To pick the right valve castings, you need to match the casting type and material to your operating environment, what flows through the valve, and what you want the valve to do. If you pick the wrong one, it can be very risky.

- 37% of valve leaks happen because the shell casting has problems.Good nuclear valve castings keep dangerous materials safe. They are strong and stop leaks and system breaks. This keeps people and nature safe.

You save money and stop shutdowns when you use good valve castings. AFI Industrial Co., Ltd. gives careful machining and solutions you can trust for your needs.

Key Takeaways

- Pick the right valve casting by matching materials to your system’s temperature, pressure, and media type. This stops leaks and problems.

- Check your valve castings often, at least every six months, to find wear and damage early. This keeps your system working well.

- Choose materials based on the media they will handle. Different liquids and gases need different casting materials for safety and good performance.

- Think about the operating conditions, like temperature and pressure, when picking valve castings. High-pressure systems need stronger materials.

- Use corrosion-resistant materials such as stainless steel or special alloys for tough environments. This makes your valves last longer.

- Talk to manufacturers for expert help and custom solutions. They can help you pick the best casting for your needs.

- Use online tools and software to make valve selection easier. These resources help you make smart choices fast.

- Follow industry standards like API and ASME to make sure your valve castings are safe and reliable. Following rules helps you avoid expensive problems.

Table of Contents

Operating Conditions

When you pick valve castings, think about where they will work. Temperature, pressure, and exposure all matter. These things change how well valves work and how long they last.

Temperature

High

High heat can change how valve castings act. The metal can stretch or bend when it gets hot. This can make seals stop working and cause leaks. Some metals get weaker if they stay hot for a long time. You need to use materials that can take the heat.

Low

Cold can make valve castings break more easily. If you use the wrong metal, it might crack. Seals and gaskets can get hard and not keep fluids in. You should pick materials that stay strong and bendy in the cold.

Extreme temperatures change valve castings in many ways:

- Materials can get weak. Heat makes them grow, cold makes them break.

- Seals may not work right. They can get too soft or too hard.

- Stress on the valve goes up. Growing and shrinking can make parts tired and not work well.

AFI Industrial Co., Ltd. knows how to make valves for any temperature. Their careful work helps you get castings that fit your needs.

Pressure

High

Valves in high-pressure places need to be very strong. If the casting is weak, it can break or leak. Always check the pressure rating before you pick a material.

Low

Low-pressure systems do not need super strong castings. You can use lighter metals. This can save money and make putting them in easier.

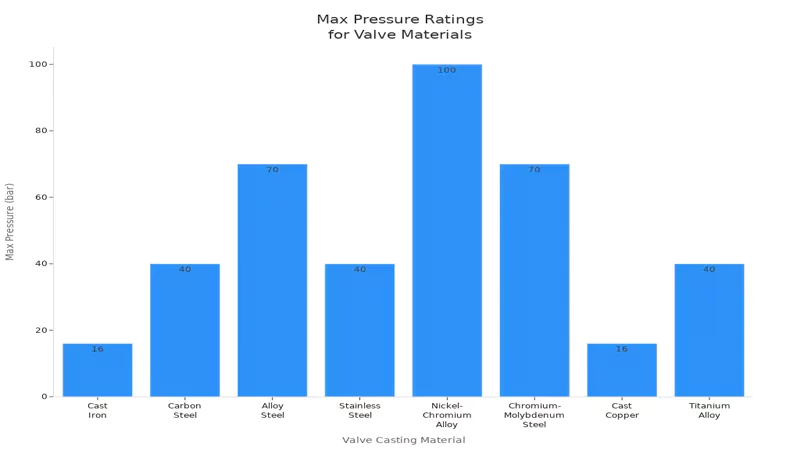

Here is a table that shows which materials work best for different pressures:

| Material | Pressure Rating | Temperature Range | Applicable Media | Common Grades |

|---|---|---|---|---|

| Cast Iron | Low to medium (up to 16 bar) | -10°C to 200°C | Water, oil, air | ASTM A126, ASTM A536 |

| Carbon Steel | Medium to high (16-40 bar) | -29°C to 425°C | Water, oil, steam | ASTM A216 WCB, ASTM A105 |

| Alloy Steel | High (40-70 bar) | -29°C to 600°C | Steam, oil, chemicals | ASTM A217 WC6, WC9 |

| Stainless Steel | Medium to high (16-40 bar) | -196°C to 800°C | Acids, alkalis, corrosive media | ASTM A351 CF8, CF8M |

| Nickel-Chromium Alloy | High (over 70 bar) | -196°C to 1,000°C | Extreme corrosive, high temp media | ASTM A494 CW6M, M35-1 |

| Chromium-Molybdenum Steel | High (40-70 bar) | -29°C to 600°C | High temp, high pressure media | ASTM A182 F22, F91 |

| Cast Copper | Low to medium (up to 16 bar) | -30°C to 250°C | Water, low corrosive media | ASTM B584 C84400, C83600 |

| Titanium Alloy | Medium to high (16-40 bar) | -196°C to 600°C | Highly corrosive media, seawater | ASTM B265, B338 |

AFI Industrial Co., Ltd. can help you pick the right casting for your pressure needs. Their team knows how pressure changes valve safety and how well it works.

Exposure

Indoor

Indoor valves do not get much damage from weather. You can use normal materials for most indoor jobs. It is easier to take care of them, and they last longer.

Outdoor

Outdoor valves must handle rain, sun, and sometimes saltwater. Rust happens faster outside, especially near the sea. Saltwater makes valves wear out five to ten times faster than freshwater.

- Valves near the sea rust more because of saltwater.

- Saltwater moves ions, which hurts metal faster.

- Oxygen in seawater makes rust even worse.

You need to pick castings that do not rust easily for outdoor use. AFI Industrial Co., Ltd. has answers for every place, even tough outdoor spots.

Media Type

You need to know what moves through your system. Liquids, gases, and corrosive stuff change how valves work. They also change how long valves last. Pick the right casting for each media type. This keeps your system safe and working well.

Liquid

Water

Water is used in many systems. It looks safe but can cause rust. Scale can build up inside valves. Wrong metals can get damaged by water. Stainless steel and coated iron stop rust. These choices help prevent leaks.

- Stainless steel does not rust and lasts longer.

- Cast iron works for low pressure water with a coating.

- Checking valves often helps find rust early.

Oil

Oil moves differently than water. It can be thick or thin. Some oils react with metals. Wrong castings can break seals or leak. Use materials that do not react with oil. Make sure they can handle oil heat.

- Bronze and stainless steel work with most oils.

- Some oils need special seals to stop leaks.

- Always check the oil before picking a valve casting.

Gas

Steam

Steam is hot and moves fast. It puts stress on valve castings. Weak metals can crack. Seals can wear out. Use castings that handle heat and pressure. Tight seals stop leaks.

- Alloy steel and stainless steel resist heat and pressure.

- Steam valves need strong bodies and tight seals.

- Maintenance keeps steam valves safe.

Air

Air is easier on valves than steam. Dust and moisture can cause rust. Blockages can happen. Use castings that do not rust. Keep air clean.

- Aluminum and stainless steel are good for air valves.

- Filters keep dust and moisture out.

- Simple designs make air valves easy to fix.

Here is a table with media types, risks, and valve needs:

| Media Type | Associated Risks | Valve Requirements |

|---|---|---|

| Gas | High pressure, extreme temperatures, corrosion | Must withstand high pressure and corrosion |

| Steam | Mechanical stress, high temperature | Precise sealing and responsiveness |

| Liquid | Chemical compatibility issues | Materials must match fluid type |

| Corrosive Liquids | Material degradation | Use stainless steel or special alloys |

Corrosive

Acid

Acids hurt metals fast. Wrong castings can fail quickly. Most chemical equipment fails because of corrosion. Stainless steel and nickel alloys stand up to acids. They keep your system safe.

- Nickel alloys like HASTELOY® and INCONEL® resist acid better.

- Mixing metals can cause galvanic corrosion.

- Always check acid type and strength before choosing.

Alkali

Alkalis also cause corrosion. They attack metals in a different way. Use materials that resist alkali damage. Stainless steel works for mild alkalis. Strong alkalis need special alloys.

- INCOLOY® and MONEL® resist alkalis very well.

- Mixing metals can make corrosion worse.

- Check all materials in your system to avoid problems.

Tip: Strong acids and alkalis need special valve castings. Picking the wrong material can cause leaks or damage. Always match your casting to the media for safe operation.

Abrasive

Abrasive media can hurt valve castings fast. You must know how slurry and particulates affect valves. The right casting helps stop leaks and damage. This also saves money on repairs.

Slurry

Slurry is a mix of liquid and solid pieces. You find slurry in mining, wastewater, and chemical plants. The solid parts rub and scrape the valve. This wears out the valve quickly.

Look for these things when picking valve castings for slurry:

- Hard Materials: Use castings made from hardened steel or special alloys. These do not scratch or grind easily.

- Smooth Surfaces: Smooth finishes help lower friction. Less friction means less damage.

- Thick Walls: Thick valve walls last longer. They can take more scraping before breaking.

- Replaceable Liners: Some valves have liners you can swap. This makes fixing them easier.

Tip: Always check the size and hardness of the particles in your slurry. Bigger and harder pieces cause more harm.

Here is a table to help you compare materials for slurry jobs:

| Material | Abrasion Resistance | Typical Use | Maintenance Needs |

|---|---|---|---|

| Hardened Steel | High | Mining, Slurry | Moderate |

| Stainless Steel | Medium | Wastewater, Slurry | Low |

| Alloy (Ni-Hard) | Very High | Chemical Slurry | Low |

| Rubber Lined Iron | High | Sand Slurry | Replace liner |

AFI Industrial Co., Ltd. gives castings with special surface treatments. These treatments help valves last longer in tough slurry places.

Particulate

Particulate media has dry solid bits like sand, dust, or powder. You see these in cement plants, food factories, and air filters. Particulates can scratch and wear down valve surfaces.

Think about these things for particulate media:

- Wear Resistance: Pick castings that do not wear out fast. Alloy steels and ceramics are good choices.

- Tight Seals: Good seals keep particles inside. This keeps your system safe and clean.

- Easy Cleaning: Valves with simple shapes are easy to clean. This stops blockages.

Note: Check your valves often to spot wear early. Change worn parts before they break.

Here is a checklist for picking valve castings for particulate media:

- Check the type and size of the particles.

- Pick materials that do not scratch or wear down.

- Make sure seals fit well.

- Plan to clean and check valves often.

AFI Industrial Co., Ltd. can help you pick the best casting for abrasive media. Their careful work and quality checks help your valves last through hard jobs.

Performance Needs

When you pick valve castings, think about how your system works each day. The right choice helps valves run well and last longer.

Flow Rate

High

If your system needs a high flow rate, look at valve size and shape. Bigger valves with wide openings let more fluid move. The flow coefficient (Cv) shows how much flow a valve can handle. Check this number when you look at valve details.

- The flow rate tells you how big the valve should be.

- Large openings let fluid move fast.

- Cv helps you match the valve to your system.

Low

For low flow rates, use valves with small openings. These valves give better control over flow. You can stop waste and keep things working well. Small valves help stop leaks and make pressure easier to manage.

Tip: Always pick the right valve size for your flow. Too big or too small can cause problems with control and waste.

Pressure Rating

Max

Every valve has a top pressure it can take. Check this before you pick a casting. High-pressure systems need strong materials and good designs. Industry rules help you choose safe and reliable valves.

| Standard Organization | Material Type | Standard Code |

|---|---|---|

| ASME/ANSI | Gray Iron | ASME B16.1 |

| ASME/ANSI | Ductile Iron | ASME B16.42 |

| ASME/ANSI | Steel | ASME B16.5 |

| AWWA | Ductile Iron | AWWA C110 |

| AWWA | Gray Iron | AWWA C110 |

| AWWA | Steel | AWWA C207 |

Fluctuation

Pressure can change quickly in some systems. You need valves that can handle these changes. Strong castings and flexible seals help stop leaks and damage. Always check how much pressure changes when your system runs.

Note: Fast pressure changes can wear out valves. Pick castings that fight stress and wear.

Sizing

Valve Size

Valve size changes how well your system works. If the valve is too small, you use more energy and it wears out fast. If the valve is too big, you lose control and waste resources.

| Valve Sizing Issue | Impact on Operational Efficiency and Reliability |

|---|---|

| Undersized Valves | More energy use, higher pressure drop, faster wear and tear |

| Oversized Valves | Poor flow control, lower efficiency, frequent overshoots |

Connection Size

You must match the valve’s connection size to your pipes and fittings. If sizes do not fit, you can get leaks or blockages. Always check the connection size before you buy.

Tip: Right sizing keeps your system safe and working well. Double-check all sizes before you install.

Valve Castings Materials

Picking the right valve castings materials is very important. It changes how well your valves work and how long they last. You should think about corrosion resistance, durability, and if it fits your system. The right material helps stop leaks, breakdowns, and expensive repairs.

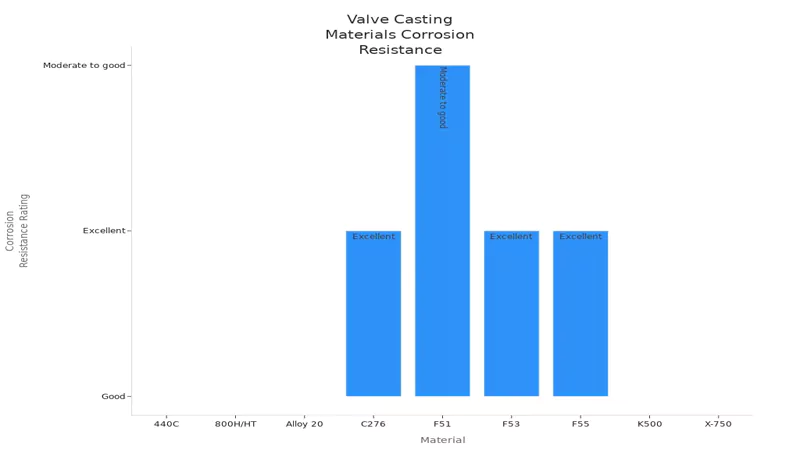

Corrosion Resistance

Corrosion can damage valve castings fast. If you use the wrong material, valves can fail in tough places. You must match the material to the chemicals, temperature, and pressure in your system.

Stainless Steel

Stainless steel is a common choice for valve castings. It does not rust and stands up to many chemicals. A thin oxide layer on stainless steel keeps it safe from harm. You find stainless steel in water, oil, and mild acid systems. It is good for places that need clean and safe work.

Alloy

Alloy materials give more protection in hard conditions. Alloys like Hastelloy, Incoloy, and Monel work well with strong acids, alkalis, and high heat. You use these alloys when stainless steel is not enough.

Here is a table that shows how different valve construction materials do in corrosive places:

| Material | Composition | Corrosion Resistance Rating |

|---|---|---|

| 440C | 17% Chrome, 3/4% Moly | Good, tempering below +800°F (+427°C) |

| 800H/HT | Incoloy | Good, used above +1100°F (+593°C) |

| Alloy 20 | 20% Chrome, 35% Nickel, 2-1/2% Moly | Good resistance to hot sulfuric acid to +800°F (+425°C) |

| C276 | Hastelloy | Excellent in a wide range of corrosive media at ambient temperatures |

| F51 | 22% Chrome, 5% Nickel, 3% Moly | Moderate to good in various environments, service to +600°F (+316°C) |

| F53 | 25% Chrome, 7% Nickel, 4-1/2% Moly | Excellent in various environments, service to +600°F (+316°C) |

| F55 | 25% Chrome, 7% Nickel, 3-1/2% Moly | High strength and good ductility, excellent corrosion resistance to +600°F (+316°C) |

| K500 | Monel | Good, mechanical properties at subzero temperatures up to +480°C |

| X-750 | Inconel | Good resistance to corrosion and oxidation, service to +1300°F (+700°C) |

Tip: Always check the chemical and temperature limits for each material before you pick your valve castings.

Durability

You want valve castings that last a long time. Durability means your valves can take wear and hits without breaking.

Wear

Wear happens when fluids or bits rub the valve surface. Stainless steel fights wear in clean systems. Alloy steel is better for sand, slurry, or other rough stuff.

Impact

Impact resistance matters if your system has sudden pressure changes. Alloy steel is stronger and tougher than stainless steel. This helps valves survive hard hits and keep working.

Here is a table that compares how tough stainless steel and alloy materials are:

| Material | Corrosion Resistance | Mechanical Properties |

|---|---|---|

| Stainless Steel | Exceptional due to passive oxide layer | Good, but not as strong as alloy steel |

| Alloy Steel | Lower than stainless steel | Superior strength, hardness, and toughness |

Note: Pick the material that fits your system’s needs. If you expect lots of wear or hits, choose alloys with more strength.

Compatibility

Valve castings must fit your system’s chemicals and temperatures. If you pick the wrong material, your valves might corrode, crack, or break.

Chemical

Chemical compatibility is very important for safety. You need to know what chemicals go through your valves. Some chemicals attack metals faster when hot or strong. Stainless steel and Monel cost more, but last longer with harsh chemicals. Look at past use and data to help you pick the best material.

- Corrosion resistance is most important with strong chemicals.

- Hotter and stronger chemicals make corrosion worse.

- Cost and valve life matter for your choice.

- Use charts and history to help you decide.

Thermal

Thermal compatibility means your valve castings can take the heat or cold in your system. Some materials work better in high heat, others stay strong in the cold. Always check the temperature range for each material.

Here is a table that shows how different materials handle heat and corrosion:

| Material | Specification | Corrosion Resistance Rating |

|---|---|---|

| 12% Chrome Steel | ASTM A487 Grade CA6NM | Corrosive application at -20°F (-30°C) to +900°F (+482°C) |

| 12% Chrome | ASTM A217 Grade CA15 | Corrosive application up to +1300°F (+704°C) |

| Hastelloy | ASTM A494 | Good for hydrofluoric acid, resistant to sulphuric and phosphoric acids to +1200°F (+649°C) |

| Inconel | ASTM A743 Grade CY-40 | Very good for high-temperature service, resistant to spangly corrosive media to +800°F (+425°C) |

Tip: Always match your valve castings to the chemicals and temperatures in your system. This helps you avoid leaks and breakdowns.

Quality Control and Technological Advancements

You want valve castings that meet high quality standards. AFI Industrial Co., Ltd. uses a strong quality control system. Their ISO 9001 certification means you get steady and good quality every time.

| Certification | Description |

|---|---|

| ISO 9001 | Certified Quality Management System, emphasizing continual improvement in quality and processes. |

| ISO 9001:2015 | Committed to continuous improvement for customer satisfaction. |

| ISO 9001 | Ensures reliable and uniform quality across all casting projects. |

New technology helps you get better valve castings. Advanced coatings make valves last longer. New alloy formulas give you lighter and stronger valves. Smart materials and additive manufacturing let you use valves in more places and make complex parts.

| Advancement Type | Description |

|---|---|

| Advanced Coatings | Enhance durability, reduce wear, and extend service life of valve castings. |

| New Alloy Formulations | Developed to withstand extreme conditions, resulting in lighter, stronger, and more corrosion-resistant valves. |

| Smart Materials | Integration leads to more efficient and adaptable valve systems for various industrial applications. |

| Additive Manufacturing | Enables production of complex valve components, improving functionality and efficiency. |

Callout: AFI Industrial Co., Ltd. uses advanced machining and strict quality checks to give you valve castings that meet your needs. Their ISO 9001 certification shows their commitment to quality and reliability.

You need to think about valve features, system needs, and new technology when you pick valve castings. The right valve construction materials help you get safe, strong, and long-lasting valves.

Selecting the Right Valve Design

When you pick a valve, think about how you want to control it. Also, look at how it connects to your pipes. Each valve design works best for certain jobs.

Manual

Handwheel

Manual valves have a handwheel for control. You turn the wheel to open or close the valve. This type is good for simple use and direct control. You do not need power or air for these valves. They work well in places where you do not change settings often.

- Manual valves cost less than other types.

- They are easy to fix because parts are simple.

- You must be there to use the valve, which can be risky in unsafe areas.

Manual valves are best for small systems or when you do not need fast changes.

Automatic

Electric

Electric valves use motors to move the valve. You can control them from far away. These valves are good when you need quick changes or cannot reach the valve. Electric valves give you exact control and help keep workers safe.

Pneumatic

Pneumatic valves use air pressure to move the valve. You can set them to open or close by themselves. These valves react fast and work well in systems that need quick changes. Pneumatic valves also help keep people safe by letting you control them from a distance.

Here is a table that shows how manual and automatic valves compare:

| Factor | Manual Valve | Automatic Valve |

|---|---|---|

| Control | Human operation | Remote or automatic |

| Precision | Limited | High |

| Safety | Human exposure risk | Minimizes human interaction |

| Cost | Lower | Higher (actuators needed) |

| Maintenance | Simple | More complex |

| Speed | Slower | Fast response |

Tip: Use manual valves for easy jobs and low cost. Pick automatic valves for safety, speed, and remote control.

Connection

Flanged

Flanged connections have flat ends with holes for bolts. You bolt the valve to the pipe. This makes a strong and tight connection. Flanged valves are good for big systems and high pressure. You must line up the flanges and use the right gasket to stop leaks. Keep the flanges even when you connect them.

- Flanged connections work for many factory jobs.

- They let fluid flow straight without losing pressure.

- You need to tighten bolts in order to stop leaks.

Threaded

Threaded connections use screw threads to join the valve and pipe. You twist the valve onto the pipe. This is simple and best for small or low-pressure systems. You may need sealant to stop leaks. Threaded valves do not need welding, but welding can make them stronger.

- Threaded connections are quick to put in.

- You use them for low-pressure jobs.

- Sealants help keep leaks away.

Note: Always check the connection type before you put in a valve. The right connection makes setup and fixing easier.

Valve Type

When you look at valves, you see many types. Each type works best for certain jobs. You need to know how each one works before you choose.

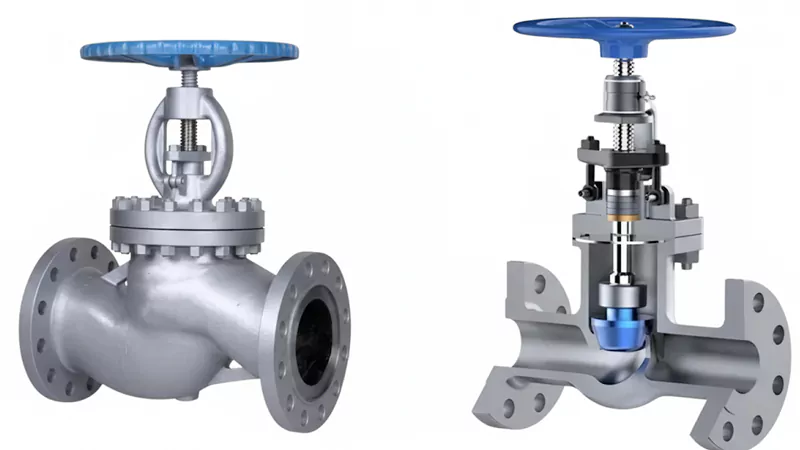

Globe

Globe valves help you control flow very well. You turn the handle, and the disk moves up or down. This lets you change how much fluid passes through. You use globe valves when you want to adjust flow, not just turn it on or off.

Key features of globe valves:

- Good for throttling and flow control

- Easy to repair

- Not the best for full open or close

Tip: Use globe valves when you need to fine-tune the flow in your system.

Ball

Ball valves use a round ball with a hole in the middle. When you turn the handle, the hole lines up with the pipe. This lets fluid move through. Turn the handle again, and the ball blocks the flow. Ball valves work fast and seal tightly.

Why pick a ball valve?

- Quick to open and close

- Great for shut-off jobs

- Lasts a long time with little care

Ball valves do not control flow as well as globe valves. You use them when you want simple on/off control.

Gate

Gate valves use a flat gate that moves up and down. When you lift the gate, fluid flows. When you lower it, the flow stops. Gate valves work best when you need the valve fully open or fully closed.

Advantages of gate valves:

- Low pressure drop when open

- Good for straight-line flow

- Not for adjusting flow

Note: Gate valves can get stuck if you use them to control flow. Use them for on/off jobs only.

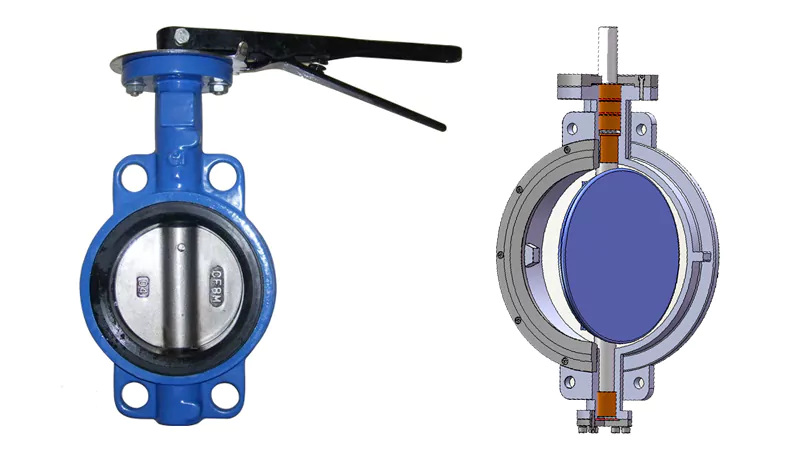

Butterfly

Butterfly valves have a disk that turns in the middle of the pipe. When you turn the handle, the disk turns and lets fluid pass. These valves are light and take up little space.

Butterfly valve benefits:

- Easy to install

- Good for large pipes

- Quick to open and close

Butterfly valves do not seal as tightly as ball valves. You use them when you need to move a lot of fluid fast.

| Valve Type | Best Use | Flow Control | Seal Tightness | Size Range |

|---|---|---|---|---|

| Globe | Throttling | Excellent | Good | Small to Medium |

| Ball | On/Off | Poor | Excellent | Small to Large |

| Gate | On/Off | Poor | Good | Medium to Large |

| Butterfly | Large Flow | Fair | Fair | Large |

When selecting the right valve, think about what your system needs. Each valve type has a special job. Pick the one that matches your flow, pressure, and control needs.

Maintenance and Compliance

Picking the right valve casting means you need to think about how you will keep it working and if it follows the rules. Maintenance and compliance help you stop problems and keep your system safe.

Maintenance

Inspection

You should check your valves often. Inspections help you find wear, leaks, or damage early. When you look at valves, check for rust, cracks, and loose parts. Also, look at seals and gaskets. Regular checks help valves last longer and let you plan repairs before something breaks.

Tip: Make a plan for inspections. Write down what you see each time. This helps you spot patterns and fix problems early.

Parts

Valve parts wear out as time goes by. Clean and oil moving parts to stop friction and rust. Change seals, gaskets, and liners when they look worn. If your valves work in high heat or pressure, check parts more often. Keep spare parts ready so you can fix valves fast and avoid long stops.

- Cleaning and oiling stop rust.

- Testing and calibration keep valves working right.

- Quick fixes stop small problems from getting worse.

AFI Industrial Co., Ltd. sends replacement parts quickly. Their service helps you get what you need fast so your system keeps running.

Standards

API

Valves must follow industry rules to be safe. The American Petroleum Institute (API) makes rules for design, materials, and testing. API standards help you pick valves that last and keep your system safe.

| Standard | Description |

|---|---|

| API Standards | Rules for design, materials, testing, and how valves work in oil and gas. |

| API 600 | Rules for gate valves used in oil and gas. |

| API 602 | Rules for small, forged steel gate valves. |

| API Specification 6D | Rules for valves in pipelines. |

| API 622, API 624 | Rules for stopping leaks in oil and gas valves. |

ASME

The American Society of Mechanical Engineers (ASME) sets rules for safety and strength. ASME standards make sure valves work under pressure and last a long time.

| Standard | Description |

|---|---|

| ASME Standards | Rules for safety, strength, and how valves work. |

| ASME B16.34 | Rules for valves in piping systems. |

| ASME BPVC | Boiler and Pressure Vessel Codes with valve rules. |

Note: Always check that your valves follow API and ASME rules. This keeps your system safe and helps you follow the law.

Regulations

Environmental

Environmental rules change which valve castings you can use. You must pick valves that stop leaks and lower emissions. Many places need valves to meet clean air and water rules.

| Regulatory Body | Standard/Regulation | Impact on Valve Selection |

|---|---|---|

| ISO | ISO 14001 | Rules for caring for the environment in valve making |

| ISO 15848 | Rules for testing valve leaks | |

| EPA | Clean Air Act | Rules for valve emissions, need low-emission valves |

| EU | Industrial Emissions Directive | Rules for controlling emissions in factories |

| REACH | Makes sure materials are safe for health and nature |

Safety

Safety rules protect people and equipment. You must use valves that follow safety codes. These codes say how strong valves must be and how they work in emergencies. Following safety rules helps you avoid accidents and fines.

AFI Industrial Co., Ltd. helps you follow all rules and standards. Their team knows the latest rules and can help you pick the right valve casting for your needs.

Consult to Select the Right Valve

If you want good results, do not choose alone. Getting help from experts helps you avoid mistakes. They can help you find the best valve for your system. You can talk to trusted companies like AFI Industrial Co., Ltd. for support and special choices.

Manufacturer

Support

Talking to a manufacturer gives you many benefits. Their team answers your questions and helps you step by step. You learn about the best casting types, materials, and designs for your job. AFI Industrial Co., Ltd. has in-house services to help with pattern making, mold making, and machining. Their engineers check every part with careful inspections. They use dimensional checks and non-destructive testing. Their ISO 9001 certified process meets industry standards.

Custom

Sometimes, your project needs a special answer. Custom valve castings give you more design choices. You can ask for castings with smooth shapes and extra strength. No-bake sand casting lets you make complex shapes and inside paths. You do not need expensive tools, so you save money on small jobs or one-time parts. You can pick from many metal alloys, like stainless steel or titanium, to fit your job. Valve investment casting helps you get tight fits and tricky shapes. This is important for high-precision jobs in places like aerospace or medical devices.

Tip: Working with a manufacturer gives you special solutions and faster production. You get the right valve for your system and avoid costly delays.

Tools

Online

You can use online tools to help pick the right valve. These tools, like ValveWorks®, use science to match your needs. You enter details like fluid type, temperature, pressure, and flow rate. The tool shows which valve castings fit your job. This saves you time and effort. You get a clear look at the pros and cons of each choice. This helps you make better decisions. Online tools also help you keep records and share info with your team.

Software

Software programs make picking the right valve even easier. You can run tests and see how each valve works in your system. The software checks if the valve is safe and fits well. You can compare different designs and materials fast. This helps you find the best fit for your project and avoid problems later.

Note: Using digital tools and expert advice helps you pick the right valve casting for good results. You get better safety, efficiency, and long-term value.

Picking the right valve casting helps your system work well and stay safe. You need to ask questions about pressure, temperature, and fluid type. You should check if the material is strong and if it works with chemicals.

- Look at the size of your system and how much fluid moves.

- Choose seals and connections that are easy to fix.

- Use the newest standards to get better quality.

Getting help from experts can save you money. AFI Industrial Co., Ltd. gives advice and does careful machining. Talk to their team for help or learn more to pick the best valve casting for your project.

FAQ

You need to match the casting material to your system’s temperature, pressure, and media. This helps you avoid leaks and damage. Always check your application’s needs before you decide.

You should inspect your valve castings at least once every six months. If your system runs in harsh conditions, check them more often. Regular inspections help you find problems early.

No, you should not use the same valve casting for all media. Each media type, like water, oil, or acid, needs a specific material. This keeps your system safe and working well.

The valve selection process helps you pick the right casting for your job. If you skip steps, you risk leaks, system failures, and higher costs. Careful selection keeps your system safe and reliable.

Your valve castings should meet API and ASME standards. These rules make sure your valves are safe and strong. Always check for certifications before you buy.

Check the chemical and temperature limits for your casting material. Make sure it matches your system’s needs. You can ask your manufacturer for help if you are not sure.

Yes, you can order custom valve castings. Manufacturers like AFI Industrial Co., Ltd. offer custom solutions for unique shapes, sizes, and materials. Custom castings help you solve special challenges.