A chamfered edge is a flat, slanted cut that joins two surfaces, creating a sloped transition instead of a sharp corner. If you’re wondering what a chamfered edge is, it is an edge treatment method that refers to this distinctive flat angle that sets it apart from other types of edges. Chamfered edges are commonly found on wood and metal, especially in tools, pipe fittings, and machine parts. Understanding what a chamfered edge is is important because this design element not only enhances safety but also makes it easier to assemble parts in practical applications.

Key Takeaways

- A chamfered edge is a flat, sloped cut. It takes away sharp corners. This makes parts safer. It also makes them easier to put together.

- Chamfers are not like fillets. Chamfers have straight, slanted cuts. Fillets have rounded edges. Chamfers are quicker and less costly to manufacture.

- Chamfered edges make things safer. They help parts fit together fast. They also stop damage like chips and cracks.

- Many jobs use chamfers. You see them in woodworking, metalwork, building, and furniture. Chamfers are used for how they work and how they look.

- You can make chamfers with hand tools, routers, saws, or machines. Always check the size and angle to make sure it is good quality.

Table of Contents

What Is a Chamfered Edge?

Chamfer Definition

If you ask, “What is a chamfered edge?” you want to learn about a special edge. A chamfer edge is a flat and slanted surface. It takes the place of a sharp corner where two sides meet. You make this edge by cutting at an angle. The angle is often 45 degrees, but it can be 30 or 55 degrees too. This cut removes the sharp tip and leaves a neat, straight edge.

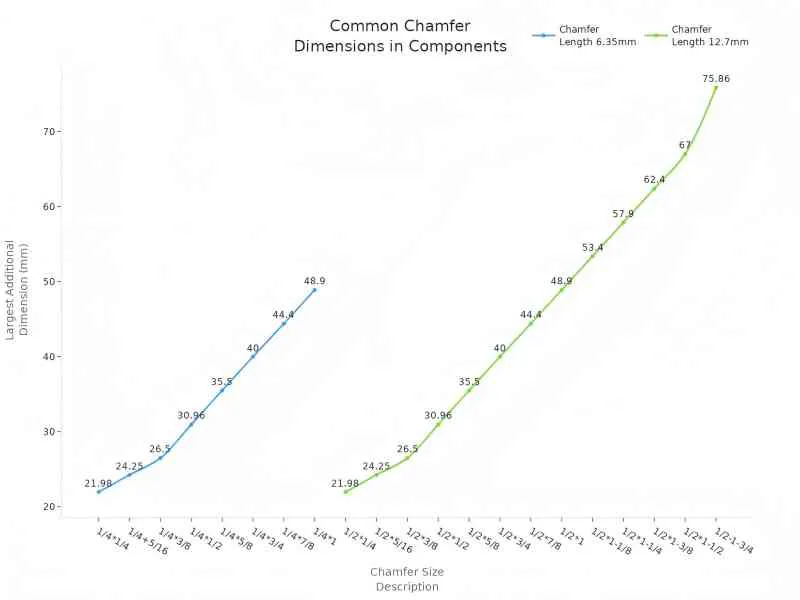

A chamfer is a sloped edge between two surfaces. You make it by cutting a slope at a right-angled corner. In engineering, chamfers are on inside and outside edges. You can describe a chamfer by its length and angle. Sometimes, you use two lengths if the sides are not the same. For example, “0.5 mm × 45°” means the flat part is 0.5 millimeters long at a 45-degree angle.

Here is a table with some common chamfer sizes for machine parts:

| Chamfer Code | Chamfer Size Description | Chamfer Length (mm) | Additional Dimensions (mm) |

|---|---|---|---|

| X00401 | 1/4*1/4 | 6.35 | 21.98, 6.35 |

| X00404 | 1/4*1/2 | 6.35 | 30.96, 12.7 |

| X00412 | 1/2*1/2 | 12.7 | 30.96, 12.7 |

| X00416 | 1/2*1 | 12.7 | 48.9, 25.4 |

Note: Most chamfers use a 45-degree angle, but other angles are possible if needed.

You can find chamfer edges on things like machine parts, tools, and furniture. The chamfer helps put pieces together, makes things safer by removing sharp points, and can stop damage or rust at the edge.

Chamfer vs. Fillet

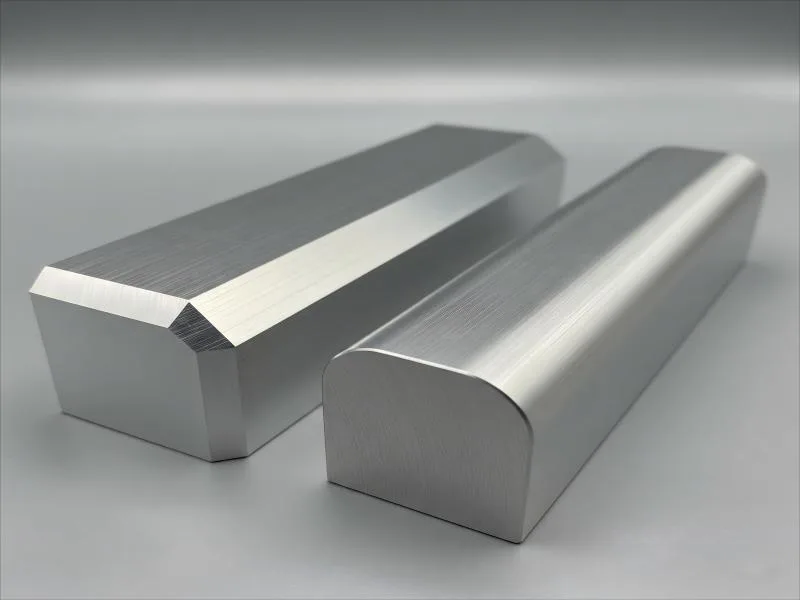

You might wonder how a chamfer is not the same as other edge shapes, like fillets. When you look at a chamfer and a fillet, you see they are very different.

- A chamfer is a flat, slanted cut that looks sharp and clean.

- A fillet is a rounded, curved edge that looks soft and smooth.

| Feature | Chamfered Edge Characteristics | Fillet Edge Characteristics |

|---|---|---|

| Shape | Beveled or flat angled cut | Rounded or curved angle |

| Appearance | Straight lines, flat surfaces, slanted edge | Smooth, curved transitions, no sharp angles |

| Primary Function | Removes sharp edges, improves assembly ease | Reduces stress concentration, smooths corners |

| Visual Effect | Sharp, angular look | Soft, rounded appearance |

In factories, chamfer edges are faster and easier to make. You can use one tool for many chamfer sizes. This saves time and money. Fillets need special tools and take longer because the machine must move in a curve.

Chamfered edges are good when you want to quickly remove sharp corners and make assembly simple. Fillets are better if you need to lower stress and make a part stronger, especially in places that get a lot of force.

If you ask, “What is a chamfered edge?” remember it is a flat, sloped surface made by cutting at an angle, not a curve. You will see chamfer edges on many things because they are easy to make and help with safety and putting things together.

Chamfer Edge Traits

Shape and Angle

When you look at a chamfer edge, you notice its flat, slanted surface. This shape comes from cutting the edge at an angle, usually around 45 degrees. You can see this in technical drawings, where the chamfer stands out as a straight line between two surfaces. The angle is important because it affects both the look and the strength of the edge. Most chamfers use a standard angle, but you can change it to fit your needs. For example, a shallow chamfer might look smoother but may not last as long under heavy use.

Tip: You can use chamfer dimensioning to show the exact size and angle of a chamfer edge in your designs. This helps others understand how the edge should look and function.

Chamfer dimensioning often includes the length of the cut and the angle. You might see notes like “2 mm × 45°” on a drawing. This tells you how much material to remove and at what angle. The two legs of the chamfer triangle, often labeled as “a” and “b,” help you measure the chamfer size. You can also find the face width, which is the length along the slanted surface.

Here is a table showing key traits you should look for when you study a chamfer edge:

| Physical Trait | Description |

|---|---|

| Angled/Beveled Edge | The edge is cut at an angle, not left sharp. |

| Leg Lengths | The two sides of the chamfer triangle, used in chamfer dimensioning. |

| Chamfer Angle | The angle between the chamfer edge and the original surface, often 45 degrees. |

| Face Width | The length along the slanted surface, sometimes called F.W. in chamfer dimensioning. |

Typical Appearance

You can spot a chamfer edge by its neat, sloped look. The flat surface makes the edge appear clean and technical. In product design, symmetrical chamfers create uniform bevels that make assembly easier and improve safety. Asymmetrical chamfers let you adjust the look or function for special needs. You often see chamfer edges on furniture, tiles, and machine parts. The straight cut makes the edge less likely to chip or wear out.

- Chamfer edges give products a modern, minimal style.

- The angle and length of the chamfer change how bold or subtle the edge looks.

- Chamfer dimensioning lets you control the appearance by adjusting the size and angle.

Chamfer edges also help reduce stress at corners, making parts stronger and less likely to break. You can use CAD tools to create variable chamfers, which balance function and style. If you work with brittle materials, you can design the chamfer to avoid cracks.

Note: Chamfer edges are easier to maintain than curved edges. The straight cut resists damage and keeps the product looking sharp.

You will find chamfer edges in many industries, from furniture to aerospace. The shape and angle make them useful for safety, assembly, and style.

Chamfer Purposes and Benefits

Safety and Comfort

Sharp corners on products can hurt you. Chamfered edges help keep you safe. They take away the sharp points. When you touch a chamfer, it feels smooth and sloped. You do not feel a dangerous edge. This makes things safer and nicer to use.

- Chamfered edges take away sharp corners, so you do not get cut or scratched.

- The sloped cut lowers stress spots, which helps stop cracks or breaks.

- You can hold products with chamfers more safely, especially if you use them a lot.

- Many chamfers have a 45-degree angle, which helps you line up parts when you put things together.

Assembly and Function

Chamfered edges help you put parts together more easily. The angled cut guides pieces into place. This saves time and stops damage.

- Chamfers help you match up parts fast, which is important in factories and workshops.

- The angled edge takes away burrs, so surfaces feel smoother and last longer.

- You can build things faster and make fewer mistakes.

- Chamfers cost less to make than curved edges, so they are used a lot in fast production.

Chamfered edges also make things last longer. They lower the chance of chips and cracks, so your tools and products stay strong. Engineers found that the right chamfer angle can help tools wear out less.

Aesthetic and Industry Uses

Chamfered edges look modern and neat in many designs. In buildings, chamfers make corners stand out and create cool shapes. Some buildings use chamfered edges for terraces and balconies. This makes outdoor spaces look nice and feel welcoming.

Many industries use chamfered edges because of how they work and how they look. Here is a table showing where you might see them:

| Industry | Primary Reasons for Using Chamfered Edges |

|---|---|

| Metal Fabrication | Makes things safer by removing sharp edges; gets edges ready for welding or fastening; helps assembly; makes things last longer. |

| Construction | Used in wood, concrete, stone, and marble; stops chipping; looks better; lasts longer; helps things stick together. |

| Machining Industry | Helps tools last longer; gives a better finish; takes away burrs and sharp edges to stop tool wear. |

| Stone and Marble | Looks fancy; stops chipping; makes smooth changes between surfaces; lasts longer and looks better. |

| Woodworking | Makes edges softer; helps glue stick; looks nicer; helps join pieces. |

You see chamfered edges in furniture, tools, buildings, and electronics. This simple edge shape keeps you safe, helps you build things, and makes products look good.

How to Make a Chamfer

Methods and Tools

You can make chamfered edges in many ways. The tool you pick depends on what you are working with. In metalworking, people use chamfer mills for neat and quick cuts. If you need to chamfer a hole, you might use a spot drill or a countersink. These tools are often made from strong stuff like carbide. Some machines, like laser cutters, can make tricky chamfers fast and very accurately. For example, the TRUMPF TruLaser Series 3000 can cut steel and aluminum well every time.

In woodworking, there are a few ways to make a chamfer:

- Hand Tools: You can use chamfer planes, block planes, files, or chisels. These are good for small jobs or when you need to be careful. They let you make tiny changes.

- Router: You can put a chamfer bit on a router. This is good for making fast and even chamfers on big pieces.

- Table Saw or Miter Saw: You can tilt the blade to the angle you want. This helps you cut nice chamfers on thick wood.

- Sandpaper: You can use sandpaper to smooth sharp edges. This works best for finishing, not for big chamfers.

Tip: Always use measuring tools like chamfer gauges or depth micrometers. These help you check if your chamfer is the right size and angle.

Automated CNC machines can make chamfers by following computer instructions. This means every edge will look the same. Using machines also helps you make fewer mistakes and work faster.

Practical Considerations

When you add chamfers, you should think about cost, material, and quality. Setting up special tools can take time and money. If you only make a few parts, chamfers can make each one cost more. If you make a lot, the cost is less for each part.

The kind of material matters too. Harder materials need stronger tools and can wear out your cutters faster. Softer materials are easier to chamfer but can leave rough spots or burrs. You should also check your tools for wear. Worn tools can make uneven chamfers or leave marks.

Some common problems are:

- Chatter: Vibrations can make the edge rough. Use stiffer tools and slow down to fix this.

- Uneven Width: This can happen if your tools are worn or set up wrong. Check and change tools often.

- Chip Management: Chips can block your tools. Use coolants and clean your tools often.

Quality control is important. Digital gauges and 3D scanners help you measure chamfers fast and well. These tools help you avoid mistakes and keep your work the same every time. Always check your chamfers to make sure they are right for your design.

Chamfered edges are flat and slanted cuts on corners. They help make things safer and smoother. These edges also make it easier to put parts together. You can find chamfered edges on furniture, electronics, bolts, and circuit boards.

- Chamfering takes away sharp points, so things are safer and last longer. It also helps when putting things together.

- Chamfers are used in architecture, manufacturing, and woodworking. They are good for how things work and how they look.

- If you know about chamfers, you can design better products. You will also notice them on many things you use every day.When you look at something at home or a machine part, see if it has chamfered edges. These edges help make things safer and stronger.

FAQ

A chamfer cuts the edge at a specific angle, usually 45 degrees. A bevel can use any angle and often covers a larger surface. You use chamfers for safety and assembly. You use bevels for style or joining materials.

You can make a small chamfer with sandpaper or a file. For bigger or precise chamfers, you need tools like a chamfer plane, router, or milling machine. Always check your work with a ruler or gauge.

You see chamfered edges on furniture, machine parts, tools, and electronics. Builders use them in wood, metal, and stone. Chamfers help products look neat and work better.

Chamfers guide parts together and prevent damage. You can fit pieces faster and more safely. The angled edge helps you avoid mistakes and makes the process smoother.