Welding Service

—–—– provides you with high quality welding solutions.

We are a professional welding team, with many years of welding experience and exquisite technology, committed to providing customers with a full range of high-quality custom welding services. No matter how complex your needs are, we can meet your expectations.

Custom Welding Projects

AFI Industrial Co., Ltd. is capable of precisely joining metal materials into specific shapes or structures through professional welding techniques. It is widely applied in fields such as industrial equipment, building components, and artistic decoration.

Welding Workshop

Professional welding technology can provide customers with high-quality welding products.

Welding Fabrication

Professional metal welding can be used to meet customers’ requirements for the product.

Welding Accessories

High quality welding products can meet customer quality requirements.

Quality Control

We are equipped with professional testing equipment and personnel, strictly controlling the welding quality to ensure that we provide customers with high-quality products.

Custom Welding Service

AFI Industrial Co., Ltd. provides customized welding services for customers. During the customization process, engineers will combine the material properties, strength requirements and design drawings to select the optimal welding solution to ensure that the finished product is durable and meets the standards. Whether it’s small-batch parts or large steel structures, our welding customization can provide you with flexible and efficient solutions to meet the diverse needs of various scenarios.

High Quality Welding Products

AFI Industrial Co., Ltd. adopts intelligent welding systems and digital welding power supplies to achieve high-precision welding within ±0.1mm. We have an experienced professional team, and the core engineers all have more than 15 years of experience in the welding industry.

The advanced welding process management system can undertake the welding processing of special materials such as super-large components (maximum single weight 60 tons, deformation ≤3mm/m), precision electronic welding (minimum weld point 0.15mm), and active metal welding (porosity of titanium/zirconium alloy < 0.5%). We implement a three-level quality inspection system to ensure that the defect rate of each batch of products is less than 0.5%, helping customers shorten the production cycle.

Custom Welding Methods

AFI Industrial Co., Ltd. has an experienced professional team. The core engineers all have over 15 years of experience in the welding industry and are proficient in various advanced welding technologies.

We use laser-arc hybrid welding technology to achieve precision fusion welding at the 0.1mm level, are equipped with a 200-ton resistance welding machine to complete the pressure welding of ultra-thick plates, and adopt vacuum brazing technology to ensure aerospace-grade welding quality. We have successfully solved the problem of deformation in high-temperature alloy welding for our clients and provided over 500 welding solutions for fields such as rail transit and new energy equipment. The first-time pass rate of our products reaches 99.5%, helping you reduce production costs.

Fusion Welding Service

Our company’s fusion welding methods include arc welding, submerged arc welding, gas shielded welding, plasma arc welding, laser welding, etc. We can provide customized welding process solutions based on your production needs to ensure welding strength, sealing performance, and process stability.

Pressure Welding Service

The common welding methods we encounter include resistance welding, friction welding, diffusion welding, ultrasonic welding, and other processes. We can match the optimal welding solution according to the characteristics of your products (material combination, production volume requirements, strength standards) to ensure the consistency of your production and help you reduce the overall cost.

Brazing Service

Our company specializes in providing brazing methods such as flame brazing, induction brazing, and electric furnace brazing. Based on your product structure, material combination, and production capacity requirements, we offer customized brazing solutions to ensure the strength, sealing performance, and long-term reliability of your joints, while also helping you optimize production costs.

Precision Welding Service

AFI Industrial Co., Ltd. specializes in precision welding services and has a professional team and a mature process database. For the micro-soldering requirements of electronic components and large-scale structural soldering, we customize solutions based on material properties, product structure, and usage environment, and ensure quality through parameter optimization. With rich experience, we respond quickly to all kinds of special welding requirements and provide practical and efficient solutions.

Welding Drawings

After receiving the customer’s drawings, our technical team will conduct a drawing review and process planning to ensure that each processing link meets the requirements of the drawings, and the product size accuracy is controlled within ±0.01mm. Our quality control system ensures that the mass-produced products are consistent with the samples and meet all the technical requirements of customers.

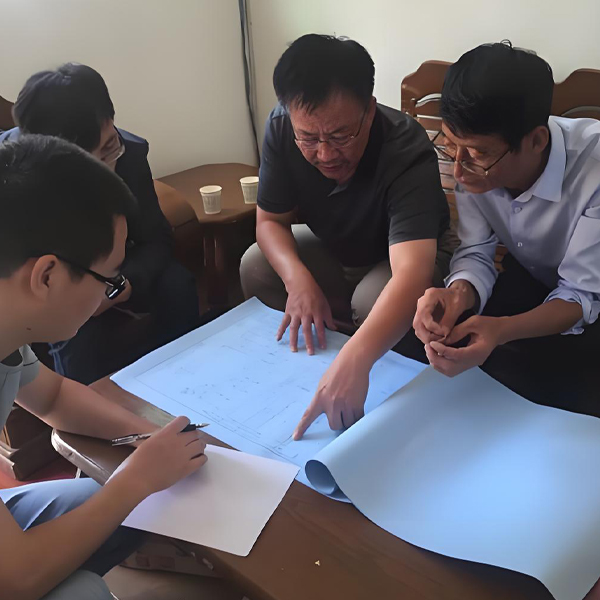

Engineer Analysis Drawing

The engineering team carried out three-dimensional tolerance analysis based on the GD&T standard. They selected the base material in combination with the ASTM material database, optimized the technical parameters through CAM programming, and simultaneously formulated the three-coordinate inspection procedures to ensure the control of μ-level form and position tolerances.

Pipe Bending

Our technical team, relying on years of processing experience, strictly adheres to standardized process flows and uses intelligent numerical control systems to precisely control processing parameters, ensuring that each product meets the dimensional accuracy and surface finish requirements of the drawings, providing customers with stable and reliable precision parts processing services.

Bending Measurement

From incoming material to the manufacturing process to delivery, quality inspection personnel test the products according to the drawings to ensure that the products fully meet the quality requirements of customers.

Custom Welding Materials

AFI Industrial Co., Ltd. offers professional metal welding services and surface treatment services. We have automated equipment and an experienced team, and are proficient in all kinds of metal processing. We adopt advanced welding, polishing, electroplating, and other technologies to ensure that the products are sturdy, durable, beautiful, and rust-proof. Tailor-made solutions for customers in accordance with international standards to meet the needs of different industries and comprehensively enhance product performance.

Carbon steel has a relatively low cost and its main components are iron and carbon. Low-carbon steel has excellent welding performance, high strength, and is less likely to produce hardened structures and cracks during welding. It is widely used in construction, Bridges, mechanical manufacturing and other fields.

The welding performance of alloy steels (such as manganese steel, chromium-molybdenum steel, etc.) is closely related to the content of their alloying elements. Special welding materials and process parameters need to be matched according to the specific composition. We formulate personalized welding plans through material analysis to ensure welding quality.

Stainless steel is corrosion-resistant, has high strength and good thermal stability. During welding, it is sensitive to hot cracks and prone to intergranular corrosion and deformation. We use processes such as inert gas shielded welding (TIG/MIG), laser welding or plasma welding to strictly control the interlayer temperature to inhibit carbide precipitation. After welding, it undergoes acid washing and passivation treatment to restore its corrosion resistance. It can ensure the long-term stable use of the weld seam in harsh environments.

The high-temperature resistance and corrosion resistance of nickel and nickel-based alloys require the selection of matching dedicated welding materials during welding, and special processes such as inert gas shielded welding should be combined. We ensure that the performance of the welded joints meets the standards by controlling the heat input and interlayer temperature.

Copper and copper alloys have good electrical and thermal conductivity. For copper welding, we use gas welding, argon arc welding, etc. During the welding process, we pay attention to preventing oxidation and cracking to ensure that the product quality meets the customer’s requirements.

- Brass

- copper

- bronze

- white copper

The tensile strength of titanium and titanium alloys can reach 900MPa, they are corrosion-resistant and biocompatible. We use 99.999% high-purity argon gas double protection welding, which can be widely used in aviation, Marine and medical devices.

The density of aluminium and aluminium alloys is approximately 2.7g/cm³, featuring high thermal conductivity and corrosion resistance. During welding, the oxide film is difficult to melt and prone to deformation. We adopt special processes such as AC TIG welding, pulse MIG welding or friction stir welding (FSW), combined with high-purity argon gas protection, to break through the surface aluminum oxide layer and prevent porosity, ensuring that the weld strength reaches over 80% of the base material. It can meet the demands of the industry.

Zinc and zinc alloys are corrosion-resistant and have excellent casting properties. Their low melting point (about 420℃) and high volatility make them prone to porosity, spatter and zinc vapor during welding. We adopt low-temperature brazing, gas shielded welding (MIG/TIG) or laser welding processes, and strictly control heat input to avoid material burning loss, which can ensure the density of the weld seam and guarantee product quality.

Professional Welding Team

AFI Industrial Co., Ltd. has a team of experienced welding experts, all of whom have over 15 years of professional welding experience. We are capable of handling a wide range of welding requirements, from 0.1-millimeter precision parts to 50-ton heavy equipment, especially in high-end manufacturing fields such as aerospace and energy equipment. With the welding technology and quality control system, the welding defect rate of our key components has always been kept below 0.5%. The team continuously optimizes the welding technology to ensure that it provides customers with reliable welding solutions that fully comply with industry standards.

Welding Engineer

Welding engineers are familiar with welding processes and can accurately plan welding structures and precision, providing customers with energy-saving and labor-saving welding solutions.

Senior Welder

Senior welders possess rich welding knowledge and superb welding skills and are capable of completing high-quality welding tasks in various complex environments.

Advanced Welding Equipment

AFI Industrial Co., Ltd. is equipped with a combination of professional welding equipment, including high-precision laser welding systems, argon arc welding workstations, and double-station shielded welding devices, forming a welding process chain. We match the welding plan based on the product characteristics to ensure stable welding results for everything from precision components to structural parts. This equipment configuration enables us to flexibly handle welding tasks of different materials and with different precision requirements, providing welding quality assurance for various industrial applications.

Laser Welding Machine

Laser welding services use high-energy beams to achieve rapid and precise connections. It features narrow weld seams (0.1-1mm), small heat-affected zones (< 0.5mm), and low deformation. It is suitable for welding thin plates and precision parts and can effectively maintain the original properties of the materials.

Argon Arc Welding Machine

Argon arc welding is a type of gas shielded welding that uses argon as the shielding gas. It can weld almost all metal materials, especially suitable for welding non-ferrous metals such as stainless steel, aluminum, and copper, and their alloys. It features high welding quality, a stable welding process, a small heat-affected zone, and minimal deformation, ensuring that the welding quality meets customer requirements.

Carbon Dioxide Gas Shielded Welding Machine

The deposition rate of the carbon dioxide gas shielded welding machine is 2 to 4 times that of manual welding, with low cost and convenient operation. It is the preferred process for welding medium and thick plates. It applies to the continuous welding of carbon steel materials such as steel structure frames, storage shelves, and construction machinery parts. Combined with high-quality welding wires like ER70S-6, it can achieve a welding speed of over 1.5 meters per minute while ensuring quality, which can meet the welding requirements of customers.

Butt Welding Machine

Laser welding services technology can achieve high-strength and precise connections of various complex workpieces. Whether it is an irregular structure or special materials, it can achieve narrow weld seams and small deformation welding. Its strength can reach over 90% of the base material, meeting the high standards of precision welding in the industrial field.

Spot Welder

Resistance welding services use electrodes to apply pressure and electricity, generating a concentrated heat source at the contact surface of the workpiece to form a metallurgical bond. This process features millisecond-level rapid prototyping and a small heat-affected zone. It is suitable for efficient welding of thin plates ranging from 0.1 to 3mm, with a single-point welding cycle controllable within 0.5 seconds. It is applied in fields such as automotive manufacturing.

How to Start Your Order

Send your drawings

Process discussion, quotation

Make a sample

Volume produce

Shipment & Payment

Shipping

Checkout

AFI Industrial Co., Ltd. has established a quality management system for CNC parts, equipped with professional testing equipment and a senior quality inspection team. We conduct all-around inspections at every stage by the customer’s drawings and technical standards to ensure that all products meet 100% of the customer’s quality requirements and industry standards.

Shipment

AFI Industrial Co., Ltd. collaborates with many well-known logistics partners worldwide. We will carefully package your products based on their characteristics and requirements, and then select the most cost-effective and fastest transportation plan for you to ensure the safe and punctual delivery of your goods.

Our Promise

With our services, you will get a trusted supplier. In the coming days, we will continue to improve our professional degree, expand our credibility, and let you get the following harvest!

Quality Guarantee

We offer a comprehensive inspection to ensure that the dimensions are accurate and the appearance meets the customer’s specifications during the welding process.

Quick Response

After receiving the order, we respond quickly within 2 hours, quote within 4 hours, and deliver according to quantity within 3-15 days.

Custom Material

We will according to the needs of customers, carefully select high-quality raw materials, customized to meet customer needs for all kinds of products.

Custom Surface Treatment

We can apply a variety of surface treatments to manufactured products according to customer requirements, including electroplating, anodizing, etc.

Arbitrary Size

We can produce products strictly in accordance with the dimensions on the drawings provided by customers, ensuring that every dimension is precise and error-free, fully meeting the quality standards.

Unlimited Quantity

Whether you need samples or mass production, we can precisely manufacture according to your requirements, ensuring that the quality of each product remains consistent.

Brand We Cooperated with

AFI Industrial Co., Ltd. has specialized in precision parts processing for 15 years and possesses multiple high-precision five-axis turning centers. We have passed the ISO9001 quality system certification. We have long been providing key components for the automotive and home appliance industries. We have rich mass production experience in products such as transmission valve bodies and heat dissipation components. Our product quality is stable and reliable, with a defect rate controlled below 0.05%.

Frequent Asked Questions

TIG welding service uses the arc generated between the tungsten electrode and the workpiece as a heat source, under the protection of inert gases (such as argon, helium, etc.), so that the welded metal is melted and connected. Tungsten electrodes do not melt in the welding process; they only play a conductive and arc role.

MIG welding service is a method of using a meltable wire as an electrode, using the burning arc between the continuous wire and the welder as a heat source to melt the wire and the base metal, and welding under the protection of an inert gas (such as argon, helium or its mixture).

Arc welding is a fusion welding method that uses an electric arc as the heat source. It converts electrical energy into thermal energy through the electric arc generated between the electrode (welding rod or welding wire) and the workpiece, melting the welding area of the welding rod (or welding wire) and the workpiece to form a molten pool. After cooling, a firm welding joint is formed. Arc welding is one of the most commonly used welding methods in modern industry, featuring flexible operation, strong adaptability, and high welding efficiency.

Cold welding is a type of welding method carried out at room temperature or near room temperature, without the need for additional heating.

It relies on pressing two clean metal surfaces together under high pressure, making them contact particularly closely. From the atomic level, the atoms on the metal surface interact with each other and then form bonds similar to those between atoms in solid metals, so that we can create a strong weld seam.

Fusion welding refers to a method in which the welding joint is heated to a molten state during the welding process and the welding is completed without applying pressure.

Our fusion welding mainly includes the following welding methods: 1. Electrode arc welding 2. Submerged arc welding 3. Gas shielded welding 4. Plasma arc welding 5. Electroslag welding 6. Laser welding, etc. According to your production needs, we can provide customized welding process solutions to help customers reduce production costs and improve production efficiency!