You might wonder, can you weld aluminum to steel? Yes, you can, but it is challenging to accomplish. Aluminum and steel respond differently to heat and pressure. When you attempt to weld them, weak compounds may form at the joint. To achieve a strong connection, you need specialized techniques such as friction stir welding, adhesive bonding, mechanical fasteners, or brazing. Both aluminum and steel require careful handling, and it’s essential to choose the right joining method to prevent weak or brittle joints.

Key Takeaways

- Joining aluminum to steel needs special ways. Use GMAW, GTAW, or friction stir welding to stop weak joints.

- Getting the surfaces ready is very important. Clean and roughen both metals to help them stick well and stop rust.

- Pick the best joining way for your project. You can use welding, adhesive bonding, mechanical fasteners, or brazing.

- Always check your joint after you finish. Look for cracks and make sure the bond is strong for safety and long use.

Table of Contents

Joining Challenges

Metal Properties

Joining aluminum to steel is not easy. These metals act differently when you work with them. Aluminum melts at a lower temperature than steel. This means aluminum can melt before steel does. You have to watch the heat so you do not ruin the aluminum. Steel can handle more heat and stays solid longer.

Aluminum and steel also expand at different rates when heated. Aluminum gets bigger faster than steel does. This can put stress on the joint. If you do not control this, cracks or weak spots can form. This is a bigger problem when using adhesive bonding. Large changes in shape can make the bond weaker. You need to think about these things to make a strong joint.

Here is a table that shows some important differences:

| Mechanical Properties | Aluminum | Steel |

|---|---|---|

| Corrosion Types | Different types, varied failure modes | Less prone to certain types |

| Fracture Mechanisms | Unique to aluminum | Depends on steel type |

| Yield Strength | Lower | Higher |

| Young’s Modulus | Lower stiffness | Higher stiffness |

| Strain Hardening Exponent | More ductile | Varies |

You also need to set welding parameters just right. If you do not, you can make mistakes. The different melting points and hardness make it tricky. You need to plan and use skill to join aluminum and steel.

Tip: Always make sure your joining method works for both aluminum and steel before you begin.

Intermetallic Compounds

When you join aluminum to steel, special compounds can form where they meet. These are called Al-Fe IMCs. They are hard and break easily. This can make the joint weak. How thick and what shape this layer is will affect the strength.

- A brittle Al-Fe IMCs layer forms where aluminum meets steel, which can make the joint weaker.

- The thickness, what it is made of, and its shape all matter for strength.

- Adding silicon or titanium can make the IMCs layer thinner.

- Nickel, chromium, titanium, and manganese can help the grain structure and make the joint stronger.

- Using zinc in the filler wire can make a new phase, FeZn10, which is less brittle and helps the joint.

You need to watch out for these compounds when joining different metals. If you do not, the joint can break when stressed. Knowing about these problems helps you pick the best way and materials to join aluminum and steel.

Choosing a Method

When you join aluminum and steel, you must pick a good method. Each way has things it does well and things it does not. You should think about what your project needs before you choose.

Welding Aluminum to Steel

Welding is a popular way to join aluminum and steel. You can use GMAW (MIG), GTAW (TIG), or friction stir welding. Welding makes a joint that will not come apart. You need special skills and tools for welding. Welding is best when you want the joint to be strong and last long. You need to watch for problems with how the metals work together. Aluminum and steel melt at different temperatures. Sometimes you need a special filler metal to help them join. Welding can make stress spots in the joint. People use welding a lot in building things.

Adhesive Bonding

Adhesive bonding uses glue or epoxy to stick aluminum and steel together. You put the adhesive on clean metal surfaces. This way makes the joint look smooth. Adhesive bonding works well for joining different metals. It spreads stress evenly across the joint. The joint usually stays together for good. Adhesive bonding does not work well with high heat. You should check if the glue or epoxy is right for your job.

Mechanical Fasteners

Mechanical fasteners like bolts, screws, or rivets join aluminum and steel without heat. You can take the joint apart if you need to. Fasteners work for many types of metals. You might see bumps or gaps where the fasteners go. Mechanical joining can make stress points in the joint. You need to make sure the fasteners fit both metals. This way is fast and does not need special tools.

Brazing

Brazing joins aluminum and steel with a filler metal. You heat the metals but do not melt them. Brazing makes the joint look nice. The joint usually stays together for good. Brazing works for some different metals. You need to pick the right filler metal so the metals join well. Brazing does not work with very high heat.

Tip: Always pick the joining method that matches your project. Think about how strong, tough, cheap, and nice-looking you want the joint to be.

Here is a table to help you compare the main joining methods:

| Joining Method | Permanence | Stress Distribution | Appearance | Compatibility | Temperature Resistance | Mechanical Resistance |

|---|---|---|---|---|---|---|

| Welding | Permanent | Local stress points | Acceptable | Limited | Very high | Special provisions |

| Brazing | Usually permanent | Fairly good | Good | Some dissimilar | Limited by filler | Fairly good |

| Mechanical Fastening | Disassembly possible | High stress points | Discontinuities | Most combinations | High | Special provisions |

| Adhesive Bonding | Permanent | Uniform load | Almost invisible | Ideal for dissimilar | Poor | Excellent fatigue |

When you pick a way to join aluminum and steel, look at these things:

- Can you use the method for your joint?

- Does the joint have enough strength?

- Is the equipment easy to get?

- Will the joint change your design?

- How fast can you make the joint?

- How much does each joint cost?

- Do you need special tools for size or weight?

- Can you test the joint without breaking it?

- Can you check the joint’s quality?

You should always make sure aluminum and steel work well together. Pick the way that fits your project the best.

Welding Aluminum to Steel

Can You Weld Aluminum to Steel?

You might ask, can you weld aluminum to steel? Many people want to know if you can join these two metals with welding. You can weld aluminum to steel, but you need to use special methods. Direct fusion welding is not a good choice. When you try to weld aluminum to steel using direct fusion, brittle intermetallic compounds form at the joint. These compounds make the weld weak. The joint can break easily.

Aluminum and steel have very different melting points. Aluminum melts much sooner than steel. The metals also expand at different rates when heated. These differences make welding aluminum to steel tricky. You need to use the right welding techniques to avoid cracks and defects.

Note: Always check the compatibility of your metals before you start welding aluminum to steel. This helps you avoid weak joints and problems later.

GMAW (MIG) and GTAW (TIG)

You can use GMAW (MIG) and GTAW (TIG) for welding aluminum to steel. These welding techniques use a filler metal to help join the two metals. You need to pick a filler that works well with both aluminum and steel. The filler stops the formation of brittle compounds. When you use GMAW (MIG), you feed a wire into the weld area. The wire melts and joins the aluminum and steel. GTAW (TIG) uses a tungsten electrode. You add the filler by hand.

Both methods need careful control of heat. If you use too much heat, you can melt the aluminum before the steel. If you use too little, the weld will not hold. You need to clean both metals before welding. Dirt and oil can ruin the weld. You also need to watch for cracks. Welding aluminum to steel with GMAW or GTAW works best for thin pieces. You can get high-quality welds if you follow the right steps.

Here is a table to help you compare GMAW (MIG) and GTAW (TIG):

| Welding Method | Filler Metal Needed | Best For | Heat Control | Skill Level |

|---|---|---|---|---|

| GMAW (MIG) | Yes | Thin materials | Medium | Moderate |

| GTAW (TIG) | Yes | Precise welding | High | Advanced |

Tip: Always use the right filler metal when welding aluminum to steel. This helps you avoid brittle joints.

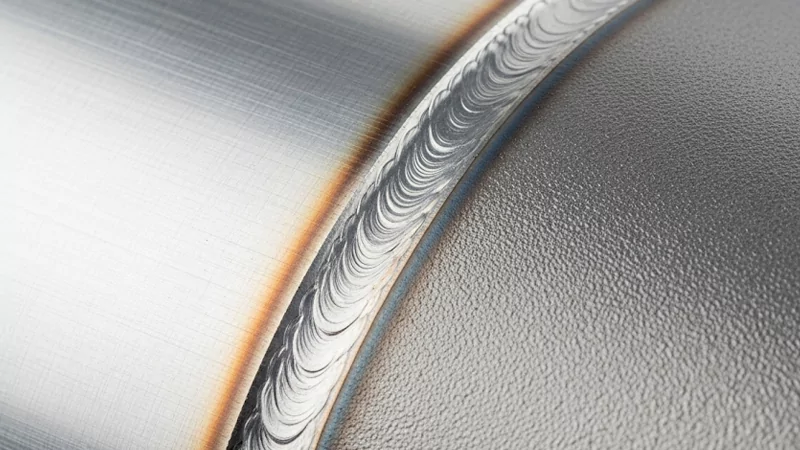

Friction Stir Welding

Friction stir welding is a newer way to weld aluminum to steel. You do not melt the metals. Instead, you use a spinning tool to mix the metals at the joint. The tool heats the metals by friction. The metals soften and blend together. This method stops the formation of brittle compounds. You get a strong joint. Friction stir welding works well for joining aluminum and steel in large sheets. You need special equipment for this method. You also need to check the compatibility of your metals. Friction stir welding gives you a smooth joint. You do not see cracks or holes. Many industries use this method for aluminum to steel bonding.

Callout: Friction stir welding is a good choice if you want a strong joint and have the right tools.

Weld Aluminum to Steel: Best Practices

You need to follow best practices when you weld aluminum to steel. Always clean both metals before you start. Remove oil, dirt, and rust. Use the right filler metal. Check the compatibility of your aluminum and steel. Control the heat during welding. Too much heat can melt the aluminum. Too little heat can make the weld weak. Watch for cracks and brittle spots. Use welding techniques that stop the formation of intermetallic compounds. GMAW (MIG), GTAW (TIG), and friction stir welding are good choices. Test your joint after welding. Make sure it is strong and does not break. If you follow these steps, you can get high-quality welds when joining aluminum and steel.

Here is a checklist for welding aluminum to steel:

- Clean both metals

- Pick the right filler metal

- Control the heat

- Check for cracks

- Test the joint

Tip: Always test your weld after you finish. This helps you make sure the joint is strong and safe.

Surface Preparation

Getting the surfaces ready helps make a strong bond. You need to clean, remove grease, and roughen both metals first. Good surface prep also keeps your joint safe from rust.

Cleaning and Degreasing

You have to get rid of all dirt, grease, and oil. Clean metal sticks together better. Use the right cleaner for each type of mess. Here is a table that shows some ways to clean:

| Cleaning Method | Description |

|---|---|

| Acidic Cleaners | Take off rust, oxide, and mineral build-up. These use acids like sulfuric or hydrochloric acid. |

| Alkaline Cleaners | Remove grease and other stuff, often with sodium or potassium hydroxide. |

| Degreasers | Solvents like alcohol or acetone take off oils and stains. |

| Mechanical Cleaning | Sandblasting and polishing scrub the surface clean. |

| Electrolytic Cleaning | Electric currents in a solution clean the metal gently. |

| Ultrasonic Cleaning | Sound waves shake off dirt without hurting the metal. |

| Solvent Cleaning | Alcohol-based cleaners get rid of oils and stains before you work. |

| Steam Cleaning | Hot steam takes off grease and stains. |

You can also use laser cleaning, chemical cleaning, sanding, solvent washing, or plasma cleaning. Always dry aluminum and steel before the next step.

Abrasion

You need to make the surfaces rougher to help them stick. Sanding or grinding makes tiny lines and grooves. These grooves help glue stick and make welded joints stronger. Studies show rougher surfaces from sanding help glue hold better. You get more strength and less chance of breaking. Using the right sandpaper grit helps things stick well. Making the surface rougher helps the joint stay strong.

| Study | Findings |

|---|---|

| Łyczkowska et al. | Sanding makes the surface rougher and helps glue stick better. |

| Effects of surface roughness parameters | The best SiC grit size gives great sticking power. |

| Surface roughness and chemistry | Making the surface rougher helps the joint get stronger. |

Always use clean tools when sanding or grinding. Wipe away dust after you finish.

Corrosion Prevention

When you join aluminum to steel, you need to stop rust. This kind of rust happens when the metals touch and get wet. You can stop rust by doing these things:

- Pick metals that are close together in the galvanic series.

- Use rubber or plastic gaskets to keep the metals apart.

- Put on coatings or use special materials to stop rust.

- Use gaskets or coatings to keep aluminum and steel from touching.

- Use a sacrificial anode for extra protection.

- Paint or coat the stronger metal to stop rust from spreading.

- Use rust stoppers in tough places.

- Make sure aluminum and steel do not touch with electricity.

Always look for open spots or gaps after you join the metals. Keeping aluminum and steel safe from rust helps your joint last a long time.

Step-by-Step Instructions

Welding Aluminum

Welding aluminum to steel takes careful planning and the right steps. You cannot use direct fusion welding because it creates weak joints. You need to use a bimetallic transition insert. This insert has one side made of aluminum and the other made of steel. Here is how you can weld aluminum to steel for a strong and lasting joint:

- Get a Bimetallic Transition Insert

Find an insert that has aluminum on one side and steel on the other. Industry experts recommend making this insert by rolling, friction welding, explosion welding, or hot pressure welding. These methods bond the two metals together and create a strong base for your weld. - Prepare the Surfaces

Clean both the aluminum and steel parts. Remove all dirt, grease, and oxide layers. Use a wire brush or sandpaper for the best results. Dry the surfaces before you start welding. - Position the Insert

Place the bimetallic insert between the aluminum and steel pieces. Make sure the aluminum side faces the aluminum part and the steel side faces the steel part. - Weld the Aluminum Side First

Start by welding aluminum to the aluminum side of the insert. This step keeps the insert from getting too hot. Use GMAW (MIG) or GTAW (TIG) for welding aluminum. Control the heat carefully. Too much heat can melt the aluminum and damage the insert. - Weld the Steel Side

Next, weld the steel side of the insert to the steel part. The aluminum helps absorb heat and protects the insert. Use the right filler metal for steel. Check your weld for cracks or weak spots. - Inspect the Joint

Look for any signs of brittle areas or gaps. Test the strength of your weld. If you see problems, clean the area and try again.

⚠️ Tip: Always wear gloves, a welding helmet, and protective clothing. Work in a well-ventilated area. Keep a fire extinguisher nearby.

Here is a table showing common hazards and how you can stay safe during welding aluminum to steel:

| Hazard Type | Description | Mitigation Strategies |

|---|---|---|

| Physical Hazards | Risks from heavy loads, falling objects, sharp edges, and machinery. | Use proper lifting techniques, appropriate equipment, and clear protocols to prevent accidents. |

| Chemical Hazards | Exposure to welding fumes, metal dust, and solvents. | Ensure proper ventilation, use personal protective equipment (PPE), and follow safe handling procedures. |

| Ergonomic Hazards | Issues from repetitive movements and awkward postures. | Implement ergonomic practices, provide training, and adjust workstations to reduce strain. |

| Fire and Explosion Hazards | Risks from welding, cutting, and flammable materials. | Implement fire prevention measures, ensure firefighting equipment is available, and promote fire safety awareness. |

🛠️ Troubleshooting:

- If the weld looks brittle, check your heat settings and make sure you used the right insert.

- If you see cracks, clean the area and try again with lower heat.

Adhesive Bonding

Adhesive bonding gives you a simple way to join aluminum and steel. You do not need special welding tools. Follow these steps for a strong bond:

- Clean Both Surfaces

Remove all grease, oil, and dirt from the aluminum and steel. Use a degreaser or alcohol-based cleaner. Dry the surfaces well. - Roughen the Surfaces

Sand both the aluminum and steel with fine-grit sandpaper. Wipe away dust. This step helps the adhesive stick better. - Apply the Adhesive

Choose an adhesive made for metal bonding. Epoxy or acrylic adhesives work well for joining aluminum to steel. Follow the instructions on the package. Spread the adhesive evenly on both surfaces. - Join the Parts

Press the aluminum and steel together. Hold them in place with clamps or weights. Make sure the parts do not move while the adhesive cures. - Let the Adhesive Cure

Wait for the adhesive to set. This can take several hours or overnight. Do not disturb the joint during this time. - Check the Bond

After curing, inspect the joint. Try to move the parts gently. If the bond feels weak, repeat the process with more surface preparation.

💡 Tip: Work in a well-ventilated area. Wear gloves to protect your skin from the adhesive.

🛠️ Troubleshooting:

- If the adhesive peels off, check if you cleaned and sanded the surfaces well.

- If the bond breaks under stress, try a different adhesive or increase the curing time.

Using Fasteners

Mechanical fasteners let you join aluminum and steel without heat or glue. You can use bolts, screws, or rivets. Here is how you can do it:

- Mark and Drill Holes

Mark where you want to join the aluminum and steel. Drill holes in both parts. Use the right size drill bit for your fasteners. - Clean the Surfaces

Remove any metal shavings, oil, or dirt from the holes and surfaces. - Insert Fasteners

Place bolts, screws, or rivets through the holes. Use washers to spread the load and prevent damage to the aluminum. - Tighten the Fasteners

Use a wrench or screwdriver to tighten the fasteners. Do not overtighten. This can strip the threads or deform the aluminum. - Check for Gaps

Look for any spaces between the aluminum and steel. Tighten the fasteners if needed. - Protect Against Corrosion

Add a plastic or rubber washer between the metals. This step helps prevent galvanic corrosion.

⚠️ Tip: Always use fasteners made from stainless steel or coated materials. This helps stop rust and keeps your joint strong.

🛠️ Troubleshooting:

- If the joint feels loose, check the hole size and fastener type.

- If you see rust, add a barrier or use corrosion-resistant fasteners.

Brazing

Brazing lets you join aluminum and steel with a filler metal. You heat the metals but do not melt them. Follow these steps for aluminum to steel brazing:

- Clean the Surfaces

Remove all dirt, grease, and oxide from the aluminum and steel. Use a wire brush or chemical cleaner. - Apply Flux

Spread flux on both surfaces. Flux helps the filler metal flow and prevents oxidation. - Heat the Joint

Use a torch to heat the aluminum and steel. Do not overheat. The metals should get hot enough to melt the filler, not the base metals. - Add the Filler Metal

Touch the filler rod to the joint. The filler should melt and flow between the aluminum and steel. - Let the Joint Cool

Remove the heat and let the joint cool slowly. Do not move the parts until the filler hardens. - Clean Off Residue

Remove any leftover flux with water or a wire brush. Inspect the joint for gaps or weak spots.

💡 Tip: Use a filler metal designed for aluminum to steel brazing. Always wear eye protection and gloves.

🛠️ Troubleshooting:

- If the filler does not flow, check your heat and flux.

- If the joint looks weak, try cleaning the surfaces again and reheating.

Inspection and Quality Control

Visual Checks

Always look closely at your aluminum and steel joint first. Checking with your eyes helps you find problems early. Look for cracks, holes, or rough spots. These can make the joint weak. Make sure the aluminum and steel parts match up well. If they do not, the joint might not stay together. The weld bead should be smooth and even. If you see lots of spatter or messy lines, the weld may not be strong. Here is a table to help you know what to check:

| Inspection Criteria | Description |

|---|---|

| Surface Examination | Look for cracks, holes, or missing spots that can make the joint weak. |

| Alignment and Fit-Up | Check if the parts are lined up before welding so the joint is strong. |

| Weld Bead Appearance | The weld bead should look the same all the way and go deep enough. |

| Identifying Common Defects | Watch for cracks, holes, missing spots, bad joining, and too much spatter. |

Tip: Always check both sides of the joint. Small problems can turn into big ones later.

Strength Testing

After you join aluminum to steel, you need to test how strong it is. Non-destructive testing (NDT) lets you check the joint without breaking it. These tests help you find hidden cracks or weak spots inside. Here are some common NDT methods you can use:

| NDT Method | Application |

|---|---|

| Ultrasonic Testing (UT) | Finds cracks or problems inside the joint. |

| Magnetic Particle Testing (MT) | Finds surface problems in metal parts. |

| Eddy Current Testing | Finds early signs of rust or metal loss. |

You can use these tests after welding or other joining ways. These tests help you make sure your joint is safe and strong.

Durability

You want your aluminum and steel joint to last a long time. The way you join the metals changes how strong and tough the joint will be. Welding gives you very strong joints but can bend the metal from heat. Adhesive bonding spreads the load better but is not as strong. Here is a table that compares how long different joining ways last:

| Joining Method | Strength | Thermal Distortion Risk | Load Distribution |

|---|---|---|---|

| Welding | Very High | High | N/A |

| Brazing | Moderate | Low | N/A |

| Adhesive Bonding | Moderate | Moderate | High |

Note: Always pick the joining way that fits your needs for strength and toughness. Check your joint often, especially if it will hold heavy things or be outside in bad weather.

Common Mistakes

Preparation Errors

People can make mistakes when getting aluminum and steel ready. If you miss steps, your joint might not work. Many people forget to clean the metal surfaces well. Dirt or oil can stop the metals from sticking together. Some people do not sand or roughen the surfaces. This makes it hard for glue or welding to hold. You need to pick the right materials and check them first. If you use the wrong alloy or skip checking, the joint can break.

Here is a table that shows common mistakes and how to avoid them:

| Preparation Error | How to Avoid It |

|---|---|

| Poor welding practices | Hire welders who know the right techniques. |

| Incorrect material selection | Check welds often for strength and quality. |

| Inadequate surface preparation | Clean and bevel edges before welding to make joints better. |

Do not design aluminum parts the same way as steel. Each metal needs its own plan. Always pick the right alloy and joint shape for your job. The best welding process depends on the metal you use.

Method Selection

Picking the wrong way to join aluminum and steel causes problems. If you choose wrong, you might get rust between the metals. This is called galvanic corrosion. Welding is hard because aluminum and steel melt at different heats. If you use the wrong process, the joint can break. Heating and cooling can make cracks or gaps. Using glue can make the joint heavy and sometimes weak. Rivets can make holes that weaken both metals.

- Galvanic corrosion can hurt your joint.

- Different melting points make welding hard.

- Heating and cooling can crack aluminum or steel.

- Glue may not hold if you do not use it right.

- Rivets can lower the strength of both metals.

You need to pick the joining way that fits your project. Always think about how strong and tough the joint needs to be. Think about where you will use the joint.

Safety Issues

Safety matters a lot when joining aluminum and steel. You must wear gloves, goggles, and safe clothes. Welding makes bright light and hot sparks. These can burn your skin or eyes. Breathing fumes from welding or glue can be bad for you. Always work in a place with good airflow. Keep a fire extinguisher close by. Do not rush or skip safety checks. If you use power tools, keep hands and clothes away from moving parts. Check your tools before you start. Safe habits help you stay safe and make your work better.

⚠️ Always follow safety rules when working with aluminum and steel. Good safety keeps you and your project safe.

Quick Checklist

Before Joining

You need to get ready before you start joining aluminum and steel. Clean both metals with a degreaser. Remove all oil, dirt, and dust. Sand the surfaces to make them rough. This helps the bond stay strong. Check the type of aluminum and steel you have. Make sure they work well together. Pick the right method for joining, such as welding, adhesive bonding, or using fasteners. Gather all your tools and safety gear. Wear gloves, goggles, and a mask. Set up your workspace so you have good light and air flow.

Tip: Always check for signs of rust or corrosion on aluminum and steel before you begin.

During Joining

Watch each step closely while you join aluminum and steel. Control the heat if you use welding. Too much heat can melt aluminum too fast. Not enough heat can make the weld weak. Keep an eye on the joint for cracks or gaps. Make sure the filler metal matches both aluminum and steel. If you use adhesive, press the metals together and let the glue cure. For fasteners, tighten bolts or screws just enough. Do not overtighten, or you might damage the aluminum. Monitor the formation of intermetallic compounds. These can make the joint brittle. Stay alert for signs of galvanic corrosion, especially when aluminum touches steel.

| Critical Steps to Monitor | Why It Matters |

|---|---|

| Heat control during welding | Prevents weak welds and protects aluminum |

| Intermetallic compound formation | Stops brittle joints from forming |

| Galvanic corrosion risk | Keeps aluminum and steel safe from rust |

After Joining

Check your work after you finish joining aluminum and steel. Look at the joint for cracks, holes, or rough spots. Test the strength by gently pulling or pressing the joint. Make sure the weld bead looks smooth if you used welding. Clean off any leftover flux or adhesive. Protect the joint from moisture to stop corrosion. If you see rust, add a coating or barrier between aluminum and steel. Inspect the joint often, especially if it will be outside or hold heavy loads.

Note: Regular checks help your aluminum and steel joint last longer and stay safe.

You can join aluminum to steel if you pick the right way and get the surfaces ready. New welding methods, like laser welding and hybrid welding, make the joint stronger and more reliable. Always clean both metals and take off the oxide layer. Use good surface prep methods like laser texturing. Follow safety rules and check your work when you finish. Use the quick checklist for each project. Learn more from places like AHSS Insights and WorldAutoSteel, which give new tips for welding aluminum and steel.

FAQ

You cannot weld aluminum directly to steel. Brittle compounds form at the joint. You need a special insert or filler metal to make a strong connection.

Epoxy adhesives work best for joining aluminum to steel. You should choose a product made for metal bonding. Always clean and roughen both surfaces before applying the adhesive.

You can prevent corrosion by using plastic or rubber washers. You should coat the metals or use a barrier. Keep moisture away from the joint to help it last longer.

You can braze aluminum to steel at home if you have the right tools. Use a torch, flux, and a suitable filler metal. Always follow safety rules and work in a well-ventilated area.

Welding with a bimetallic transition insert gives you the strongest joint. Friction stir welding also creates a strong bond. You need special equipment and skills for these methods.