Sandblasting

Sandblasting, finely crafted, give new life to the metal, upgrade the surface texture, show extraordinary charm! AFI Industrial Co., Ltd. provides customers with customized sandblasting surface treatment services!

Sandblasting Process

The compressed air is used as the power to form a high-speed jet beam to spray the spray material (copper ore, quartz sand, emery, iron sand, sea sand) to the surface of the workpiece to be treated at high speed, so that the appearance or shape of the workpiece surface is changed.

Due to the impact and cutting effect of abrasive on the surface of the workpiece, the surface of the workpiece obtains a certain degree of cleanliness and different roughness, so that the mechanical properties of the surface of the workpiece are improved, so that the fatigue resistance of the workpiece is improved, the adhesion between it and the coating is increased, the durability of the coating is extended, and the flow of the coating is also conducive to the decoration.

Custom Sandblasting Service

AFI Industrial Co., Ltd. can provide professional sandblasting surface treatment according to your needs. We use different media, such as steel grit and glass beads, to ingeniously create matte or smooth finishes, enhancing the appearance and performance of the products. Our precision sandblasting can ensure the surface quality of the products, enhance durability and meet the quality requirements of the products.

About Sandblasting

Before sandblasting, there may be oxide layer, rust, welding slag or uneven defects on the metal surface, which will affect the appearance and adhesion of the subsequent coating; After sandblasting, the surface becomes uniform and rough, and the old coating and impurities are completely removed, presenting a matte texture, enhancing the adhesion and corrosion resistance of the coating, while improving the beauty and durability of the product.

Before Sandblasting

After Sandblasting

Sand-blast Equipment

Sandblasting equipment is an efficient equipment for metal surface treatment, which drives abrasive high-speed injection to the surface of the workpiece through compressed air to achieve surface cleaning, roughness, strengthening and beautifying effects. AFI Industries Co., Ltd. has a wide range of sandblasting equipment to meet customer requirements for their products.

Automatic Conveying Dand Blasting Machine

The compressed air system provides power and uses the negative pressure formed in the spray gun by the high-speed movement of the compressed air flow to suction the abrasive through the sand pipe and spray out through the nozzle.

Box Type Sand Blasting Machine

The surface of the workpiece is cleaned, roughened or strengthened by high-speed spraying of abrasive particles.

Sandblasting Material

Metal materials suitable for sandblasting surface treatment include stainless steel, aluminum alloy, titanium alloy, brass, copper, oxygen free copper, electrical pure iron, magnesium alloy, etc .

After sandblasting, the surface quality and corrosion resistance of these metal materials can be significantly improved .

The effect of different metal materials after sandblasting

Brass, copper, oxygen free copper, electrical pure iron, magnesium alloy : these metal materials can also obtain good surface effect after sandblasting treatment, suitable for different industrial applications .

Stainless steel : stainless steel has excellent corrosion resistance, sandblasting treatment can further improve its surface quality and corrosion resistance .

Aluminum alloy : aluminum alloy light weight, high strength, corrosion resistance, sand blasting treatment can improve its surface finish and mechanical properties, widely used in aerospace and automotive industries .

Titanium alloy : titanium alloy has high strength and corrosion resistance. Sandblasting can remove the oxide film on the surface and improve the surface finish and mechanical properties .

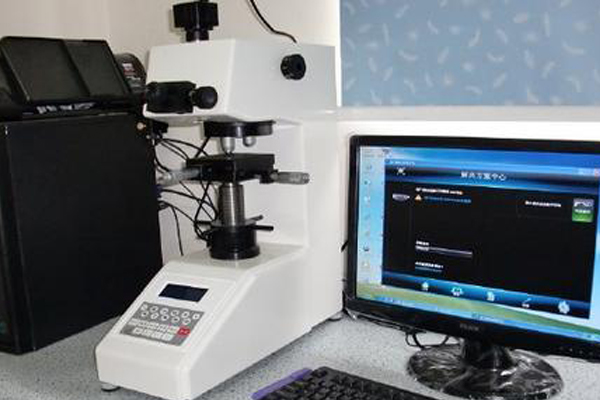

Sandblasting Testing Equipment

The quality inspection of sand-blast process involves many aspects of testing equipment. AFI Industries’ inspection enables a comprehensive assessment of the quality of the sandblasted surface treatment to ensure that the surface achieves the desired roughness and cleanliness, providing a good basis for subsequent coating or other processing steps.

Microscope

Finish meter

Roughness detector

We Promise

Your satisfaction and trust is our eternal pursuit, let us work together to create excellent quality and service, witness every moment of success.

Frequent Asked Questions

Metal materials suitable for sandblasting surface treatment include stainless steel, aluminum alloy, titanium alloy, brass, copper, oxygen free copper, electrical pure iron, magnesium alloy, etc .

After sandblasting, the surface quality and corrosion resistance of these metal materials can be significantly improved .

The roughness range of AFI Industrial Co., Ltd. is Ra 1.6-12.5μm, depending on the type of abrasive (such as Ra 3.2μm for steel shot and Ra 1.6μm for glass beads).

The sandblasting surface treatment of AFI Industrial Co., Ltd. is widely used in various industries such as automobiles, construction, medical care, and electronics.

AFI Industrial Co., Ltd. can carry out sandblasting treatment for various processes, including turning, casting, welding, etc. For mirror-finished products that have been finely ground and polished, we do not recommend sandblasting treatment.