Choosing the right material is crucial, and understanding the differences between 1018 vs 4140 steel can help you make the best choice for your project. The key distinction lies in their chemical composition and mechanical properties. 4140 steel contains higher amounts of carbon, chromium, and molybdenum, which gives it greater strength and hardness compared to … Read more

Tech Support

A titanium alloy mixes titanium metal with other elements to make it better. People like titanium alloys because they are strong, light, and can handle heat well. Elements like vanadium or molybdenum change how titanium acts by affecting the phases inside the metal. Titanium alloys do not rust easily because they have a tough oxide … Read more

Sheet metal stamping forms metal into exact parts for many uses. First, you pick the right material and use special tools. Careful planning and strong quality checks help stop errors. If you follow all steps, you will make strong and exact parts for cars, electronics, and planes. The world market for sheet metal stamping was … Read more

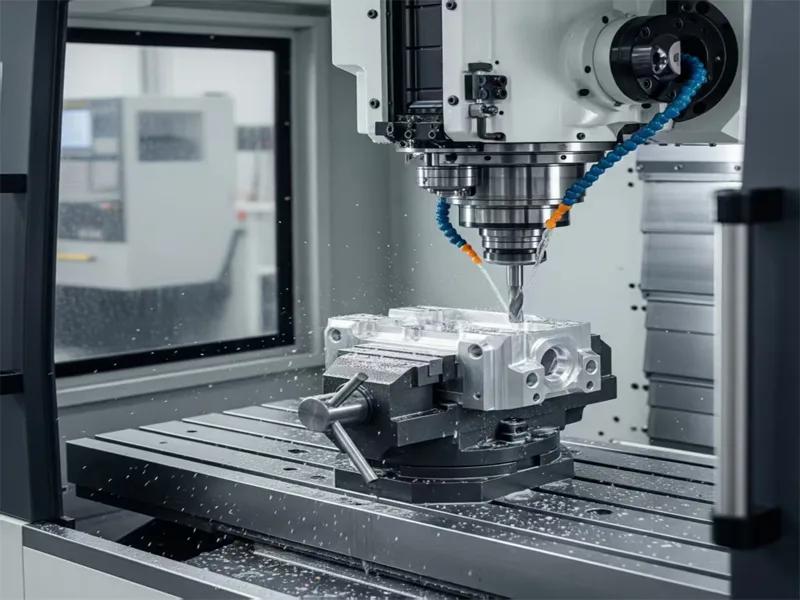

Milling is a way to cut material off a workpiece. This helps make exact shapes. CNC milling uses computers to control the process. The operator sets up the CNC machine. The machine moves the cutting tool very accurately. CNC milling is good for making hard parts. It gives the same results each time. Many industries … Read more

You can get very accurate results with copper CNC machining. Copper is special because it carries electricity and heat very well. This makes it important for electronics, heat exchangers, and connectors. CNC machining copper helps you make complex shapes for springs, non-sparking tools, and aerospace bushings. AFI Industrial Co., Ltd. makes custom copper parts using … Read more

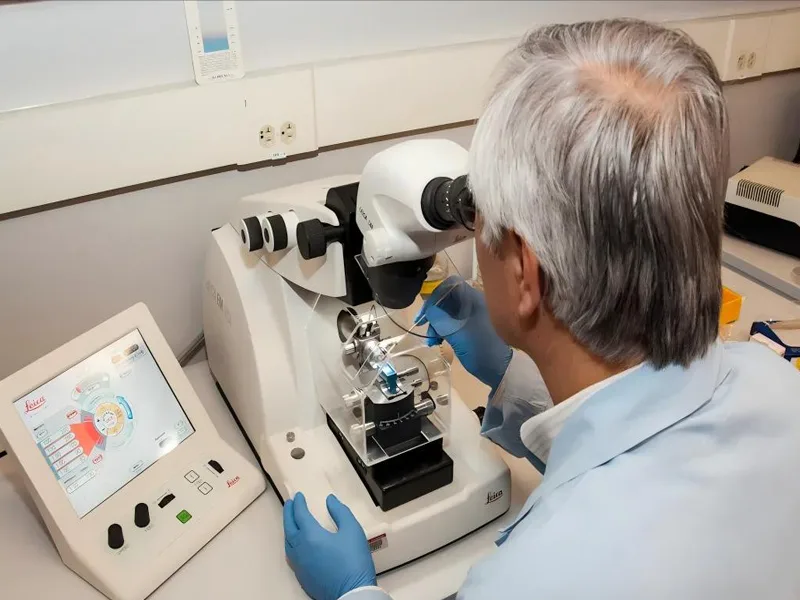

When you apply full annealing of copper, you observe significant changes. The copper becomes softer and more pliable. The grains inside the copper grow larger during the full annealing of copper process. Microhardness tests confirm that copper subjected to full annealing is less hard. This reduction in hardness occurs because the grains increase in size. … Read more

When you machine aluminum alloy 6061 T6, always use sharp carbide tools and the right lubrication. Sharp tools and the right tool shape keep cuts clean. This helps stop the built-up edge from forming. Studies show that using the right tool angles and coatings, like TiN, controls heat and cutting forces. This makes machining more … Read more

You can use an X-ray fluorescence spectrometer to study materials; this is a non-destructive elemental analysis. First, you need to prepare the sample well. Set up the X-ray fluorescence spectrometer the right way and make sure it is calibrated. Run the test and look at the results carefully. The X-ray fluorescence spectrometer does not damage … Read more

You can see that Rockwell, Brinell, and Vickers hardness tests are different. Each test uses its own indenter and way to measure. This changes how accurate, fast, and costly the test is. For example, Rockwell testing is quick and gives results right away. Brinell and Vickers take longer and need special tools. The table below … Read more

The most common surface treatments for stainless steel in 2025 are electroplating, painting, powder coating, anodizing, galvanization, passivation, and plasma treatment. Manufacturers use these methods to make stainless steel stronger. These treatments help stop rust and make the surface look nicer. Data shows that finishing and hardening the surface can lower rust, especially for 316 … Read more