Polishing

Polishing, let the luster bloom, the details achieve perfection – bring mirror-like brilliance to the surface of your product, release extraordinary charm! AFI Industrial Co., Ltd. to provide customers with polishing surface treatment services!

Polishing Process

Polishing refers to a processing method that uses mechanical, chemical or electrochemical actions to reduce the surface roughness of a workpiece in order to obtain a bright and smooth surface.

It uses polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece.

Surface Neutralization

Thoroughly clean the surface of the matrix workpiece to remove excessive roughness, debris, grease and other contaminants.

Vew-spuelen

Remove impurities, ensure that the surface of the workpiece is clean, and lay a good foundation for the subsequent electrolytic polishing.

Electrochemical Polishing

The workpiece is immersed in a polishing solution at a specific temperature (usually 60-90℃), and the microscopic protrusions on the surface are dissolved through chemical reactions.

Wash and Dry

Remove the residual electrolyte and electrolytic products on the surface of the workpiece to prevent them from causing corrosion on the surface of the workpiece.

Cleaning can use water washing, ultrasonic cleaning or chemical cleaning methods.

Custom Polishing Service

AFI Industrial Co., Ltd. provides professional custom polishing services. With advanced polishing technology and experienced technical team.

About Polishing

Before polishing, the product surface may have defects such as roughness, lack of luster or scratches, which will affect the overall appearance and texture.

After our professional polishing treatment, the surface of the product becomes as smooth as a mirror, with a significant improvement in gloss and fineness. This not only enhances the aesthetic appeal of the product but also improves its durability and protective performance, endowing it with new vitality.

Before Polishing

After Polishing

Polissoir

AFI Industrial Co., Ltd. has a complete range of polishing equipment, which can be selected according to the different needs of customers and the characteristics of the workpiece, and customized efficient and professional services for customers to ensure the quality and efficiency of product surface treatment.

Electrolytic Polishing Production Line

The metal workpiece is used as an anode, immersed in a specific electrolyte, and anodic dissolution occurs on the surface of the workpiece by applying a direct current, so as to achieve surface changes.

Magnetic Polishing Machine

The magnetic effect generated by the magnetic field distribution makes the magnetic steel needle and the workpiece fully grind in an integral and multi-angle way to achieve the effect of mirror-like effect.

Material

Metal materials (such as stainless steel, aluminum and aluminum alloys, copper and copper alloys, titanium and titanium alloys, carbon steel, etc.), non-metal materials (such as plastics, glass, ceramics, jade, gemstones, etc.) as well as wood and composite materials can all undergo polishing treatment.

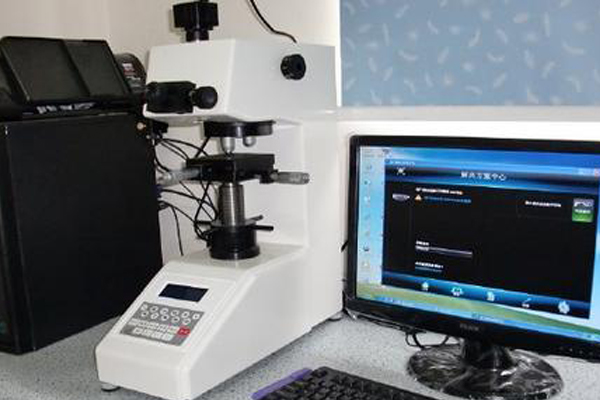

Testing Equipment

The quality inspection of polishing surface treatment process involves many aspects of inspection equipment. AFI Industrial Co., Ltd. comprehensively assesses the quality of the entire process through testing equipment to ensure that the surface finish meets the expected standards.

Hardness tester

Surface roughness meter

Finish meter

Dial indicator

We Promise

Your satisfaction and trust is our eternal pursuit, let us work together to create excellent quality and service, witness every moment of success.

Frequent Asked Questions

Polishing is a process that removes microscopic protrusions on the surface of materials through physical, chemical or electrochemical methods, making them smooth, flat or even achieving a mirror-like effect.

Metallic materials such as stainless steel, aluminum alloy, copper alloys (such as brass and bronze), titanium alloy, as well as non-metallic materials like glass, ceramics, stone and plastic, are all suitable for polishing treatment.

The surface roughness of polishing (usually expressed by Ra value or Rz value) depends on the material, polishing process and processing accuracy. The roughness range that different processes can achieve varies significantly. The roughness range of AFI Industrial Co., LTD. ‘s polishing process can be achieved from 0.01Ra to 3.2Ra according to the customer’s product requirements.

The polished product has a smoother surface, can clearly reflect images, has no scratches on the surface, and has controllable textures. The functionality, durability and hygiene of the product surface can be customized according to the customer’s requirements.

The price of polishing varies depending on the material. Generally speaking, the price of mirror (Ra 0.1μm) may be 3 to 5 times that of ordinary (Ra 0.8μm).