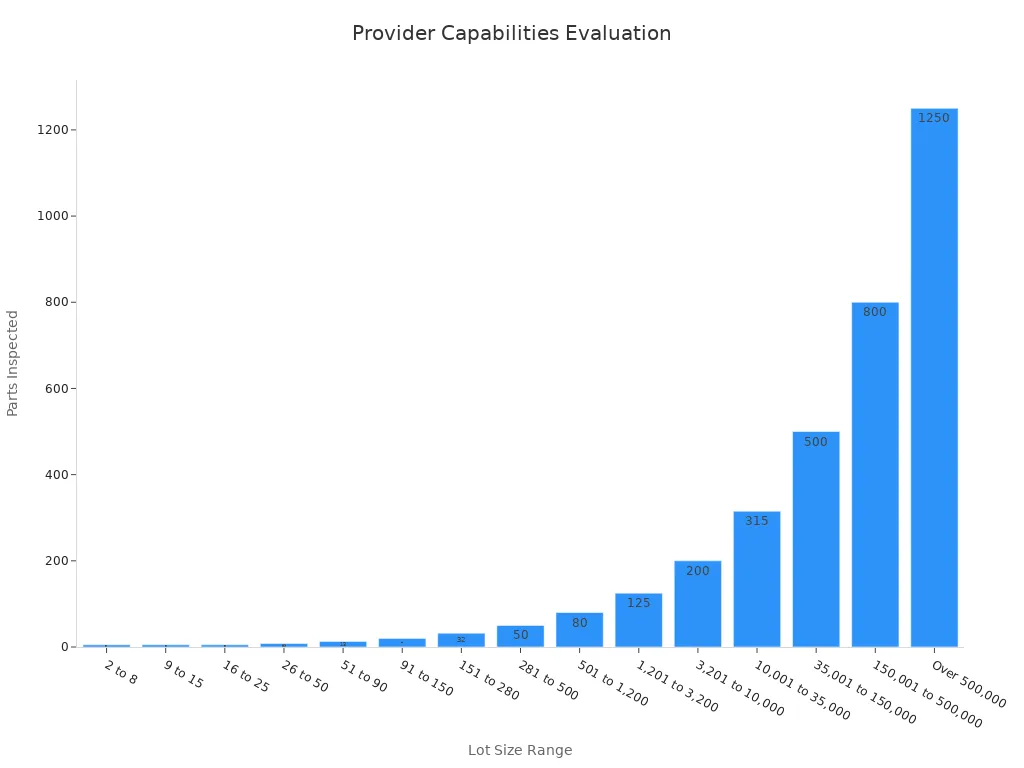

You want to pick the best Sheet Metal Fabrication partner for your project in 2025? Start by matching your project needs to the provider’s strengths. Look at their experience, technology, and quality control. Check for strong communication and reliable delivery. Use a step-by-step review. Want proof of quality? Providers inspect hundreds of parts per lot for accuracy—see how many get checked at each stage:

Table of Contents

Key Takeaways

- Make sure you know what your project needs. Think about the part size, features, materials, and finishes.

- Choose a provider with lots of experience. They should use new technology and have a skilled team. This helps you get parts that are fast, correct, and reliable.

- Check if they have quality certifications. Make sure they use strong quality control. This helps you get parts that meet your standards every time.

- Find someone who talks with you clearly and quickly. They should give you clear prices. This helps you avoid surprises and keeps your project on track.

- Pick a partner who delivers on time. They should be flexible and able to grow with your project. This helps you succeed for a long time.

Project Needs

Scope & Specifications

You should know what you want before starting. Think about the size and shape of your parts. Decide what features your parts need. Most projects need tight tolerances and clear details. Many companies use ISO 2768-1:1989 to make sure parts fit well. Here is a table with common requirements:

| Quality Metric Category | Details / Specs | Standards |

|---|---|---|

| Dimensional Accuracy | Fine, medium, coarse, very coarse tolerances | ISO 2768-1:1989 |

| Material Specs | Type, thickness, grain direction, finish | ASTM, ISO |

| Surface Finish | Matte, textured, gloss, semi-gloss | Industry standards |

| Welding Symbols | Standardized for clarity | Industry standards |

Giving clear specs helps the fabricator avoid errors. When parts are precise, they fit together easily. This saves you time and money. CNC and laser cutters help make parts accurate. Skilled workers and good quality checks keep things running smoothly.

Materials & Finishes

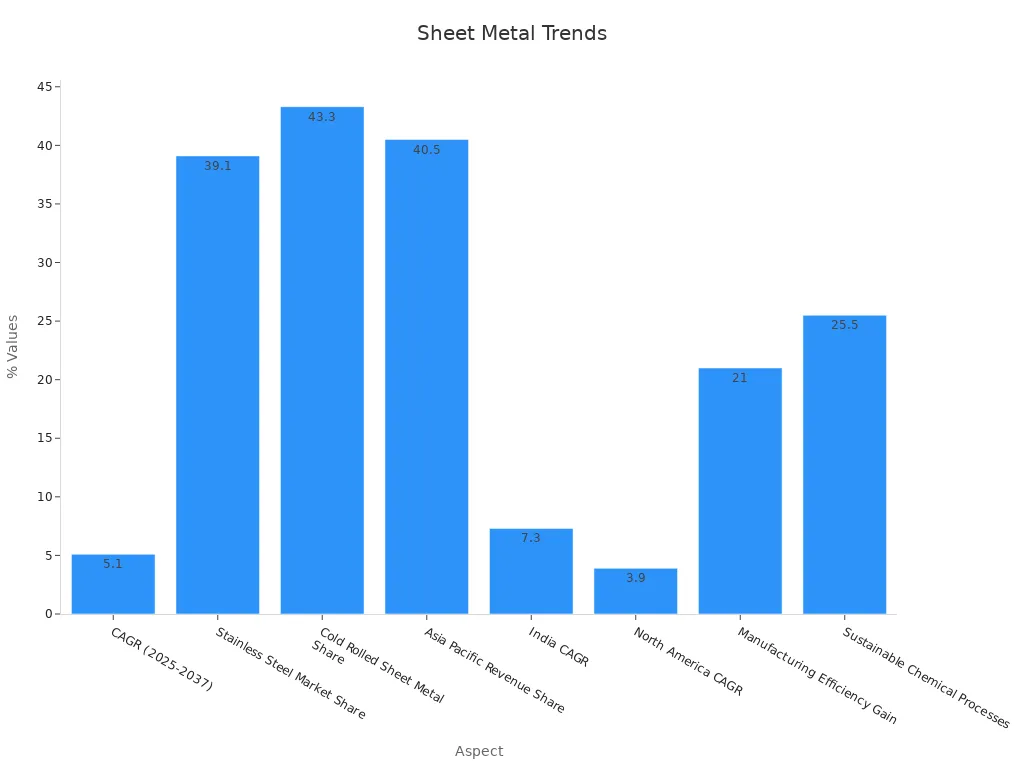

Picking the right material is important. Steel is strong and not too expensive. Stainless steel does not rust and is good outside or in food factories. Aluminum is light and works well in cars or planes. Copper and brass are used in electronics and sound. Titanium is strong and light, so it is good for planes and medical tools. Some jobs need special custom steel fabricator alloys for extra strength.

Tip: The finish you choose is important too. A good finish can stop rust, make your part look better, and help it last longer. Common finishes are painting, plating, anodizing, and polishing. These finishes can also make your product safer and easier to clean.

Timeline & Budget

You want your project finished on time and on budget. About 43% of companies finish projects within budget most times. Good project management tools can help you work faster. You can save up to 20% on costs. Making fast decisions helps projects succeed. Planning your timeline and budget helps your project do well.

- Make clear deadlines for each step.

- Watch your spending as you go.

- Use new tools to stay organized.

The Sheet Metal Fabrication market is growing. Planning ahead helps you stay ready.

Sheet Metal Fabrication Expertise

Experience & Technology

You want a team that knows their job well. Experience is very important. AFI Industrial Co., Ltd. has worked for over 15 years. They use machines like CNC punch presses and laser cutters. These machines help make parts fit right and look good.

See how new technology helps:

| Metric / Aspect | Value / Description |

|---|---|

| Precision Tolerance | ±0.005 inches |

| Cutting Speed (CO2 lasers) | Over 50 inches per second |

| Automated Quality Evaluation Accuracy | More than 95% accuracy using AI on laser-cut metal foils |

| Output Increase (Industry 4.0) | Up to 30% more parts without extra input |

| Market Growth Projection | $4,676.1 million market size in 2025 for laser fabric cutting machines |

You get parts made faster and with fewer mistakes. Laser cutting is popular because it is quick and accurate. AFI uses these tools for small and big parts.

Note: New technology helps companies work better and faster. It helps even when there are not enough skilled workers. Digital tools, robots, and automation keep projects moving.

Process Capabilities

You need more than just cutting metal. Find a team that does many Sheet Metal Fabrication services. AFI can do laser cutting, plasma cutting, and waterjet cutting. They also do bending, stamping, welding, and assembly. They work with aluminum, steel, copper, and titanium.

Why is this important? A company with many skills gives you better parts. You wait less and get your order on time. Good processes mean less downtime and more reliable parts. If machines break, big companies can lose up to 11% of their money. AFI uses smart systems to keep machines working well.

Here is what good processes can do:

| Metric / Outcome | Quantified Benefit | Description / Context |

|---|---|---|

| Defect rate reduction | 8.49% decrease | Custom software cuts down on mistakes |

| Machine breakdown time | Reduced by more than half | Less downtime, more parts made |

| Output increase | Up to 30% more parts | Industry 4.0 boosts daily production |

| Raw material waste reduction | 29.6% less waste | Smarter processes save money and resources |

| Manufacturing cost reduction | 19.73% lower costs | Fixing bottlenecks saves money without hurting quality |

You want a partner who can do small jobs and big orders. AFI’s setup lets you get what you need, when you need it.

Skilled Workforce

Machines help, but people matter most. You want a Sheet Metal Fabrication team with skilled workers. They should know how to use the newest tools. AFI trains their team and keeps them learning.

Here are some facts about training:

- It can cost up to $40,000 to replace one skilled worker.

- More than half of manufacturers say losing workers is bad for business.

- By 2025, over 80% of big companies will use new software to train teams.

- Jobs needing more skills are growing the fastest.

- Companies use AI and virtual reality to help workers learn better.

Tip: A provider with a strong, trained team gives you better parts, fewer mistakes, and faster service.

A skilled team, new technology, and good processes all help. When you pick a provider like AFI Industrial Co., Ltd., you get a Sheet Metal Fabrication partner ready for any job.

Quality & Reputation

Certifications & Standards

You want your parts made consistent quality every time. Certifications help you know a company does good work. If a company has ISO 9001 or other certifications, they follow strict rules. These rules set clear goals for the company:

- Try to lower mistakes by 10% in one year.

- Aim to deliver 95% of orders on time.

- Use Statistical Process Control (SPC) to cut scrap by 20%.

- Track progress with Key Performance Indicators (KPIs).

Companies use these goals to keep quality high. They also teach their workers to reach these goals. You can trust a company that meets these standards to do a good job.

Quality Control

high-quality fabrication Sheet Metal Fabrication companies check every part. They use control plans and special tests. Some tests are mechanical, and some do not hurt the part. These checks make sure your parts match your needs. AFI Industrial Co., Ltd. keeps mistakes below 0.5%. This means you get parts that are almost always right.

Tip: Ask your company how they check parts. A good answer means they care about quality.

Quality control also means watching every step. Companies use smart tools to find problems early. This saves you time and money.

Customer Reviews

You want to know if a company keeps its promises. Look for reviews, stories, and case studies from customers. The best companies share stories from happy clients. Some show how they finished big jobs for aerospace or electronics. These stories show their skills and that they are reliable.

When you read reviews, look for:

- Orders delivered on time

- Good quality every time

- Clear and helpful communication

- How they fix problems

A good reputation means you can trust them with your project.

Pricing & Service

Transparent Quotes

You should always know what you pay for. Ask for a quote that lists every cost. This way, you see where your money goes. It helps you avoid extra fees or surprises. If a company gives you a clear quote fast, they respect your time.

Value vs. Cost

Price is important, but value is too. The cheapest choice is not always best. You should look at what you get for your money. Many companies use special tools to check if costs are fair. Here is a table that shows ways to compare value and cost:

| Numerical Analysis Method | Description | Tool/Platform | Real-Life Example / Outcome |

|---|---|---|---|

| Should Cost Analysis | Identifies cost outliers, improves supplier collaboration, evaluates design/manufacturing alternatives rapidly | aPriori | Signify increased should cost analysis capacity by 8x, optimizing costs across product portfolio |

| Cost vs. Mass Analysis | Compares expected cost based on mass, material, and process to identify design inefficiencies | N/A | N/A |

| Simulation-Driven Costing | Uses 3D CAD models and manufacturing process models to generate rapid, detailed cost estimates | aPriori | Carrier saved up to $30 million in critical project costs |

| Bulk Costing Analysis | Evaluates multiple parts/assemblies to identify cost-saving opportunities | aPriori | Thompson Aero Seating reduced costs by 40% on top 50 most expensive parts |

| Physics-Based Process Models | Incorporates machine and material data libraries to analyze costs down to machine level | aPriori | TE Connectivity negotiated cost reductions by analyzing supplier cost structures in detail |

These methods help you get the most for your budget.

Communication

Good communication makes your project go smoother. You want quick answers and clear updates. Companies like AFI Industrial Co., Ltd. reply to most questions in a few hours. Here are some ways to see how well a company communicates:

| Metric Name | Description | Importance for Communication Efficiency and Inquiry Response Times |

|---|---|---|

| First Response Time (FRT) | Time taken to initially reply to a customer inquiry. | Measures how quickly inquiries are acknowledged, impacting customer satisfaction and trust. |

| Resolution Time | Duration from customer request initiation to full resolution. | Evaluates efficiency in resolving inquiries, ensuring timely closure of issues. |

| Ticket Volume | Total number of customer inquiries received in a period. | Indicates workload on support teams and helps allocate resources for timely responses. |

| Customer Satisfaction Score (CSAT) | Customer rating of satisfaction with service. | Reflects customer perception of communication effectiveness and overall service quality. |

| First Contact Resolution Rate (FCR) | Percentage of inquiries resolved on first interaction. | Shows effectiveness in resolving issues quickly without need for follow-ups, improving communication efficiency. |

| Average Handle Time (AHT) | Average time spent handling a customer inquiry. | Helps assess efficiency of support agents in managing inquiries. |

| SLA Response Times | Benchmarked maximum allowed response times per service agreements. | Provides industry standards and targets for timely responses, ensuring commitments to customers are met. |

When you get fast, helpful replies, you feel good about your project.

Delivery & Flexibility

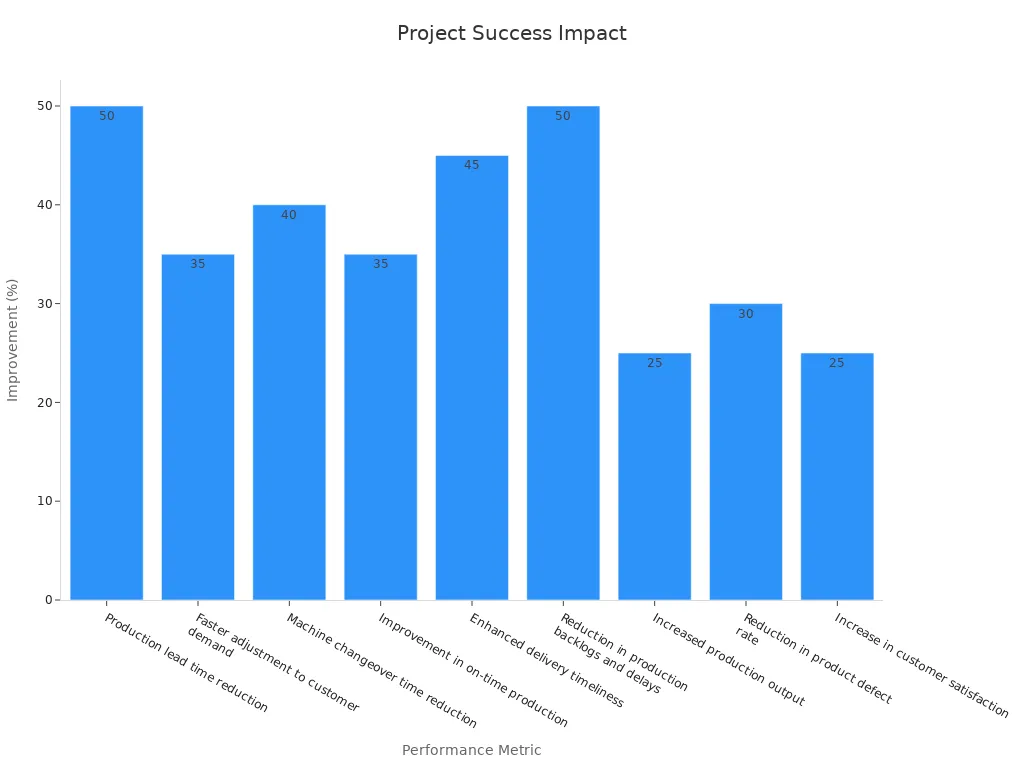

You want your parts delivered on time and made right. Fast delivery and flexible production help your project succeed. Smart systems can cut wait times by half and make changes faster. They also help deliver more orders on time and reduce delays. Look at this chart to see how delivery and flexibility help projects do better:

If you pick a provider who works fast and can change orders, you get better results and happier customers.

Picking the best partner means you must know your project goals first. You should find a provider whose skills match what you need. Check if they have good experience and use the right technology. See how they make sure their work is high quality.

- The best companies watch their sales, delivery times, and profits. This helps show they can do a good job for you.

- Good partners can make more parts when needed. They use smart inspections and watch their work in real time.

- Working with the same company for a long time saves money. It also gives you better parts and fewer late orders.

Look at a few different providers before you choose. Make sure they talk clearly and have done good work before. Your project will do better if you pick a team that can grow with you.

FAQ

You can choose from steel, stainless steel, aluminum, copper, brass, and titanium. Each material has its own strengths. Pick the one that fits your project best. If you are not sure, ask your provider for advice.

Most companies deliver in 3 to 15 days. The time depends on your order size and part complexity. Want it faster? Tell your provider early. They may offer rush options.

Ask your provider about their quality checks. Look for ISO certifications and low defect rates. Companies like AFI inspect every step and use advanced tools to catch mistakes early.

Yes, you can! Many providers, including AFI, handle small custom orders. You do not need to order in bulk. Just share your design and needs.

You have lots of choices: anodizing, painting, powder coating, electroplating, sandblasting, and polishing. Each finish helps protect your parts and makes them look better. Ask which finish works best for your project.