Slip casting uses liquid clay and plaster molds to make ceramics, and it’s important to understand what slip casting is. This method shapes pieces with great accuracy, making it an excellent choice for beginners. You can start with slip casting because it provides steady results and helps you create sets that look the same. Many … Read more

Tech Support

You often see eight metals used in casting. These are gray iron, white iron, ductile iron, stainless steel, carbon steel, aluminum, copper-based alloys, and nickel-based alloys. Picking the right casting metals is important. Each metal has special properties. These include chemical composition, carbon content, and machinability. These things change how the metal is used in … Read more

You can see clear differences between bronze, brass, and copper when you look at what is in bronze made of and how they act. Copper is a pure element. Brass is made from copper and zinc. Bronze is usually made from copper and tin. Bronze is strong and does not rust easily, making it good … Read more

You might ask what is alloy steel. Alloy steel is steel with extra elements like manganese, nickel, or chromium. These elements change how the steel acts. They make alloy steel stronger and tougher. Alloy steel also resists wear and rust better. The table below shows how alloy steel is different from carbon steel and stainless … Read more

You can spot brushed metal by its thin, straight lines and dull shine. This finish does not show fingerprints easily and hides scratches well. That is why people like it for appliance panels, elevator walls, and furniture. Special tools are used to brush the metal. This makes the surface smooth but also a little bumpy. … Read more

How etching on Metal perfectly? You can do well in etching if you use a good beginner’s guide. Getting ready is very important. New people often have problems like etching too much or too little. Sometimes the design does not transfer well. Not cleaning enough can also cause trouble. You should know what is etching … Read more

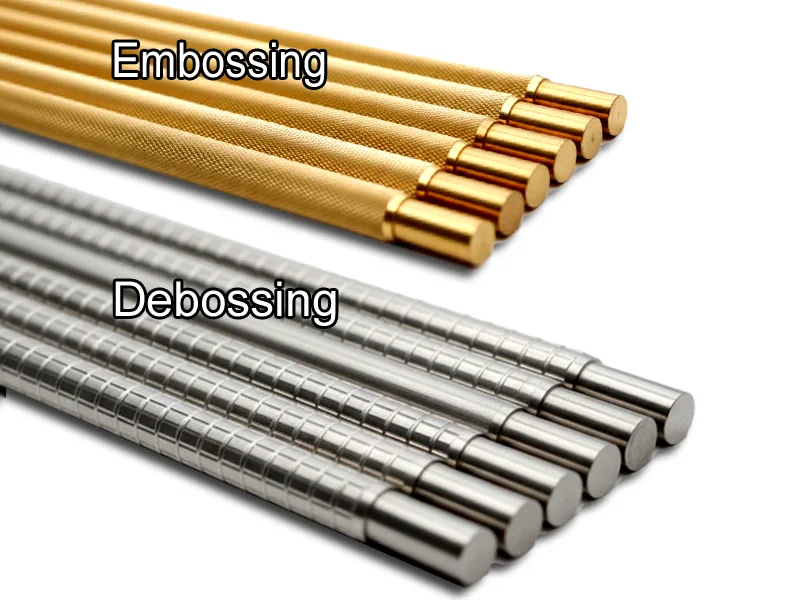

Embossing and debossing are two strong ways to make designs better in printing and packaging. Embossing makes a raised pattern on the top of the material. Debossing makes a sunken pattern instead. These methods change plain materials and help products look and feel special, and achieve the purpose of enhancing product packaging. Recent numbers show … Read more

You discover the key difference between MIG and MAG welding by looking at the shielding gas. MIG welding uses inert welding gas, while MAG welding relies on active gas. This choice affects which metals you can weld and how much you spend. For mild steel, MAG welding often costs less—sometimes saving you Rs. 20 per … Read more

You may ask what makes anodized aluminum different from aluminum hard anodized. The biggest difference is how strong it is. Aluminum hard anodized cookware does not scratch or dent as easily as regular anodized cookware. You get a pan that stays strong, even if you use it a lot. The special process makes the surface … Read more

Zinc electroplating puts a thin zinc layer on metal with electricity. This gives strong rust protection because zinc works like a shield. If there is water or salt, zinc will corrode first and protect the metal. Post-treatments like passivation add more layers, so things last longer. Thicker zinc coatings protect even better in tough places. … Read more