Imagine you want stainless steel that can handle tough use. PVD coating on stainless steel gives you many good things. It makes the steel stronger and helps stop rust. You also get more choices for how it looks. You can see these changes in real tests. It’s the best finish for stainless steel. For example, pvd-coated stainless steel is about 22% stronger. It also rusts much less.

| Coating Type | Substrate | Fatigue Limit Change | Corrosion Rate |

|---|---|---|---|

| TiN on 316L | Stainless steel | ~22% increase | One order of magnitude lower |

With PVD coating, the surface lasts longer. It looks nicer and needs less care.

Key Takeaways

- PVD coating makes stainless steel tougher and harder. It helps stop scratches and rust.

- The coating gives many colors and finish choices. These colors stay bright and do not fade.

- PVD-coated stainless steel is simple to clean. You only need gentle care to keep it shiny.

- This coating process uses less energy. It does not use harmful chemicals, so it is good for the environment.

- PVD coating lasts much longer than paint or powder coating. It saves money over time.

- It works best on simple shapes and small parts. It may not work well for big or tricky items.

- PVD-coated stainless steel is great for buildings, hardware, jewelry, and decor. It is strong and looks nice.

- The starting cost is higher, but you save money later. The low upkeep and long life make PVD coating a smart choice.

Table of Contents

PVD Coating

PVD Process

Physical Vapor Deposition, or PVD, is a modern way to make surfaces stronger and more attractive. You can use PVD to add a thin, tough layer to many materials. This process works especially well for stainless steel. You get a high-performance coating that lasts longer and looks better.

Thin Film Technology

PVD uses thin film technology to create a special layer on the surface. The layer is very thin, usually between 0.03 and 0.08 microns. Even though it is thin, it is very hard and durable. You can see this in jewelry and tools that keep their shine and color for years.

Protective Layer

The PVD coating forms a protective layer that bonds at the molecular level. This means you get strong adhesion, so the coating does not peel or flake. The layer protects against scratches, water, and corrosion. You can trust PVD to keep your stainless steel looking new, even in tough conditions.

Tip: PVD coatings are waterproof and resist damage from daily use. You do not have to worry about rust or tarnish.

The PVD process has several steps. Each step helps make sure the coating is smooth, even, and long-lasting.

- You start by cleaning the stainless steel. This removes dirt, grease, and oxides.

- You load the clean items into a vacuum chamber.

- The chamber gets pumped to a high vacuum. This keeps the air out and helps the coating stick better.

- You treat the surface in the vacuum to help the coating bond.

- The coating material, like titanium nitride, gets vaporized and settles on the stainless steel.

- After coating, you may polish or clean the surface again.

- Finally, you check the quality and package the finished product.

You can see different PVD methods in the table below:

| PVD Process Type | Common Coatings | Process Temperature (°C) | Main Stainless Steel Uses |

|---|---|---|---|

| Cathodic Arc PVD (CAPVD) | TiAlN, TiN, CrN, AlCrN | 200-400 | Metal forming, cutting tools, oxidation resistance |

| Magnetron Sputtering PVD (MSPVD) | TiN-HQ, CrN-HQ | 100-200 | Optical parts, plastic molding |

| Thermal Evaporation | N/A | N/A | General thin film deposition |

| Sputter Deposition | N/A | N/A | Thin film coatings |

| Arc Vapor Deposition | N/A | N/A | Metal vaporization |

| Ion Plating | N/A | N/A | Thin film formation |

| Electron Beam Evaporation | N/A | N/A | High melting point materials |

Cathodic arc and magnetron sputtering are the most common PVD methods for stainless steel. You get coatings that are hard, smooth, and built to last.

PVD on Stainless Steel

You get the best results when you use PVD coating on stainless steel. The process creates a tough titanium nitride layer that bonds tightly to the surface. This makes the coating much stronger than electroplating. Electroplating can peel or wear off, but PVD stays in place.

- PVD coating on stainless steel gives you a scratch-resistant and corrosion-resistant finish.

- The coating keeps its color and shine for a long time.

- You get a waterproof surface that does not tarnish or rust.

- PVD is a durable coating. It works best on hard metals like stainless steel. Softer metals do not hold the coating as well.

You can use PVD for jewelry, kitchen tools, and building parts. The finish looks luxurious and lasts for years. You do not have to worry about chipping or fading. PVD coating on stainless steel is the smart choice when you want beauty and strength in one.

Durability

If you pick PVD coating for stainless steel, the surface gets much tougher. PVD makes the metal stronger and helps stop scratches and rust, it enhanced durability. This means the steel lasts longer and stays in good shape. You can count on PVD-coated stainless steel; it’s your sustainable option.

Scratch Resistance

PVD puts a hard layer on top of stainless steel. This layer is harder than the steel itself. The table below shows how much harder the surface gets:

| Sample | Hardness (GPa) | Coating Thickness (µm) |

|---|---|---|

| Stainless steel substrate | 2.6 ± 0.1 | – |

| D2250 coating | 4.4 ± 0.4 | 1 |

| TiN coating | 8.5 ± 1.4 | 0.7 |

| D2250-TiN double layer | 12.3 ± 1.7 | 1.6 |

A double-layer PVD coating makes the steel almost five times harder. This helps stop scratches and dents from happening. In tests, PVD-coated steel keeps its nice look much longer. The coating works like a shield, so you do not see damage from daily use.

- PVD coatings add a thin, strong layer that fights wear.

- The hard surface keeps away scratches and scrapes.

- The finish stays shiny and smooth, even after lots of use.

- PVD-coated parts wear out less than half as fast as plain ones.

- Some PVD coatings are up to 100 times more resistant to abrasion than bare steel.

Corrosion Resistance

PVD coatings help stainless steel fight rust and stains. The coating makes a tight layer that blocks water, salt, and chemicals. This keeps the metal safe from rust. In salt spray tests, PVD-coated steel lasts over 1200 hours without rusting. Plain steel rusts much sooner.

- PVD coatings like Zirconium Nitride protect better than plain steel.

- The coating stays strong in tough tests, while plain metal gets damaged.

- Special PVD coatings with oxygen-doped chromium give almost full protection. They keep corrosion very low and stay strong for a long time.

- The surface does not crack or peel, even after being in harsh places.

You can use PVD-coated steel outside, in kitchens, bathrooms, and anywhere you need strong rust protection.

Wear Protection

PVD coatings help stainless steel last longer by stopping wear. The hard, smooth layer lowers friction and keeps parts from wearing out fast. This means you do not have to fix or replace things as often. PVD-coated surfaces fight abrasion, scuffing, and pitting, even in busy places.

- The coating acts like a dry lubricant, lowering friction in moving parts.

- PVD-coated bearings last three to four times longer than plain ones.

- The coating does not peel or crack, so it keeps working.

- You get two or three times more protection than with plain steel.

Many industries use PVD-coated steel because it is so tough. You see it in cars, cutting tools, medical devices, electronics, and building materials. The chart below shows where PVD-coated steel is used most:

You can use PVD-coated steel in rough places and places where people touch a lot. The strong coating keeps your things looking new and working well for years. You get better durability, more abrasion resistance, and long-lasting strength every time you use it.

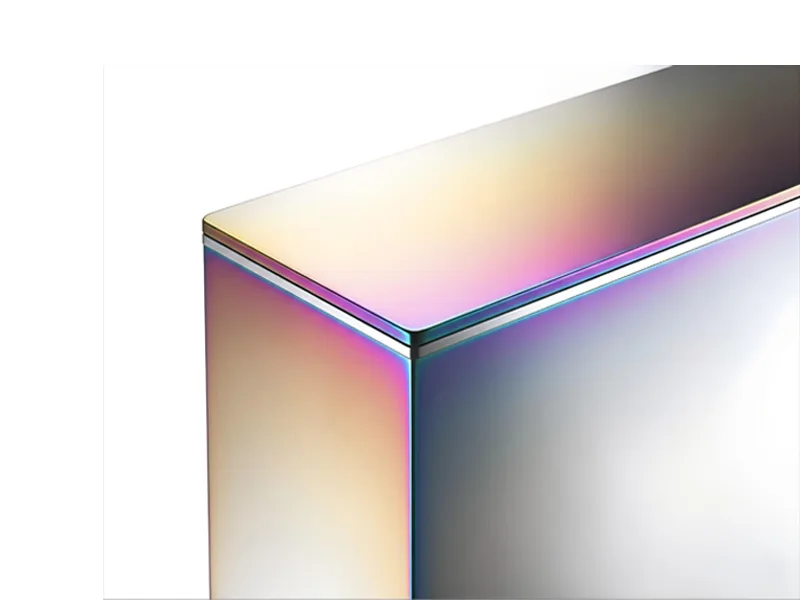

Appearance

If you pick PVD-coated stainless steel, you get many design choices. Your product can look special with bright colors and cool finishes. Every piece will look the same. You get more than just a strong layer. You also get a nice look that lasts a long time.

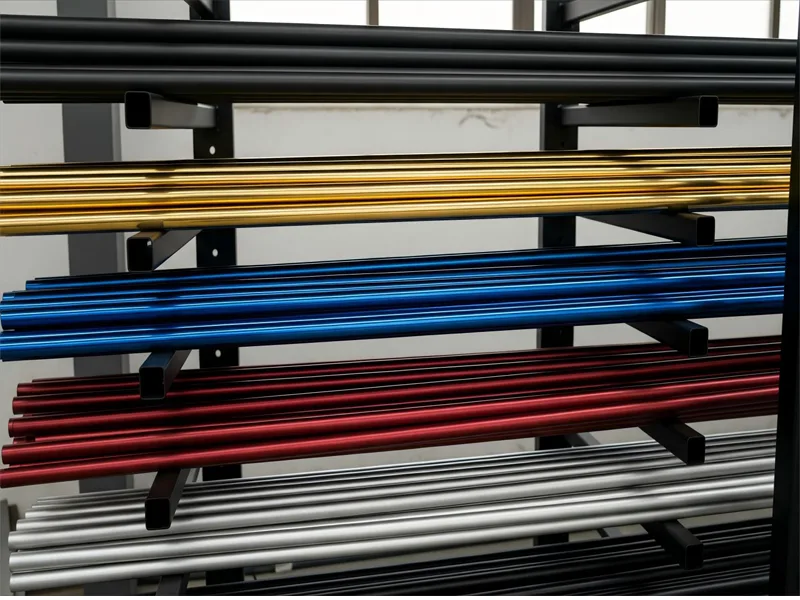

Color Options

You can choose from many stainless steel color sheets with PVD coating. The colors stay bright and do not fade. Here are some popular choices you might like:

- Gold, rose gold, and bronze give a warm, fancy look

- Black and dark grey look bold and modern

- Blue and dark red stand out and look unique

- Silver-gray gives a classic, clean style

PVD coatings use different materials to make these colors. Titanium nitride makes gold. Diamond-like carbon gives a deep black. These coatings fight wear and bad weather. Your stainless steel color sheets will look good for years.

| Color | Coating Material(s) | Stability and Durability Characteristics |

|---|---|---|

| Gold | TiN, real gold | Stable, does not fade, abrasion-resistant |

| Rose Gold | ZrN, real gold | Uniform, abrasion-resistant |

| Coffee | TiN with pigments | Thin ceramic, texture visible |

| Black | TiAlCN | Wear and weather resistant |

| Dark Grey | TiAlCN | Abrasion-resistant |

| Blue | TiAlN | Oxidation resistant |

| Bronze | TiAlN | Ceramic coating |

| Dark Red | ZrN | Thin ceramic coating |

These colors stay bright, even in tough places. PVD-coated stainless steel is best when you want it to look good and last long.

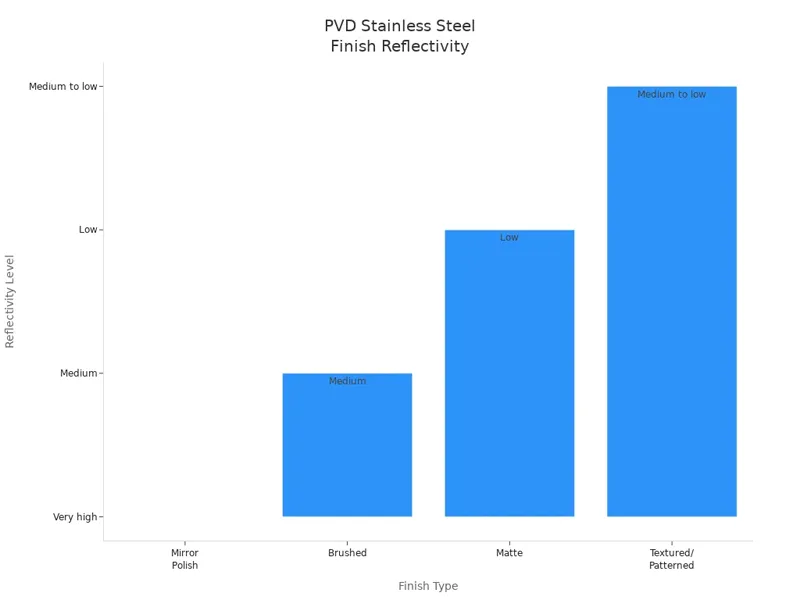

Finish Variety

You have lots of choices for how your stainless steel color sheets look. Each finish changes the style and feel. Some finishes are shiny like a mirror. Others are soft and not shiny. You can also pick finishes with patterns or textures for more style.

| Finish Type | Reflectivity Level | Texture Description | Typical Uses | Maintenance Considerations |

|---|---|---|---|---|

| Mirror Polish | Very high | Smooth, ultra-shiny, mirror-like | Jewelry, watches | Shows fingerprints, needs frequent cleaning |

| Brushed | Medium | Fine lines, subtle texture | Kitchenware, hardware | Durable, resists scratches, moderate upkeep |

| Matte | Low | Soft, non-reflective, foggy | Tools, car parts | Hides fingerprints, low maintenance |

| Textured/Patterned | Medium to low | 3D patterns like waves or grids | Watch faces, decor | Varies by pattern complexity |

Smooth finishes look modern and shiny. Brushed finishes feel softer. Matte finishes hide fingerprints and dirt. No matter what you pick, you get a finish that fits your style.

Consistent Look

You want every piece to look the same, even in big orders. PVD coating uses smart machines and computers to keep each item the same color and finish. This stops color changes and keeps your products matching.

- Vacuum machines stop color changes from dyes.

- Careful controls let you pick the exact color.

- Special tools check the color to match what you want.

- Coil PVD lets you cut sheets and keep the finish the same.

- Computers help keep the finish even in every batch.

When you buy PVD-coated stainless steel, every piece will match. Your kitchen, bathroom, or building will look neat and professional. You can trust PVD to give you the same color and finish every time.

Note: PVD-coated stainless steel is a great way to get a matching, high-quality look for any project.

Maintenance

Easy Cleaning

You want your stainless steel to look good with little effort. PVD-coated stainless steel makes this possible. The surface is simple to maintain and does not need harsh chemicals or special tools. You can follow these steps to keep your PVD-coated items clean:

- Use mild dish soap and water with a soft foam sponge or microfiber towel.

- Avoid abrasive scrubbing pads like Scotch-Brite to prevent scratching the coating.

- Do not use abrasive cleaners such as SoftScrub or Barkeeper’s Friend.

- Stay away from ammoniated products and bleach, which can harm the PVD layer.

- For hard water stains, use a 50:50 vinegar and water solution for no more than 30 minutes, then rinse well.

- Use bottom rinse grids to keep sinks dry and avoid leaving wet towels or sponges on the surface.

- Do not leave cast-iron cookware in the sink to prevent rust particles from sticking.

- Clean regularly with gentle scrubbing to keep the finish bright.

These steps help you protect the thin, hard PVD layer. Uncoated stainless steel can handle rougher cleaning, but PVD-coated surfaces need gentle care. You will find that PVD-coated stainless steel is simple to maintain and keeps its shine longer.

Stain Resistance

PVD coating gives stainless steel a hard, thin, and uniform layer. This layer bonds tightly to the metal, making the surface more resistant to scratches, corrosion, and fingerprints. You will notice that dirt and stains do not stick easily. The smooth surface keeps away grime, so you spend less time cleaning. In places like elevator doors or public railings, PVD-coated stainless steel stays clean and bright even with heavy use.

The coating also stands up to chemicals and water. You do not have to worry about stains from spills or weather. The PVD process adds a titanium film that protects against wear and corrosion. This makes your stainless steel last longer and look better. You get a surface that is both beautiful and tough, perfect for busy spaces.

Cost Savings

Choosing PVD-coated stainless steel saves you money over time. The coating can make your stainless steel last up to ten times longer than other finishes. You will not need to replace or repair items as often. Even though the first cost is higher, the long-term savings are clear. You spend less on cleaning supplies and labor because the surface is easy to clean and stays looking new.

Here is a quick look at the benefits:

| Benefit | Description |

|---|---|

| Longer lifespan | Fewer replacements, lowering overall costs |

| Low maintenance | Easy to clean, saving time and money |

| Lasting appearance | Consistent color, maintaining aesthetic appeal |

| Eco-friendly | Sustainable production contributing to value |

You will see that PVD-coated stainless steel is a smart investment. Its resistant surface and simple to maintain qualities mean you get more value for your money. You enjoy a product that looks great, lasts longer, and costs less to care for.

Environmental Impact

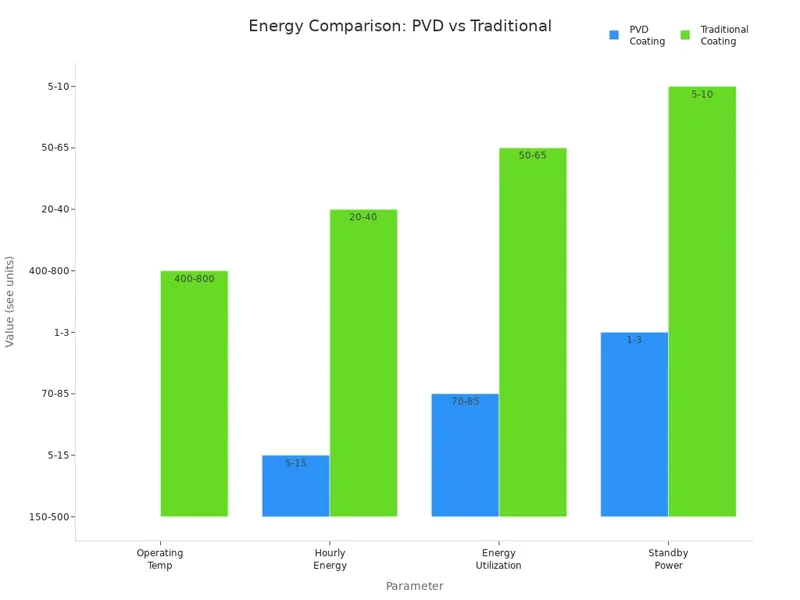

Eco-Friendly Process

When you pick PVD coating for stainless steel, you help the earth, it’s eco-friendly and sustainable. The PVD process uses less energy than old coating methods. It also makes less pollution. You do not need to heat things as much, so you save power. The environmentally friendly process works at lower heat and uses less electricity when running or waiting.

| Parameter | PVD Coating Process | Traditional Coating Methods |

|---|---|---|

| Operating Temperature | 150-500°C | 400-800°C |

| Hourly Energy Consumption | 5-15 kWh | 20-40 kWh |

| Energy Utilization Rate | 70%-85% | 50%-65% |

| Standby Power Consumption | 1-3 kW | 5-10 kW |

The table shows that PVD uses less energy and works better. The process does not need water to rinse, so it saves more resources. You do not have to heat solvents or make much waste. PVD coating is a smart choice if you want to help the planet.

PVD coating products often meet strict green rules. Some lines, like TechCoat, have special certificates for being good for the environment and saving energy.

| PVD Coating Product Line | Environmental Attribute | Certifications Mentioned |

|---|---|---|

| TechCoat 100 (TiN) | Environmentally Friendly Technology | Nadcap, ISO 9001:2015, ISO 14001:2015, ISO 50001:2018 |

| TechCoat 200 (TiCN) | Environmentally Friendly Technology | Same as above |

| TechCoat 400 (CrN) | Environmentally Friendly Technology | Same as above |

Note: PVD coating helps you reach green building goals and supports eco-friendly factories.

No Harmful Chemicals

PVD coating does not use dangerous chemicals. The process skips harsh acids, strong cleaners, and toxic liquids. You do not need rough cleaners or polishes. Other ways, like electroplating, can make toxic waste, but PVD does not.

- No harsh acids or strong cleaners

- No dangerous or smelly chemicals

- No harmful liquids

- No toxic waste

PVD keeps workers and nature safe. The process keeps air and water cleaner and lowers health risks. You can feel good because your choice is safer for everyone.

Sustainability

PVD-coated stainless steel helps the planet stay healthy. The thin PVD layer does not stop the steel from being recycled. You can recycle it just like plain steel. This saves resources and helps the Earth.

PVD coatings last a long time and keep their color and shine. You do not need to replace or fix things as much, so you make less waste and save money. The process makes very little bad waste or smoke, so it is good for the environment.

- PVD-coated stainless steel can be recycled

- The process uses less energy and produces less pollution

- Products last longer, so there is less trash

- Less cleaning and fixing means less harm to the earth

By picking PVD coating, you help make the world cleaner. The process supports green building and helps you reach your eco goals.

PVD vs Other Finishes

PVD vs Electroplating

PVD and electroplating are very different. PVD makes stainless steel much harder and stronger. Electroplating wears off faster, especially with lots of use or water. PVD is better for strength and lasts longer.

| Feature | PVD Coating | Electroplating |

|---|---|---|

| Durability | Enhanced hardness and wear resistance; great for high-performance uses | Softer and less durable |

| Corrosion Resistance | Superior adhesion and protection | Moderate corrosion resistance |

| Process Complexity | More complex and costly | Simpler and cost-effective |

| Environmental Impact | Environmentally beneficial | Uses hazardous chemicals |

| Application Suitability | Preferred for long-lasting, high-stress, and eco-friendly uses | Good for moderate corrosion resistance and looks |

PVD keeps its color and shine for a long time. The coating does not peel or fade. Electroplating can lose color and break down. It costs less at first, but you may need to fix or replace it more. PVD saves money over time because it lasts longer.

Note: PVD uses a cleaner process and does not use toxic chemicals. This makes it safer for people and the earth.

PVD vs Powder Coating

PVD and powder coating both protect steel, but they work differently. PVD makes a thin, hard layer. This layer is much harder than powder coating. PVD resists scratches, fading, and wear, even in busy places.

| Aspect | PVD Coating | Powder Coating |

|---|---|---|

| Environmental Impact | Eco-friendly, no waste or harmful gases | Generally eco-friendly but uses polymers |

| Durability | High hardness, wear, and corrosion resistance | Less durable, best for decorative uses |

| Coating Thickness | Very thin (0.5 to 5 microns), highly durable | Thicker, less dense, good corrosion resistance |

PVD coatings last longer and keep their color and shine. Powder coating can chip or fade, especially outside. PVD uses less energy and does not produce harmful gases. This helps the environment and fits green building needs.

PVD vs Paint

Paint is a common finish, but it is not as strong as PVD. Paint can chip, fade, and break down in busy places. PVD bonds tightly to the steel. This makes it tough against scratches, rust, and sunlight.

| Advantage Category | PVD Coating Benefits | Paint Limitations / Comparison |

|---|---|---|

| Durability | Strong atomic-level adhesion; scratch-proof, corrosion-proof, UV-proof; wear-resistant in high-use areas | Paint chips, breaks down, less physically durable |

| Appearance | Deep, rich finish with many colors and textures; uniform finish on large panels | Paint fades, chips, and needs frequent retouching |

| Maintenance | Resistant to fingerprints, stains, weathering; less polishing and repair needed | Needs frequent maintenance and repairs |

| Environmental Impact | Cleaner process, no toxic waste produced | Paint produces toxic waste and harmful emissions |

| Application Suitability | Great for high-touch, exposed, or harsh environments (e.g., elevator doors, public railings) | Paint degrades faster in such environments |

| Longevity & Cost-effectiveness | Long-lasting finish that stays intact over time, reducing long-term costs | Shorter lifespan, higher maintenance costs |

PVD coatings can last over 25 years. They need less care and keep looking new. Paint needs touch-ups and can make waste that hurts the earth. If you want a finish that is strong, pretty, and easy to care for, PVD is the best choice.

Applications

PVD-Coated Stainless Steel in Architecture

You can see PVD-coated stainless steel in many new buildings. Architects like it because it is strong and looks nice. It works inside and outside. People use it for building fronts, wall panels, and screens. The coating keeps rain, salty air, and sun from hurting the surface. This makes it good for buildings near the ocean or in cities with bad weather.

| Architectural Application | Benefits Observed |

|---|---|

| Facades | Stronger, resists rust, stands up to weather, looks shiny and comes in many colors and textures |

| Interior Design (lobbies, partitions, wall panels) | Looks fancy, easy to design, can have patterns, good for art and use |

| Decorative Elements (grilles, screens) | Gives privacy, looks cool, can be made in special shapes |

| Signage and Branding | Stands out, strong, lasts in bad weather, helps people remember brands |

The surface does not scratch or stain easily. The color stays bright for a long time. You can pick from many colors to fit your style. The process is also good for the earth, so you help nature while making something nice.

Tip: PVD-coated stainless steel is easy to clean and stays shiny, even in busy places.

PVD Coating on Stainless Steel Hardware

You can use PVD coating on hardware to make it last longer. The coating puts a hard layer on top to stop wear and rust. You see it on door handles, hinges, and tools. The coating fills tiny holes, so hardware feels smooth and is easy to wipe clean. It keeps small details sharp, unlike some other finishes.

- PVD coatings like TiN and CrN make hardware harder and less slippery.

- Hardware with this coating lasts longer, even with lots of use.

- Tests show coated parts can be used thousands of times with little harm.

- The coating sticks well, so it does not peel off.

Check your hardware often for damage. If you see scratches, fix them fast to keep the coating strong. When you use stainless steel color sheets for hardware, you get both style and strength. This makes PVD-coated stainless steel a smart pick for homes, offices, and factories.

PVD in Jewelry and Decor

Jewelry and decor made with PVD-coated stainless steel stay looking new for years. This material can handle daily use. It does not scratch or lose its shine easily. You find it in rings, bracelets, watches, and even kitchen tools.

- Jewelry with PVD-coated stainless steel comes in colors like gold, rose gold, black, and blue.

- You can choose finishes like matte, brushed, or hammered for a special look.

- The coating keeps things shiny and smooth, even after many uses.

- Decor items like faucets, cutlery, and fancy accessories use this coating for beauty and strength.

Stainless steel color sheets let you match your jewelry or decor to your taste. You get lots of choices for both everyday and fancy events. The coating can also add extra features, like fighting germs, for more value.

Note: PVD-coated stainless steel is great for buildings, hardware, and decor. You get something strong, stylish, and simple to care for.

Considerations

Upfront Cost

When you choose PVD-coated stainless steel, you will notice a slightly higher upfront cost compared to non-coated options. This happens because the PVD process uses special equipment and skilled workers. The price increase is not huge, but you will pay a bit more at first. Many people find this extra cost worth it. You get a product that lasts longer, looks better, and resists rust and scratches. Over time, you save money because you do not need to replace or repair your stainless steel as often. The strong finish keeps its color and shine for years. If you want a smart investment, PVD-coated stainless steel gives you value that lasts.

Tip: The higher initial price pays off with lower maintenance and replacement costs in the future.

Application Limits

PVD coating works best on certain shapes and sizes. You need to know these limits before you decide. Here are some key points to keep in mind:

- PVD coating can struggle to cover complex shapes or parts with many small features.

- Large stainless steel pieces may need special, expensive equipment because of the size of the vacuum chamber.

- The size and shape of your part must fit inside the vacuum chamber used for PVD.

- The coating is very thin, usually between 0.2 and 5 microns. This may not work if you need a thick layer.

- If your part has a tricky shape, it can be hard to prepare the surface well. This can affect how well the coating sticks.

- Getting an even coating on big or detailed parts is difficult because of these limits.

If you have a simple, flat, or small part, PVD coating is a great choice. For large or complex items, you may need to check with a specialist to see if PVD will work for you.

Maintenance Tips

You want your PVD-coated stainless steel to look its best for a long time. Good care helps you get the most from your investment. Here are some easy tips:

- Clean the surface with mild soap and water. Use a soft cloth or sponge.

- Avoid rough pads or harsh cleaners. These can scratch the coating.

- Dry the surface after cleaning to stop water spots.

- Do not use bleach or strong chemicals. These can damage the PVD layer.

- For tough stains, use a mix of vinegar and water. Rinse well after.

- Check your items often for scratches or wear. Fix small problems early to keep the coating strong.

Note: Regular, gentle cleaning keeps your PVD-coated stainless steel looking new and bright.

By understanding the cost, knowing the limits, and following simple care steps, you make the most of PVD-coated stainless steel. This helps you enjoy its beauty and strength for many years.

You notice that PVD coating is the best finish for stainless steel. It makes stainless steel stronger and keeps it looking nice. Cleaning is simple because the surface stays smooth. PVD coating is better for the Earth since it is a cleaner process. Many companies use PVD-coated stainless steel because it works well. If you want your project to last and look good, try PVD coating.

FAQ

PVD stands for Physical Vapor Deposition. You use this process to put a thin, hard layer on stainless steel. This layer makes the metal stronger and more colorful.

Yes, you can use PVD-coated stainless steel outside. The coating protects against rain, sun, and salty air. Your surfaces will stay shiny and resist rust for many years.

You clean PVD-coated stainless steel with mild soap and water. Use a soft cloth or sponge. Avoid rough pads and harsh cleaners. This keeps the coating smooth and bright.

Yes, PVD coating lets you pick many colors. You can choose gold, black, blue, or other shades. The color stays bright and does not fade easily.

PVD-coated stainless steel is safe for food contact. The coating does not react with food or drinks. Many kitchens and restaurants use it for sinks, counters, and tools.

PVD coating lasts a long time. You can expect it to stay strong and colorful for 10 to 25 years. The surface resists scratches, stains, and fading.

Yes, you can recycle PVD-coated stainless steel. The thin coating does not stop recycling. You help the environment by choosing this material.

Tip: If you want a strong, colorful, and easy-to-clean surface, PVD-coated stainless steel is a smart choice.