You want every project with riveting sheet metal to be strong and last long. Follow these important tips:

- Pick rivets and tools that fit your materials and thickness.

- Make holes carefully. Do not use wrong sizes or the joints will be weak.

- Figure out rivet length by adding material thickness to 1.5 times the stem diameter.

- Check each joint to see if it fits flat and the mandrel breaks are clean.

- Use continuous riveting for the best results.

Studies show that picking the right rivet and tool helps make joints strong and reliable. If you learn these steps, you can build safer and longer-lasting things.

Key Takeaways

- Pick the right rivet type and tools. Think about your sheet metal’s material and thickness. This helps make strong joints.

- Drill holes carefully. Use the correct sizes. This stops weak joints and makes sure the fit is tight.

- Figure out rivet length by adding the materials’ thickness to 1.5 times the stem diameter. This gives the best grip.

- Check each joint after you finish riveting. Make sure rivets are flat and tight. This stops problems later.

- Use continuous riveting methods. This makes your joints stronger and last longer.

- Always stay safe. Wear safety glasses and gloves when you work.

- Keep your workspace clean and neat. This lowers accidents and helps you work better.

- Check and care for your tools often. This makes sure they work well and give you good rivet joints.

Table of Contents

Riveting Sheet Metal

Joint Strength

You want every rivet to hold your sheet metal together with maximum strength. When you use the right rivet and install it correctly, your joint can handle heavy loads and last for years. If you choose the wrong rivet material, the joint can break or fail under stress.

For example, a rivet head might pull through the sheet, or the rivet rod could snap. These problems often happen when you do not match the rivet to the job. Solid riveting gives you the most strength, which works best for heavy equipment. Blind riveting is a bit weaker but much faster to install. Self-piercing rivets offer strength close to spot welds and resist corrosion well.

In real projects, riveted aluminum panels in tall buildings can reach shear strengths of 420 MPa. Railcars use rivets to keep side panels strong for 25 years or more. You can also join different materials with rivets and avoid corrosion issues. Good riveting avoids heat damage, so your joints last longer.

Safety

You must always think about safety when working with rivets and sheet metal. Flying metal pieces can hurt your eyes, so wear safety glasses. Loud tools can damage your hearing, so use ear protection. Gloves protect your hands from sharp edges and hot surfaces.

If you work near electricity, follow lockout rules and check all equipment. Good airflow keeps you safe from fumes. Training helps you and your team avoid mistakes. When you use the right rivet and tools, you lower the risk of accidents. Always keep your workspace clean and organized to prevent slips and trips.

Tip: Always check your personal protective equipment before you start any riveting job.

Quality

Quality matters in every rivet joint you make. You want each rivet to sit flat and tight against the metal. If you rush or use poor technique, the rivet may not hold well. Manufacturers often list high shear values for rivets, but these numbers come from perfect lab tests.

In real life, you should expect about half that strength. Careful drilling and placing each rivet in the right spot help you avoid weak joints. If you cut or measure wrong, your quality checks may not show the true strength of your rivet joint. Always test your finished work to make sure it meets your needs. Good manufacturing practices help you get the most from every rivet.

Rivet Selection

Sheet Metal Rivets

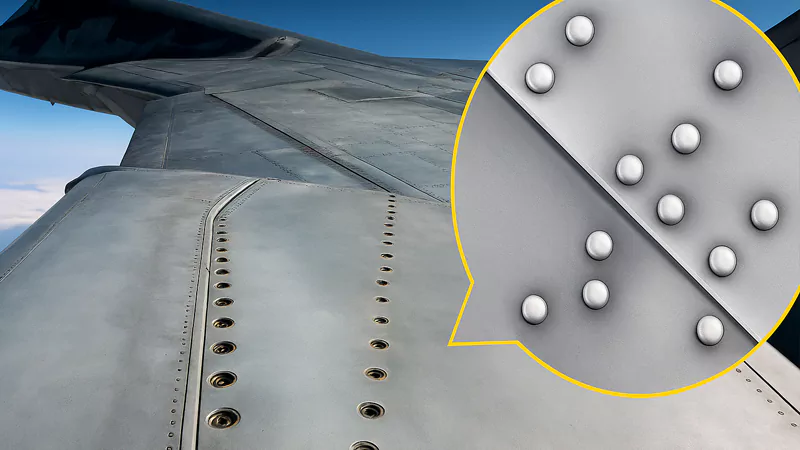

You have many options when choosing sheet metal rivets. Each type works best for certain jobs. Solid rivets give you high strength and last a long time. You often see them in aircraft, ships, and heavy machinery.

Blind rivets help you when you can only reach one side of the metal. These rivets expand and lock the sheets together. You use blind rivets in electronics, home repairs, and even aerospace projects. Drive rivets work well for non-through holes, like when you attach nameplates.

Self-piercing rivets can join two sheets without drilling a hole first. These are great for joining steel and aluminum. Semi-tubular rivets need less force to install and fit well in commercial devices.

Here is a quick guide to the most common types of rivets for sheet metal:

| Rivet Type | Best Use Case |

|---|---|

| Solid Rivets | Aircraft, construction, high-strength joints |

| Blind Rivets | Electronics, home repairs, tight spaces |

| Drive Rivets | Nameplates, panels, non-through holes |

| Self-Piercing Rivets | Joining dissimilar metals, high-stress joints |

| Semi-Tubular Rivets | Commercial devices, electrical applications |

| Structural Rivets | Heavy-duty, load-bearing sheet metal joints |

You should match the type of rivet to your project needs. Structural rivets give you extra strength for load-bearing joints. Blind rivets save you time and work well in hard-to-reach places. Semi-tubular rivets make assembly easier when you need speed and reliability.

Rivet Materials

The material of your rivet matters for strength and corrosion resistance. You want to match the rivet material to your sheet metal. Using the same metal helps prevent corrosion. For example, aluminum rivets work best with aluminum sheets. Steel rivets fit steel sheets. Coated rivets protect against rust and last longer in wet places.

Zinc-plated steel gives you moderate protection. Uncoated steel can resist corrosion for a while, but not as long as coated or aluminum rivets. High nitrogen steel rivets show little corrosion under the head, but you may see some deposits elsewhere. The rivet head size also affects how much water or salt can get in. Smaller heads may let in more moisture, which can cause rust.

Tip: Always check if your rivet and sheet metal are compatible. This step helps you avoid joint failure from corrosion.

Rivet Length

You need the right rivet length for a strong joint. Start by measuring the thickness of both sheets you want to join. Add these numbers together. This total is your grip range. Pick a rivet with a grip range that matches or slightly exceeds this number. If you use a rivet that is too short, it will not hold the sheets tight. If it is too long, it may stick out or not form a proper head. For most jobs, you want the rivet length to be the total material thickness plus 1.5 times the rivet stem diameter. This formula helps you get a secure fit.

Follow these steps to choose the right rivet length:

- Measure the thickness of both sheets.

- Add the numbers to get the total grip range.

- Choose a rivet that matches or is just longer than this range.

A good fit means your sheet metal rivets will hold tight and last longer. Structural rivets and blind rivets both need careful length selection for best results. Semi-tubular rivets also require the right grip range to form a solid joint.

Tools

Choosing the right tools and equipment for riveting makes your job easier and your results stronger. You need to focus on three main items: the rivet gun, the bucking bar, and the drill bits. Each tool plays a key role in making sure every rivet holds tight and looks clean.

Rivet Gun

You use a rivet gun to drive each rivet into the sheet metal. The rivet gun gives you control over how hard and fast you set the rivet. Most rivet guns deliver slower blows, which helps you avoid mistakes and lets you control the impact rate. Look for a rivet gun with an easy throttle or trigger. This feature gives you positive control and helps you set each rivet exactly where you want it.

You need to match your rivet gun to the type of rivet and the material you work with. Softer metals like aluminum work best with pneumatic rivet guns. If you use steel or titanium, you may need a hydraulic rivet gun for extra power.

Here is a table showing the most important features to look for in a rivet gun:

| Feature | Description |

|---|---|

| Material Compatibility | Different metals need different rivet guns. Pneumatic for aluminum, hydraulic for steel or titanium. |

| Rivet Size | Each rivet gun handles certain rivet diameters. Pick one that fits your rivet size. |

| Production Volume | High-volume jobs need faster rivet guns. Pneumatic or hydraulic tools boost productivity. |

Tip: Always check your rivet gun before starting. Make sure it matches your rivet size and material.

You want your rivet gun to work smoothly. If the throttle sticks or the blows come too fast, you may damage the rivet or the sheet metal. A good rivet gun helps you set each rivet with confidence.

Bucking Bar

The bucking bar supports the rivet while you use the rivet gun. You hold the bucking bar against the tail of the rivet. The rivet gun hits the head, and the bucking bar shapes the tail into a tight fit. The choice of bucking bar affects the quality of your finished rivet joint. Steel bucking bars work for most jobs. They are heavy and transmit vibrations well.

Tungsten alloy bucking bars are compact and dampen vibrations, which helps in tight spaces. Copper bucking bars are softer and prevent surface marks, but they wear out quickly. Lead bucking bars absorb energy and do not mar the surface, making them useful in aerospace work.

Here is a table to help you pick the right bucking bar:

| Material | Properties | Applications |

|---|---|---|

| Steel | Durable, heavy, low cost | General use, many rivet types |

| Tungsten Alloy | High density, vibration damping | Limited access jobs |

| Copper | Soft, prevents marring, wears fast | Delicate materials |

| Lead | Soft, absorbs energy, non-marring | Aerospace applications |

You need to keep your bucking bar clean and free of dents. A damaged bucking bar can ruin the shape of the rivet tail. Always match your bucking bar to the rivet and the sheet metal. This step helps you avoid weak joints and surface damage.

Note: Hold the bucking bar firmly. If you let it slip, the rivet may not form correctly.

Drill Bits

Drill bits prepare the holes for each rivet. You want clean, accurate holes so the rivet fits snugly. For steel sheets, use standard drill bit sizes. Rivet nuts hold tight if you install them in properly drilled holes. For aluminum sheets, pick a drill bit that is 0.1mm smaller than the standard size. Aluminum is soft and can expand, so a snug fit prevents the rivet from loosening. Stainless steel needs high-quality drill bits. Use cobalt or carbide-tipped bits, and replace them often. Apply cutting fluid to reduce heat and keep your drill bits sharp.

Here is a table with drill bit recommendations:

| Material | Recommended Drill Bit Size | Notes |

|---|---|---|

| Steel Sheets | Standard Sizes | Rivet nuts withstand repeated tightening and pulling. |

| Aluminum Sheets | 0.1mm smaller than standard | Snug fit prevents loosening. |

| Stainless Steel | High-quality bits required | Use cobalt or carbide-tipped bits; apply cutting fluid. |

| General Tools | Handheld Electric Drill | Good for common metals; keep drill straight for accurate holes. |

| Drill Press | Best for precision; keeps holes vertical and consistent. | |

| Specialized Drill Bits | Use HSS or cobalt for metals; sharp bits for plastics or aluminum. |

You want to use the right drill bit for each job. Dull or wrong-sized bits can make holes too big or rough. This mistake leads to loose rivets and weak joints. Always check your drill bits before you start. Keep them sharp and clean for the best results.

Tip: Organize your tools and equipment for riveting before you begin. This habit saves time and helps you avoid mistakes.

You need the right rivet gun, bucking bar, and drill bits for every sheet metal project. These tools and equipment for riveting help you set each rivet with strength and precision. When you use the right tools, your rivet joints last longer and look better.

Rivet Installation Process

The rivet installation process is the heart of any successful project involving riveting sheet metal. You need to follow each step carefully to get strong, clean, and reliable joints. Let’s break down the process so you can master every detail.

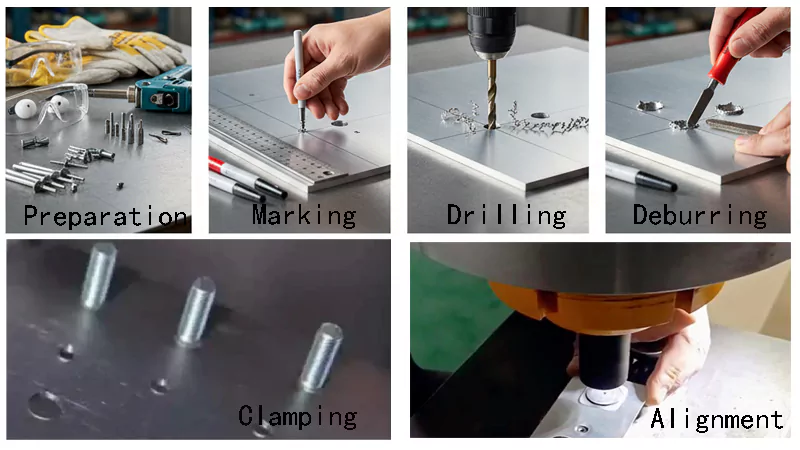

Preparation

Before you start, gather all your tools and safety gear. You need your rivets, rivet gun, bucking bar, drill bits, and protective equipment. Good preparation helps you avoid mistakes and keeps your work area safe.

Marking

Start by marking the exact spots where you want to place each rivet. Use a ruler or layout tool to measure and space your marks evenly. A center punch helps you make a small dent at each mark. This dent keeps your drill bit from slipping. Accurate marking ensures your holes line up perfectly, which is key for strong joints.

Drilling

Next, drill holes at each marked spot. Use a drill press if you want the most precise results, but a handheld drill works well for most jobs. Make sure your drill bit matches the size of your rivet. If the hole is too big, the rivet will not hold tight. If it is too small, you may damage the sheet metal. Drill straight and steady to avoid rough edges.

Deburring

After drilling, you will see small metal burrs around the holes. Use a deburring tool or a round file to remove these sharp edges. Clean holes help the rivet fit snugly and prevent cracks or weak spots. Always check both sides of the sheet for burrs. A smooth hole gives you a better finish and a stronger joint.

Tip: Always wear safety glasses and gloves during preparation. Metal shavings can be sharp and dangerous.

Clamping

Clamping holds your sheets together so they do not move during the rivet installation process. Place the sheets on a flat surface and use clamps to keep them tight. Make sure the edges and holes line up before you clamp. A good clamp stops the sheets from shifting, which helps you get perfect alignment.

Here is a table of best practices for clamping and preparing your sheets:

| Best Practice | Description |

|---|---|

| Surface preparation | Clean, remove burrs, and make sure sheets are flat. |

| Hole preparation | Drill holes to the correct size for your rivet. |

| Use of washers | Place washers to prevent crushing thin sheet metal. |

| Sequential tightening | Tighten clamps in a cross-pattern for even pressure. |

You want to avoid over-tightening, which can bend or damage the sheet. Use just enough pressure to keep everything in place.

Alignment

Proper alignment is critical when riveting sheet metal. If your holes do not line up, the rivet will not go through both sheets, and your joint will be weak. Check that all holes match up before you start installing rivets. In professional settings, technicians use temporary fasteners like clecos or alignment pins to hold everything in place. These tools keep the sheets perfectly aligned until you finish the rivet installation process.

- Proper alignment gives your joint maximum strength and a clean look.

- Temporary fasteners help you keep everything in place while you work.

- In large projects, you might use dozens or even hundreds of alignment pins to hold parts together before setting the final rivets.

Note: Take your time with alignment. A few extra minutes here can save you hours of rework later.

When you follow these steps, you set yourself up for success in every riveting sheet metal project. Careful preparation, clamping, and alignment make the rest of the process much easier and help you achieve professional results.

Rivet Placement

You need to place each rivet with care to get the strongest joint. Good placement helps your sheet metal project last longer and stay safe. When you work with different shapes, like tubes and flat sheets, make sure the parts fit together well. If you skip this step, your rivet joint may not hold.

Here are some tips to help you place each rivet for the best results:

- Check that all holes line up before you insert the rivet. Proper hole alignment gives your joint more strength.

- Make sure the parts you join sit flat against each other. This step is important when you join different shapes.

- Pick a rivet length that matches the thickness of your materials. If the rivet is too short or too long, the joint will be weak.

- Do not set rivets against cantilevered or unsupported edges. These spots can bend or break under pressure.

- Use washers or flanged rivets when you join different materials or soft materials. Washers help spread the load and keep the rivet from pulling through.

Tip: Always double-check your rivet placement before you start setting them. A small mistake here can lead to big problems later.

When you follow these steps, you help your rivet joints stay strong and look neat. Careful placement also makes the next steps easier.

Setting the Rivet

After you place the rivet, you need to set it the right way. This step locks the sheets together and gives you a tight, lasting joint. You want every rivet to hold firm and look clean.

Follow these steps to set each rivet:

- Insert the rivet through the aligned holes. Push it in until the head sits flat against the sheet metal.

- Use your rivet gun to expand the stem. Squeeze the trigger or handle. The rivet will swell and grip the sheets tightly.

- Check the joint. The rivet should feel tight, and the head should sit flat. If you see gaps or loose spots, the joint may not be strong.

- Trim any extra stem if needed. Some rivets leave a bit of stem sticking out. Use a cutter to remove it.

- Sand the rivet head if you want a smooth finish. This step is optional but gives your project a polished look.

- Apply a protective coating to the rivet and the joint. This coating helps prevent rust and keeps your work looking good.

Note: Do not stop in the middle of setting a rivet. Finish each one before moving to the next. This habit helps you avoid weak joints.

You should inspect every rivet after you set it. Look for tight fits and clean breaks. If you find a loose rivet, remove it and try again. Good technique at this stage means your sheet metal project will last longer and stay safe.

Best Practices

Metal Compatibility

You need to watch what metals you join with each rivet. Using the same metal for both the rivet and sheet helps stop corrosion. This makes your joints last longer. If you join aluminum and steel, the aluminum can rust faster. This happens more if the joint gets wet or is near saltwater. Rust can make your rivet weak and hurt the sheet metal.

Galvanic corrosion also makes the weaker metal get thinner. This lowers the strength and can make the joint break. Always pick a rivet that matches your sheet metal. This is one of the best ways to keep your joints strong and safe.

Tip: Use aluminum rivets with aluminum sheets and steel rivets with steel sheets. This helps stop rust and keeps your project strong.

Tool Handling

You must use your tools carefully to protect your sheet metal. This helps you get the best results from every rivet. First, make sure your materials line up before you put in the rivet. Only use your rivet gun when it is pressed flat on the rivet head. Hit the rivet head straight with a steady blow. Light taps help shape the rivet head without hurting the metal.

If you use a hammer, hit the rivet head with the flat side. Start with soft hits and use more force if needed. Use cranes or hoists to lift heavy sheet metal parts. Move each part gently so you do not dent or scratch it. Teach yourself and your team how to use tools the right way. These steps help you avoid accidents and keep your rivet joints neat.

- Line up your materials before putting in the rivet.

- Use the rivet gun only when it is flat on the rivet head.

- Hit the rivet head straight with a steady blow.

- Shape the rivet head with light taps, using more force if needed.

- Use cranes or hoists for heavy sheet metal.

- Move parts gently to stop damage.

- Teach everyone good riveting skills.

Note: Always check your rivet gun before you start. A clean, working tool helps you set each rivet just right.

Continuous Riveting

Continuous riveting makes your sheet metal projects stronger and last longer. When you set each rivet one after another, you avoid weak spots. This makes your joints more solid. This method works well in tall buildings, airplanes, railcars, and bridges. Riveted aluminum panels on steel frames can be very strong and last up to 25 years. In airplanes, millions of rivets hold the panels together. Bridges with riveted joints handle heavy loads better than welded ones. Continuous riveting also helps aluminum alloys last longer by 18%.

| Application Area | Shear Strength (MPa) | Fatigue Life (Years) | Notes |

|---|---|---|---|

| High-rise buildings | 420 | 25 | Riveted aluminum panels on steel frames. |

| Aerospace (Boeing 787) | 45 kN | N/A | Millions of rivets used for fuselage panels. |

| Railcar manufacturing | N/A | 25 | Riveted joints withstand dynamic loads. |

| Bridge construction | 20% higher than welded | N/A | Riveted connections endure cyclic loading. |

| Aluminum alloys testing | N/A | 18% better | Riveted joints show improved fatigue life. |

Tip: Do not stop while setting a rivet. Finish each rivet before you move to the next one for the strongest joint.

Inspection

You want every riveted joint to be strong and safe. Inspection helps you find problems early. Always check your work after you finish riveting. This step makes sure your joints are good and last longer.

First, look at each rivet closely. See if the heads sit flat on the sheet metal. Make sure there are no cracks or gaps. Use a ruler or probe to measure rivet height and spacing. If you see a loose rivet or a bent head, mark it for fixing.

For bigger projects, you can use advanced inspection tools. Computer vision systems use cameras and software to spot defects fast. These tools find problems your eyes might miss. Magneto-optical imaging works well for aircraft parts. It finds cracks and rust inside the metal without hurting it. Automated defect detection tools like YOLOv5 object detection make inspections quick and accurate. These tools save time and help you make fewer mistakes.

Here is a table with common ways to inspect riveted sheet metal joints:

| Inspection Method | Description |

|---|---|

| Visual Inspection | Manual checks using probes and rulers to look for gaps, cracks, and bent rivet heads. |

| Computer Vision | Uses cameras and software to detect external joint defects, following industry standards. |

| Magneto-Optical Imaging | Non-destructive testing for surface and subsurface cracks and corrosion, often used in aircraft. |

| YOLOv5 Object Detection | Automated system for finding defects in self-pierce riveting joints, faster than manual checks. |

| Automated Defect Detection | Computer vision approach that lowers costs and improves quality documentation. |

Check every joint before you move to the next step. If you find a problem, fix it right away. Take out loose or damaged rivets and put in new ones. Sand rough edges and add a protective coating if needed.

Keep your workspace neat during inspection. Put your measuring tools, cameras, and probes in a safe spot. Clean your tools after you use them. Taking care of your tools helps you get good results and keeps inspections accurate.

Tip: Make inspection a regular habit. This helps you follow best practices and build strong, safe sheet metal projects.

You can use manual or automated inspection methods. Both help you find mistakes and make your work better. Pick the method that fits your project and budget. Careful inspection helps you trust every riveted joint.

Troubleshooting

Misalignment

Misalignment happens when holes do not match up. You might see gaps or uneven spots after setting a rivet. This makes your joint weak and can look messy. Mark each spot before you drill to help prevent this. Use a center punch so your drill bit stays in place. Always check if your sheets line up before clamping them. If holes do not match, you can make the hole bigger or use a rivet with a larger head. Sometimes you need to take out the rivet and try again. Good alignment helps every rivet stay tight and keeps your sheet metal strong.

Tip: Use temporary fasteners like clecos to hold sheets together while you work. This helps you avoid misalignment and saves time.

Loose Rivets

Loose rivets can make your joint fail. You might feel movement or hear rattling when you touch the joint. This often happens if the hole is too big or you do not press hard enough when installing. Fix loose rivets right away to keep your project safe.

Here are ways to fix loose rivets:

- Use sealant or glue for a quick fix. This holds the rivet until you can replace it.

- Put in a new rivet of the same size and material for a permanent fix.

- Clean the area with a wire brush before adding the new rivet.

- Press down with the right amount of force when setting the new rivet. This makes sure it fits tight.

- For special materials, use welding or soldering for metal, and epoxy for plastic or composites.

Always check your joints after you put in each rivet. If you find a loose one, do not ignore it. Fixing it early helps your sheet metal last longer.

Deformation

Deformation means your sheet metal bends or warps near the rivet. You might see dents, bulges, or cracks close to the joint. This can happen if you use too much force or if the rivet is too big for the sheet. Thin sheets bend more easily. Pick the right rivet size and use washers to spread out the pressure. Always set your rivet with steady, gentle force. If you see bending, take out the rivet and flatten the sheet before trying again. Good technique helps you avoid damage and keeps your joints neat.

| Problem | Cause | Solution |

|---|---|---|

| Misalignment | Bad marking or drilling | Line up holes, use bigger rivet |

| Loose Rivet | Hole too big, not enough force | Replace rivet, clean area |

| Deformation | Too much force, wrong rivet | Use washers, press gently |

Note: Careful planning and checking help you avoid most problems with rivet joints.

Sheet Damage

Sheet damage can ruin your project and make your rivet joints weak. You want to keep your sheet metal smooth and strong during the riveting process. If you rush or use the wrong technique, you might see dents, scratches, or buckling near the rivet holes. These problems can lower the strength of your joint and make your work look messy.

Follow these best practices to prevent sheet damage when you install each rivet:

- Install Cleco sheet holders in every third hole before you start. This keeps your sheets lined up and stops them from shifting while you work.

- Begin riveting in the middle of the run. After that, set rivets at the ends, then fill in the rest. This pattern helps you avoid buckling and keeps the sheet flat.

- Use rivet tape or blue masking tape to hold each rivet in place. The tape protects the area around the rivet and stops scratches.

- Make sure your riveting tool sits square with the rivet. If the tool tilts, it can damage the sheet or bend the rivet head.

- Try back riveting if you want a smooth finish. This method helps you avoid surface marks on the finished skin.

Tip: Always check your sheet for dents or scratches before you move to the next step. Fix small problems early so they do not get worse.

You should use gentle pressure when you set each rivet. If you press too hard, you might bend the sheet or leave marks. Keep your workspace clean and organized. This helps you avoid dropping tools or bumping the sheet metal. If you see any damage, stop and fix it before you continue. Good habits help you build strong, neat rivet joints every time.

Rivet Removal

Sometimes you need to remove a rivet from your sheet metal. You might find a loose rivet, a bent head, or a damaged joint. Removing a rivet the right way helps you avoid extra sheet damage and keeps your project safe.

You have several methods for safe rivet removal:

- Grinding: Use a rotary tool with a fiberglass-reinforced cutting disc or carbide burrs. This method works well and does not make sparks.

- Chiseling: Modify a flat screwdriver or use a woodworking chisel to cut the rivet. Make sure you do not overheat the tool.

- Drilling: Drill a hole slightly larger than the rivet’s mandrel. Start with a center punch to keep the drill bit in place. Drill slowly to avoid damaging the sheet.

Here is a step-by-step guide for removing a rivet with a drill:

- Select a drill bit that is just a little larger than the rivet’s mandrel.

- Use a center punch to make a starting point on the rivet head.

- Place the drill bit on the mark you made.

- Drill slowly through the center of the rivet head.

- Increase pressure a bit as you drill through the rivet body.

- Stop drilling when you feel the rivet head separate from the shaft.

- Remove any leftover pieces of the rivet with pliers or a punch.

Note: Always wear safety glasses when you remove a rivet. Small metal pieces can fly off and hurt your eyes.

If you take your time and use the right method, you can remove a rivet without damaging your sheet metal. After you finish, check the hole for burrs or rough edges. Clean the area before you install a new rivet. Careful removal helps you keep your project strong and neat.

Checklist

You want every sheet metal project to succeed. Use this checklist to make sure you follow the best steps for strong and safe joints. Review each item before you start and after you finish. This helps you avoid mistakes and build reliable connections.

🛠️ Rivet Preparation

- Gather all tools and safety gear.

- Choose the correct rivet type for your sheet metal.

- Match the rivet material to your sheets to prevent corrosion.

- Measure the thickness of both sheets and select the right rivet length.

- Inspect each rivet for damage or defects.

📏 Marking and Drilling

- Mark each rivet location with a ruler or layout tool.

- Use a center punch to keep the drill bit steady.

- Drill holes to the exact size needed for your rivet.

- Remove burrs from each hole for a smooth fit.

🤝 Clamping and Alignment

- Clamp sheets tightly so they do not move.

- Check that all holes line up before inserting any rivet.

- Use temporary fasteners if you need extra help with alignment.

🔩 Rivet Placement and Setting

- Insert each rivet through the aligned holes.

- Make sure the rivet head sits flat against the sheet.

- Use the rivet gun only when pressed firmly on the rivet head.

- Shape the rivet tail with the bucking bar for a tight fit.

- Do not stop mid-process; finish setting each rivet before moving on.

🧪 Inspection and Troubleshooting

- Inspect every rivet joint for gaps, cracks, or loose rivets.

- Replace any rivet that does not sit tight or looks damaged.

- Fix misalignment by removing and reinstalling the rivet.

- Use sealant or washers if you need extra strength.

🧹 Workspace and Tool Care

- Keep your workspace clean and organized.

- Store rivet tools in a safe place after use.

- Clean and maintain your rivet gun, bucking bar, and drill bits.

Tip: Always double-check your rivet joints before you finish the project. Careful inspection helps you catch problems early.

| Step | What to Check | Why It Matters |

|---|---|---|

| Rivet Selection | Type, material, length | Prevents weak joints |

| Hole Preparation | Size, burr removal | Ensures tight fit |

| Clamping | Sheet alignment, pressure | Avoids misalignment |

| Rivet Setting | Head position, tail shape | Gives strong connection |

| Inspection | Gaps, cracks, loose rivets | Improves safety & quality |

Use this checklist every time you work with a rivet. You will build stronger, safer, and longer-lasting sheet metal joints.

You can make strong sheet metal joints if you follow important steps. Get your workspace ready and collect the tools you need. Pick rivets that fit your materials. Use good technique for every joint you make. Check your work and fix any mistakes you find.

- Look at the checklist before you begin.

- Use the best tips for each project.

Remember, learning how to rivet sheet metal well helps you build safer and longer-lasting joints.

FAQ

You should measure the thickness of your sheets. Pick a rivet that matches the material and grip range. Use aluminum rivets for aluminum sheets and steel rivets for steel sheets.

Clamp your sheets tightly before you start. Begin riveting in the middle, then work toward the ends. Use washers for thin sheets to spread the pressure.

Loose rivets often come from holes that are too big or not enough force during setting. Always drill the correct size and press firmly with your rivet gun.

Tip: Inspect each rivet after installation to catch loose ones early.

Yes. Use a drill bit slightly larger than the rivet’s mandrel. Drill slowly through the center. Remove leftover pieces with pliers. Clean the hole before installing a new rivet.

Wear safety glasses, gloves, and ear protection. These items protect you from flying metal, sharp edges, and loud noises.

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Protects your eyes |

| Gloves | Shields your hands |

| Ear Protection | Reduces noise damage |

Look for flat rivet heads and tight fits. Check for cracks, gaps, or bent rivets. Use a ruler to measure spacing. For large projects, use cameras or computer vision tools.

Stop and check your markings. Use a center punch for accuracy. If holes still do not match, you can enlarge the hole or use a rivet with a bigger head.