To pick the best cnc chamfer bit for metal machining, look at material compatibility, bit shape, coating, and size. Using a carbide cutter or carbide cutters gives you strong results and makes the tool last longer, especially with metals. Always match the chamfer angle to your part and make sure the bit fits your machine. AFI Industrial Co., Ltd. gives you trusted precision machining services for your needs.

Here is a quick guide for common selection rules and bit materials:

| Criteria | Importance in Selection |

|---|---|

| Workpiece Material | Use carbide cutters for hard metals to get the best results. |

| Bit Geometry | Pick the shape based on the cut and finish you want. |

| Coating | Choose coated carbide cutter for better strength and heat control. |

| Tool Size | Select the right size for your cnc chamfer bit for metal machining. |

Table of Contents

Key Takeaways

- Choose a chamfer bit that matches your metal type to ensure sharp cuts and longer tool life.

- Pick the right bit shape and number of flutes based on the metal and finish you want.

- Use a 45° chamfer angle for strong, safe edges unless your design needs a different angle.

- Select coatings like TiN or TiAlN to protect your tool from heat and wear for smoother cuts.

- Confirm your chamfer bit size fits your part and CNC machine to avoid damage and get clean chamfers.

- Always inspect your chamfer bit before use to catch wear or damage and prevent tool failure.

- Set proper feed and speed settings to keep your tool sharp and your chamfers smooth.

- Maintain and clean your chamfer bits regularly to extend their life and improve machining quality.

CNC Chamfer Bit for Metal Machining

What Is a CNC Chamfer Bit

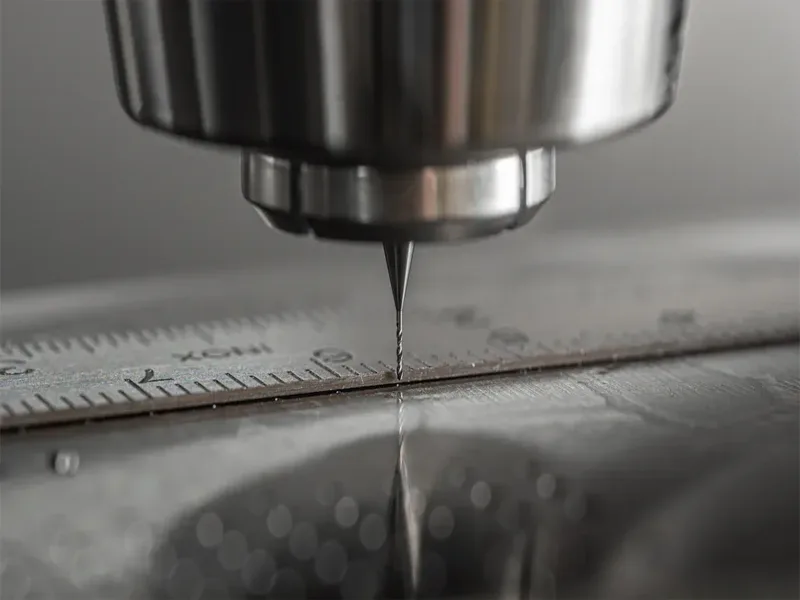

A CNC chamfer bit for metal machining is a special tool. You use it to make a sloped edge on metal parts. This sloped edge is called a chamfer. The tool goes into a CNC machine and shapes the edge at a certain angle. Chamfers are common on parts that need smooth edges or must fit together well. Chamfer machining takes away sharp corners. This makes parts safer and easier to touch.

When you work with metal, you need a strong tool. A CNC chamfer bit for metal machining uses hard materials like carbide. This helps the tool last longer and cut better. You can use these bits on many metals, like steel, aluminum, or brass. AFI Industrial Co., Ltd. gives you high-quality chamfer tools for your metalworking jobs.

Role in CNC Chamfering

CNC chamfering means using a CNC machine to cut chamfers on metal parts. This step is important in many jobs. You want your parts to look nice, fit right, and be safe. A CNC chamfer bit for metal machining helps you do all these things.

Here is a table that shows what a chamfer bit does in chamfer machining:

| Primary Function | Explanation |

|---|---|

| Improving Machining Accuracy | Makes exact chamfers so parts meet standards and stops mistakes from adding up. |

| Optimizing Cutting Performance | Made to lower friction and heat, cuts metal well, and helps the drill bit last longer. |

| Improving Part Appearance | Takes away sharp edges and leaves smooth, clean surfaces, which looks better in important industries. |

| Enhancing Assembly Precision | Makes sure parts fit tight by cutting corners right, so there are fewer gaps and mistakes when building. |

| Improving Operational Safety | Stops injuries by taking away sharp edges, making the workplace safer for everyone. |

When you use the right chamfer tools, your cnc chamfering projects turn out better. You also make your work area safer and your products stronger.

Types of Chamfer Bits

You can pick from different chamfer bits for your cnc chamfer bit for metal machining jobs. Each type is best for certain tasks. Here are some common types:

- Single-flute chamfer bits: These bits cut fast and leave a smooth edge. You use them for quick chamfer machining on soft and hard metals.

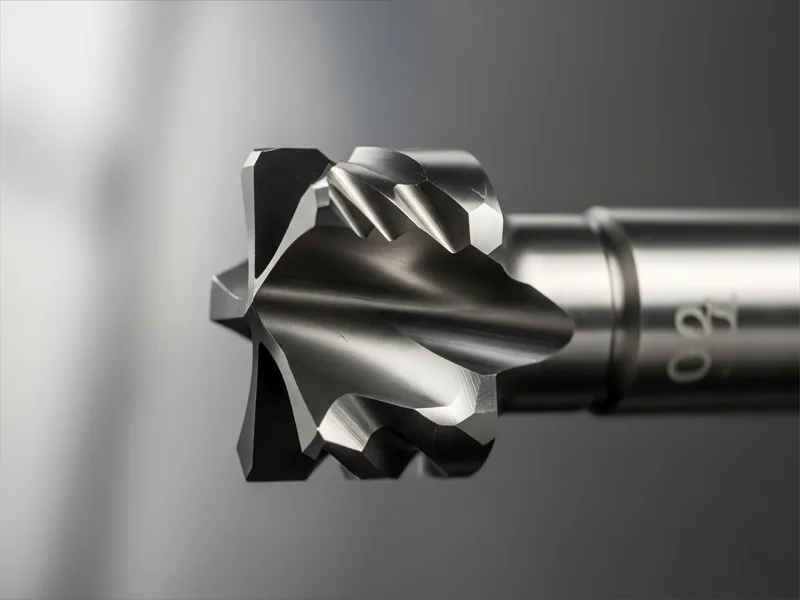

- Multi-flute chamfer bits: These bits have more cutting edges. They give a finer finish and are good for detailed chamfer machining.

- Adjustable chamfer bits: You can change the angle on these bits. They help when you need different chamfer angles for different parts.

- Solid carbide chamfer bits: These are very strong and last a long time. You use them for tough cnc chamfering on hard metals.

When you choose a chamfer bit, think about the metal, the angle, and the finish you want. AFI Industrial Co., Ltd. has many chamfer tools to help you get the best results in your cnc machining work.

Key Selection Factors

Material Compatibility

You must use the right chamfer bit for your metal. Each metal, like aluminum or steel, needs its own tool. Hard metals, like titanium, need bits made from carbide or with diamond-like coatings. These special materials help the chamfer bit last longer and not wear out fast.

Always check if your chamfer bit can handle your metal’s hardness. The right bit will cut well and stay sharp for a long time.

Here are some things to remember about material compatibility:

- Aluminum, steel, titanium, and ceramics all need different bits.

- Hard metals work best with carbide or diamond-like coatings.

- Your tool should cut well and not wear down quickly.

- Coatings and good settings help your bit last and make better chamfers.

This table shows which chamfer bit material works for each job:

| CNC Bit Material Type | Key Properties | Suitable Metal Hardness and Applications |

|---|---|---|

| Ultra-hard (PCD, PCBN) | Very tough, cuts fast, lasts long | Best for very hard metals like quenched steel and high-speed steel |

| Solid carbide (SC) | Hard, resists wear, but can break | Good for soft and hard metals, plastics, and wood |

| Coated bits (TiC, TiN, TiAlN) | Better at stopping wear, heat, and rust | Works for steel, stainless steel, aluminum, and layered materials |

| High-speed steel (HSS) | Not as hard, wears faster | Best for soft metals, wood, PVC, and acrylic |

If your metal is harder, you need a tougher chamfer bit. This keeps your chamfer sharp and your tool working longer.

Bit Geometry

The shape of your chamfer bit changes how smooth your chamfer is. You should look at the tool angle, flute design, and burr shape.

Chamfer bit angles go from 30° to 90°. Single-angle chamfer mills make even edges and exact angles. Flute design matters too. If you cut soft metals, single-flute cutters work fast and clear chips well. For hard metals, multi-flute cutters (2 to 4 flutes) are stronger and give a smoother finish.

Helical flutes help move chips away and make the surface nicer, especially for soft metals. Four-flute bits are stiffer and good for hard metals. You can pick different burr shapes:

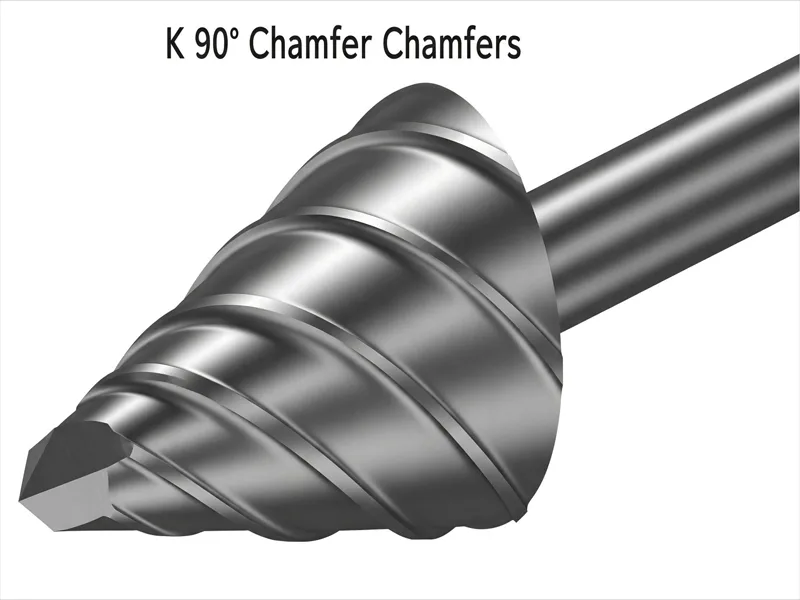

- J-shape (60° conical): Good for beveling, chamfering, and sharp angled cuts.

- K-shape (90° conical): Best for right-angled chamfers and V-shaped cuts.

- M-shape (pointed cone): Helps you cut angles in small spaces.

Picking the right shape and coating gives you sharp, clean chamfers and removes metal well.

Chamfer Angle

The chamfer angle you pick changes how strong and nice your part is. A chamfer takes away sharp corners, so your part does not crack and lasts longer. The most common chamfer angle is 45°. This angle is easy to machine and makes strong, safe edges.

A 45° chamfer is great for deburring and helps bolts sit flat. It also spreads out stress, so your part is stronger.

Other angles, like 30° or 60°, change the size and slope of your chamfer. This matters for how parts fit and look. A 60° chamfer is good for bolts and screws, but it does not spread stress as well as a 45° chamfer.

Here are some facts about chamfer angles:

- Chamfers make edges safer and help stop injuries.

- A 45° chamfer is best for strength and looks.

- A 60° chamfer helps with assembly but spreads less stress.

- The right angle makes your part fit better, look better, and be safer.

- If the angle is too big or too small, your part can get weak or not seal right.

Always match your chamfer angle to your design, how you put parts together, and safety needs. This way, your chamfer tools will work their best.

Coating Types

You need to pay close attention to coating types when you choose a chamfer tool. The coating on your chamfer bit helps you cut metal better and makes your tool last longer. Different coatings work best for different metals and cutting speeds.

Here are some common coating types you will see on chamfer tools:

- TiN (Titanium Nitride): This gold-colored coating gives your chamfer bit more hardness. It helps you cut steel and other metals with less friction.

- TiAlN (Titanium Aluminum Nitride): This coating works well for high-speed chamfer jobs. It protects your tool from heat and lets you cut hard metals like stainless steel.

- TiCN (Titanium Carbonitride): This coating gives you extra wear resistance. You can use it for tough chamfer tasks on cast iron or other hard metals.

- AlTiN (Aluminum Titanium Nitride): This coating stands up to very high heat. It is good for fast chamfer cuts on hard materials.

Tip: Always match the coating to your metal and your cutting speed. The right coating keeps your chamfer tool sharp and strong.

A good coating will help your chamfer bit resist heat and wear. This means you get a smoother chamfer and your tool lasts longer. If you use the wrong coating, your chamfer bit may wear out too fast or not cut cleanly.

| Coating Type | Best For | Main Benefit |

|---|---|---|

| TiN | Steel, general metals | Hardness, low friction |

| TiAlN | Stainless, hard metals | Heat resistance |

| TiCN | Cast iron, hard metals | Wear resistance |

| AlTiN | High-speed, hard jobs | High heat resistance |

You should always check the coating before you start your chamfer job. The right choice will help you get a clean, smooth chamfer every time.

Tool Size

You must pick the right tool size for your chamfer job. The size of your chamfer bit affects how deep and wide your chamfer will be. If you use a bit that is too small, you may not get the full chamfer you need. If you use a bit that is too large, you could damage your part or your machine.

Here are some things to think about when you choose your chamfer tool size:

- Chamfer width: This is how wide you want your chamfer to be. Measure your part and pick a bit that matches the width you need.

- Chamfer depth: This is how deep the chamfer goes into the metal. Make sure your tool can reach the right depth without cutting too much.

- Bit diameter: The diameter of your chamfer bit should fit your machine and your part. A larger diameter can make a wider chamfer, but it needs more power.

- Length of cut: Some chamfer bits have a longer cutting edge. This helps you make a longer chamfer in one pass.

Note: Always check your machine’s limits before you pick your chamfer tool size. The right size keeps your chamfer smooth and your machine safe.

If you use the right size, you will get a clean chamfer that fits your design. You will also avoid tool breakage and wasted material.

Shank Type

The shank is the part of your chamfer bit that fits into your CNC machine. You need to choose the right shank type to make sure your chamfer bit stays secure and cuts straight.

There are a few common shank types for chamfer tools:

- Straight shank: This is the most common type. It fits most CNC machines and gives you a steady, straight chamfer.

- Weldon shank: This shank has a flat side. It locks into your machine and stops the chamfer bit from spinning.

- Tapered shank: This type gives you extra grip. It is good for heavy-duty chamfer jobs or when you need extra strength.

| Shank Type | Best Use | Benefit |

|---|---|---|

| Straight shank | General chamfering | Easy to use, versatile |

| Weldon shank | High-torque chamfer operations | Prevents slippage |

| Tapered shank | Heavy-duty chamfering | Extra holding strength |

Tip: Always match your shank type to your CNC machine. A good fit keeps your chamfer bit steady and your chamfer accurate.

If you pick the right shank, your chamfer tool will not slip or wobble. This helps you get a perfect chamfer every time.

Carbide Cutter Advantages

Precision and Durability

When you choose a carbide cutter for chamfer machining, you get high precision and long-lasting performance. Carbide cutters have a very hard structure. This means they keep their sharp edge even after many uses. You can rely on them to make clean, accurate cuts every time.

Carbide cutters do not wear down quickly. They can handle tough jobs and keep working well. You will notice that your parts have smooth edges and exact angles. This is important when you want the best results in metalworking.

Here are some reasons why carbide cutters stand out:

- They resist heat and stay sharp at high speeds.

- You can use them on many metals, such as steel, stainless steel, and titanium.

- They last longer than regular steel tools.

- You get a smooth finish, which helps your parts fit together better.

Tip: If you want the best carbide cutter for your project, always check the tool’s sharpness and coating. This helps you get the most out of your chamfer machining.

Performance in Metal Machining

Carbide cutters give you strong performance in metal machining. You can use them for fast and efficient work. They let you cut at higher speeds without losing quality. This saves you time and helps you finish more parts in less time.

You will see the advantages of cnc chamfer machining when you use carbide cutters. They help you make parts that meet strict standards. You also get less downtime because you do not need to change tools as often.

Here is a table that shows how carbide cutters help in metal machining:

| Feature | Benefit for Metal Machining |

|---|---|

| High heat resistance | Cuts metals without losing sharpness |

| Long tool life | Reduces tool changes and saves money |

| Fast cutting speeds | Increases productivity |

| Smooth surface finish | Improves part quality and fit |

| Versatile use | Works on many types of metals |

You can trust carbide cutters for both small and large jobs. They work well with CNC machines and help you get the best results. The best carbide cutter will give you the precision and speed you need for any chamfer machining task.

Note: Using carbide cutters is one of the main advantages of cnc chamfer machining. You get better quality, faster work, and tools that last longer.

If you want to improve your metalworking, choose carbide cutters. They offer the best mix of strength, speed, and accuracy.

Application Matching

Metal Type and Thickness

You need to match your chamfer bit to the metal type and thickness for the best results. Each metal has its own hardness and reacts differently to cutting. For example, aluminum cuts easily, but stainless steel needs a tougher tool. Thicker metals require stronger bits that can handle more pressure.

When you choose a chamfer bit, think about these points:

- Smaller diameter bits work well for detailed work or tight spaces. You should use slower speeds with these bits to avoid breaking them.

- Larger diameter bits remove more material quickly. They help when you need to chamfer thick or wide edges.

- Shorter tools give you better stability and more precise cuts. Use them for thin metals or when you want a smooth finish.

- Longer tools reach deeper into the metal. You need them for thick parts, but they may bend more, so you must cut carefully.

Always check the thickness of your metal before you start. The right bit size and length help you get a clean chamfer and protect your tool from damage.

CNC Machine Compatibility

Your cnc machine must fit the chamfer bit you choose. Not every machine can hold every tool. You should check the shank size and type before you begin. Some machines use straight shanks, while others need Weldon or tapered shanks.

Look at your machine’s spindle speed and power. Some bits need high speeds to cut well, but others work better at slow speeds. If your machine is not strong enough, the bit may not cut cleanly. Always match the bit’s requirements to your cnc machine’s abilities.

You should also check the tool holder. A good fit keeps the bit steady and stops it from slipping. This helps you make accurate chamfers and keeps your machine safe.

Surface Finish Needs

The finish you want on your part affects your chamfer bit choice. If you need a smooth, shiny edge, pick a bit with more flutes. Multi-flute bits cut finer and leave fewer marks. For a rougher finish, single-flute bits work faster but may leave lines.

Coatings on the bit also change the finish. Some coatings reduce friction and heat, giving you a cleaner edge. If you want a perfect look, use a coated bit and set your machine to the right speed.

You should always test on a scrap piece first. This lets you see the finish and adjust your settings before you work on the real part.

Step-by-Step Selection Guide

Identify Metal Properties

Start your selection process by looking at the metal you want to machine. Every metal has its own hardness, toughness, and density. These properties affect how your chamfer tool will perform. For example, aluminum is soft and easy to cut. Stainless steel is much harder and needs a stronger tool. If you use the wrong tool, your chamfer may not be clean or may wear out too fast.

Check if your metal is soft, medium, or hard. Soft metals like aluminum allow for faster chamfering. Hard metals like titanium or hardened steel need carbide tools for the best results. You should also think about the metal’s abrasiveness. Some metals cause more wear on your chamfer tool. Always match your tool material to the metal for a smooth and accurate chamfer.

Define Machining Goals

You need clear goals before you start your chamfer project. Setting these goals helps you pick the right tool and get the best results. Follow these steps to define your machining goals:

- Decide on the exact chamfer dimensions you need, such as angle and width. This ensures your chamfer meets both design and mechanical needs.

- Think about the type, hardness, and density of your metal. These factors affect which tool you should use and how you set your machine.

- Choose the right chamfer angle. Most metal parts use a 30 to 45-degree angle. Pick the angle that fits your design and function.

- Select a tool that matches your metal and the finish you want. Carbide tools work best for hard metals and give a smooth chamfer.

- Adjust your machine’s speed, feed rate, and cutting depth to match your metal and tool. This keeps your chamfer smooth and your tool in good shape.

- Check your chamfer often during machining. Make small changes if needed to keep your chamfer within your project’s requirements.

Tip: Always combine mechanical needs, ease of manufacturing, and how your part looks when you set your machining goals. This approach helps you choose the right chamfer tool and settings for every job.

Select Bit Geometry

Choosing the right bit geometry is key to getting a perfect chamfer. The geometry includes the shape, angle, and number of flutes on your tool. Here are some important points to help you select the best bit geometry:

- Pick the geometry based on your machining task. Use different shapes for roughing, finishing, or profiling.

- Look at your metal’s softness or abrasiveness. Softer metals need tools with fewer flutes for better chip removal. Harder metals need more flutes for a smoother chamfer.

- Use a higher helix angle if you want better chip clearance and less cutting force. This helps your chamfer tool last longer.

- Choose the flute count based on your needs. Two-flute tools remove chips quickly in soft metals. Three or more flutes give you a finer finish in hard metals.

- Solid carbide tools give you more rigidity and precision. They help you make a clean chamfer, especially in tough metals.

- Add a coating like TiN or ZrN if you want your tool to last longer and your chamfer to look better, especially with abrasive metals.

- Adjust your machine’s speed and feed rate to match your tool geometry and metal. This keeps your chamfer smooth and prevents tool wear.

- Match the rake and relief angles to your metal. The right angles help you cut efficiently and avoid work hardening.

Note: Always make sure your tool geometry matches your chamfer goals, the metal you are working with, and the finish you want. This step ensures your chamfer is clean, accurate, and meets your project’s needs.

Choose Coating

You need to pick the right coating for your chamfer tool. The coating helps your tool last longer and cut better. Each coating works best for certain metals and speeds. You should always match the coating to your job.

Here are some common coatings you will see on chamfer tools:

- TiN (Titanium Nitride): This coating gives your chamfer tool more hardness. It works well with steel and other metals. You get less friction and a longer tool life.

- TiAlN (Titanium Aluminum Nitride): This coating protects your chamfer tool from heat. You can use it for high-speed chamfer jobs and hard metals like stainless steel.

- TiCN (Titanium Carbonitride): This coating adds extra wear resistance. It is good for tough chamfer jobs on cast iron or hard metals.

- AlTiN (Aluminum Titanium Nitride): This coating stands up to very high heat. You can use it for fast chamfer cuts on hard materials.

Tip: Always check the metal you want to chamfer. Pick a coating that matches the metal and the speed you plan to use.

A good coating will help your chamfer tool resist heat and wear. You will get a smoother chamfer and your tool will last longer. If you use the wrong coating, your chamfer tool may wear out too fast or not cut cleanly.

Here is a table to help you choose the right coating for your chamfer tool:

| Coating Type | Best For | Main Benefit |

|---|---|---|

| TiN | Steel, general metals | Hardness, low friction |

| TiAlN | Stainless, hard metals | Heat resistance |

| TiCN | Cast iron, hard metals | Wear resistance |

| AlTiN | High-speed, hard jobs | High heat resistance |

You should always test your chamfer tool on a sample piece. This lets you see if the coating works well with your metal. You can then adjust your choice if needed.

Confirm Tool Size

You must confirm the size of your chamfer tool before you start. The size affects how deep and wide your chamfer will be. If you pick the wrong size, your chamfer may not fit your design.

Follow these steps to confirm your chamfer tool size:

- Measure the width you want for your chamfer. Use a ruler or caliper for accuracy.

- Check the depth you need for your chamfer. Make sure your tool can reach this depth without cutting too much.

- Look at the diameter of your chamfer tool. It should fit your CNC machine and your part.

- Choose a tool with the right length of cut. Some chamfer tools have a longer cutting edge for deeper chamfers.

- Make sure the tool size matches your machine’s limits. A tool that is too big can damage your part or your machine.

Note: Always double-check your measurements before you start your chamfer job. The right size gives you a clean, safe chamfer every time.

You should also think about the type of chamfer you want. A small tool works well for detailed chamfer work or tight spaces. A large tool helps you chamfer thick or wide edges quickly.

Here is a checklist to help you confirm your chamfer tool size:

- Chamfer width matches your design

- Chamfer depth fits your part

- Tool diameter fits your machine

- Length of cut is enough for your chamfer

- Tool size is safe for your CNC machine

When you follow these steps, you get a perfect chamfer that meets your needs. You also protect your tool and your machine from damage.

CNC Chamfering Mistakes

Wrong Bit Selection

You might think any chamfer tool will work for your project, but choosing the wrong bit can cause big problems. If you use a bit that does not match your metal type or chamfer size, you risk poor results and tool damage.

For example, a bit made for wood will not last long on steel. You may see rough edges, uneven chamfers, or even broken tools. Always check the bit’s material, size, and angle before you start. This step helps you avoid wasted time and money. If you want tips for achieving optimal results, match your chamfer bit to your metal and project needs every time.

Ignoring Coating

Many people overlook the coating on their chamfer tools, but this mistake can shorten tool life and ruin your finish. The coating protects your tool from heat, friction, and wear. If you ignore the coating type, you may see these problems:

- Ceramic coatings are much harder than most metals. You need special tools, like diamond-coated or CBN bits, to avoid fast tool wear.

- Using regular carbide tools on hard coatings causes the tool to wear out quickly. You get more friction and a poor surface finish.

- If you do not consider coating thickness and how well it sticks, you may see chipping or peeling. This leads to uneven chamfers and lower part quality.

- Some coatings change how heat moves away from the tool. If you ignore this, you may get thermal cracks or unstable machining.

- Skipping the right coating leads to early tool failure, more downtime, and higher costs.

You should always pick a chamfer tool with the right coating for your metal and job. This is one of the best tips for achieving optimal results in cnc chamfering.

Overlooking Feed and Speed

Feed and speed settings play a huge role in chamfer quality. If you set them too high or too low, you risk tool breakage, rough surfaces, and even part damage. When you use the wrong settings, your tool can get too hot. This causes it to wear out faster and may leave a rough chamfer. If the feed is too slow, the tool rubs instead of cutting, which makes the metal harder and shortens tool life.

If the speed is too high, you get vibration, chatter, and poor chip removal. This leads to uneven chamfers and possible workpiece deformation. You should always follow the recommended settings for your tool and metal. Good chip removal and proper coolant use help keep your chamfer smooth and your tool in top shape.

Pro Tip: Use a calculator or chart to set your feed and speed. This helps you get the best chamfer and keeps your tools working longer.

If you want your cnc chamfering projects to succeed, pay close attention to bit selection, coating, and machine settings. These steps help you avoid common mistakes and get the best results every time.

Skipping Tool Inspection

You might feel tempted to skip tool inspection when you want to save time. This shortcut can lead to big problems in CNC chamfering. If you do not check your chamfer bit before each job, you risk tool failure, poor part quality, and even machine damage.

When you skip inspection, you miss signs of wear or damage. A dull or chipped bit cannot cut cleanly. You may see rough edges, uneven chamfers, or even broken parts. Sometimes, a worn tool can break inside your CNC machine. This can stop your work and cost you money for repairs.

AFI Industrial Co., Ltd. always checks tools before every job. Their quality control team uses a simple checklist. You can use a similar process to keep your tools and parts in top shape.

Here is a basic tool inspection checklist you can follow:

- Look for visible wear: Check the cutting edge for chips, cracks, or dull spots.

- Check the coating: Make sure the coating is not peeling or worn away.

- Inspect the shank: Look for bends or damage that could affect tool stability.

- Test the fit: Insert the tool into the holder and make sure it fits tight.

- Spin the tool: Rotate the bit by hand to check for wobble or imbalance.

Tip: Always inspect your chamfer bit under good light. Use a magnifier if you need to see small cracks or chips.

If you find any problems, replace the tool before you start machining. Never try to use a damaged bit. This step protects your machine and your workpiece.

Common issues you can catch with regular inspection:

| Problem Found | What Happens If Ignored | How Inspection Helps |

|---|---|---|

| Dull cutting edge | Rough chamfers, tool breakage | Ensures clean, sharp cuts |

| Chipped flute | Uneven edges, part defects | Prevents scrap and rework |

| Worn coating | Overheating, fast tool wear | Extends tool life |

| Bent shank | Vibration, poor accuracy | Keeps cuts precise |

You should set a routine for tool inspection. Check your chamfer bit before every shift or after a set number of parts. This habit helps you catch problems early.

AFI’s experience shows that regular inspection reduces downtime and improves part quality. You can avoid costly mistakes and keep your CNC chamfering process smooth. Remember, a few minutes spent on inspection can save hours of trouble later. 🛠️

Tool Longevity Tips

Installation and Setup

You set the stage for a long-lasting CNC chamfer bit during installation. Always start by cleaning the bit and the tool holder. Dirt or burrs can cause the bit to sit unevenly. This leads to poor cuts and faster wear. Place the bit into the holder with care. Make sure the shank fits snugly. Align the bit so it points straight. Tighten the clamp to keep the bit from moving during use. If the bit feels loose, check the holder for damage. A secure fit prevents slippage and protects both the tool and your machine.

Tip: Use a torque wrench if your machine recommends it. This helps you avoid over-tightening, which can bend or crack the bit.

Maintenance and Cleaning

Routine maintenance and cleaning keep your chamfer bits sharp and reliable. You should follow these steps every time you use your tool:

- Clean the bit and all surfaces before installation. Remove any dirt or metal shavings. This step prevents inaccuracies and reduces wear.

- Inspect the bit for signs of wear or defects. Look for chips, cracks, or dull edges. Replace the bit if you see damage.

- Use proper installation techniques. Clamp the bit tightly and align it correctly. This reduces deformation and keeps the bit in good shape.

- Make sure the bit is mounted securely. A loose bit can slip or break during operation.

- Store the bit in a safe place after use. Use a case or holder to prevent bending, scratches, or other damage.

These steps help you maintain the performance of your CNC chamfer bits. Clean tools cut better and last longer. Regular care also helps you avoid costly mistakes and downtime.

Monitoring Wear

You need to watch for signs of wear to keep your chamfer bits working well. Check the cutting edge before each job. A sharp edge gives you smooth, accurate chamfers. If you see chips or dull spots, replace the bit. Listen for changes in sound during machining. Unusual noises can mean the bit is wearing out. Measure your finished chamfers. If the size or angle changes, your bit may need attention.

Note: Set a schedule for checking your tools. Regular inspections help you catch problems early and keep your machining process smooth.

A well-maintained chamfer bit saves you time and money. You get better results and fewer tool changes. With good habits, your CNC chamfer bits will serve you well for many projects.

Summary and Checklist

Key Steps Recap

You have learned how to choose the best CNC chamfer bit for metal machining. Here is a recap of the most important steps:

- Check Material Compatibility

Make sure your chamfer bit matches the metal you want to machine. Use carbide cutters for hard metals like steel or titanium. - Select the Right Bit Geometry

Pick the shape and number of flutes that fit your job. Use single-flute bits for fast cuts on soft metals. Choose multi-flute bits for smooth finishes on hard metals. - Match the Chamfer Angle

Decide on the angle you need. A 45° angle works for most jobs. Use other angles if your design needs them. - Choose the Best Coating

Select a coating that fits your metal and speed. TiN, TiAlN, TiCN, and AlTiN are common choices. The right coating helps your tool last longer. - Confirm Tool Size and Shank Type

Measure your part. Pick a tool size that matches your chamfer width and depth. Make sure the shank fits your CNC machine. - Set Up and Inspect Your Tool

Install your chamfer bit carefully. Check for wear or damage before you start. Use the right feed and speed settings.

Tip: Always follow these steps before every project. This helps you get clean chamfers and keeps your tools in good shape.

Quick Reference

You can use this checklist to make sure you have everything covered before you start machining:

| Step | What to Check | Done? |

|---|---|---|

| Material Compatibility | Is the bit right for your metal? | [ ] |

| Bit Geometry | Does the shape and flute count fit your job? | [ ] |

| Chamfer Angle | Did you pick the correct angle? | [ ] |

| Coating Type | Is the coating matched to your metal? | [ ] |

| Tool Size | Does the size fit your part and machine? | [ ] |

| Shank Type | Will the shank fit your CNC holder? | [ ] |

| Tool Inspection | Did you check for wear or damage? | [ ] |

| Machine Settings | Are feed and speed set correctly? | [ ] |

✅ Use this table before every job. You will save time, avoid mistakes, and get the best results.

If you follow this guide, you will choose the right CNC chamfer bit every time. You will also keep your tools and machines working well. For expert help or custom solutions, you can always reach out to AFI Industrial Co., Ltd. for precision machining services.

To pick the best CNC chamfer bit for metal machining, start by checking if it works with your metal. Look at the shape of the bit, the coating, and the size. Using carbide cutters gives you strong results. Always follow a checklist to help you remember each step. Each step helps you make clean and accurate chamfers. If you want good results and expert help, trust AFI Industrial Co., Ltd. Try these tips on your next project and watch your machining get better. 🚀

FAQ

You should use carbide for most metal machining. Carbide stays sharp and lasts longer than high-speed steel. It works well with hard metals like steel and titanium.

Check your part’s design. Most metal parts use a 45° angle. If your drawing shows a different angle, match your bit to that. The right angle helps your parts fit and look better.

You can use carbide bits for both aluminum and steel. For the best results, pick a bit with the right coating. TiN works well for steel. Uncoated or TiAlN-coated bits work well for aluminum.

Inspect your chamfer bit before every job. Look for chips, dull edges, or worn coatings. Regular checks help you avoid tool failure and keep your parts looking good.

If you use the wrong feed or speed, your bit may wear out quickly or break. You might see rough edges or uneven chamfers. Always follow the tool maker’s recommendations.

Most CNC machines use standard tool holders. Make sure your holder matches the shank type of your chamfer bit. A good fit keeps your bit steady and your cuts accurate.

Coatings like TiN or TiAlN reduce heat and friction. They protect your bit from wear. You get smoother cuts and longer tool life. Always match the coating to your metal type.

You can contact AFI Industrial Co., Ltd. for expert advice. Their team helps you pick the best chamfer bit for your project. They offer precision machining services and support.