A titanium alloy mixes titanium metal with other elements to make it better. People like titanium alloys because they are strong, light, and can handle heat well. Elements like vanadium or molybdenum change how titanium acts by affecting the phases inside the metal. Titanium alloys do not rust easily because they have a tough oxide layer. They work well in the body and are hard to break, so they are used in medicine. The mix of these good features makes titanium alloys useful in many jobs.

Key Takeaways

- Titanium alloys are made by mixing titanium with other elements. This makes the metal stronger and lighter. It also helps the metal resist rust and heat.

- There are three main types of titanium alloys. They are called alpha, beta, and alpha-beta. Each type has special features for different jobs.

- Titanium alloys are strong but not heavy. This makes them great for airplanes, medical implants, and sports gear.

- These alloys do not rust easily because they have a tough oxide layer. This layer helps them last longer in places like seawater and chemical plants.

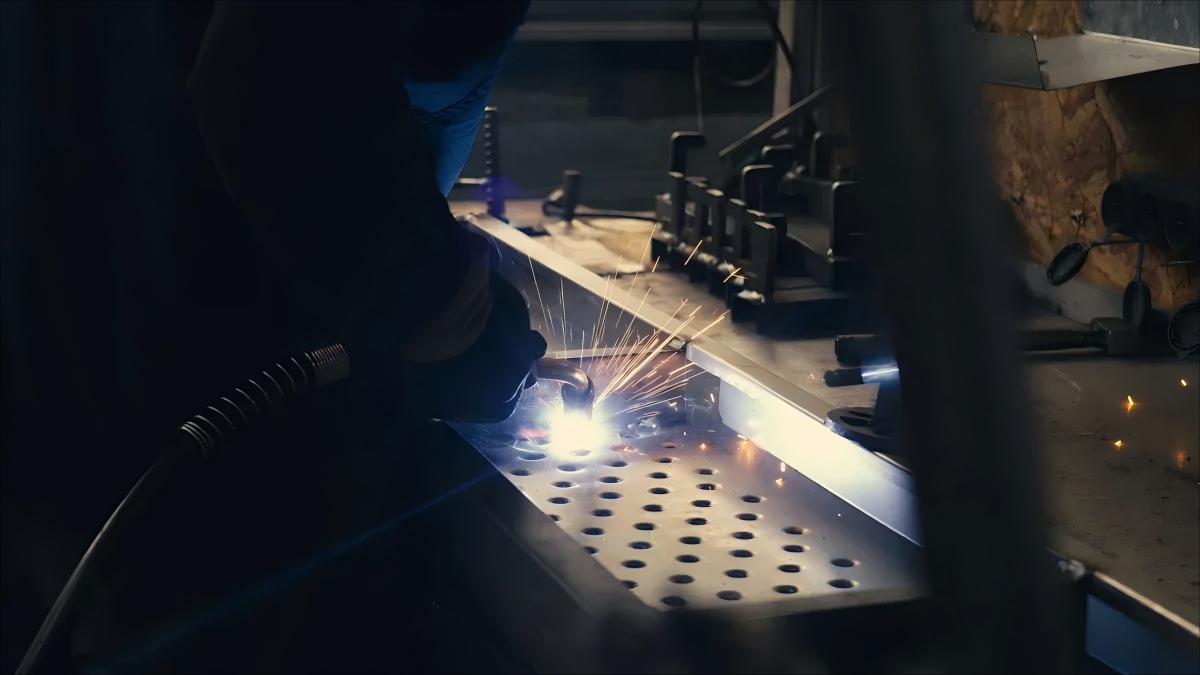

- You need special ways to cut and weld titanium alloys. This is because they are very strong and can be sensitive to heat.

Table of Contents

Titanium Alloy Basics

What Is a Titanium Alloy

A titanium alloy is made by mixing titanium with other elements. This helps titanium work better for different jobs. Ti-alloy is stronger and tougher than pure titanium. They also do not rust as easily. Engineers use these alloys when they need strong and light materials. Ti-alloy stays strong even when it gets very hot. This is why they are used in jet engines and spacecraft.

The elements added to titanium change its structure. Some elements help the alloy stay strong when it is hot. Others make it easier to shape or stop it from cracking. Ti-6Al-4V is a common alloy. It has 6% aluminum and 4% vanadium. Aluminum makes the alloy stronger by helping the alpha phase. Vanadium makes it tougher and easier to bend by helping the beta phase. Ti-6Al-4V is good at handling impacts and does not break easily. It works well in tough places.

Alloying Elements

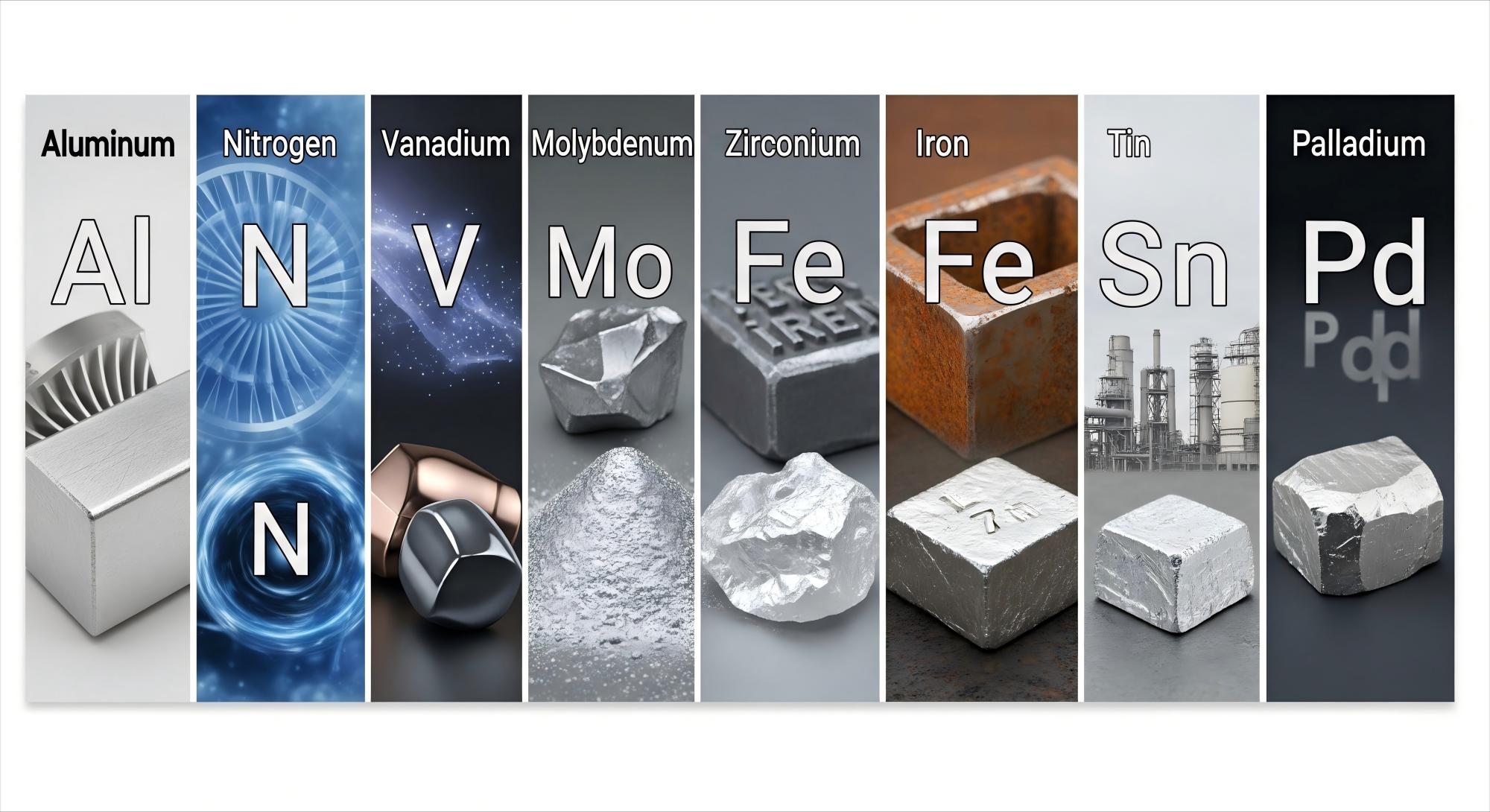

Alloying elements change how titanium alloys act. Each element helps the alloy in a special way. Some make it stronger. Others help it resist rust or make it easier to shape.

Tip: The elements you choose decide how the Ti-alloy will work.

Here are some common alloying elements and what they do:

| Alloying Element | Classification | Role and Effect on Titanium Alloys |

|---|---|---|

| Aluminum (Al) | Alpha (α) stabilizer | Helps form the α-phase, makes it stronger, stops rust, raises α/β transus temperature |

| Oxygen (O) | Alpha (α) stabilizer | Makes it stronger but harder to bend |

| Nitrogen (N) | Alpha (α) stabilizer | Helps form the α-phase |

| Vanadium (V) | Beta (β) stabilizer | Helps form the β-phase, makes it easier to bend and tougher, lowers density |

| Molybdenum (Mo) | Beta (β) stabilizer | Stops rust, especially when it is hot |

| Iron (Fe) | Beta (β) stabilizer | Helps form the β-phase |

| Zirconium (Zr) | Neutral element | Does not change the phases much |

| Tin (Sn) | Neutral element | Does not change the phases much |

| Palladium (Pd) | Special additive | Stops rust in tough places |

Aluminum helps the alpha phase and makes the Ti-alloy stronger. It also helps stop rust. Vanadium helps the beta phase. This makes the alloy easier to bend and tougher. In Ti-6Al-4V, aluminum and vanadium work together. They give the alloy strength, toughness, and help stop cracks. Ti-6Al-4V can be very strong, up to 1000-1100 MPa. It stays strong up to 300°C. It also does not break or crack easily. This is important for planes and medical tools.

Molybdenum and chromium help Ti-alloy resist rust. Molybdenum makes a layer that protects the alloy in harsh places. Chromium helps keep the surface safe and stops rust. These elements make titanium alloys good for implants and chemical equipment.

Titanium alloys are grouped by the elements added and the phases they form. Alpha alloys use elements like oxygen to make them stronger, but they can be harder to bend. Beta alloys use elements like vanadium or molybdenum. These are easier to shape and heat treat. Alpha-beta alloys use both types of elements. They are strong, tough, and easy to work with.

Types of Titanium Alloys

Titanium alloys are sorted into three main groups. These are alpha alloys, beta alloys, and alpha-beta alloys. Each group has special features. This makes them good for different uses.

Alpha Alloys

Alpha alloys mostly have the alpha phase. This phase has a hexagonal close-packed structure. Their microstructure shows round alpha grains and thin, needle-like alpha precipitates. Aluminum and oxygen help keep the alpha phase stable. These elements make the alloy stronger at high temperatures. They also raise the temperature at which the alloy changes phase. Oxygen makes the alloy stronger, but too much can make it brittle. Special ways of making the alloy, like powder metallurgy, control how much oxygen is inside. This also helps control the grain size. These things help the alloy be strong and bend without breaking.

Alpha alloys do not rust easily. They stay strong even when it is very hot. They cannot be made stronger by heat treatment. But they keep their strength up to 600°C. These alloys work well in tough places. People use them in airplanes for engine covers and compressor blades. They are also used in medical implants. This is because they do not react with body fluids and are safe for the body.

Note: Alpha alloys cannot be made stronger by heat, but they work well in both hot and cold places.

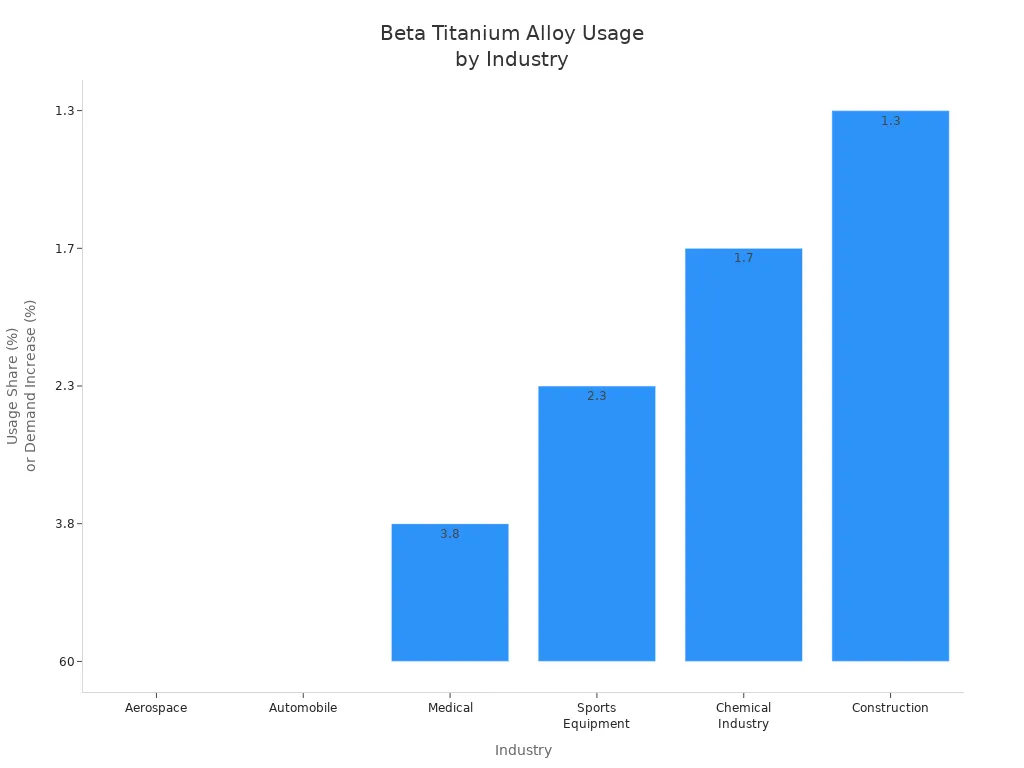

Beta Alloys

Beta alloys have a body-centered cubic structure. They have elements like vanadium, molybdenum, and iron. These elements help form the beta phase at lower temperatures. Beta alloys can be made stronger by heat treatment. They are easy to shape and weld. This makes them simple to join together.

More than 60% of all beta Ti-alloys are used in planes and cars. These strong alloys are also used in medical tools, sports gear, and chemical factories. They do not rust easily and can be shaped into many forms.

Alpha-Beta Alloys

Alpha-beta alloys have both alpha and beta phases. They use alpha stabilizers like aluminum and tin. They also use beta stabilizers like vanadium and molybdenum. This mix gives them strength, toughness, and makes them easy to shape. Alpha-beta alloys can be heat-treated. This lets them be medium or very strong, depending on how they are made.

| Property | Alpha Alloys | Alpha-Beta Alloys | Beta Alloys |

|---|---|---|---|

| Phase Composition | Alpha | Alpha + Beta | Beta |

| Heat Treatability | No | Yes | Yes |

| Tensile Strength | Low–High | Medium–Very High | Low–Very High |

| High Temp Stability | Excellent | Good | Limited |

The most common alpha-beta alloy is Ti-6Al-4V. It is strong, does not rust, and can be made stronger by heat. Alpha-beta alloys are used in airplane parts, medical implants, and engine parts that get very hot.

Key Properties of Titanium Alloys

Strength-to-Weight Ratio

Titanium alloys are strong yet lightweight. This is called a high strength-to-weight ratio. Engineers compare Ti-alloy to steel and aluminum. Titanium alloys are stronger for their weight than both. Aluminum is light but not as strong as Ti-alloy. Steel is strong but much heavier. Titanium alloys are both strong and light. This makes them good for many things.

| Material | Density (g/cm³) | Tensile Strength Range (MPa) |

|---|---|---|

| Aluminum | ~2.7 | 40 – 570 |

| Titanium | ~4.5 | 240 – 950 |

- Titanium alloys are strong and not too dense, so their strength-to-weight ratio is high.

- Aluminum is lighter but not as strong, so its strength-to-weight ratio is lower.

- Steel is heavy, so its strength-to-weight ratio is lower than Ti-alloy.

People use titanium alloys in airplanes to make them lighter. Lighter planes use less fuel and can carry more things. Ti-alloy is also used in jet engines and spacecraft. Their high strength-to-weight ratio makes them a great choice for these jobs.

Note: Titanium alloys are as strong as steel but weigh almost half as much. This helps planes go farther and faster.

Corrosion Resistance

Titanium alloys do not rust easily. They make a thin oxide layer on the outside. This layer keeps the metal safe from rust and damage. In the ocean, Ti-alloy can last for many years without rusting. Tests show that after 16 years in dirty seawater, Ti-alloy still does not rust. Chemical plants and water factories use titanium alloys because they do not rust or wear away, even in hot water that moves fast.

| Alloying Element | Role in Corrosion Resistance Improvement |

|---|---|

| Aluminum (Al) | Makes the oxide layer more stable |

| Vanadium (V) | Helps stop pitting corrosion |

| Molybdenum (Mo) | Improves resistance in acids |

| Zirconium (Zr) | Makes the passive film stronger |

| Tantalum (Ta) | Keeps the oxide film stable in tough spots |

- Titanium alloys do not wear away in fast water, even with sand.

- Pitting and crevice corrosion rarely happen, except when it is very hot.

- Special elements like aluminum and vanadium make the oxide layer even stronger.

Tip: Titanium alloys are a smart pick for the ocean and chemical jobs because they do not rust.

Heat and Oxidation Resistance

Titanium alloys can handle heat well. They stay strong at high temperatures. This is important for engines and turbines. Most Ti-alloy works up to 500°C to 600°C. Above this, oxidation can be a problem. The metal can get weak and break. Elements like chromium, vanadium, and aluminum help Ti-alloys handle heat, but only up to a point.

| Material Type | Maximum Service Temperature | Key Heat Resistance Characteristics |

|---|---|---|

| Titanium Alloys | Up to ~550-600°C | Good for moderate high temperatures; limited above 600°C |

| Nickel-Based Superalloys | 600°C to 1500°C | Best for very high temperatures; used in hottest engine parts |

Nickel-based superalloys can take more heat than titanium alloys. But Ti-alloy is lighter and still strong. This is why people use them when weight matters more than heat.

Alert: Do not use Ti-alloys above 600°C for a long time. They can lose strength and break.

Toughness and Fatigue Resistance

Titanium alloys are tough and do not break easily. They can handle being bent or hit many times. This makes them safe for planes, cars, and medical tools. Titanium alloys also do not crack after many cycles of stress. This is better than stainless steel, which can crack over time.

- Titanium alloys last longer under stress than stainless steel.

- They keep their shape and strength for many years.

- This makes them good for parts that move or shake a lot.

Note: Titanium alloys are strong and tough, but they can wear on the surface if not treated.

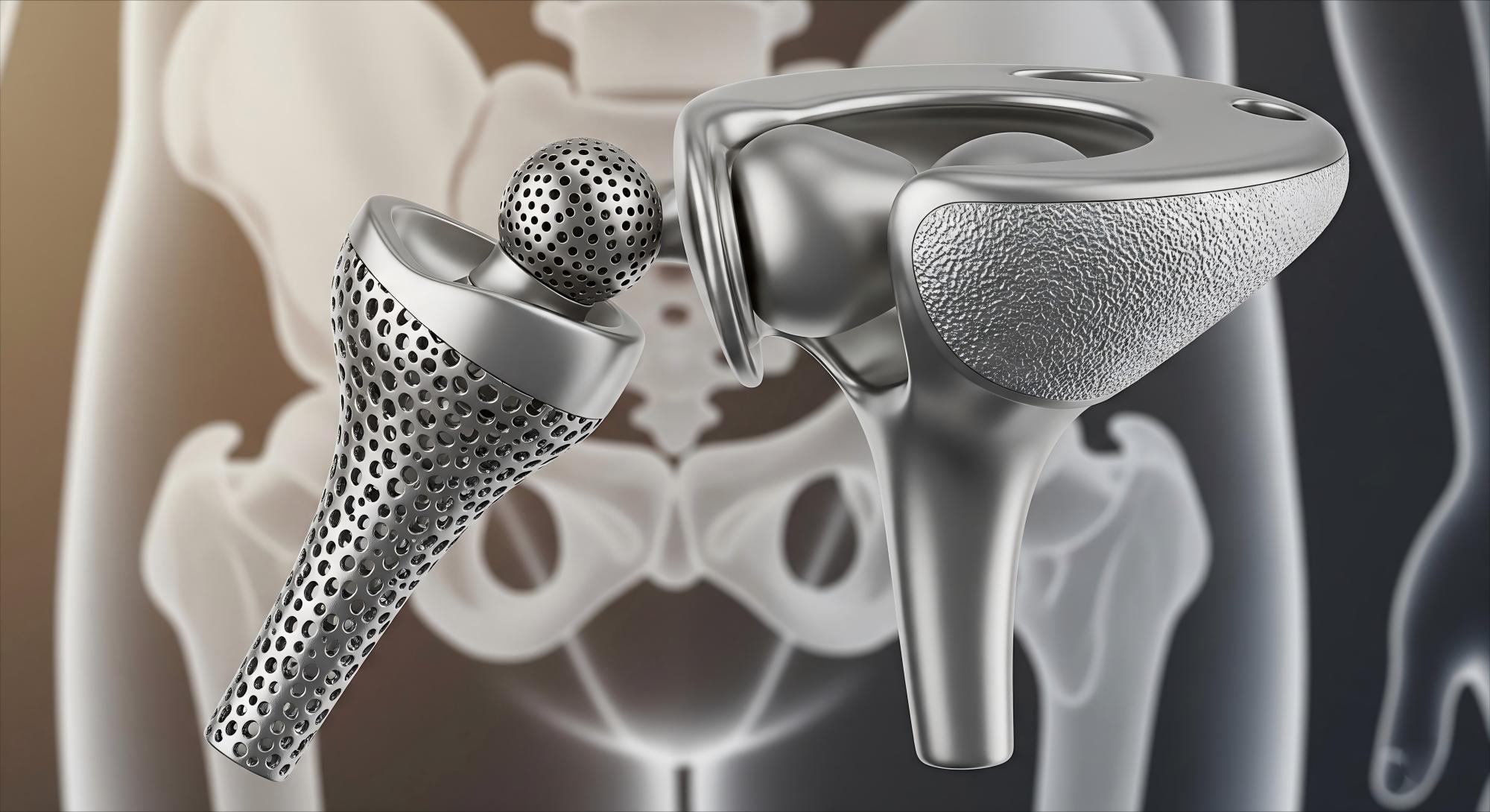

Biocompatibility

Titanium alloys are safe to use in the body. Doctors use them for bone implants, dental screws, and new joints. New beta-type titanium alloys do not hurt bone cells. These alloys help bone cells grow better than older alloys. Animal tests show no bad or allergic reactions. Ti-alloys are close to bone in stiffness. This helps bones heal and stay strong.

- Most body reactions to titanium alloys are mild and go away fast.

- The body makes a thin tissue layer around the implant, but there is little swelling.

- Titanium alloys do not rust in the body unless the surface is damaged.

- Tiny bits of wear can cause swelling, but this is rare with good design.

Tip: Titanium alloys are safe and work well for medical implants because they do not rust and are good for the body.

Titanium Alloy Grades and Uses

Common Grades (e.g., Ti-6Al-4V)

Engineers pick different titanium alloy grades for many jobs. Ti-6Al-4V is the most used grade. It is also called Grade 5. This alloy has 6% aluminum and 4% vanadium. Ti-6Al-4V is strong and tough. It is easy to weld. It keeps its strength when it gets hot. It does not rust easily. Ti-6Al-4V is lighter than some steels but just as strong. People use it in planes, medical tools, and sports gear.

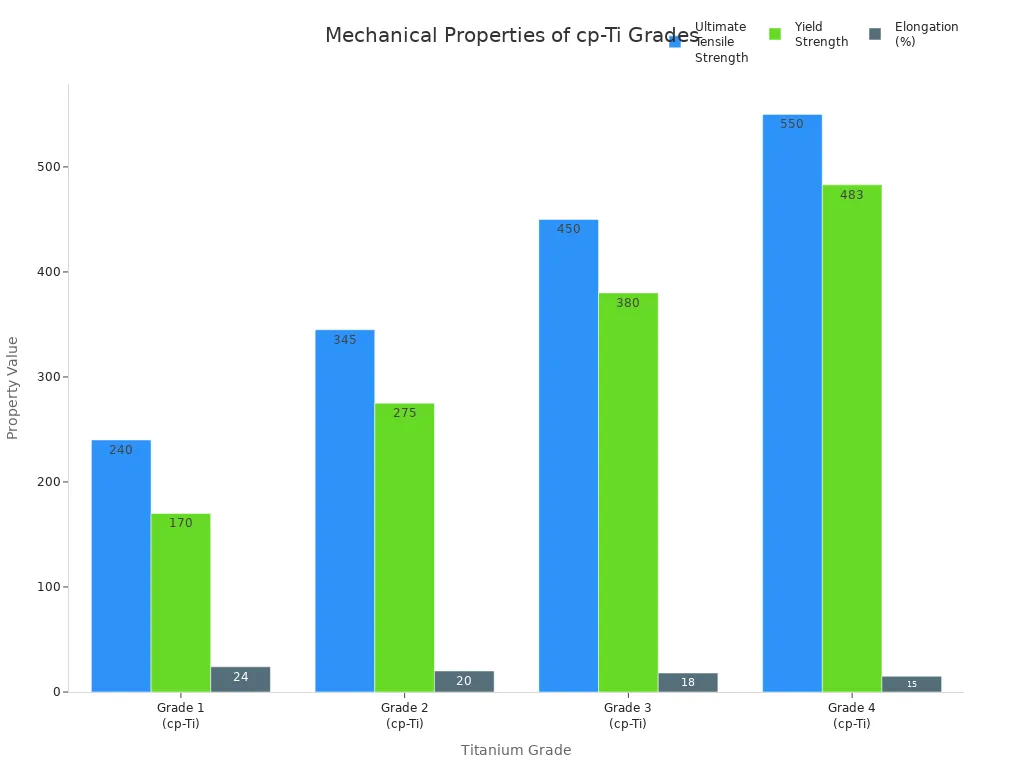

Commercially pure titanium grades are called cp-Ti. These are Grades 1 to 4. They are not as strong as Ti-6Al-4V. But they bend more and do not rust. Grade 1 is the softest and bends the most. Grade 4 is the strongest of the cp-Ti grades. Scientists found that Ti-6Al-4V and cp-Ti have similar surfaces. Both are safe for the body. Ti-6Al-4V is better for bone implants because it is stronger. Cp-Ti is good for dental work.

| Titanium Grade | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Grade 1 (cp-Ti) | ~240 | ~170 | 24 |

| Grade 2 (cp-Ti) | ~345 | ~275 | 20 |

| Grade 3 (cp-Ti) | ~450 | ~380 | 18 |

| Grade 4 (cp-Ti) | ~550 | ~483 | 15 |

Industry Applications

Titanium alloys are important in many fields. Planes use them for engines, frames, and landing gear. They are strong and light. This helps planes use less fuel. The Boeing 787 Dreamliner uses titanium alloys to stay light and strong. Doctors use titanium alloys for bone implants and tools. These alloys are safe for the body and do not rust.

Car makers use titanium alloys for valve springs, exhausts, and suspension parts. These parts are lighter and last longer. Chemical plants use titanium alloys for pipes and tanks. They do not rust, even with harsh chemicals. Sports gear makers use titanium alloys in golf clubs, bikes, and tennis rackets. Athletes like lighter gear that lasts a long time.

| Industry Application | Key Uses and Characteristics | Market Position |

|---|---|---|

| Aerospace | Aircraft engines, airframes, structural forgings; lightweight, high strength, corrosion resistance | Largest market share; CAGR 4.1% (2022-2027) |

| Medical | Orthopedic implants, surgical instruments; biocompatibility, corrosion resistance | Significant driver; high demand for implants and devices |

| Automotive | Valve springs, exhaust systems, suspension springs; lightweight for fuel efficiency | Growing demand for lightweight vehicles |

| Chemical | Petrochemical plants, LNG plants, seawater desalination | Noted as an important end-use sector |

| Sports Utility | Golf clubs, bicycles, tennis rackets, skiing plates | Recognized as an end-use industry |

Tip: Titanium alloys help make products lighter, stronger, and safer in many fields.

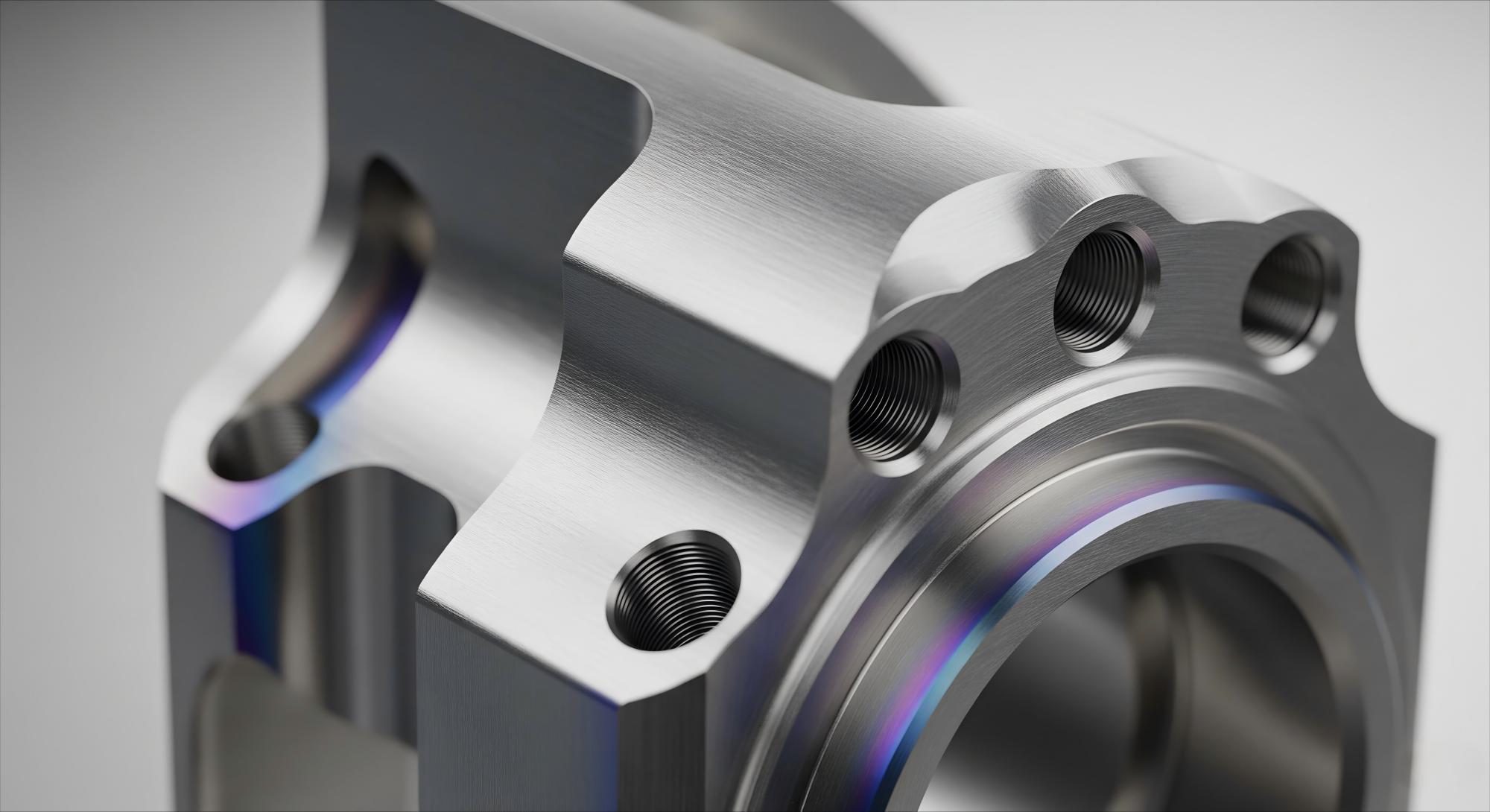

Working with Titanium Alloys

Machining Challenges

Titanium alloys are hard to machine. Beta titanium alloys like Ti5553 and Ti1023 are even stronger than Ti-6Al-4V. This extra strength makes cutting them harder. Titanium’s low modulus of elasticity means it bends away from tools. Machinists must use sharp tools and strong machines. Machines need to be stiff and have powerful spindles. Coolant systems spray lots of cold liquid on the cutting area. This keeps things cool and helps tools last longer.

| Challenge | Explanation |

|---|---|

| Low Thermal Conductivity | Heat stays at the cut, so tools wear out fast. |

| High Chemical Reactivity | Titanium reacts with tools when hot, making them wear out. |

| Work Hardening | The metal gets harder as you cut it, so it is tougher to machine. |

| Low Modulus of Elasticity | Titanium bends away from tools, so sharp tools and strong setups are needed. |

| High Strength-to-Weight Ratio | You must control cutting speed and feed carefully. |

| Coolant Application | Strong coolant flow keeps tools cool and working well. |

| Advanced Techniques | Fast, ultrasonic, and very cold machining help a lot. |

Special ways of machining help tools last longer:

- Climb milling makes less heat and stops hard spots.

- Trochoidal milling uses curved paths to clear chips better.

- Keeping the tool contact steady stops shaking and overload.

- Cooling with lots of liquid or very cold air keeps things cool.

- MQL sprays a tiny mist to protect tools and save coolant.

Tools for titanium have special shapes to stop shaking. They have smooth grooves and deep spaces for chips. Strong tool cores and tough edges help them last. The right angles keep the edge strong and stop it from wearing out.

Welding and Heat Treatment

Welding titanium alloys needs clean work. Workers wear special gloves to keep out oil and dirt. They use tools just for titanium and clean parts with acetone. Grinding or filing removes oxides, but not steel wool. Welders use pure argon gas to shield the weld. They keep the gas on until the weld cools below 500–800°F. Gas also protects the inside of the weld. Special shields and lenses help cover the weld with gas.

| Welding Method | Description and Application | Contamination Prevention Measures |

|---|---|---|

| Gas Tungsten Arc Welding | Good for thin titanium; needs argon gas for shielding | Clean work, argon gas, filler for thick parts |

| Gas Metal Arc Welding | Used for thick pieces; saves money on big jobs | Shielding gas, clean materials |

| Plasma Arc Welding | Fast and works for plates up to 13 mm | Needs shielding and clean work |

| Electron Beam Welding | Used in planes; done in a vacuum | Vacuum keeps weld clean |

| Laser Beam Welding | No vacuum needed; uses gas to shield | Argon or helium gas |

| Friction Welding | Good for rods and tubes; no gas needed | Clean joint surfaces |

| Resistance Welding | Works for sheets and covers | Shielding and clean work |

Heat treatment changes how titanium alloys act. Heating and cooling change the alpha and beta phases. Elements like molybdenum and tantalum make the alloy stronger and less stiff. Heat treatment can make titanium tougher and help it last longer. Stress relief lowers leftover stress. Annealing makes it softer and more stable. Solution treating and aging make it stronger by changing its structure.

Alloy Selection

Picking the right titanium alloy depends on the job. Engineers look at strength, toughness, rust resistance, and heat tolerance. For planes, they pick alloys that are strong and light. Medical implants need alloys that are safe for the body and not too stiff. Chemical plants need alloys that do not rust in acids or seawater. Machinists want alloys that are easy to cut and last long.

Tip: Always pick an alloy that fits the job. This keeps things safe, works well, and lasts a long time.

Titanium alloys help engineers make things that are strong and light. These materials are also safe for many uses. Each type of alloy has its own special features. Some alloys are better for certain jobs than others. Picking the right grade helps things last longer and work well.

- Engineers need to choose alloys that fit the job.

- They should look at what is good and what is hard about each alloy.

Titanium alloys have lots of good points, but picking the right one is important for the best results.

FAQ

Titanium alloys have extra elements like aluminum or vanadium. These elements make the alloy stronger and tougher. They also help stop rust. Pure titanium is softer and bends more. Engineers pick alloys when they need strong, light parts.

Titanium alloys do not rust easily. They make a hard oxide layer on the outside. This layer keeps water and chemicals out. In tough places, titanium alloys last longer than steel or aluminum.

Doctors use titanium alloys for bone screws and dental implants. They also use them for new joints. These alloys do not react with body fluids. Most people do not have allergies to them. Titanium alloys help bones heal and stay strong.

Titanium alloys are strong and light. Planes need parts that are tough but not heavy. Titanium alloys help planes use less fuel and carry more things. They also work well in hot jet engines.

| Property | Titanium Alloy | Steel | Aluminum |

|---|---|---|---|

| Strength | High | High | Medium |

| Weight | Low | High | Low |

| Rust Resistance | Excellent | Poor | Good |

Machinists have problems like tools wearing out and heat building up. Titanium alloys bend away from cutting tools. They also get harder as you cut them. Workers use sharp tools, strong machines, and lots of coolant to help.

Note: Special ways of machining make the job easier and safer.