Swaging vs crimping, there are two different metal forming methods. When choosing between them, you should think about what your project needs. You also need to think about cost and what your industry requires. The swaging process makes strong connections. But it usually costs more at first and needs special training. The crimping process costs less at the start. It is good for jobs with many parts. Different industries use these methods for certain jobs. Check the table below to see common uses:

| Industry | Application Description |

|---|---|

| Automotive and Transportation | Making safe electrical connections in cars, like wiring harnesses and battery ends. |

| Aerospace | Making sure wires in planes are connected safely, like in avionics and communication systems. |

| Construction and Heavy Machinery | Making strong connections in hydraulic hoses and wires for machines to work well. |

You should pick the method that fits your project’s needs for strength and safety. Each technique has its own good points.

Key Takeaways

- Swaging is best for jobs with high pressure. It gives strong and long-lasting connections. Crimping costs less and works for medium pressure jobs. It is a fast choice for many projects. Use swaging for tough jobs like hydraulic lines. Crimping is good for electrical connections. Swaging needs special machines and training. Crimping only needs simple hand tools. Always pick the right method for your project. This keeps things safe and reliable. Check your connections after swaging or crimping. Look for cracks or loose spots. Think about the cost and how hard each method is. Do this before you choose. Ask experts for help with high-pressure or important jobs. This helps you get the best results.

Table of Contents

Swaging Overview

Process

Swaging changes the shape and size of metal tubes or rods. This process is done without heat. Swaging is a cold working method. Swaging machines have split dies that open and close fast. The dies press on the metal and make it smaller. Sometimes, the dies hammer the metal to shrink it. Here are the steps you follow:

- Put the metal piece inside the swaging machine.

- The machine has two or four split dies that move together and apart. A motor powers the dies.

- The dies squeeze or hammer the metal to make it thinner.

- You can use a mandrel inside the tube to control wall thickness.

Swaging machines work quickly and handle many shapes and sizes. You can use them for tubes, rods, and wires. Swaging is useful for making strong connections in many projects.

Materials

Swaging works with many metals. Steel and its alloys are used a lot. They get stronger and harder during swaging. Copper, lead, and zinc alloys also work well. Swaging makes the metal harder and stronger. The finish is smooth and the hardness is even. Here is a table with common materials and their properties:

| Material | Mechanical Properties Relevant to Swaging |

|---|---|

| Steel and Alloys | Work hardening, hardness distribution, fatigue strength |

| Copper and Alloys | Work hardening, surface residual stresses |

| Lead and Alloys | Work hardening, surface residual stresses |

| Zinc and Alloys | Work hardening, surface residual stresses |

Swaging machines help the metal handle more stress and last longer. The process makes the metal stronger for tough jobs.

Industrial Applications

Swaging is used in many industries. It makes strong and safe connections. In aerospace, swaging is used for hydraulic and fuel lines. These parts must be light and strong. In cars, swaging helps make exhaust systems and suspension parts. These parts need to handle stress and shaking. Construction uses swaging to join and fasten metal parts. These connections keep buildings and bridges safe.

- Aerospace: Hydraulic lines, fuel lines

- Automotive: Exhaust systems, suspension parts

- Construction: Fastening and joining metal parts

Swaging machines are flexible for many uses. You can use them for high-pressure systems, metal tubes, and rods. Swaging is known for its strength and reliability in hard jobs.

Strength

Swaging gives you strong and reliable connections. When you use swaging, you change the shape of the metal without heat. This process makes the metal harder and tougher. You can use swaging for jobs that need to handle high pressure. For example, swaging works well for hydraulic lines and heavy-duty cables. The metal becomes stronger because the dies press and shape it tightly. You get a smooth finish and even hardness across the part.

If you need a connection that will not slip or break, swaging is a good choice. The process helps the metal resist bending and stretching. You can trust swaging for safety in important projects. Many industries use swaging when they need the highest strength. You see swaging in aerospace, construction, and automotive work. The connections last a long time and keep people safe.

Tip: Always check the strength requirements for your project before you choose swaging. This method works best when you need maximum durability.

Pros

Swaging offers many benefits for your projects. Here are some reasons you might choose swaging:

- You get very strong connections that last.

- Swaging works with many types of metal, including steel, copper, and alloys.

- The process does not need heat, so you avoid changing the metal’s structure too much.

- Swaging machines can handle different shapes and sizes.

- You can use swaging for high-pressure systems and heavy loads.

- The finished parts look smooth and professional.

Swaging helps you save time on large jobs. The machines work quickly and can repeat the same process many times. You also get a clean finish, which makes your project look better.

Cons

Swaging has some drawbacks you should consider. Here are a few points to keep in mind:

- You need special machines and tools for swaging.

- The cost to start swaging is higher than crimping.

- You may need training to use swaging machines safely.

- Swaging works best with metal parts. It does not suit plastic or soft materials.

- The process can be noisy and may need extra safety steps.

If you only need a simple connection or work with softer materials, swaging might not be the best choice. You should weigh the pros and cons before you decide.

Crimping Overview

Process

Crimping joins hoses or wires by squeezing them with a tool. You use a strong force to press a connector onto a wire or hose. Most people use a hand tool for crimping. First, you take off the wire’s insulation or get the hose ready. Then, you put the wire or hose into the connector. Next, you squeeze the connector tight with the crimping tool. This locks the wire or hose in place. The connection stays strong and keeps out water. This helps stop electrical problems. Swaging changes metal for big jobs, but crimping is for smaller tasks. Crimping is fast and does not need much training.

Materials

You can crimp many kinds of materials. Metals are used most in electrical and hydraulic work. Each material has its own good points for crimping. Here is a table with common materials and how they work:

| Material Type | Performance Characteristics |

|---|---|

| Stranded Annealed Copper | Commonly used for crimped connections; varies in strand number and diameter. |

| Tin Plated Conductors | Comparable performance to bare conductors; used based on application requirements. |

| Silver Plated Conductors | Reduces contact resistance; used in environments with high contact resistance requirements. |

| Copper Alloys (Brass, etc.) | Good mechanical properties; high electrical and thermal conductivity; corrosion resistant. |

| K88 High-Conductivity Alloy | Enhances mechanical strength and heat resistance while maintaining high conductivity. |

Pick the right material for your job. Stranded copper is good for most electrical work. Silver-plated wires help when you need less resistance. Copper alloys are strong and do not rust easily.

Industrial Applications

Crimping is used in many fields. It is common in electrical and hydraulic work. You use crimping to put connectors on wires in cars, planes, and buildings. Crimping also joins hoses in hydraulic systems. These connections are strong and last a long time. They also seal tightly.

Crimped connections are strong and last long. They do not leak and seal well. This makes them good for high-pressure hydraulic jobs. Good crimping keeps hydraulic systems safe and working right. Bad crimping can cause leaks, lost pressure, and safety problems.

You can count on crimping for important jobs. It keeps electrical systems safe and helps hydraulic systems work under pressure. You see crimping in cars, planes, factories, and green energy projects. Crimping works for both small and big jobs.

Strength

When you use crimping, you create a secure connection between wires or hoses and their fittings. This method gives you a strong bond that resists pulling and vibration. Crimped connections hold up well in many environments. You can trust them in cars, planes, and buildings.

Crimping works best for moderate pressure systems. You do not need to worry about leaks or loose wires if you follow the right steps. The connection stays tight and does not come apart easily. You can use crimping for electrical work, hydraulic hoses, and even some plumbing jobs.

Tip: Always check your crimping tool and connectors before you start. A good tool makes a stronger connection.

Crimped joints do not need solder or glue. You save time and avoid extra steps. The finished connection looks neat and professional. You can rely on crimping for safety and durability in everyday projects.

Pros

Crimping offers many advantages for your work. Here are some reasons you might choose this method:

- You can finish jobs quickly with simple tools.

- Crimping does not need heat, so you avoid burns and fire risks.

- The process works well for many wire sizes and hose types.

- You do not need special training to start crimping.

- The connection resists moisture and corrosion.

- You can use crimping in tight spaces where other methods do not fit.

| Benefit | Description |

|---|---|

| Speed | You complete connections fast. |

| Safety | No heat or chemicals needed. |

| Versatility | Works for many wires and hoses. |

| Reliability | Connections last and resist damage. |

| Cost-effectiveness | Tools and materials cost less than other methods. |

Crimping helps you save money and time. You get reliable results with less effort.

Cons

You should know the limitations of crimping before you choose it for your project. Here are some points to consider:

- Crimping may not work for very high-pressure systems.

- You need the right size connector and tool for each job.

- Poor technique can lead to weak connections.

- The connection may fail if you use the wrong material.

- You cannot use crimping for some large or heavy-duty cables.

Note: Always match your crimping tool and connector to the wire or hose size. Mistakes can cause safety problems.

Crimping works best for moderate jobs. If you need maximum strength or work with special materials, you should look at other methods.

Swaging vs Crimping

Connection Method

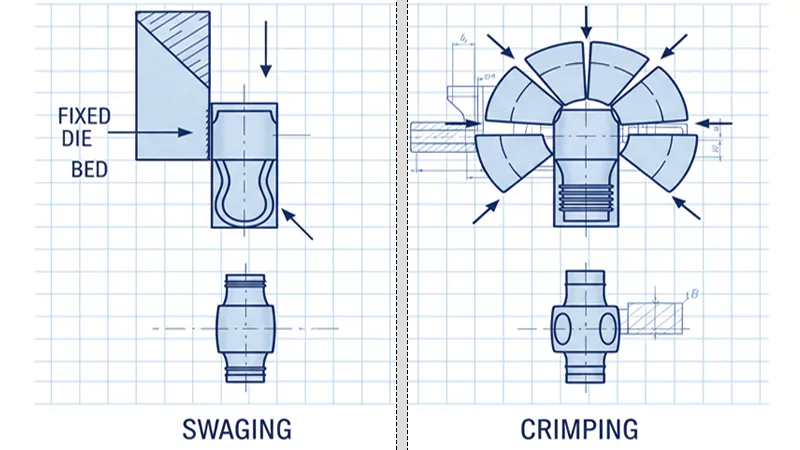

Swaging and crimping join parts in different ways. Swaging changes the metal’s shape by pushing the hose into the fitting. The die makes the ferrule smaller on one end. This forms a space for extra hose. Swaging uses a fixed die bed to do this. The metal fits tightly, so the joint is strong.

Crimping works another way. The tool squeezes the whole ferrule at once. Segment dies close all around it and press down evenly. Crimping needs more force because it presses the whole area. The wire or hose stays in place because it is held tight.

- Swaging pushes the hose into the fitting from one end.

- Crimping squeezes the whole ferrule at once with segment dies.

- Swaging uses a fixed die bed.

- Crimping uses dies that close around the ferrule.

Both ways make strong joints. Swaging gives a space for extra hose, which helps the joint stay strong. Crimping holds the fitting evenly, which helps stop leaks.

Pressure Range

Pick the right method for your pressure needs. Swaging is best for high-pressure jobs. You can use swaging for hydraulic lines, strong cables, and metal tubes. The reshaped metal can handle more stress and keeps the connection safe.

Crimping is good for medium pressure jobs. You see crimping in electrical work, plumbing, and some hydraulic systems. The connection stays tight and does not shake loose, but it may not work for very high pressure like swaging.

| Method | Best Pressure Range | Common Uses |

|---|---|---|

| Swaging | High-pressure systems | Hydraulic lines, cables |

| Crimping | Moderate pressure | Electrical, plumbing |

Check your project’s pressure needs before you pick a method. Swaging gives extra strength for hard jobs. Crimping is good for normal tasks.

Tooling

You need different tools for each method. Swaging needs a machine with split dies and a fixed die bed. You put the metal part in, and the dies change its shape. The machine can work with many shapes and sizes. You might need training to use swaging tools safely.

Crimping uses hand tools or powered crimpers. The tool has segment dies that close around the ferrule. You squeeze the handle or use a motor to press down. Crimping tools are easier to use and cost less. You can finish jobs fast without special training.

Tip: Pick your tool based on your project size and skill. Swaging machines are for big or high-pressure jobs. Crimping tools are for small or medium tasks.

Always match your tool to the connector and material. The right tool helps you make safe and strong connections.

Reliability

When you pick how to connect things, reliability is very important. You want your connections to last a long time and stay safe. Swaging and crimping give different levels of reliability for your work.

Swaging makes a very strong and lasting connection. The process changes the metal’s shape and locks it tight. Swaged joints are trusted in high-pressure systems. These connections can handle shaking, pulling, and bending. Swaging is used in airplanes, bridges, and big machines. Swaged parts almost never fail if you do it right.

Crimping also gives reliable connections, but you must use the right tool and method. Crimped joints work well in electrical jobs and medium pressure work. You can crimp fast and do it over and over. If you use the wrong connector or make a bad crimp, the connection might not hold. Good crimping keeps out water and stops rust. You see crimping in cars, houses, and factories.

Tip: Always check your connections after swaging or crimping. Look for cracks, loose spots, or gaps. Good connections keep your project safe.

Here is a table to help you compare reliability:

| Method | Reliability Level | Best Use Cases | Common Risks |

|---|---|---|---|

| Swaging | Very High | High-pressure, heavy-duty | Needs skilled operation |

| Crimping | High | Electrical, moderate pressure | Tool or connector mismatch |

Pick swaging if you need the most strength and safety. Crimping is good for normal jobs if you use the right tools. Reliable connections keep people and equipment safe.

Choosing a Method

Application Needs

You should start by looking at your project’s applications. Each method works best for certain types of assembly. Swaging fits jobs that need strong and lasting connections. You see swaging in cable railings, rigging, and heavy-duty cable wire assembly. This process changes the shape of metal parts, making them tough and secure. You use swaging when you want your cable to hold up under high pressure or heavy loads.

Crimping works well for smaller applications. You use crimping to attach connectors to wires or hoses. This method is fast and easy. You see crimping in electrical work, plumbing, and some cable assemblies. Crimping gives you a tight fit for wires in cars, homes, and machines. You do not need special training to use crimping tools.

Tip: Match your method to the job. Swaging is best for strong cable assemblies. Crimping is better for quick wire connections.

Industry Use

Different industries prefer swaging or crimping for their own reasons. You see swaging in places where strength matters most. Military and sailing industries use swaging for rigging and assembly. Swaging keeps cable secure and strong, even in tough conditions. Architectural projects use swaging for cable railings. This keeps buildings safe and looking good.

Crimping is popular in electrical work. You use crimping for compact connections in wires and cables. This method saves time and fits small spaces. You see crimping in cars, homes, and factories.

Here is a table showing how industries choose between swaging and crimping:

| Industry | Application Type | Reason for Preference |

|---|---|---|

| Electrical | Smaller applications | Crimping is efficient for compact connections. |

| Military | Rigging and assembly | Swaging provides strength and tight tolerances needed. |

| Sailing | Rigging equipment | Swaging ensures durability under high loads. |

| Architectural | Cable railings | Swaging maintains structural integrity and strength. |

You should look at what your industry uses most. If you work with cable in buildings or boats, swaging is often the top choice. If you work with wires in electronics, crimping is usually better.

Cost

Cost plays a big role in your decision. Swaging needs special machines and trained workers. You pay more at the start for swaging tools. You also spend more on labor and maintenance. Swaging pays off when you need strong cable assemblies that last a long time.

Crimping costs less to begin. You buy simple hand tools or small machines. You do not need much training. Crimping works well for jobs with many small assemblies. You save money on labor and tools. You finish your applications quickly.

Note: Think about your budget and the size of your project. Swaging costs more but gives you strong cable connections. Crimping saves money and time for smaller assemblies.

If you need to join cable for a big building or ship, swaging is worth the investment. If you need to connect wires in a car or home, crimping helps you save money.

Selection Checklist

Key Questions

Before you choose between swaging and crimping, you should ask yourself some important questions. These questions help you avoid mistakes and make sure your project works well. Use this checklist to guide your decision:

- What type of connection do you need?

Swaging pushes the assembly through a tapered die. This creates a continuous and strong compression. Crimping compresses a metal ferrule around the hose using segmented dies. This forms a mechanical interlock. Think about which method fits your connection needs best. - What pressure will your system handle?

Swaging works better for high-pressure systems. Crimping is good for moderate pressure. If your project needs to handle a lot of force, swaging may be the safer choice. - What materials are you working with?

Some materials work better with swaging. Others fit crimping. Make sure your hose, wire, or tube matches the method you pick. - Do you have the right tools and training?

Swaging needs special machines and skilled workers. Crimping uses simpler tools and less training. Check if you have what you need before you start. - Could over-crimping or over-swaging damage your parts?

Over-crimping can weaken the hose structure. It can also damage internal layers and cause early failure. Too much compression can restrict fluid flow. This leads to pressure drops and less efficiency. - How important is speed and cost for your project?

Crimping is faster and costs less at the start. Swaging takes more time and money but gives stronger results.

Tip: Always match your method to your project’s safety and strength needs. Never rush this step.

Steps

You can follow these steps to make the best choice for your project:

- Prepare your materials.

Make sure wires, hoses, or tubes are clean and cut to the right length. Good preparation helps you get a strong connection. - Review your project’s requirements.

Check the pressure, environment, and safety needs. Decide if you need a high-strength connection or a quick, simple one. - Select the right method.

Choose swaging for high-pressure or heavy-duty jobs. Pick crimping for moderate pressure or when you need to work fast. - Set up your tools.

For crimping, set up the crimper, terminal, and anvil correctly. For swaging, make sure the machine and dies fit your material. - Check key quality factors.

Look at crimp force, height, width, and pull-out force. Make sure the strip length and insulation window are correct. These checks help you avoid weak or unsafe connections. - Inspect your finished connection.

After you finish, check for cracks, loose spots, or gaps. A good connection should look smooth and feel solid.

Note: Careful setup and inspection keep your project safe and reliable. Never skip quality checks.

By following this checklist, you can choose the right method and avoid common mistakes. Your project will be safer and last longer.

Mistakes to Avoid

Tool Use

You need to use the right tool for each job. Picking the wrong tool can mess up your work. People often make mistakes with swaging and crimping tools. You can stop these problems if you know what to look for.

- If you use the wrong crimping tool or set it wrong, the hydraulic connection gets weak.

- If you do not handle a swaging tool right, the compression may be bad or fail.

- Dropping or using a swaging tool carelessly can break it and make it unsafe.

- Mixing different tools can cause over-crimping or under-crimping. This is dangerous.

- If your tool does not fit the wire size or connector, the connection will not work.

Always check your tool before you begin. Make sure it fits your wire, hose, or fitting. Using the wrong tool can make your connection leak or break.

Material Match

You must match your materials the right way. Picking the wrong material can make your connection fail. Hoses and couplings must work together, especially for high-pressure jobs. The materials you choose affect strength, how long it lasts, and if it rusts.

Fittings need to bend enough to crimp without cracking. They also need to be strong for high pressure and many uses. If the material is too thin, crimping hard can strip the coating. This makes the metal rust faster. If the material is too thick, it can flake off when crimped. This can hurt your dies and make the connection weak.

| Mistake | Possible Consequence |

|---|---|

| Wrong material pairing | Leaks, failures, or rust |

| Too thin material | Coating stripped, rust risk |

| Too thick material | Flaking, die damage, weak joint |

| Poor ductility | Cracking during crimping |

Tip: Always check the specs for your hose, wire, and fittings. Make sure they work well together. Good material choices keep your project safe and strong.

Application Fit

You need to match the method to your project. Swaging and crimping are best for certain jobs. Using the wrong method can make weak spots or leaks.

A bad crimp can leave gaps or weak spots. This causes leaks and unsafe connections. Not following the right crimp steps can make things fail. Swaging is best for high-pressure and tough jobs. Crimping is good for medium pressure and smaller parts.

- Swaging is best for strong, long-lasting cable and hydraulic line connections.

- Crimping works for quick wire connections and medium pressure hoses.

- Using the wrong method for your job can make it fail early.

Note: Always check your project’s needs before you pick a method. The right choice keeps your connections safe and strong.

If you avoid these mistakes, your connections last longer and work better. Careful tool use, smart material choices, and matching the method to the job help you build safe and strong assemblies.

Expert Advice

Technique

You can get better results with swaging and crimping by using expert tips. First, pick the right tool for your job. Always use a crimping tool made for your connector. Do not use pliers or vise grips because they do not press evenly. Choose the right connector size for your wire gauge. This helps the connector fit tight and stops loose wires.

Put the connector in the crimp tool the right way. Squeeze the crimper all the way so you do not make weak spots. If you use good technique, your connections will last longer and not come loose. Crimped connections are strong in places with lots of shaking, like cars and planes. When you follow these steps, your work looks neat and works better than other ways.

Tip: Always check your tool and connector before you start. Good prep gives you strong and safe joints.

Expert-recommended steps for crimping and swaging:

- Use a crimping tool made for your connector.

- Pick a connector size that matches your wire gauge.

- Place the connector right and squeeze the tool all the way.

- Crimp connections do not shake loose and work in tough places.

- Good technique makes your connections strong and look professional.

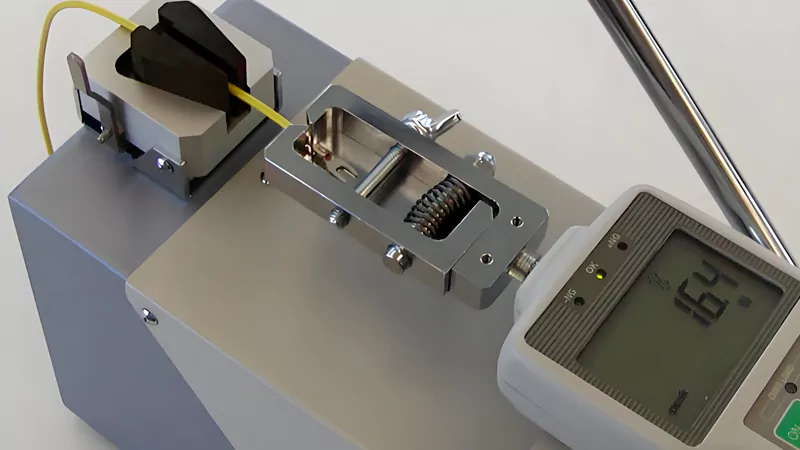

Quality Checks

Quality checks keep your connections safe and strong. You should test your swaged and crimped joints to make sure they are good. Experts use different ways to check if the connections are strong. One common test is called the “Pull and Break” test. You pull the wire until it comes apart or breaks. Write down the highest force and see if it meets the standard minimum pull force. This tells you if your connection is strong enough.

Pull at a steady speed. Do not jerk or pull too fast. This makes your test results correct. Many industries have rules for these tests. Here are some examples:

| Standard | Description |

|---|---|

| NASA-STD-8739.4 | Tells how to check crimp strength for NASA projects. |

| EN 2591 | Explains how to test pulling force and strength. |

| MIL-STD-202-H | Lists ways to test strength for different terminal types. |

Note: Always use the right test for your industry. Quality checks help you stop problems and keep your project safe.

- Pull at a steady speed when you test.

- Check your results against the standard minimum pull force.

- Look for cracks, gaps, or loose spots in your connections.

When to Consult

Sometimes you need to ask an expert for help. If you work with high-pressure systems or safety jobs, talk to a pro. Swaging and crimping for planes, the military, or big buildings need special skills. Experts know how to pick the right materials, tools, and follow strict rules.

Ask for help if you are not sure about your technique or if your connections do not pass tests. Pros can teach you, check your work, and suggest better tools or materials. If your project uses new materials or is very complex, expert help can save time and stop mistakes.

Callout: Always ask for help when safety or reliability is very important. Expert advice makes sure your connections meet the best standards.

You should choose swaging for high-pressure and heavy-duty jobs. Crimping works best for quick, moderate-pressure connections. Always match your method to your project’s needs. Use the checklist to guide your decision. Ask experts for help with critical tasks.

Remember: Careful planning keeps your connections safe and strong.

- Review your requirements.

- Pick the right method.

- Check your work for quality.

FAQ

Swaging reshapes metal to form a tight connection. Crimping compresses a connector around a wire or hose. You use swaging for high strength. You use crimping for quick, reliable connections in electrical or moderate-pressure jobs.

No, you cannot. Swaging needs special machines that reshape metal. Crimping tools only squeeze connectors. Always use the right tool for your method to keep your connections safe and strong.

Crimping is safer for beginners. You use simple hand tools and need less training. Swaging requires special machines and more skill. If you are new, start with crimping.

Always check your connection by pulling gently. If it feels loose, redo it. For critical jobs, use a pull test or follow industry standards. Good connections do not move or slip.

You should not use swaging on plastic. Swaging works best on metal. Crimping can work on some plastic connectors, but always check the manufacturer’s instructions first.

Over-crimping can damage wires or hoses. Over-swaging can weaken metal parts. Both mistakes can cause leaks or failures. Always follow tool guidelines and check your work.

Yes, you do. Clean your tools after each use. Check for wear or damage. Well-maintained tools make safer and stronger connections.

Crimping usually costs less for small projects. You buy simple tools and spend less on training. Swaging costs more because you need special machines and skilled workers.