friction. This helps the surface look better and makes the tool last longer.

Milling vs. Other Methods

Milling is different from other ways to cut material. In milling, the tool spins and the workpiece stays still. In turning, the workpiece spins, and the tool does not move. Turning is best for round or tube-shaped parts. Milling can make more shapes and details. Drilling uses a spinning drill to make holes. Drilling cannot shape surfaces like milling can. CNC milling can move the tool in many directions. This lets it work on many sides of a part.

CNC machining includes milling, turning, and drilling. Milling is the best for making hard shapes. Additive manufacturing builds parts by adding layers. Milling takes away material to show the final shape. CNC milling is very accurate and gives a nice finish, even on tricky shapes. The best method depends on the part’s shape, what it is made of, and how exact it needs to be.

| Method | Tool Movement | Workpiece Movement | Best For | Typical Parts |

|---|---|---|---|---|

| Milling | Rotating tool | Stationary | Complex shapes, contours | Brackets, housings |

| Turning | Stationary tool | Rotating | Cylindrical parts | Shafts, bushings |

| Drilling | Rotating drill bit | Stationary | Holes | Fasteners, connectors |

CNC Milling Process

The CNC milling process uses computers to shape materials into exact parts. This process has many steps to make sure the parts are good and reliable. AFI Industrial Co., Ltd. uses special CNC machines with 3-axis, 4-axis, and 5-axis to get very accurate parts and smooth surfaces.

Steps

Setup

The setup step gets the CNC machine ready for milling. The operator picks the right material and puts it on the machine table. The operator puts in the right cutting tools and types the CNC program into the machine. AFI’s team checks all the settings to make sure the machine will move the right way for the part. This careful setup helps stop mistakes and makes sure the parts are good.

Tooling

Tooling means picking and putting in the right cutting tools. The choice depends on the material, the part’s shape, and how smooth the surface needs to be. AFI uses strong alloy tools and new CNC technology to get tight tolerances like ±0.01mm and smooth surfaces like Ra0.8. Checking and taking care of tools often helps keep them working well and last longer.

Cutting

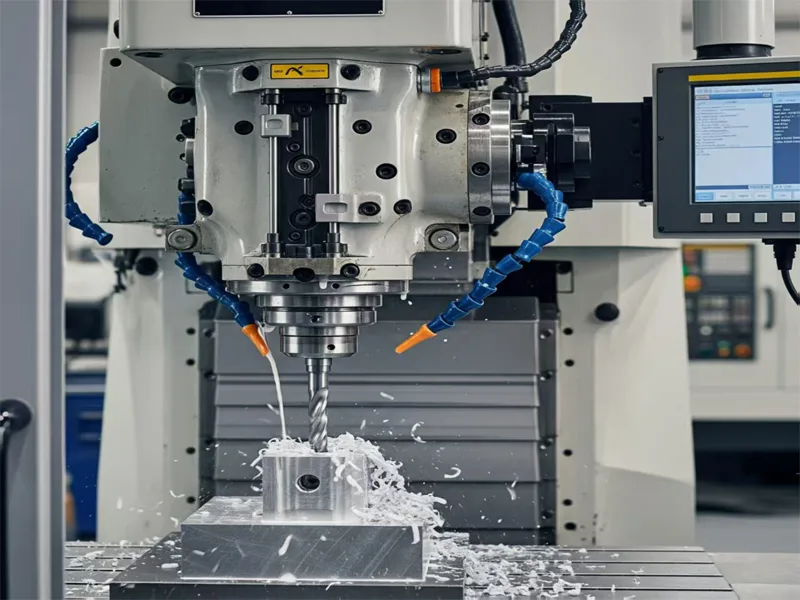

In the cutting step, the CNC machine follows the program to cut away material. The machine moves the cutting tool very carefully to shape the part. AFI’s CNC machines watch the process in real time to change cutting settings and keep the quality the same. Coolant systems help lower heat and friction, which makes the surface smoother and keeps the tools safe.

Inspection

Inspection is a very important part of the CNC milling process. AFI checks parts in many ways to make sure they meet high standards:

- Raw Material Inspection: Checks the material before machining.

- First Article Inspection (FAI): Looks at the first part to find problems early.

- In-Process Inspection: Watches size and surface during machining.

- Dimensional Inspection: Uses special tools to check all sizes.

- Surface Finish Inspection: Checks if the surface is smooth enough.

- Visual Inspection: Look for any marks or problems.

- Assembly and Fit-Up Inspection: Makes sure parts fit together right.

- Final Inspection: Checks everything before shipping.

Note: AFI’s quality team uses special equipment to check every step, helping with both quick samples and big jobs.

CNC Programming

CNC programming tells the machine how to move and cut the part. The CNC program has instructions for tool paths, speeds, and how deep to cut. Skilled programmers use CAD/CAM software to make good tool paths and avoid extra moves. AFI’s team uses simulation software to test the CNC program before making parts, which helps stop mistakes and keeps things running smoothly.

Important parts of CNC programming that help with speed and accuracy are:

- Checking and taking care of tools and machine setup.

- Adjusting cutting settings like feed rate and speed for each material.

- Making tool paths better to cut down tool changes and save time.

- Using good parts and picking the right tools for each job.

- Using simulation software to find and fix mistakes before cutting.

- Making sure the machine is set up right and the axes work together for hard parts.

AFI helps with both small samples and big jobs. Their team keeps learning about new CNC technology to keep their work at a high level. This helps them make good parts for aerospace, cars, electronics, and medical devices.

| Common CNC Milling Challenges | Causes/Descriptions | Mitigation Strategies |

|---|---|---|

| Tool Wear | Tools get worn out and lose accuracy | Check tools often, use strong tools, use cooling |

| Programming Complexity | Code mistakes, need for skill | Use good CAD/CAM software, train workers, test code first |

| Vibration and Chatter | Tools not balanced, not mounted right | Check tool balance, mount tools tightly |

| Calibration Errors | Machine not set up right | Calibrate the machine often |

| Dust and Debris Accumulation | Not cleaning enough | Clean the machine often to stop dirt |

| Operator Error | Not enough training, mistakes | Train operators well and often |

| Tooling Problems | Wrong or dull tools | Check and change tools when needed |

| Quality Control Issues | Tool wear, material, or setup changes | Use process control, check during and after machining |

| Production Speed Challenges | Need to balance speed and accuracy | Run machines at safe speeds to avoid problems |

AFI’s advanced CNC machines and skilled team help solve these problems, so every order gets good, reliable parts.

CNC Milling Machines

Vertical

A vertical CNC milling machine has a spindle that points down. The cutting tool moves up and down to shape the part. This type is found in many shops. It is good for jobs that need detail and accuracy. Operators can see the work area well. This helps them set up and check the part.

Vertical CNC milling machines are used to make molds and test parts. They are also good for small batches. These machines work best with softer materials and parts with fine details. Many shops pick vertical CNC milling machines because they cost less. They also do not need much space. These machines are simple to set up and use. That is why many people use them for general work.

| Aspect | Vertical CNC Milling Machine |

|---|---|

| Spindle Orientation | Vertical, moves up and down |

| Tool Geometry | Long, thin tools for detail work |

| Cutting Capabilities | Best for precision, softer materials, single-sided parts |

| Productivity | Compact, easy to set up, good for small runs |

| Cost | Lower initial and maintenance costs |

| Typical Applications | Mold making, prototypes, intricate parts |

| Space Requirement | Fits in smaller workshops |

Vertical cnc milling machines let you see and reach the work easily. This makes them great for jobs that need lots of changes or close checks.

Horizontal

A horizontal CNC milling machine has a spindle that points sideways. The cutting tool moves from the side across the part. This design helps chips and heat move away fast. This keeps the tool and machine safe. Horizontal CNC milling machines use short, thick tools. These tools can cut deeper and faster. These machines are best for big jobs and making many parts. They can cut many sides of a part in one setup. This saves time and helps make parts more exact.

Car and heavy machine companies use horizontal CNC milling machines. They like them for their speed and power. These machines need more room and skilled workers. But they are great for tough materials and large parts.

| Aspect | Horizontal CNC Milling Machine |

|---|---|

| Spindle Orientation | Horizontal, moves side to side |

| Tool Geometry | Short, thick tools for heavy cuts |

| Cutting Capabilities | Great for high-volume, hard materials, multi-face machining |

| Productivity | Fast material removal, stable for large jobs |

| Cost | Higher initial and maintenance costs |

| Typical Applications | Automotive, industrial, large parts |

| Space Requirement | Needs more floor space |

Horizontal cnc milling machines are best for fast, big jobs where strength and speed are important.

3-Axis

A 3-axis CNC milling machine moves the tool in three ways. It can go left and right, forward and back, and up and down. This lets the machine make flat surfaces, slots, and holes. 3-axis CNC milling machines are best for simple shapes. They are good for parts that do not need to be worked on from many sides. These machines are easy to program and cost less than others. Many small shops use 3-axis CNC milling machines for basic parts. They are good for short jobs. These machines need more setups for hard parts. But they still give good accuracy for most work.

| CNC Machine Type | Axes of Movement | Complexity | Precision | Setup | Applications | Cost & Programming |

|---|---|---|---|---|---|---|

| 3-Axis | X, Y, Z | Simple | Good | More | Basic parts | Low, easy |

3-axis cnc milling machines are a good choice for simple jobs. Many shops use them because they are reliable and easy to use.

4-Axis

A 4-axis CNC milling machine can spin the workpiece. It moves the tool left, right, forward, back, up, and down. The rotary axis lets the machine turn the part around one axis. This helps the tool reach more sides without stopping. Operators use 4-axis CNC milling machines for parts with holes on many faces. The rotary axis, called the A-axis, spins the part for angled cuts and tricky shapes.

AFI Industrial Co., Ltd. uses advanced 4-axis CNC milling machines for accurate parts. Their machines make both small samples and big batches. The AFI team sets up the rotary table to fit the part’s design. They pick strong alloy tools for tight fits and smooth surfaces. The machines follow computer instructions to move the tool and table together. This makes parts faster and with fewer mistakes.

4-axis CNC milling machines are good for gears, cams, and turbine housings. These machines cut slots, drill holes, and shape curves on many sides. The rotary axis helps make features at angles that a 3-axis machine cannot do. Many industries use 4-axis CNC milling machines because they are flexible. Aerospace companies need them for brackets and housings with features on many faces. Automotive shops use them for engine parts and molds. Electronics makers use them for cases and connectors with tricky shapes.

Operators save time with 4-axis cnc milling machines. They do not need to stop and reset the part for each side. This lowers mistakes and keeps the work fast.

AFI’s CNC milling centers use fast controls to keep the rotary axis smooth. Their skilled team checks each part during and after making it. They use inspection tools to measure angles, holes, and surface finish. The company helps with quick samples and big jobs. AFI’s machines work with many materials like aluminum, steel, and plastics.

The table below shows how 4-axis CNC milling machines are used:

| Application | Typical Parts | Benefit of 4-Axis Machining |

|---|---|---|

| Aerospace | Brackets, housings | Multi-face features, tight angles |

| Automotive | Engine parts, molds | Complex shapes, fewer setups |

| Electronics | Cases, connectors | Angled holes, curved surfaces |

| Industrial | Gears, cams | Rotary cutting, precision |

A 4-axis CNC milling machine gives makers more ways to design parts. It helps make parts with features on many sides in one setup. AFI Industrial Co., Ltd. uses these machines to make custom, high-quality parts for many industries.

CNC Milling Operations

Face Milling

Face milling is a common CNC milling operation. The cutting tool has many inserts. These inserts sit sideways to the workpiece. The tool spins fast and cuts off material from the top. This makes the surface flat and smooth. Face milling works for rough and finish steps. Operators use it to take away extra material quickly. It also gets the part ready for more machining.

Car and airplane companies use face milling a lot. They make engine blocks, cylinder heads, and big plates. Face milling is good for making large, flat surfaces fast. The tool choice depends on the material. PVD-coated inserts work for most metals. CBN inserts are best for steel and cast iron. PCD inserts are great for high-silicon aluminum. These last longer and give better finishes.

The surface finish in face milling depends on many things. Wiper inserts help remove tool marks. They let you use faster feed rates and still get smooth surfaces. Operators control the spindle speed and how deeply the tool cuts. They also check how the inserts sit to stop vibration. A good setup helps the part meet tight tolerances and look clean.

Tip: Wiper inserts and balanced toolholders help make the surface smoother. This is important when using high-speed cnc milling.

Peripheral Milling

Peripheral milling is another key CNC milling operation. The sides of the cutting tool touch the workpiece. The tool moves next to the surface. This makes thin, deep cuts. Peripheral milling is great for making slots and grooves. It is also good for profiles that need high accuracy.

Peripheral milling is not the same as face milling. Here are some differences:

| Aspect | Peripheral Milling | Face Milling |

|---|---|---|

| Cutting Action | Uses the side of the tool; strong side forces | Uses the end of the tool; wide cutting forces |

| Material Removal Rate | Slower, focused area | Faster, covers more area |

| Precision | Better for small details | Best for big flat surfaces |

| Typical Applications | Gears, slots, keyways | Plates, frames |

Peripheral milling uses less of the tool at once. This means it removes material more slowly but is more exact for small features. Operators use it for parts that need tight tolerances, like gears and keyways. The surface may need extra work because ridges or marks can show up.

Note: Use peripheral milling for tricky grooves or profiles. Face milling cannot make these shapes.

Slotting

Slotting is a special CNC milling operation. It makes slots, keyways, and grooves in a part. Operators use different ways to get the right slot shape:

- End Milling: Good for straight slots and closed pockets. It uses ramp-down and trochoidal paths to lower cutting force and help tools last longer.

- Side Milling: Makes slots along the cutter’s sides. It keeps the cutting force steady. Operators watch the spindle load to stop chatter.

- Trochoidal Milling: Best for deep or wide slots. It controls side forces and helps chips move out. This boosts speed and tool life.

- Plunge Milling: Cuts down tool bending in hard materials.

Slotting lets operators make complex slot shapes in one setup. They can reach tight tolerances, like ±0.02 mm. High-pressure coolant helps move chips out and makes the surface better. This is important for tough materials. Operators use both up milling and climb milling. The choice depends on the material and how strong the machine is.

Slotting is good for making parts fit together exactly. It also helps create tricky features fast. But deep slots can bend the tool. Carbide tools cost more than HSS for big CNC milling jobs.

Tip: Trochoidal milling helps tools last longer and work better. It keeps the cutting load steady and lowers heat.

Drilling

Drilling is a basic step in CNC milling. It makes round holes in a part. The drill bit spins and goes straight down. This lets the machine make holes of many sizes and depths. Drilling is needed for parts that use bolts, pins, or let fluids pass through.

CNC drilling is fast and accurate. The machine follows a set path for each hole. Most CNC drilling keeps holes within ±0.1 mm to ±0.05 mm. This is good for most jobs, but milling can be even more exact. Milling can reach tolerances as tight as ±0.01 mm. This is better for parts that need very high accuracy, like in cars or airplanes.

| Operation | Typical Tolerance Range | Explanation |

|---|---|---|

| CNC Drilling | ±0.1 mm to ±0.05 mm (±0.002″) | Only moves up and down; best for making holes with steady accuracy. |

| CNC Milling | As tight as ±0.01 mm | Moves in many directions; makes detailed shapes and very exact parts. |

Drilling uses different drill bits. Some common ones are twist drills, center drills, and step drills. The type depends on the hole size and what the part is made of. Operators use coolant to keep the drill cool and move chips away. This helps the drill last longer and keeps the hole clean.

Tip: For deep holes, peck drilling is used. The drill comes out often to clear chips and stop it from getting too hot.

Drilling is quick and works well for many holes at once. CNC milling machines can switch between drilling and other steps without stopping. This saves time and makes work faster.

Contour Milling

Contour milling shapes the edges of a part. The tool moves along a curved or slanted path. This makes it tricky to handle shapes like rounded corners and sloped sides. Contour milling is very flexible. It is used for parts in planes, cars, and electronics.

Modern CNC machines use special software to plan the tool’s path. The tool moves smoothly along the edge. This keeps the surface even and lowers tool marks. Operators can change the speed and depth for each pass. This helps get a smooth finish and a tight fit.

Contour milling has some problems. Hard materials can wear out tools fast. Thin parts may bend from heat. Tricky shapes need careful planning to avoid mistakes. Car and plane parts often need tolerances as tight as ±0.01 mm. The surface must also be smooth for strength and sealing.

| Main Challenge | Description | Modern CNC Milling Solutions |

|---|---|---|

| Material Hardness | Hard metals wear tools and hurt the finish. | Use strong coatings, set the right speed, and watch cutting force. |

| Thermal Distortion | Heat can bend thin parts. | Use coolant, check temperature, and adjust for heat. |

| Complex Geometries | Hard shapes need careful cutting. | Use smart milling plans and advanced software. |

| Tight Tolerances | Some parts need very small error. | Use special holders and measure during cutting. |

| Superior Surface Finish | Smooth surfaces help parts last longer. | Use fine tools and change spindle speed as needed. |

Operators use special tools and holders to fix these issues. They pick the best tool for each job. Coolant and sensors help control heat. Good software helps plan the tool’s path. These steps help contour milling make smooth and exact parts.

Contour milling is important for making parts with curves and angles. It lets designers make strong and light parts. CNC milling steps like contour milling help companies make better products with less waste.

Advantages

Precision

Precision is a big benefit of CNC milling. Computers guide the cutting tool very closely. This makes the tool move with great accuracy. Operators can reach tolerances of less than 0.01mm. These tolerances are much tighter than older milling methods. Parts fit together well and work as planned. AFI Industrial Co., Ltd. uses advanced CNC milling machines for tight fits. Their skilled team follows strict steps and trains often. This keeps accuracy high. Surface finishes are smoother and measured in Ra. Smooth surfaces help parts last longer and look nice.

The table below shows how CNC milling compares to older ways:

| Aspect | CNC Milling / Precision Machining | Traditional / General Machining |

|---|---|---|

| Tolerances | Can hold tolerances less than 0.01mm; sometimes in tens of microns | Less consistent; depends heavily on operator skill |

| Repeatability | High repeatability due to computer control; minimal human error | Lower repeatability; operator-dependent |

| Surface Finish | Better, smoother finishes measured in Ra (micrometers) | Generally rougher finishes |

| Operation Mode | Computer-controlled automation | Manual operation requiring skilled machinists |

| Batch Suitability | Ideal for large production runs with tight tolerances | More suited for small runs or single pieces |

| Complexity | Can handle complex parts requiring tight tolerances | Limited by manual skill and machine capability |

CNC milling lowers mistakes and keeps every part the same. This is very important for the aerospace and medical industries. These fields need high accuracy.

Versatility

CNC milling is very flexible. The machines work with many materials. These include aluminum, steel, stainless steel, copper, brass, titanium, plastics, wood, and glass. Operators can change materials quickly. This helps with custom jobs and new designs. AFI’s CNC milling centers use 3-axis, 4-axis, and 5-axis machines. These machines make flat surfaces and complex shapes. Five-axis machines reach almost any angle. This is great for tricky parts in the aerospace and medical fields.

- CNC milling works with over 50 engineering materials.

- The process supports single custom parts and big runs.

- Operators can make pockets, threads, chamfers, slots, and cavities.

- Multi-axis machines create detailed engravings and curved surfaces.

- The technology keeps material properties strong and stable.

AFI’s team trains often to learn new materials and machine features. This helps them solve hard design problems and meet customer needs.

Tip: Cnc milling works for both prototypes and mass production. This makes it a good choice for many industries.

Efficiency

Efficiency is another big benefit of CNC milling. Automation speeds up production. One operator can run several machines at once. Computer control and automatic tool changers help with this. This means more parts made and lower labor costs. AFI’s CNC milling centers work all day and night. This gives faster delivery and less downtime.

The table below shows how CNC milling makes production faster:

| Milling Type | Machines Operated | Parts Produced per Hour | Output Multiplier Compared to Manual |

|---|---|---|---|

| Manual Milling | 1 | 10 | 1x |

| CNC Milling | 2 | 20 (each machine) | 4x (total 40 parts per hour) |

CNC milling uses software to plan tool paths and speeds. This cuts down waste and keeps accuracy high. Operators train to set up machines fast and fix problems quickly. AFI’s process works for small batches and big orders. Customers get fast service and reliable results.

Note: Automated cnc milling systems save time and money. They also keep quality high.

Repeatability

Repeatability means a CNC milling machine can make the same part again and again. Each part comes out the same as the last one. This is important for companies that need many matching parts. When repeatability is good, all parts fit together and work right.

CNC milling uses computers to perform the same steps every time. The machine does not skip or forget any moves. This keeps the process steady and helps make parts very accurate. AFI Industrial Co., Ltd. uses advanced CNC milling centers for this. Their machines can keep tight tolerances, even with big batches.

Some things help CNC milling stay repeatable:

- Picking the right cutting tools for each job keeps cuts clean and makes parts match.

- Keeping feed rates and spindle speeds steady stops problems like chipping or burning. This helps all parts stay the same.

- Checking tools often and changing them before they wear out stops mistakes in size and shape. This keeps accuracy high.

- Using automatic tool changers saves time and makes sure the best tool is always ready.

These steps help the machine keep the same accuracy from start to finish. AFI’s team checks every step of making parts. They use special tools to measure each part. This careful work means customers get parts that meet their needs every time.

Repeatability also helps make parts faster. When machines make fewer mistakes, production goes quicker. AFI’s CNC milling service works for both small and large orders. Their team trains often to learn new ways to keep accuracy and repeatability high.

Tip: Good repeatability in CNC milling means less waste, lower costs, and better products for everyone.

Limitations

Cost

CNC milling costs can change for each project. The price of a machine depends on its size and brand. Machines with more axes cost even more. If you need very exact parts, costs go up. Skilled workers and better machines are needed for tight tolerances. Automation helps lower labor costs, but buying machines costs a lot at first.

Setting up and programming the machine costs money, too. These costs stay the same no matter how many parts you make. If you make more parts, each part costs less. Other costs change with each job. These include material, time spent machining, tools, and labor. Harder part designs take longer to make and need more checks. This makes the job cost more. The material you pick also changes the price. Hard materials take longer to cut and wear out tools faster.

Good milling needs the right tools, correct speeds, and careful setup. These steps help tools last longer and waste less material.

The main things that affect CNC milling cost are:

- Machine size and axes

- How exact the cuts are

- Milling time and cycles

- Type of CNC machine

- Part shape and size

- Number of parts made

- Worker skill

- Tools and supplies

- Delivery time

- Material cost

- Power used

CNC milling costs more to start than other methods. But automation helps save money when making lots of parts.

Material Limits

Picking the right material is important in CNC milling. Some materials are easy to cut and cost less. Others are hard and need special tools, which cost more. Aluminum and some steels are popular because they work well and are not too expensive. Plastics like ABS and nylon are good for simple parts and save money. Special materials like titanium or carbon fiber take longer to cut and wear out tools faster.

| Material Type | Machinability | Raw Material Cost | Tool Wear | Typical Use Cases |

|---|---|---|---|---|

| Aluminum (6061-T6) | High | Low | Low | General, aerospace, auto |

| 1018 Carbon Steel | Medium | Medium | Medium | Mechanical, industrial |

| 304 Stainless Steel | Medium | Medium | Medium | Medical, food, marine |

| ABS Plastic | High | Low | Low | Electronics, prototypes |

| Titanium | Low | High | High | Aerospace, medical |

| Carbon Fiber | Low | High | High | High-performance parts |

Material limits change how long it takes to cut, how long tools last, and the total cost. Some materials need special coatings or coolants to keep tools safe. How easy it is to get the material and how long it takes to arrive also matter for the project.

Complexity

CNC milling has trouble with very complex shapes. Cutting tools must reach every surface, but inside features and steep cuts are hard to get to. The part must be held steady, and tricky shapes may need special holders to stop shaking and maintain accuracy.

Three-axis machines work best for simple shapes. Workers must move the part for each side, which can lower accuracy. Five-axis machines can turn the bed or toolhead between steps. This helps make parts faster and more exact. Continuous five-axis machines move all axes at once. They can make smooth, curved shapes. These machines cost more and need skilled workers.

| Limitation Aspect | Description |

|---|---|

| Tool Access & Workholding | Tools must reach all surfaces; custom fixtures may be needed |

| Manual Repositioning | Needed for 3-axis machines; lowers accuracy |

| Multi-axis Machines | Allow complex shapes; increase cost and require skilled operators |

| Subtractive Nature | Milling removes material; limits internal features and steep undercuts |

Complex shapes take longer to make, need more setup, and need extra checks. Advanced machines help, but they cost more and need more training. CNC milling works best for parts that are not too hard to reach or shape.

Maintenance

Maintenance is very important for CNC milling machines. It helps the machines work well and last longer. If you do not take care of them, they can break or stop working properly.

CNC milling machines need care every day, week, and season. Operators have a list of steps to keep machines working well:

- Daily cleaning takes away chips and dust. This stops dirt from hurting the machine.

- Lubrication of moving parts happens each day. Lubrication helps parts move easily and last longer.

- Regular inspection looks for worn parts like chucks and bearings. Changing these parts early stops big problems.

- Calibration is done every week or month. Calibration keeps the machine making accurate parts.

- Electrical checks look for bad wires or loose connections. These checks help stop fires or power problems.

- Seasonal maintenance checks for changes in heat or wetness. This keeps the machine safe all year.

Regular maintenance helps machines run without stopping. It stops surprise problems and keeps work on time.

Operators use special ways to find problems early:

- Vibration monitoring finds loose or bent parts before they break.

- Thermography looks for hot spots that mean something is wrong.

- Tribology checks the oil and tiny bits to plan when to add more oil.

- Visual inspection helps find cracks, leaks, or other trouble.

- Ultrasonics and nondestructive testing find hidden problems without stopping the machine.

These smart checks help fix small problems before they get worse. Finding trouble early means less time fixing and longer machine life.

A simple maintenance plan could look like this:

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Cleaning | Daily | Stops dirt and keeps the machine working |

| Lubrication | Daily | Makes parts last longer |

| Vibration Monitoring | Weekly | Finds problems before they get big |

| Calibration | Monthly | Keeps parts the right size |

| Parts Inspection | Monthly | Stops breakdowns and keeps work fast |

| Environmental Checks | Seasonally | Stops heat or cold from hurting the machine |

Good maintenance keeps CNC milling machines working right. It also saves money and stops lost work time. When operators follow a good plan, they protect the machine and make sure every part is high quality.

Applications & Materials

Industries

Many industries use CNC milling because it is precise and flexible. Companies in manufacturing, cars, energy, electronics, and building use this process. It helps them work faster and save money. Aerospace and medical fields also need CNC milling for hard and detailed parts. These industries like CNC milling because it can make more parts as needed. It also helps them reach tough green goals. New technology like AI, IoT, and automation make CNC milling smarter and easier to use. More government help and growing cities make more companies want CNC milling, especially where cities are growing fast.

AFI Industrial Co., Ltd. works with many industries, such as:

- Aerospace

- Automotive

- Electronics

- Medical devices

- Industrial machinery

- Consumer products

- Energy and infrastructure

Companies pick CNC milling because it gives the same good results for both small and big jobs.

Materials

CNC milling can use many materials, and each has special benefits. AFI Industrial Co., Ltd. makes parts from aluminum, brass, copper, bronze, steel, alloys, plastics, stainless steel, wood, and stone. The table below lists common materials and their main good and bad points:

| Material | Advantages | Disadvantages |

|---|---|---|

| Aluminum | Light, strong, easy to cut, does not rust, conducts well | Costs more, not strong enough for heavy loads |

| Stainless Steel | Strong, lasts long, does not rust, handles heat, many looks | Hard to cut, costs more, heavy |

| Brass | Easy to cut, conducts well, does not rust, looks nice | Costs more, not very strong |

| Plastics | Light, easy to cut, cheap, many types | Not strong, can react to chemicals, not very stable |

| Titanium | Strong but light, does not rust, safe for the body | Costs a lot, hard to cut, tools wear out fast |

AFI knows how to work with both metals and non-metals. This helps customers pick the best material for their part.

Surface treatments make CNC machining parts work better and look nicer. Some common choices are anodizing, electroplating, spraying, brushing, sandblasting, and polishing.

Anodizing is used a lot for aluminum. It helps stop rust and lets you pick colors. Bead blasting makes the surface smooth and dull by taking away tool marks. Powder coating puts on a hard, colored layer for more protection. Polishing and brushing make the surface smoother and change how it feels. Heat treatments like annealing and tempering change how strong and tough the part is.

The best finish depends on what the part does, how it should look, and how long it needs to last.

Products

CNC milling makes many different products for many industries. The table below shows popular product types, examples, and why CNC milling is good for them:

| Product Category | Examples | Features Making Them Suitable for CNC Milling |

|---|---|---|

| Automotive | Engine parts, chassis components | Precise, always the same, can make hard shapes |

| Aerospace | Turbine parts, structural elements | Very exact, strong, uses tough metals |

| Consumer Electronics | Circuit boards, enclosures, components | Small, detailed, tricky shapes |

| Industrial Machinery | Heavy-duty and precision components | Very accurate, can make big and small parts |

| Materials Used | Aluminum, stainless steel, brass, plastics | Easy to cut, strong, does not rust or wear out fast |

AFI Industrial Co., Ltd. makes custom CNC machining parts for these uses. They make sure every part meets high quality and works well.

Milling helps make materials into exact parts. CNC milling uses computers to control the process. This makes parts very accurate and easy to repeat. Many industries use CNC milling, like aerospace, cars, medical, and electronics. Some main benefits are:

- Very accurate for hard shapes and close fits

- Same quality every time with less waste

- Quick samples and making lots of parts fast

- Works with many materials and shapes

AFI Industrial Co., Ltd. is a trusted CNC milling company:

| Strength | Details |

|---|---|

| Expert Team | Skilled workers and designers handle each project |

| Quality Control | Careful checks and good tools give great results |

| Fast Service | Quick prices and delivery help with urgent jobs |

| Industry Experience | Success in aerospace, medical, and other fields |

CNC milling is important for making things today. AFI gives strong, high-quality help for every job.

FAQ

What is the main purpose of milling?

Milling takes away material from a solid block. This helps make parts with exact shapes. The process also gives smooth surfaces.

What types of materials can CNC milling handle?

CNC milling works with metals like aluminum and steel. It also cuts brass, plastics, wood, and stone. AFI Industrial Co., Ltd. can use many materials.

What makes CNC milling different from manual milling?

CNC milling uses computers to control the machine. Manual milling depends on the operator’s skill. CNC machines make parts more exact and the same every time.

What industries use CNC milling the most?

Aerospace, automotive, electronics, and medical fields use CNC milling. These industries need very exact and reliable parts.

What are the key benefits of CNC milling?

CNC milling gives high accuracy, quick production, and repeatable results. It can make hard shapes and work with many materials.

What is a 5-axis CNC milling machine?

A 5-axis CNC milling machine moves in five directions. This lets it make tricky shapes and reach hard spots.

What surface treatments can milled parts receive?

Milled parts can get anodizing, electroplating, sandblasting, brushing, spraying, or polishing. These treatments help parts look better and last longer. They also protect against rust.