Pipe couplings, which are essential types of pipe couplings, join pipes together to create strong, leak-free joints.Various types of couplings play an important role of functions in piping system, effectively stopping leaks and maintaining the integrity of pipes under pressure. The type of pipe coupling you choose is crucial, as it can significantly impact the precision and reliability of your system. For example:

- High tolerance couplings with wedge style threads create tight seals. These seals are metal-to-metal and perform exceptionally well in challenging conditions.

- Adhering to API standards in manufacturing ensures that connections remain robust.

- Modern materials, such as manganese phosphate coatings, enhance the longevity and performance of couplings.

AFI Industrial Co., Ltd. employs rigorous quality checks and utilizes advanced machinery to produce pipe couplings tailored to your specific needs. Selecting the right coupling is vital for ensuring that your operations remain safe and efficient.

Key Takeaways

- Pipe couplings help make strong, leak-free pipe connections. They keep things safe and working well.

- Picking the right coupling type, permanent or removable, affects how well your pipes work.

- Permanent couplings make strong, lasting connections. Removable couplings make repairs and changes easy.

- Knowing about different couplings, like threaded, flanged, and compression, helps you choose the best one.

- Using good materials like stainless steel or brass makes couplings last longer and work better.

- Doing regular checks and picking the right coupling lowers repair time and costs. This keeps your factory working well.

- Always think about pressure, temperature, and if materials match when picking a pipe coupling.

- Talking to experts, like those at AFI Industrial Co., Ltd., can help you get custom solutions for your needs.

Table of Contents

Pipe Couplings Overview

What Are Pipe Couplings

Pipe couplings join two or more pipes together. These parts are small but very important. They help build strong piping systems in factories. Pipe couplings come in many shapes and sizes. Their main job is to connect pipes. This lets fluids or gases move safely and easily.

Pipe couplings do several things in manufacturing:

- They let you make a pipe longer or finish a pipe run.

- You can use them to change the size of a pipe.

- They help fix pipes that are broken or leaking.

- They connect pipes that are the same or different sizes.

- They keep pipes strong and connected.

Picking the right pipe coupling helps your system work well. AFI Industrial Co., Ltd. makes high-quality pipe couplings. These couplings meet strict rules. Their skill in making parts means you get good products every time.

Why Pipe Couplings Matter

Pipe couplings help keep your factory system safe and working well. When you connect pipes with a good coupling, you stop leaks and keep pressure steady. This saves money and stops problems.

Here are ways pipe couplings help stop leaks and keep systems strong:

- They make tight connections between pipe pieces. This keeps everything strong.

- You can use them to make pipes longer, change sizes, or fix leaks.

- Most couplings use materials that match the pipes. This gives strength and makes sure they fit together.

- Some couplings stay in place forever. Others can be taken off. This helps with fixing and taking care of pipes.

- Special couplings, like compression and slip couplings, work in different situations and help stop leaks.

Good pipe couplings also help your factory work better. For example, a new Tee Pipe design helps fluids flow and keeps pressure steady. Using strong materials means you fix things less often and your system lasts longer. Rubber couplings bend and seal well. This stops leaks and keeps things moving. Socket couplings are simple to put in. This saves time and work.

AFI Industrial Co., Ltd. uses new machines and checks quality carefully. They make pipe couplings that help your system work better. Their knowledge makes sure you get the right coupling. This helps your factory stay safe and save money.

Types of Pipe Couplings

Pipe couplings are very important in factories. There are many types of pipe couplings. Each type is made for a special job. Knowing about the types helps you pick the best one.

Tip: The right pipe coupling keeps your system safe. It also stops leaks and makes fixing things easier.

Here is a table that lists the main types of pipe couplings and what they do:

| Coupling Type | Definition |

|---|---|

| Permanent Coupling | Uses soldering, brazing, or glue to make a strong and sealed joint. It is meant to last a long time. |

| Removable Coupling | Usually has threads, so you can put it on or take it off easily. It is sealed with things like hemp or tape. |

Permanent Couplings

Permanent coupling makes pipes stay together for a long time. You use this when you do not want to take the pipes apart. Permanent couplings are good for systems that must stay closed and safe.

Welded

Welded couplings use heat to join pipes. The ends of the pipes melt and stick together. This makes a very strong and leak-free joint. Welded couplings are used where safety is very important. You see them in chemical plants and oil refineries.

Brazed/Soldered

Brazed and soldered couplings use melted metal to connect pipes. You heat a filler metal and let it flow into the space. This makes a tight and hard connection. Brazed couplings can handle high heat and pressure. Soldered couplings are used in plumbing and HVAC. Both types give you a strong bond.

Note: Permanent couplings do not need much care. You cannot take them apart easily, so they are not good for systems that need lots of repairs.

Here is a table that shows the good and bad sides of permanent and removable couplings:

| Type of Coupling | Advantages | Disadvantages |

|---|---|---|

| Permanent Coupling | Strong, lasts long, and needs no care | Hard to take apart; not good for many repairs |

| Removable Coupling | Easy to take apart; good for fixing things | Not as strong; can wear out over time |

Removable Couplings

Removable coupling lets you join and unjoin pipes easily. You use this when you need to fix, change, or move pipes. Removable couplings are used a lot in factories.

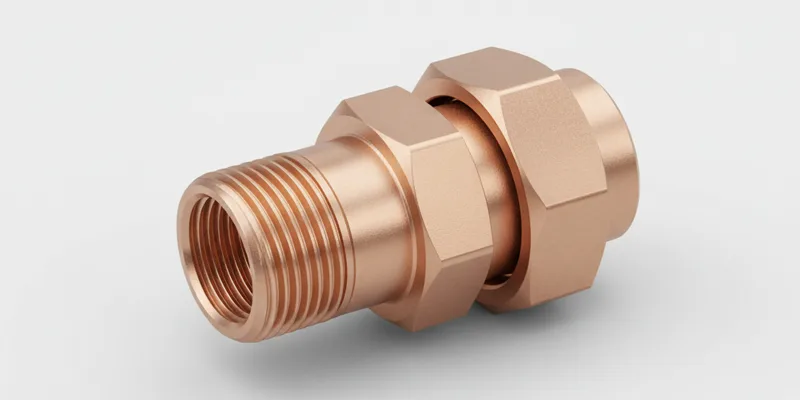

Threaded

Threaded couplings have screw-like threads. You twist the pipes together to make them tight. You can untwist them to take the pipes apart. Threaded couplings are used in water, gas, and oil systems. They are good for quick and easy connections.

Flanged

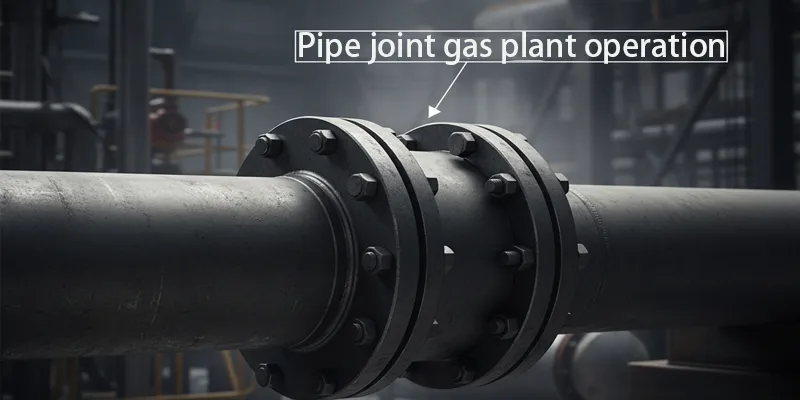

Flanged couplings use flat rings called flanges. You bolt the flanges together to join the pipes. Flanged couplings make it easy to take pipes apart and put them back. You see them in big factories, like power plants and water plants.

Grooved

Grooved couplings have grooves at the ends of the pipes. You use a clamp to hold the pipes together. Grooved couplings are fast to put on and take off. You see them in fire systems and HVAC.

Compression

Compression couplings use a sleeve and nuts to squeeze the pipes. You tighten the nuts to stop leaks. Compression couplings are good for joining pipes made from different things. You use them in plumbing, labs, and places where pipes move.

Note: Removable couplings save time when you fix things. You can take pipes apart fast and do not need special tools.

You use removable couplings for these jobs:

- Joining different kinds of pipes

- Handling high pressure

- Making repairs and changes easy

- Letting pipes move a little

Here are some good things about using removable couplings in factories:

- They help keep piping systems safe and working well.

- They are a cheap and smart way to join many kinds and sizes of pipes.

- They let you fix things fast in important systems.

Quick release couplings let you connect or disconnect pipes fast. This helps stop leaks and saves time. You can make changes quickly, so your factory keeps running.

Tip: Removable couplings are used a lot in factories. Their design makes fixing and changing systems easy, which is great for busy places.

The type of pipe couplings you pick changes how your system works. Permanent coupling is strong and lasts a long time. Removable coupling is easy to use and fix. If you know about the types, you can make better choices for your factory.

Common Types of Pipe Fittings

Pipe couplings play a key role in connecting pipes and keeping your manufacturing system strong. You need to know about the various types of pipe fittings to make smart choices for your factory. When you ask, “what is a pipe fitting?” you learn that it is a part that joins, changes, or repairs pipes. Industrial pipe fittings come in many shapes and sizes. Each type has a special job.

Full Coupling

Full coupling is one of the most common industrial pipe fittings. You use full coupling when you want to join two pipes together. This fitting covers both ends of the pipes. It creates a tight and leak-proof seal. Full coupling works best in high-pressure systems. You see it in heavy-duty jobs, like oil and gas plants. The strong design helps metal pipes stay connected under stress.

Here is a table that shows how full coupling and half coupling compare:

| Type of Coupling | Application | Performance |

|---|---|---|

| Full Coupling | Used in high-pressure systems, ideal for heavy-duty applications | Robust, designed for metal pipes, ensures reliable and leak-proof connections under stress |

| Half Coupling | Versatile, used in maintenance and temporary setups, suitable for confined spaces | Flexible, connects various materials, ideal for plumbing and industrial processes |

Full coupling gives you a reliable connection. You do not need to worry about leaks or weak spots. This makes it a top choice for many types of pipe fittings in factories.

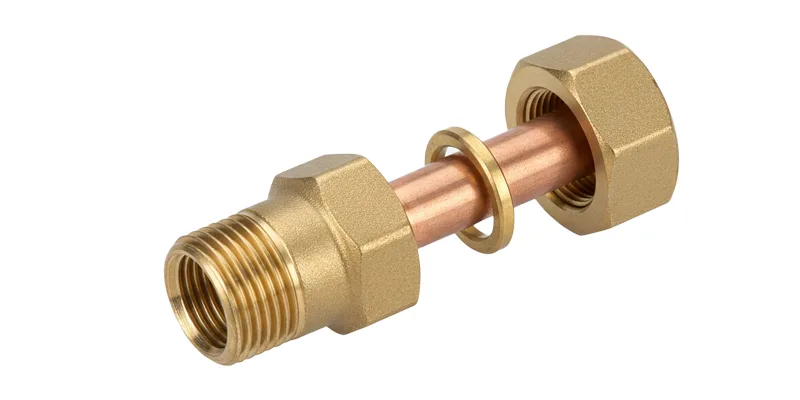

Half Coupling

Half coupling is another important industrial pipe fitting. You use half coupling when you need to connect a pipe to a fitting, valve, or piece of equipment. This fitting only covers one end of the pipe. It is very flexible. You can use half coupling in tight spaces or for quick repairs. It works well with different materials, such as steel, copper, or plastic.

Half coupling helps you make changes to your system. You can add new pipes or fix old ones without taking everything apart. This saves you time and money. Many factories use half coupling for maintenance and temporary setups.

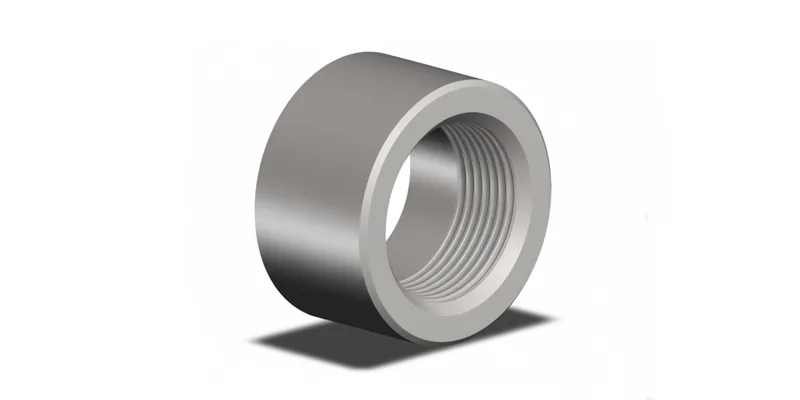

Reducing Coupling

Reducing coupling is a special type of industrial pipe fitting. You use reducing coupling when you need to join pipes of different sizes. This fitting makes a smooth transition from a big pipe to a small pipe. It helps your system run better.

Reducing couplings improve efficiency in precision manufacturing. They create smooth connections between shafts. This reduces energy loss from misalignment and vibrations. Your machines run faster and last longer. You spend less on repairs. Reducing couplings also help transfer torque and spread loads evenly. This keeps conveyor systems and wind turbines working without problems.

You find reducing coupling in many industrial pipe fittings. It is perfect for systems that need to change pipe sizes or handle different pressures.

Tip: When you choose the right pipe coupling, you make your system safer and easier to repair. The various types of pipe fittings help you build, fix, and upgrade your factory.

Here are some of the most widely used types of pipe fittings in manufacturing:

- Threaded fittings twist together for a snug fit.

- Sweat fittings use melted solder for a leak-free joint.

- Slip fittings attach plastic pipes with liquid cement.

- Compression fittings join pipes tightly with pressure.

- Flare fittings connect high-pressure pipes.

- Clamp fittings use a clamp for a secure hold.

- Crimp fittings attach a metal ring with a tool.

Industrial pipe fittings support system modifications and repairs. You can change pipe sizes, fix leaks, or add new equipment. This keeps your factory running smoothly.

Compression Coupling

Compression coupling is used a lot in factories. You pick this fitting when you want to join two pipes fast. You do not need to weld or thread the pipes. The fitting has three parts: a nut, a ring called a ferrule, and a body. When you turn the nut, the ring squeezes the pipe. This makes a tight seal that stops leaks.

You see compression fittings where quick connections are needed. They work with metal and plastic pipes. You do not need special tools, just a wrench to tighten the nut. This makes putting them in simple and quick.

Compression coupling is good for water, gas, or chemical systems. You find them in labs, factories, and home plumbing. The best part is you can take the pipes apart and put them back together. This helps you fix or change things without cutting the pipe.

Here are some reasons to use compression fittings:

- They make a strong, leak-proof seal.

- You can use them with many pipe types.

- They are easy to put in and take out.

- They let you fix or upgrade pipes quickly.

Compression coupling helps your system work well. These fittings help you avoid stopping work and lower repair costs. Using the right pipe coupling keeps your factory safe and efficient.

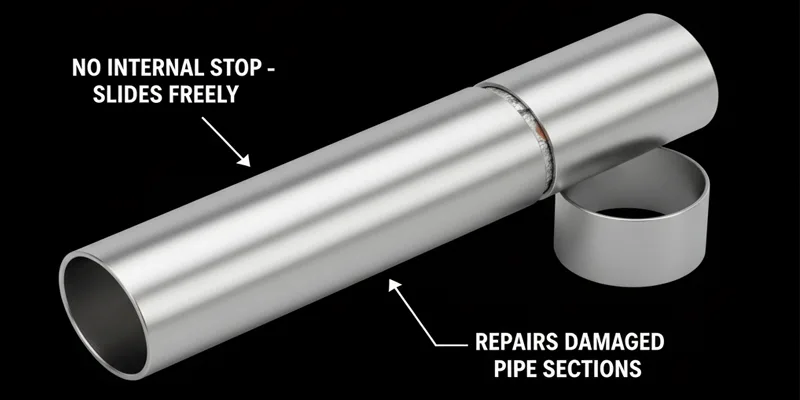

Slip/Repair Coupling

Slip or repair coupling is another helpful fitting in factories. You use this when you need to fix a broken pipe fast. The design lets the coupling slide over two pipe ends. This makes it easy to swap out a bad part without moving everything.

Repair couplings are very flexible. You can use them with pipes made from different things. The slip and telescoping styles help you fit new pipes to old ones. This makes them great for upgrades and changes.

Slip couplings are good in emergencies. If you have a big leak, you can cut out the bad pipe and slide the coupling on. The fitting can handle high water pressure, so you do not worry about leaks after fixing it.

Here are ways slip or repair couplings help your system:

- Great for quick fixes or upgrades

- Can handle pipes that do not line up

- Good for water main repairs and temporary fixes

You can use these fittings to keep your factory working, even when things go wrong. Slip couplings help you save time and money by making repairs fast. You do not need to stop your whole system for long. This means less waiting and more work done.

When you pick the right fittings, your factory gets stronger and more flexible. Slip and repair couplings help you solve problems and keep things running.

Applications in Manufacturing

Fluid and Gas Systems

Pipe couplings are used in many fluid and gas systems in factories. These systems need strong connections to work well. Pipe couplings connect pipes for water, gas, and other fluids. You can find them underground, in water lines, and in factories.

Here is a table that shows pipe coupling applications in fluid and gas systems:

| Application Area | Description |

|---|---|

| Plant Maintenance | Used for connecting and fixing pipes. |

| Power Plants | Needed for moving fluids and gases. |

| Water and Gas Delivery Facilities | Important for safe delivery of water and gas. |

| Manufacturing | Helps fluids and gases move through the system. |

| Structural Engineering | Used in building strong structures. |

| Architecture | Needed for both looks and how things work. |

Couplings help you join pipes fast when you fix or upgrade things. This means you do not have to stop work for long and help you maintaining efficiency. In water and gas delivery, good couplings stop leaks and protect pipes from pressure changes.

High-Pressure Environments

Factories sometimes use systems with very high pressure. You need couplings that can handle strong forces and keep pipes safe. Schedule 80 fittings are used a lot because they are thicker than Schedule 40. This helps them handle more pressure without breaking.

You might see these couplings in chemical plants or places that clean water. Here are some reasons why these couplings are good for high-pressure jobs:

- They do not bend or break, even with strong forces, they have good durability.

- The inside is smooth, so fluids move easily and dirt does not build up.

- They do not get damaged by harsh chemicals.

- They are light, so you can put them in quickly.

Picking the right pipe coupling keeps ensuring safety for your system and working well. It also saves time and money when you put them in.

Automation Integration

Modern factories use machines to make work faster and safer. Coupling systems are important for this. Robots can move, load, and unload couplings without people. This saves money and keeps workers away from danger.

Automation helps your factory in many ways:

- Robots can work all day and night, so work never stops.

- Special sensors help robots find and move couplings exactly right.

- Machines move couplings quickly from one place to another, so everything flows smoothly.

- There are fewer mistakes because machines follow the same steps every time.

When you use machines with your coupling systems, your factory works better and stays safe. You also make sure every pipe coupling fits just right, so your whole system runs smoothly.

Importance of Coupling Selection

Precision and Reliability

Picking the right coupling is very important in factories. The correct pipe coupling helps machines work with great accuracy. It also keeps your system working well every day. If you use the wrong coupling, pipes might not fit together right. This can make leaks or even break your equipment. You want to stop these problems so your work goes smoothly. Here are some ways choosing the right coupling helps your system:

- It fixes misalignment, so your process stays accurate.

- It stops early failures by using couplings with the right torque.

- It keeps your system reliable and avoids problems.

A good coupling makes your system strong and long-lasting. It holds pipes tight, so you do not worry about leaks or breaks. This helps your work stay efficient. It also keeps workers and equipment safe in every part of your factory.

AFI Industrial Co., Ltd. checks quality very carefully. The company has ISO 9001 certification, which is a worldwide quality rule. This means you get pipe couplings that are strong and last a long time. You can trust every coupling to help your system work well and stay safe.

Maintenance and Downtime

Maintenance is a big job in every factory. If you pick the right coupling, fixing things is easier and faster. Cost-effective maintenance allows you to spend more time on actual work.

A strong and tough coupling means fewer repairs. It also lowers the chance of sudden breakdowns. Here is how the right coupling helps with maintenance and downtime:

- You fix things less often because the coupling lasts longer.

- You avoid expensive shutdowns by using couplings that fit well.

- You keep your system working at its best.

The right pipe coupling lets you plan repairs instead of rushing to fix things. You can change or fix parts quickly, so your factory keeps running. This saves money and protects your equipment.

AFI Industrial Co., Ltd. follows ISO 9001:2015 rules. This shows they care about quality and always want to get better. You can count on AFI to give you couplings that help you work safely, last long, and save money.

Tip: Always make sure your coupling fits your system’s needs. This easy step can help you work better and stop long delays.

Materials and Choosing Pipe Couplings

When you pick a pipe coupling, you must think about the material. The right material helps your system last longer and work better. Each material has special features for different jobs. You also need to think about rust, pressure, corrosion protection and heat. Below are the most common materials for pipe couplings and tips for picking the best one.

Common Materials

Stainless Steel

Stainless steel is a popular choice in many factories. It does not rust and can handle high pressure. You see stainless steel couplings in food, chemical, and marine systems. Stainless steel 304 works in most places. Stainless steel 316 protects even better from rust in tough spots.

Brass

Brass couplings are easy to make and look nice. They do not rust and work well in plumbing and HVAC. You might use brass if you want a strong and good-looking connection that will not rust.

Plastic

Plastic couplings, like PVC or CPVC, are light and cost less than metal. They do not rust and resist many chemicals. You use plastic couplings in water, drains, and some chemical systems. PEX plastic bends easily and works well where pipes might freeze.

Here is a table to help you compare the main materials:

| Material | Key Properties | Applications |

|---|---|---|

| Stainless Steel | High strength, excellent corrosion resistance | Food, chemical, marine, pharmaceutical |

| Brass | Good corrosion resistance, easy to machine | Plumbing, HVAC, decorative |

| Plastic (PVC, CPVC, PEX) | Lightweight, chemical resistance, flexible | Water, drainage, irrigation, heating |

Selection Criteria

You need to think about a few things when you pick a coupling. The right choice keeps your pipes safe and your system working well. Here are some important things to check:

| Criteria | Description |

|---|---|

| Material Compatibility | Make sure the coupling matches the pipe and the fluid inside. |

| Pressure and Temperature Ratings | Check that the coupling can handle your system’s pressure and heat. |

| Application | Decide if you need the coupling for connecting or repairing pipes. |

| Pipe Material(s) | Know what your pipes are made of—metal or plastic. |

| Correct Size | Measure your pipes so the coupling fits perfectly. |

| Operational Parameters | Define the normal and maximum pressures and temperatures. |

| Component Ratings | Ensure all parts can handle extreme conditions. |

Tip: Always check industry standards and certifications, like ISO or AWWA, before you install. Certified couplings work well and meet safety rules.

When you plan to install, think about what flows in your pipes. Stainless steel is best for harsh chemicals. Brass is good for water and air. Plastic is great for low-pressure water or drains. If you are not sure how to pick the right pipe fitting, look at the fluid, pressure, and heat in your system.

AFI Industrial Co., Ltd. can help with custom solutions. You get pipe couplings made just for your needs. Their new technology and quality checks make sure every coupling fits right. You also get fast delivery, much quicker than waiting for parts from far away. AFI’s team can make special couplings for unique jobs, giving you more choices for any project.

Picking the right pipe coupling keeps your factory safe and running well. When you look at and improve your pipe couplings, you get lots of good things:

| Benefit | Description |

|---|---|

| Improved Safety | Helps protect workers and buildings from harm |

| Reduced Downtime | Quick to put in, so work does not stop |

| Lower Total Costs | Cuts down on repair and worker costs |

| Ease of Installation | Makes upgrades and checks easy to do |

Beyond Traditional Processes: Our Custom Manufacturing Services

Powder Metallurgy and Investment Casting

For pipe coupling components with complex shapes that require mass production, powder metallurgy and investment casting are highly cost-effective solutions. For example, some complex couplings made of stainless steel or special alloys can be integrally formed through casting, reducing the need for subsequent machining.

Zinc and aluminum alloy die casting

For pipe couplings that require lightweight properties combined with high strength and a good surface finish, can produce them with high efficiency and consistency on a large scale.

Why Choose Us as Your Partner?

- One-Stop Solution: Whether your project requires high-precision CNC turning, milling, or cost-effective powder metallurgy, investment casting, or die casting, we can provide a one-stop custom manufacturing service.

- Quality Assurance: We strictly follow ISO standards to ensure every metal part meets the most stringent quality requirements.

- Customization Capability: We can produce custom pipe couplings of any specific material, size, or function based on your drawings and needs, solving the problem of not finding suitable products on the market.

AFI Industrial Co., Ltd. has many coupling choices, like adaptors, fittings, and clamps. Their team knows how to fix problems and help with special needs. Check your pipes and see if you need better couplings. You can ask AFI for help or get a special coupling made just for you.

FAQ

A pipe coupling connects two pipes. You use it to make a strong, leak-free joint. This helps your system move fluids or gases safely and keeps everything working well.

You look at the pipe material, size, pressure, and temperature. You also check what flows inside the pipe. Always match the coupling to your system’s needs for the best results.

Yes, you can. Removable couplings like threaded or flanged types let you take pipes apart and put them back together. This makes repairs and upgrades much easier.

The material affects how long the coupling lasts and how well it works. For example, stainless steel resists rust. Plastic works well with water. You pick the material based on your system’s needs.

You might get leaks, weak joints, or even system failure. The wrong coupling can also cause more repairs and downtime. Always pick the right type to keep your system safe.

Look for certifications like ISO 9001. These show the coupling passed strict tests. You can trust certified products to work well in your system.

You use a slip or repair coupling when you need to fix a broken pipe fast. This type slides over the pipe ends and helps you make quick, strong repairs without moving other pipes.