You need parts that are strong and last a long time for modern manufacturing. Surface hardening of steels makes the outside hard but keeps the inside tough. This helps parts resist wearing down and scratching, so they last longer. When you use surface hardening, parts can handle more use before breaking. This means they can go through more cycles without failing.

The table below shows how surface hardening makes important properties better:

| Aspect | Description |

|---|---|

| Fatigue Strength | Higher because the material changes from the outside in. |

| Lifespan Impact | Parts last longer when used over and over. |

| Material Variation | The change from hard outside to tough inside helps parts work better. |

Surface hardening is very important for gears, shafts, and other parts that get a lot of stress in today’s factories.

Key Takeaways

- Surface hardening makes steel parts hard on the outside. The inside stays strong and tough. This helps the parts last longer. It also helps them resist scratches and wear. Carburizing and nitriding are ways to make steel surfaces harder. These methods help steel work better. Surface hardening is very important for gears, shafts, and tools. These parts face a lot of stress. The best hardening method depends on the part’s use. It also depends on the kind of steel. Surface hardening can save money. You can use cheaper steel inside. Only the outside needs to be hardened. Car makers and airplane companies use surface hardening a lot. It keeps things safe and strong. Knowing about surface hardening is helpful. It helps people make good choices in manufacturing.

Table of Contents

Surface Hardening of Steels

What Is Surface Hardening

Surface hardening makes the outside of steel much harder than the inside. The inside stays tough and can bend without breaking. It is like putting a strong shell around the steel. To do this, you heat the steel and cool it fast. Sometimes, you add things like carbon or nitrogen to the outside. This makes a hard layer that stops scratches and wear.

Surface hardening helps protect parts that rub or get hit a lot. Gears, axles, and hand tools often use this process.

Some common ways to do surface hardening are:

- Case hardening adds carbon to the outside.

- Nitriding uses nitrogen to make the surface harder.

- Flame hardening and induction hardening heat the outside fast and cool it quickly.

Surface vs. Through Hardening

You might wonder how surface hardening is different from through hardening. Through hardening makes the whole steel part hard, not just the outside. This makes the part very strong but also easy to break if hit hard. Through hardened parts can snap because they cannot bend much.

Surface hardening gives a hard shell and a softer inside. This lets the part take hits better and not crack as easily. The table below shows the main differences:

| Through Hardening | Surface Hardening (Case Hardening) |

|---|---|

| Hard all the way through | Hard outside, soft inside |

| Not good for heavy impacts | Good for taking hits |

| Breaks easily if bent | Can bend a little without breaking |

With surface hardening, you get a tough outside and a strong inside. The part can last longer and handle more stress.

Key Benefits

There are many good things about surface hardening steel parts. Here are some of the main benefits:

- Parts do not wear down as fast when things slide on them.

- They can handle more bending and twisting.

- Hardened parts last longer, so you do not need to replace them as much.

- The process helps parts work longer in tough places.

- The hard outside stops scratches and damage.

- The whole part gets stronger and works better for longer.

Tip: If your parts need to work in hard places, surface hardening helps them last.

Many industries use surface hardening. You see it in car gears, airplane shafts, and big machines. It is also used in tools like hammers and screwdrivers. Surface hardening helps your parts stay strong, safe, and ready to use.

How Surface Hardening Works

Surface and Core Properties

When you use surface hardening, you change the way steel behaves. The outside of the steel becomes very hard, while the inside stays softer and tougher. This difference helps your parts resist wear and damage on the outside, but still absorb shocks and impacts without breaking.

You can see how much harder the surface gets compared to the core by looking at the numbers. The table below shows some common steels and their hardness after surface hardening. The “HRc” stands for Rockwell Hardness, a scale that measures how hard a material is.

| Steel Type | Surface Hardness (HRc) | Core Hardness (HRc) |

|---|---|---|

| 8620 Steel | >65 HRc (after nitriding) | 24-26 HRc |

| 15-5 PH Steel | >65 HRc (after nitriding) | 46-50 HRc |

| M-50 Steel | >65 HRc (after nitriding) | 64-65 HRc |

Note: A higher HRc number means a harder surface. You get a tough shell that protects the softer, strong core.

This combination gives you the best of both worlds. The hard surface fights off scratches, dents, and wear. The softer core lets the part bend a little under heavy loads, so it does not crack or snap. You can use these parts in places where both strength and toughness matter, like gears, shafts, and tools.

Process Overview

You can harden the surface of steel in a few different ways. Each method changes the outside layer, but keeps the inside mostly the same. Here are the main steps you might see in surface hardening:

- Layer Addition Techniques

You can add a new layer to the steel. This includes coatings or hardfacing. These methods put a hard material on top of the steel, making the surface much tougher. - Substrate Modification Methods

You can also change the surface itself. Diffusion processes, like carburizing or nitriding, add elements such as carbon or nitrogen into the steel. Selective hardening uses heat to treat only certain areas, making them hard while leaving the rest of the part softer.

Tip: You should choose the method that fits your part’s needs. Some methods work better for certain shapes or sizes.

When you follow these steps, you create a steel part that lasts longer and works better in tough jobs. You get a hard, protective shell and a strong, flexible core. This makes your parts ready for the demands of modern manufacturing.

Hardening Techniques

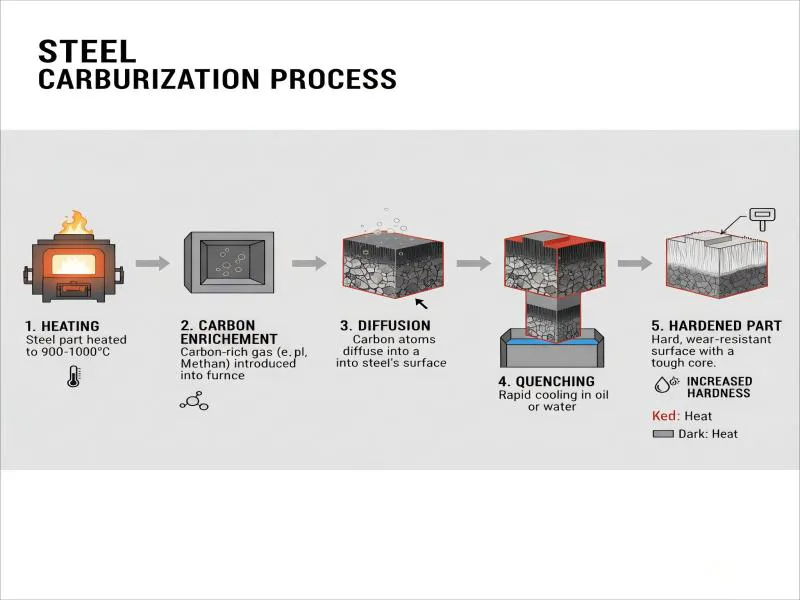

Carburizing

Carburizing is a very common way to harden steel. This process adds carbon to the outside of steel parts. The extra carbon makes the surface much harder. The inside stays strong and tough. Carburizing works well for gears and shafts. It helps these parts last longer and not wear out fast.

You put the steel part in a furnace with carbon-rich gas or solid. The heat lets carbon move into the surface. After heating, you cool the part quickly. This makes a hard shell and keeps the core strong.

Here are some ways carburizing helps:

- Makes the surface harder and stops wear

- Helps parts that spin or move last longer

- Gives deep hardening for better safety

- Keeps the inside tough so it does not break

- Lets you pick how hard you want the surface

Carburizing helps parts work better and last longer in hard jobs.

You can choose how deep the hard layer goes. Most carburized parts have a layer about 0.035 inches deep. Some lighter cases are about 0.016 inches deep. The surface can get as hard as 57 HRC. The inside stays around 33 HRC. Carburizing is great for parts that need to be safe and strong.

Nitriding

Nitriding is another way to harden steel surfaces. This process adds nitrogen to the outside of steel. Nitriding uses lower heat than carburizing. This means the steel keeps its shape better. Nitriding works best for steels with aluminum, chromium, or molybdenum. These elements help make a very hard nitride layer.

You put the steel in a furnace with nitrogen gas. The nitrogen moves into the surface and makes a thin, hard layer. This layer gives you many good things:

- Makes the surface very hard

- Stops wear and lowers friction

- Helps parts last longer under stress

- Protects against rust and chemicals

- Changes the size or shape very little

The table below shows why nitriding is useful:

| Advantage | Description |

|---|---|

| Increased Hardness | Makes a very hard surface layer |

| Improved Wear Resistance | Lowers wear and friction |

| Enhanced Fatigue Strength | Helps parts last longer when used a lot |

| Improved Corrosion Resistance | Stops rust and chemical damage |

| Minimal Dimensional Changes | Keeps the same shape and size |

| Cost-Effective | Uses less energy and saves time |

Nitriding is smart when you need a hard surface and want to keep the part’s shape.

Nitriding is used for engine parts, gears, and tools. It works well for steels with nitride-forming elements. It helps parts resist both wear and rust.

Flame Hardening

Flame hardening uses a hot flame to heat the steel’s surface. You cool the part fast with water. This makes the outside hard and keeps the inside tough. Flame hardening is good for big or odd-shaped parts. It is used for machine beds, rails, and heavy gears.

You can use flame hardening for just one area of a part. The process is flexible and does not need costly tools. It works well for small batches or special shapes.

Here are some things to know about flame hardening:

- Best for big, heavy, or odd parts

- Not good for making lots of the same part

- Getting the right hardness takes skill

- Costs less than some other ways

Flame hardening is a good choice if you want to save money and only need to harden certain spots.

The table below compares flame hardening to other methods:

| Feature | Induction Hardening | Flame Hardening | Case Hardening (Carburizing/Nitriding) |

|---|---|---|---|

| Heat Source | Electromagnetic Induction | Oxy-fuel Flame | Furnace (chemical diffusion) |

| Hardening Depth | 0.5 – 5 mm (adjustable) | 1 – 6 mm | 0.2 – 2 mm (can go deeper) |

| Speed | Very Fast | Moderate | Slow |

| Control | Highly Controllable | Manual or Semi-automated | Automated but time-consuming |

| Distortion | Minimal | Moderate | Low to Moderate |

| Cost | High initial cost | Low equipment cost | Medium to High operating cost |

| Best For | Precision parts, automation | Large, heavy components | Deep hardening, wear resistance |

Each method has its own good points. Flame hardening is a good mix of low cost and flexibility for big or special parts.

Induction Hardening

Induction hardening gives you a fast and efficient way to make steel surfaces hard. You use an electric coil to create a magnetic field. When you place the steel part inside the coil, the surface heats up quickly. You then cool the part right away with water or oil. This makes the outside very hard, while the inside stays tough.

You can use induction hardening for many parts, such as:

- Gears

- Shafts

- Axles

- Pins

- Machine tools

This method works best when you want to harden only certain areas. You can control which parts of the steel get hard. This helps you save time and energy.

Induction hardening lets you treat just the surface you need. You do not waste energy on the whole part.

How Induction Hardening Works

You start by placing the steel part inside a coil. The coil sends out a strong magnetic field. This field heats the surface of the steel in seconds or minutes. After heating, you cool the part fast. The quick change in temperature makes the surface hard.

You can change the depth of the hard layer by adjusting the power and time. Most parts get a hard layer between 1 and 5 millimeters deep. The rest of the part stays soft and strong.

Why Choose Induction Hardening?

Induction hardening stands out because it is much faster and more energy-efficient than other methods. You can see this in the table below:

| Method | Process Speed | Energy Efficiency |

|---|---|---|

| Induction Hardening | Faster | More efficient |

| Case Hardening | Slower | Less efficient |

You can also look at how long each process takes and how much energy it uses:

| Method | Processing Time | Energy Consumption |

|---|---|---|

| Induction Hardening | Minutes/Seconds | Low |

| Carburizing | Several Hours | High |

Induction hardening uses less energy because you only heat the surface. You do not need to heat the whole part for hours. This saves you money and helps the environment.

Tip: If you want to save time and energy, induction hardening is a smart choice.

Benefits and Limitations

Benefits:

- Fast processing time

- Low energy use

- Precise control over hardening depth

- Less part distortion

- Good for automation and large batches

Limitations:

- Works best on certain steel types

- Needs special equipment

- Not ideal for very large or odd-shaped parts

Induction hardening gives you a hard, wear-resistant surface and a strong core. You get parts that last longer and work better in tough jobs. Many factories use this method for high-stress parts that need to stay strong and reliable.

Note: Induction hardening helps you make parts that are both tough and efficient to produce.

Choosing a Technique

Application Needs

When you select a surface hardening method, you must think about how you will use the steel part. The job the part does matters a lot. If you need gears, bearings, or tools that face high stress and wear, you should look at induction hardening or nitriding. These methods give you a hard surface that resists damage and keeps working for a long time. If you need parts that bend or move, like structural pieces or machine frames, you may want a process that keeps the steel tough and flexible, such as annealing or normalizing.

Tip: Always match the hardening method to the job your part will do. A gear needs a hard shell for wear resistance, while a frame needs toughness.

You can see how different needs lead to different choices:

- Induction hardening and nitriding work best for parts that face lots of wear and fatigue.

- Case hardening creates a strong outer layer for gears and bearings.

- Surface hardening helps cutting blades keep their edge and absorb impacts.

- The right technique makes your parts last longer and perform better, especially in cars and heavy machines.

Material Suitability

You must check if your steel is right for the hardening process you want. The way steel is made inside affects how well it can be hardened. Steel has structures like martensite, austenite, and pearlite. These structures change how hard and strong the steel can get. Carbon content is very important. More carbon means you can make the steel harder. Alloying elements like chromium or molybdenum also help. They make the steel tougher and more resistant to wear.

Here are some things to look for:

- Steel with high carbon works well for carburizing and induction hardening.

- Steels with elements like aluminum or chromium are good for nitriding.

- If your steel has special alloys, it may resist rust and last longer.

Note: Always check the steel’s makeup before you choose a hardening method. The right mix of elements gives you the best results.

Cost Factors

You need to think about cost when you pick a hardening technique. Some methods cost more because they need special tools or lots of energy. Others work better for big batches or simple shapes. If you only need a few parts, flame hardening may save you money. Induction hardening costs more at first but works fast and saves energy for large runs.

The table below shows what you should consider:

| Factor | Description |

|---|---|

| Material Compatibility | Check if your steel can handle the process. |

| Required Hardness And Depth | Decide how hard and deep you want the surface. |

| Geometric Complexity | Complex shapes may need special methods. |

| Production Volume | Large batches may lower the cost per part. |

| Cost-Effectiveness | Some methods save money for big jobs, others for small runs. |

| Post-Treatment Requirements | Some parts need extra steps after hardening. |

| Desired Surface Finish | Think about how the part should look and feel. |

| Distortion And Dimensional Stability | Some jobs need parts to stay the same size and shape. |

| Heat Treatment Equipment Availability | Make sure you have the right tools for the job. |

| Safety And Environmental Concerns | Some methods use chemicals or flames, so safety matters. |

💡 Tip: Weigh the cost against the benefits. The best method gives you strong, long-lasting parts without wasting money.

Applications

Automotive

Surface hardening is used a lot in cars. Car makers use it to help parts last longer. It also helps them work better when under stress. Many car parts face friction, pressure, and lots of movement. Surface hardening helps these parts not wear out fast. It keeps them working well for a long time.

Here is a table that lists some car parts that get better with surface hardening and what changes:

| Component | Benefits |

|---|---|

| Axle Shafts and CV Joints | Better at handling stress and less wear |

| Differential Gears | Harder surface for smoother power transfer |

| Transmission Gears | Keep their shape and do not get damaged easily |

| Camshafts | Stronger outside, less damage from rubbing |

| Drive Shafts and Axles | Good mix of hard and flexible for stress |

| Differential Components | Less wear, smoother power, less noise |

| Bearing Races | Harder outside, less damage on the surface |

| Crankshafts and Camshafts | Less wear, last longer |

| Connecting Rods | Can take a lot of stress |

| Gears and Shafts | Hard outside stops wear, tough inside stays strong |

| Ball Joints and Tie Rods | Hard outside for lots of movement |

| Brake Discs and Drums | More wear resistance for steady braking |

When car parts are surface hardened, cars last longer. They also need fewer repairs. Cars are safer because important parts do not break easily.

Aerospace

In planes and helicopters, safety is very important. Surface hardening helps protect parts from strong forces and tough places. You find this in landing gear, airframes, and engine parts.

- Burnishing makes the outside harder, so parts do not wear out fast.

- These methods put pressure on the surface. This stops cracks from starting and spreading.

- Landing gear and airframes get the most help. They carry heavy loads and must stay strong for many flights.

Other ways like electroplating and anodizing are also used. These protect parts from rust and wear. Anodizing is good for stopping rust, which is needed for parts in rain, salt, or changing weather.

Note: Surface hardening in planes means safer flights and longer-lasting parts. It helps stop failures and keeps people safe.

Machinery

Machines in factories work all day. Surface hardening helps machine parts last longer and not break. You see it in gears, bearings, shafts, and fasteners.

- Gears get a hard outside to stop wear from turning.

- Bearings last longer because their surfaces do not wear out fast.

- Shafts stay strong and can bend a little under heavy loads.

- Fasteners hold machines together and do not break or strip.

Surface hardening gives machines many good things:

- Parts wear out slower, so you fix them less often.

- Parts can handle stress over and over again.

- You save money by using cheaper inside material and only hardening the outside.

- You can make the surface special for jobs like stopping rust or heat.

- The inside stays bendy, so parts do not snap.

When you look at where surface hardening is used, you see it helps cars, planes, and machines work safely and well. This process helps every part last longer, no matter where it is used.

Other Industries

Surface hardening does not just help cars, planes, or machines. You see this process in many other industries that need strong, long-lasting steel parts. When you look at heavy equipment, railways, and tool making, you find that surface hardening makes a big difference. You can see how many fields rely on this process in the table below:

| Industry | Notable Examples |

|---|---|

| Heavy Equipment | Machinery components |

| Industrial | Tools and dies |

| Rail | Rail system components |

| Tool & Die | Precision tools and dies |

You use surface hardening in heavy equipment like bulldozers and cranes. These machines work in tough places and face lots of stress. Their gears, pins, and bushings need to stay strong and resist wear. When you harden the surface, these parts last longer and do not break as easily.

In the rail industry, trains and tracks must handle heavy loads every day. You find surface-hardened steel in rails, wheels, and couplings. This hard shell helps stop dents and cracks. It also keeps trains running safely and smoothly.

Factories and workshops use many tools that need a hard surface. Precision tools, dies, and molds must keep their shape and edge. Surface hardening gives them a tough outside, so they do not wear down fast. You get better results and save money because you do not need to replace tools as often.

Tip: If you want your tools or machine parts to last longer, surface hardening is a smart choice.

You also see surface hardening in products that face high pressure or impact. Here are some examples:

- Chains and shackles

- Fasteners and screws

- Engine camshafts

- Rifle bolts

These items must stay strong and safe, even when used over and over. A hard surface protects them from scratches, dents, and bending. You get better safety and longer part life.

Surface hardening helps many industries work better. You get parts that last longer, need less repair, and keep people safe. When you choose surface hardening, you invest in quality and performance for your business.

Importance in Modern Manufacturing

Durability

You want steel parts to last a long time, even in hard places. Surface hardening puts a tough layer on the outside. This layer helps stop scratches, dents, and rubbing. The inside stays strong and can bend without breaking. This means the part can take heavy loads and sudden hits.

- Surface hardening makes the outside harder, so it wears down slower.

- These ways keep the inside soft and tough, which helps when parts get a lot of stress.

- Carburizing and nitriding change the surface, making it harder and better at fighting wear.

- Many fields, like cars and planes, use surface hardening so parts last longer in rough places.

When you use surface hardening, your parts last longer and work better, even with lots of use.

Performance

Surface hardening does more than help parts last. It also makes them work better. When you harden the outside, you make the surface stronger. This means fewer scratches and cracks. The hard layer also helps parts not break after many uses.

Surface hardening changes how tools wear out and how strong parts are. If the surface gets very hard (over 45 HRC), it can be harder to cut or shape. You might see more heat and force when making the part. Sometimes, this can cause small cracks or make the part weaker if not done right. Tools can wear out faster, so you need to check them often. Even with these problems, having a hard surface is usually worth it. You get parts that work better and last longer in tough jobs.

Cost-Effectiveness

Surface hardening helps save money in different ways. You do not need to use expensive steel for the whole part. You can use cheaper steel inside and only harden the outside. This means you spend less on materials. You also fix and replace parts less often because they last longer.

| Benefit | Description |

|---|---|

| Material Cost Reduction | Use cheaper steel inside and only harden the outside. |

| Streamlined Production | Make parts faster and save money over time. |

| Enhanced Component Lifespan | Parts last longer and need less fixing or replacing. |

Many companies pick surface hardening because they can use low-carbon steel inside. You still get strong parts without paying for expensive steel. Over time, you save money on making and fixing parts.

Tip: Surface hardening helps you get parts that last longer, work better, and cost less to make and keep working.

Surface hardening makes steel parts stronger and last longer. This process helps parts not break or wear out fast. It also saves money because you do not need to replace parts often. Many companies now use new ways to harden steel that use less energy. The table below shows some new things happening with surface hardening:

| Trend Description | Key Points |

|---|---|

| Induction Heating Advances | Hardening is faster and uses smart controls |

| Automotive and Aerospace Growth | More need for strong, light parts |

| Smart Manufacturing | Machines use IoT and robots for better work |

Factories now use things like AI to watch the process and robotic arms to help. If you want the best steel parts, learn about new research and better ways to test them. Surface hardening lets you make safer and stronger things for the future.

FAQ

You use surface hardening to make the outside of steel parts much harder. This helps your parts resist wear, scratches, and damage while keeping the inside tough and strong.

You see the biggest benefits in gears, shafts, tools, and machine parts. These parts face lots of friction, stress, and movement. Surface hardening helps them last longer and work better.

You need to check the steel type first. Some steels work better with certain hardening methods. Steels with more carbon or special alloys respond best to processes like carburizing or nitriding.

You increase the lifespan of your parts by making the surface harder. This means your parts resist wear and damage, so you replace them less often and save money.

You can save money with surface hardening. You use cheaper steel for the core and only harden the outside. Some methods cost more at first, but you spend less on repairs and replacements.

You usually see very little change in size or shape. Methods like nitriding keep your parts stable. You need to choose the right process to avoid distortion.

You find surface hardening in automotive, aerospace, machinery, rail, and tool-making industries. These fields need strong, long-lasting steel parts for safety and performance.

You look at your part’s job, steel type, cost, and how much hardness you need. You pick the method that fits your needs and gives you the best results.