Mild steel fabrication involves transforming mild steel into useful products through cutting, joining, and finishing processes. People use mild steel because it is strong, bendable, and easy to work with. These features help produce items such as car parts, machines, energy tools, household items, and building frames. Knowing how to shape mild steel, picking the right kind, and using good finishes help your project stay safe and last longer. The choices you make in mild steel fabrication can change how much your product costs and how well it works.

Key Takeaways

- Mild steel has low carbon. It is strong and bends easily. You can shape it without much trouble. This makes it great for many projects.

- Grades like ASTM A36 and EN 1.0038 are common. They are strong and easy to weld. People use them in building and making things.

- Fabrication steps are cutting, forming, and joining. Laser cutting, bending, and MIG welding work well. These methods give exact and strong results.

- Finishing methods include painting, powder coating, galvanizing, and plating. These protect mild steel from rust. They also make it look better.

- Mild steel is cheap and easy to find. It is simple to use. This helps you save money and finish projects faster.

- Mild steel can rust and is not as strong as some steels. Using protective finishes helps stop rust. Picking the right grade lowers risks.

- Mild steel is used in building, cars, factories, energy, and custom jobs. It is popular because it is useful and dependable.

- Plan your project well. Pick the right material, design, and team. This will help you get strong, safe, and lasting results.

Table of Contents

What Is Mild Steel Fabrication

Mild Steel Definition

You often see mild steel used in many projects because it is a type of low-carbon steel. Mild steel contains between 0.05% and 0.25% carbon. This low carbon content makes mild steel softer and easier to shape than other steels. You can bend, cut, and weld mild steel without much trouble. People choose mild steel for sheet metal fabrication because it is not brittle and does not crack easily. Mild steel is also less expensive than other metals, so you can use it for large projects without spending too much.

Tip: Mild steel is sometimes called low-carbon steel. You will find it in construction, automotive, and manufacturing industries.

Fabrication Overview

Mild steel fabrication means you take mild steel and turn it into useful products. You use different steps to change the shape and size of the steel. You can make parts for buildings, cars, machines, and more. The process of steel fabrication usually follows these steps:

- Cutting: You cut the steel to the size and shape you need. You can use laser cutters, plasma torches, or water jets for this step.

- Bending: You bend the steel to get the right form. Machines like cornice brakes or rollers help you do this quickly.

- Assembling or Welding: You join the pieces together. You can weld, use adhesives, or rivet the parts to finish the product.

Sheet metal fabrication uses these steps to make flat sheets into strong parts. You can use mild steel for many metal fabrication projects because it is easy to work with and does not break easily.

Key Properties

You need to know the main properties of mild steel before you start any fabrication project. Mild steel has special features that make it a top choice for sheet metal fabrication and other metal fabrication tasks. Look at the table below to see how mild steel compares to other types of steel:

| Property | Mild Steel (Low Carbon Steel) | Medium to High Carbon Steel |

|---|---|---|

| Carbon Content | 0.05% to 0.25% | 0.3% to 1.5% |

| Ductility | High | Moderate to Low |

| Strength | Moderate | High |

| Hardness | Lower | Higher |

| Brittleness | Low | Higher |

| Weldability | Good | Generally poor |

| Fabrication Ease | Easy to shape, form, weld | More difficult due to hardness and brittleness |

You can see that mild steel has high ductility and good weldability. These features make mild steel fabrication simple and safe. You can shape, cut, and weld mild steel without special tools. Mild steel does not break easily, so your finished products last longer. You should choose mild steel for projects that need strong, flexible, and easy-to-work-with materials.

Mild Steel Grades

When you start a fabrication project, you need to pick the right type of low-carbon steel. Not all grades work the same way. Some grades bend more easily. Others have better weldability or strength. You should know the most common grades before you choose.

Common Grades

ASTM A36

ASTM A36 is one of the most popular grades of low-carbon steel. You find it in many construction projects. This grade has good strength and excellent weldability. You can cut, bend, and shape it with simple tools. ASTM A36 works well for making beams, plates, and bars. You often see it in bridges, buildings, and heavy equipment.

EN 1.0038

EN 1.0038 is another common grade of low-carbon steel. People also call it S235JR. This grade is popular in Europe. It has a balance of strength and flexibility. You can use EN 1.0038 for frames, pipes, and structural parts. It is easy to weld and form. Many builders use it for both indoor and outdoor projects.

Other Grades

You may also see other grades like IS 2062, JIS SS400, and DIN ST37. Each grade has its features. Some grades have higher strength. Others resist corrosion better. You should always check the grade before you start your project. The right grade helps your product last longer and work better.

Note: Always ask your supplier for the grade certificate. This helps you make sure you get the right type of low-carbon steel for your job.

Selection Criteria

You need to think about several things when you choose a grade of low-carbon steel for your project:

- Carbon content affects how easy it is to shape and weld the steel. Most low-carbon steel grades have between 0.14% and 0.20% carbon.

- Look at how easy the steel is to work with. Low-carbon steel bends and welds without much effort.

- Cost matters. Low-carbon steel usually costs less than stainless steel or aluminum.

- Think about corrosion. Low-carbon steel can rust if you do not protect it. You may need to paint or galvanize it for wet places.

- Check the strength you need. Low-carbon steel is not as strong as some other metals, but it works well for many uses.

- Consider where you will use the steel. Wet or salty places can cause rust, so you may need extra protection.

- Match the grade to your project needs. Some jobs need more strength or better corrosion resistance.

- Remember that small changes in the mix of elements can change how the steel acts. If you are not sure, talk to an expert.

You can use this list to help you pick the best low-carbon steel grade for your next fabrication project. The right choice makes your work easier and your product better.

Mild Steel Fabrication Processes

When you work with mild steel fabrication, you use several main processes to turn raw steel into finished products. Each step in sheet metal fabrication shapes, cuts, or joins the steel differently. You need to pick the right process for your project to get the best results.

Cutting

Cutting is the first step in most sheet metal fabrication projects. You need to cut mild steel into the right size and shape before you can form or join it. There are several ways to cut mild steel, and each method has its strengths.

Shearing

Shearing uses a straight blade to cut through mild steel sheets. You place the steel between two blades and apply force. The top blade moves down and slices the steel. Shearing works best for straight cuts on flat sheets. You can use it for quick, simple jobs in sheet metal fabrication.

- Shearing is cost-effective and fast.

- It works well for thin sheets.

- The edges may not be as smooth as with other methods.

- Tolerances for shearing are usually wider, especially as the steel gets thicker.

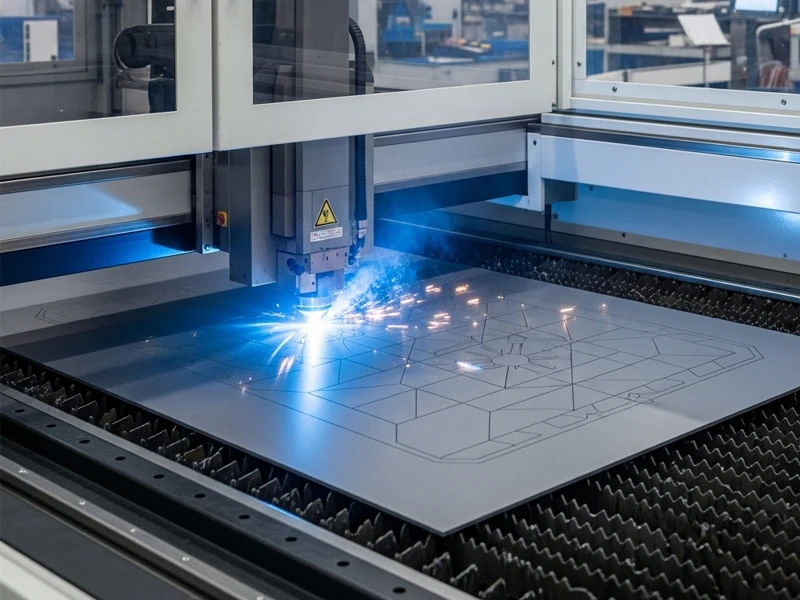

Laser

Laser cutting uses a focused beam of light to melt or burn through mild steel. You can make very precise cuts with a laser. This method is popular in metal fabrication when you need detailed shapes or tight tolerances.

- Laser cutting gives you smooth edges and sharp corners.

- You can cut complex patterns easily.

- It works well for both thin and thick sheets.

- Tolerances can be as tight as ±0.1 mm for thin sheets and ±0.3 mm for thicker sheets.

Plasma

Plasma cutting uses a jet of hot plasma to slice through mild steel. You use this method for thicker sheets or when you need to cut quickly. Plasma cutting is common in both sheet metal fabrication and heavy metal fabrication.

- Plasma cutting is fast and works on thick steel.

- The edges may need extra finishing.

- Tolerances are good but not as tight as laser cutting.

Tip: The type of cutting you choose affects the accuracy of your parts. For example, laser cutting gives you the best precision, while shearing is better for simple, straight cuts. Always check the tolerances you need for your project.

Here is a table showing typical tolerances for different cutting methods:

| Cutting Method | Typical Tolerance (Thin Sheets) | Typical Tolerance (Thick Sheets) |

|---|---|---|

| Shearing | ±0.3 mm | ±0.5 mm |

| Laser | ±0.1 mm | ±0.3 mm |

| Plasma | ±0.2 mm | ±0.4 mm |

You should always specify your tolerances clearly. Industry standards like GD&T and ASME Y14.5 help make sure your parts fit and work as planned.

Forming

After cutting, you need to form the steel into the right shape. Forming changes the flat sheet into a three-dimensional part. You use forming in almost every sheet metal fabrication project.

Bending

Bending uses a press brake or a roller to bend mild steel at an angle. You place the steel on a die and push it with a punch. Bending is common in making brackets, frames, and enclosures.

- Bending works best for straight, simple bends.

- You can make U-shapes, L-shapes, and channels.

- The bend radius depends on the thickness of the steel.

Rolling

Rolling forms mild steel into curved shapes. You pass the steel through rollers that bend it into a curve or cylinder. Rolling is useful for making pipes, tanks, and round parts in metal fabrication.

- Rolling can handle large sheets and thick steel.

- You can make both gentle curves and tight cylinders.

- The process is fast and repeatable.

Stamping

Stamping uses a die and a press to shape mild steel. You can punch holes, emboss patterns, or form complex shapes. Stamping is common in high-volume sheet metal fabrication.

- Stamping is fast and good for making many parts.

- You can create detailed shapes and patterns.

- The dies can be expensive, so stamping is best for large runs.

Note: The forming process you choose depends on your part’s shape and how many you need. For custom jobs, bending and rolling work well. For mass production, stamping is the best choice.

Joining

Once you cut and form your steel, you need to join the pieces together. Joining is a key part of mild steel fabrication. You can use welding, bolting, or riveting to make strong, lasting joints.

MIG Welding

MIG welding uses a wire electrode and a shielding gas to join mild steel. You feed the wire through a gun and melt it to fuse the steel pieces. MIG welding is fast and easy to learn.

- MIG welding works well for both thin and thick steel.

- You get strong, clean joints.

- It is common in automotive and general metal fabrication.

TIG Welding

TIG welding uses a tungsten electrode and a separate filler rod. You control the heat and filler by hand. TIG welding gives you precise, high-quality welds.

- TIG welding is best for thin sheets and detailed work.

- You get clean, neat welds with little spatter.

- It takes more skill and time than MIG welding.

Stick Welding

Stick welding uses a coated electrode to join mild steel. You strike an arc between the electrode and the steel. Stick welding works well outdoors and on rusty or dirty steel.

- Stick welding is tough and reliable.

- You can use it in many positions and conditions.

- The welds may need more cleaning after.

Bolting

Bolting joins steel parts with nuts and bolts. You drill holes in the steel and tighten the bolts to hold the pieces together. Bolting is common in construction and heavy metal fabrication.

- Bolting is quick and easy to take apart.

- You do not need special skills or tools.

- The joints are strong but may loosen over time.

Riveting

Riveting uses metal pins called rivets to join steel parts. You insert the rivet through holes in the steel and hammer or press the end to hold it in place. Riveting is common in bridges, buildings, and old vehicles.

- Riveting makes strong, permanent joints.

- You can use it where welding is not possible.

- The process is slower than bolting or welding.

When you choose a joining method, think about the strength you need, the look of the joint, and how easy it is to assemble or take apart. For example, coil welding is often used in continuous steel strip production. It gives you strong, seamless joints and works well for thin sheets from 0.5 mm to 3 mm. You should also consider the cost, the tools you have, and the skill level needed.

Quality control is important in joining. You need to check for defects like cracks or incomplete fusion. Use inspection methods such as visual checks, ultrasonic testing, or radiography to make sure your joints are safe and strong.

Machining

Low-carbon steel is a widely used material, often used in the manufacture of various components and structural parts due to its low cost, good plasticity, and ease of machining. However, while low-carbon steel can be processed in a variety of ways, its low carbon content and soft texture can lead to specific issues during cutting, such as difficulty breaking chips and the tendency for them to stick together, forming a built-up edge. These issues can affect machining quality and efficiency.

Given these characteristics, for fabricated mild steel products, the appropriate machining method for mild carbon steel should be selected based on the product and actual needs.

Turning

Turning is commonly used to machine cylindrical or conical parts made of mild steel. Because mild steel is tough and prone to chip entanglement, appropriate tooling and cutting parameters are crucial. High cutting speeds and inserts with wiper edges are often used to avoid built-up edge and improve surface quality.

Milling

Milling is a machining process that uses a rotating, multi-edged tool to remove metal. When milling mild steel, concerns about built-up edge and burrs are also important. It’s recommended to select a tool geometry with a more positive rake angle and optimize the cutting edge to prevent chips from clinging to the cutting edge during tool withdrawal.

Drilling

Drilling is a process for boring holes into mild steel. During the drilling process, attention must also be paid to chip formation and removal. Choosing the right drill bit design, such as one with a specially ground chisel edge, can improve chip removal and process stability.

EDM

Using electric spark discharge to remove metal is suitable for machining parts with high hardness or complex geometry.

Heat treatment

Annealing

Annealing is the process of heating low-carbon steel to a specific temperature, holding the temperature for a period of time, and then slowly cooling it to achieve a near-equilibrium microstructure. The primary purpose of annealing is to reduce hardness, increase plasticity and toughness, eliminate internal stress, and refine the grain size, thereby improving the machinability of low-carbon steel.

Normalizing

Normalizing involves heating low-carbon steel to the austenitic zone and then cooling it naturally in air. Normalizing results in a faster cooling rate than annealing. The primary function of normalizing is to refine the grain size and homogenize the structure, thereby eliminating structural defects introduced during casting, forging, and welding. After normalizing, the mechanical properties of low-carbon steel are generally superior to those in the annealed state.

Quenching

Quenching involves heating low-carbon steel to the austenitic region, holding the steel at that temperature, and then rapidly cooling it. Due to its low carbon content, low-carbon steel typically fails to form a martensitic structure after quenching, resulting in a less pronounced hardening effect. Therefore, quenching is not typically performed on low-carbon steel alone; instead, it is combined with other processes such as carburizing.

Carburizing

Carburizing is the most common surface heat treatment method for low-carbon steel. By placing a low-carbon steel workpiece in a carbon-rich medium at high temperature, carbon atoms penetrate the surface, forming a hard, high-carbon layer while retaining the toughness and plasticity of the steel. This treatment imparts high surface hardness and wear resistance while maintaining good internal toughness. It is commonly used in the manufacture of gears, shafts, and other components.

Carbonitriding

Carbonitriding is a heat treatment method that simultaneously infiltrates carbon and nitrogen atoms into the surface of low-carbon steel. Compared to carburizing, carbonitriding operates at lower temperatures, reduces deformation, and improves the wear resistance and fatigue strength of the workpiece.

In short, due to its low carbon content, mild carbon steel has poor hardenability. Therefore, in practical applications, mild carbon steel is usually not subjected to simple quenching treatment to increase hardness. Instead, it is subjected to surface heat treatment processes such as carburizing and carbonitriding to improve its surface wear resistance and hardness while maintaining the toughness of the core to meet specific performance requirements.

Finishing and Surface Treatments

Finishing is the last step in mild steel fabrication. You use finishing to protect your parts and make them look better. Good finishing helps your products last longer and work better in tough places.

Painting

Painting gives you a simple way to protect mild steel from rust and damage. You can use paint to create a barrier between the steel and the air. This barrier stops water and oxygen from reaching the metal. You keep your project safe and looking good.

You find several common painting methods for mild steel. Each method uses special coatings to block corrosion. Here are the main types:

- Epoxy coatings: You use epoxy to form a tough film on the steel. Epoxy resists chemicals and moisture.

- Nylon coatings: Nylon gives you a smooth finish and strong protection against wear.

- Urethane powders: Urethane adds a hard layer that stands up to sunlight and weather.

You usually apply paint in layers. The first layer is the primer. The primer sticks to the steel and helps stop rust. The next layer is the intermediate coat. This coat adds thickness and strength. The last layer is the finish coat. The finish coat protects against rain, sun, and dirt.

Tip: Always clean the steel before you paint. Dirt or oil can make the paint peel off.

Painting works well if you apply it the right way. You need to cover every part of the steel. If you miss a spot, rust can start. You may need to strip and repaint the steel after a few years. Painting is one of the easiest and cheapest ways to stop corrosion.

Here is a table to help you compare painting methods for mild steel:

| Coating Type | Protection Level | Common Uses | Cost |

|---|---|---|---|

| Epoxy | High | Pipes, tanks, frames | Moderate |

| Nylon | Moderate | Tools, handles | Low |

| Urethane Powder | High | Outdoor parts | Moderate |

You can choose the best paint for your project by looking at how much protection you need and how much you want to spend. Painting helps you keep mild steel strong and safe for many years.

Plating

Plating is a way to protect mild steel and make it look nice. You put a thin layer of another metal on the steel. This layer can stop rust, make it shiny, or make it harder. Many industries use plating because it helps mild steel last longer and work better.

There are different ways to do plating. Each method has its own good points and best uses. Here is a table that shows the most common plating methods for mild steel:

| Plating Technique | Description and Benefits | Preferred Applications and Industries |

|---|---|---|

| Electroplating | Uses electric current to deposit metals like zinc, nickel, chrome, and tin onto mild steel surfaces. | Corrosion protection, wear resistance, decorative finishes; automotive, aerospace, electronics, medical devices |

| Electroless Nickel Plating | Chemical deposition without electric current, providing uniform coating even on complex shapes. | Enhances hardness, corrosion resistance, surface finish; used in electronics, aerospace, medical devices |

| Chrome Plating | Provides a hard, wear-resistant, corrosion-protective, and decorative mirror-like finish. | Automotive parts (bumpers, fasteners), industrial tooling, hydraulic components |

| Nickel Plating | Improves hardness, corrosion resistance, and surface finish. | Automotive, aerospace, electronics, decorative and protective coatings |

| Zinc and Zinc-Nickel Plating | Protective coatings replacing cadmium plating due to environmental regulations. | Aerospace, automotive, industrial applications requiring toxic-free corrosion protection |

| Tin Plating | Non-toxic, excellent solderability, corrosion protection, and ductility. | Electrical connectors, battery terminals, food-grade components, electronics |

Electroplating uses electricity to add a metal layer to mild steel. Metals like zinc, nickel, chrome, or tin stick to the steel. This stops rust, makes the steel harder, and gives it a shiny look. You see electroplated parts in cars, planes, and electronics.

Electroless nickel plating does not use electricity. You dip the steel in a special liquid. Nickel covers the steel evenly, even on tricky shapes. This gives a smooth, hard, and rust-proof finish. You find this plating in electronics, planes, and medical tools.

Chrome plating makes the steel very shiny and hard. It protects from rust and wear. You see chrome on car bumpers, fasteners, and tools. Nickel plating also makes steel harder and shinier. It is good for both looks and protection.

Zinc and zinc-nickel plating keep mild steel from rusting. These coatings are safer for the environment than old cadmium plating. You use them in cars, planes, and machines that need safe, strong protection.

Tin plating is safe and easy to solder. You use it for electrical parts, battery ends, and food-safe items. Tin plating keeps mild steel from rusting and makes it easy to connect wires.

Plating gives you many ways to protect and improve mild steel. You can pick the best method based on how you will use the part, how much protection you need, and what look you want. Plating helps your projects stay strong, safe, and nice-looking for years.

Tip: Plating can help mild steel look new and last longer. Always choose the plating method that fits your project’s needs.

Powder Coating

Powder coating uses dry powder instead of liquid paint. You spray the powder onto the steel and then bake it in an oven. The powder melts and forms a hard, smooth layer. Powder coating gives you a tough finish that resists scratches and chips. Many people use powder coating in sheet metal fabrication for outdoor furniture, tools, and machine parts.

You should pick your finishing method based on how you will use the part. If you need strong rust protection, choose galvanizing. If you want a smooth, colorful look, try powder coating or painting. For shiny, decorative parts, plating works best. The right finish can make your fabrication project last longer and look better.

Finishing also helps you meet safety and industry rules. Some projects need special coatings to pass tests or follow laws. Always check what your project needs before you start finishing.

Here is a quick table to help you compare finishing methods in sheet metal fabrication:

| Finishing Method | Rust Protection | Appearance | Durability | Common Uses |

|---|---|---|---|---|

| Painting | Good | Many colors | Moderate | Frames, panels, enclosures |

| Powder Coating | Very good | Smooth, many colors | High | Tools, furniture, machines |

| Galvanizing | Excellent | Dull gray | Very high | Fences, pipes, outdoor parts |

| Plating | Good | Shiny | Moderate | Car parts, appliances |

You should always test a small piece before finishing the whole batch. This helps you check the look and strength of the finish.

Finishing is a key part of both fabrication and sheet metal fabrication. It protects your work, makes it look good, and helps it last. When you plan your next project, think about which finish will give you the best results.

Advantages of Mild Steel Fabrication

If you pick mild steel fabrication, you get many good things. These benefits help you save money, work faster, and find materials easily. Here are the main advantages of mild steel fabrication.

Cost

You want your project to cost less. Mild steel fabrication helps you save money because mild steel is cheaper than most metals. Look at the table below to see the price difference:

| Metal Type | Cost Range (per kg) | Relative Cost Position |

|---|---|---|

| Mild/Carbon Steel | Lower end | Generally cheapest among three |

| Aluminum | $1.50 to $3 | More expensive than mild steel, cheaper than stainless |

| Stainless Steel | $2 to $5 | Most expensive among the three |

Mild steel is the cheapest metal in the list. You spend less on materials, so you can use mild steel for big jobs without spending too much. This makes mild steel a smart pick for building, making things, and custom work. You also save money and increase your cost-effectiveness because mild steel is easy to cut, bend, and weld.

If you want strong parts and low costs, mild steel fabrication is a great choice.

Workability

You need materials that are simple to shape and join. Mild steel is easy to work with. Many things make mild steel simple to use:

- Low carbon content (about 0.05% to 0.25%) makes mild steel soft and easy to bend or cut.

- Small amounts of manganese and silicon make mild steel stronger and more flexible.

- Malleability and ductility let you form mild steel into many shapes.

- You can use cutting, stamping, forging, and drilling.

- Mild steel welds well with MIG, TIG, and stick welding, so you get strong joints.

- Good cleaning and treatments help you get better results.

- The mix of chemical and mechanical features lets you use mild steel in many jobs.

You can work with mild steel using basic tools and machines. You do not need special equipment or advanced skills. This makes mild steel easy to use for many projects.

Availability

You want to start your project right away. Mild steel is easy to find all over the world. You can buy mild steel in sheets, bars, pipes, and plates. Suppliers keep lots of mild steel in stock, so you get what you need fast.

Mild steel is simple to get for small or big jobs. You do not have to wait long or worry about shortages. This helps you finish your project on time and keeps your work moving.

Mild steel is easy to find, so you can plan and build without worry. You do not have to stress about running out or paying high prices.

When you look at the good things about mild steel fabrication, you see why many people use it. You get low costs, easy work, and plenty of supply. These advantages help you finish projects faster and get better results.

Drawbacks in Mild Steel Fabrication

Corrosion

You face corrosion as one of the main drawbacks in mild steel fabrication. Corrosion happens when mild steel reacts with moisture and oxygen in the air. You see rust forming on the surface, which weakens the metal over time. Many things can speed up corrosion. Here are some common causes:

- Moisture and oxygen in the air

- Chlorides from salt or chemicals

- High humidity and rainfall

- Pollutants like sulfur dioxide

- Temperature changes

- Soil type and pH levels

- Marine environments with salt spray

You notice that corrosion starts quickly when humidity reaches 70-80% and temperatures go above 32°F. In soil, corrosion rates change depending on moisture, pH, and chloride levels. Mild steel corrodes slowly in good soil, but aggressive soil can cause rates over 20 microns per year. Coastal and marine areas make corrosion worse because of salt and tidal conditions.

When you expose mild steel to coastal air, the corrosion rate rises at first. Rust forms and speeds up metal loss. After several cycles, a protective rust layer develops. This layer slows down corrosion and helps the steel last longer. The rust acts like a shield, blocking harmful ions and reducing damage. You see the corrosion rate drop and stabilize over time, but it never stops completely.

If you want to reduce corrosion, you need to use protective coatings, paints, or galvanizing. Regular checks and maintenance help you spot rust early and keep your project safe.

Strength Limits

You also need to think about strength limits when you work with mild steel. Mild steel has lower strength than other types of steel. You can bend and shape it easily, but it does not hold up under heavy loads or extreme stress. This is another reason why you must consider the drawbacks in mild steel fabrication.

Here is a table comparing the strength of mild steel to other metals:

| Material | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| Mild Steel | 250 | 400 |

| High Carbon Steel | 500 | 800 |

| Stainless Steel | 520 | 860 |

| Aluminum | 70 | 150 |

You see that mild steel has moderate strength. It works well for many projects, but you should not use it for parts that need high strength or must carry heavy loads. If you push mild steel too hard, it can bend, deform, or even break. You need to check your design and make sure mild steel fits your needs.

Always match the material to your project. If you need more strength, look at other metals or use thicker sections of mild steel.

You must understand the drawbacks of mild steel fabrication before you start your project. Corrosion and strength limits affect how long your product lasts and how safe it stays. When you know these risks, you can plan better and choose the right solutions.

Applications of Mild Steel Fabrication

Construction

You see mild steel used a lot in building things. Builders use mild steel to make strong frames for buildings and bridges. It is easy to shape and weld, so it fits many designs. Workers cut beams and columns to the right size. They join them with welding or bolts. You find mild steel in roof trusses, stairs, and handrails. Mild steel does not bend or break easily, so buildings stay safe. People also use it for fences, gates, and scaffolding. These uses help you build fast and keep workers safe.

Tip: You can fix mild steel easily. If a part breaks, you can cut it out and weld in a new piece.

Automotive

You use mild steel every time you ride in a car or bus. Car makers use mild steel for frames, panels, and engine mounts. It bends into many shapes, so you get smooth car bodies and strong frames. You see mild steel in exhaust pipes, seat frames, and suspension arms. It is easy to weld, so workers join parts quickly. This makes cars safe, cheap, and simple to fix. Mild steel keeps costs low and repairs easy.

Here is a table that shows how mild steel is used in vehicles:

| Mild Steel Part | Automotive Use |

|---|---|

| Chassis | Main frame structure |

| Body Panels | Doors, hoods, roofs |

| Suspension Arms | Wheel support |

| Exhaust System | Pipes and mufflers |

| Seat Frames | Passenger safety |

Manufacturing

You find mild steel in many factories and machines. Factories use mild steel to make tools and equipment. You get strong, mild steel parts that help machines work well. Workers use cutting, bending, rolling, and welding to make different shapes. They finish the surface to stop rust and wear.

Here are some real examples of mild steel in manufacturing:

- Grain bucket elevators use Q235B carbon steel for strength. Workers cut, shape, and weld the steel, then coat it to stop rust. They test the elevator to make sure it works safely.

- Ultrasonic cleaning machine covers need a smooth surface. Workers use laser cutting, folding, and TIG welding to make tight parts. They finish the surface to protect it from damage.

Quality checks are important in factories. Workers use scans and X-rays to check welds. 3D laser scans help make sure parts fit right. These steps make sure mild steel products are strong and last a long time.

You can count on mild steel fabrication to make strong and reliable parts for your machines.

Energy

You see mild steel play a big role in the energy industry. Power plants, oil and gas companies, and renewable energy projects all use mild steel parts. You can find mild steel in pipelines, storage tanks, wind turbine towers, and even solar panel frames. Mild steel works well because it is strong, easy to weld, and costs less than many other metals.

When you build pipelines for oil, gas, or water, you need a material that bends without breaking. Mild steel gives you this flexibility. Workers use welding and rolling to make long, strong pipes. These pipes carry fuel and water over long distances. You also see mild steel in storage tanks. These tanks hold oil, chemicals, or water. Fabricators use cutting, bending, and joining to shape the steel into large, leak-proof containers.

Wind energy uses mild steel for towers and frames. You need tall, sturdy towers to hold wind turbines. Mild steel stands up to strong winds and heavy loads. Workers use custom sheet metal fabrication to make each tower fit its location. Solar farms also use mild steel for panel frames and mounting systems. The steel keeps panels in place and helps them last for years.

Here is a table that shows where you find mild steel in the energy sector:

| Energy Application | Mild Steel Use |

|---|---|

| Oil & Gas Pipelines | Pipes, valves, fittings |

| Power Plants | Tanks, boilers, support beams |

| Wind Energy | Turbine towers, frames |

| Solar Energy | Panel frames, mounts |

Note: You must protect mild steel from rust, especially outdoors. Use painting, galvanizing, or plating to keep your energy equipment safe.

Mild steel helps you build safe and reliable energy systems. You can shape it for many uses, and it stands up to tough jobs. The applications of mild steel fabrication in energy keep power flowing and fuel moving every day.

Custom Projects

You can use mild steel for many custom projects. If you have a special idea or need a unique part, mild steel gives you the freedom to create. Artists, inventors, and builders all use mild steel for custom sheet metal fabrication. You can make furniture, signs, sculptures, or machine parts that fit your exact needs.

Custom projects often start with a drawing or a plan. You choose the size, shape, and finish. Fabricators cut, bend, and weld the steel to match your design. You can add holes, curves, or special features. Mild steel parts can be small, like brackets, or large, like gates and railings.

Here are some examples of custom projects you might see:

- Decorative gates and fences for homes or parks

- Custom car parts or motorcycle frames

- Art sculptures for public spaces

- Special machine parts for factories

- Furniture like tables, chairs, or shelves

Tip: Always talk to a skilled fabricator before you start a custom project. They can help you pick the right grade and finish for your mild steel parts.

Custom sheet metal fabrication lets you turn your ideas into real products. You get strong, lasting results that match your vision. Mild steel makes it easy to build something new, whether you need one part or many.

Choosing the Right Approach

Project Needs

You need to start by understanding what your project requires. Every project has different goals, so you must look at the function and how each part will connect. When you plan your fabrication, think about these important factors:

- Define the main purpose of your design. Decide how each part will attach to others.

- Pick the right material type and thickness. Consider strength, corrosion resistance, weight, and cost.

- Plan hole sizes and where you will place them. Make sure holes are at least as wide as the material is thick. Keep holes away from edges and bends to avoid weak spots.

- Decide if you need hems on the edges. Hems make edges safer and stiffer, but may add cost and need special tools.

- Think about how you will bend the metal. Use the same bend radius for all bends. Add relief cuts to prevent tearing. Try to keep all bends in the same direction to save time.

- Check flange lengths. Flanges should be at least four times the thickness of the material to avoid problems during fabrication.

Adopting these steps helps you reduce mistakes, save money, and get better results from your fabrication services.

Material Selection

Choosing the right material is key to making your project last. You must look at how the material will perform in your environment. The table below compares carbon steel and stainless steel, two common choices for sheet metal fabrication:

| Aspect | Carbon Steel | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Needs coatings; can rust without care | Resists corrosion naturally |

| Longevity | Shorter life in wet places; needs upkeep | Lasts longer with less maintenance |

| Suitability | Good for dry uses; fuel, water, fire safety | Best for harsh chemicals, food, or medicine |

| Maintenance | Needs regular checks and new coatings | Needs little care; safer for food and medicine |

| Cost | Lower upfront cost | Costs more but lasts longer |

| Environmental Impact | Not good for salty or wet places | Works well in tough environments |

| Regulatory Compliance | Not for food or medicine | Meets food and drug rules |

| Performance Factors | Easy to shape and strong | Handles heat and stress better |

You should match your material to your project’s needs. If you want to save money and work in a dry place, carbon steel works well. If you need your product to last in wet or harsh places, stainless steel is a better choice. Good material selection helps you get the most from your sheet metal fabrication services.

Partner Selection

You need an experienced partner to get the best results from your manufacturing services. AFI Industrial Co., Ltd. is a company with extensive experience in metalworking. They’ll help you select materials, plan your design, and provide cutting, bending, CNC machining, and other services to ensure your project is completed on time.

Tip: Choose a partner who listens to your needs and explains each step. Good communication leads to better results and fewer surprises.

Picking the right approach means looking at your project needs, choosing the best material, and working with a trusted partner. This helps you get strong, safe, and cost-effective results from your fabrication.

You now know why mild steel fabrication is important for many projects. Your choices in material and process shape the strength, cost, and safety of your work.

- Think about your project needs before you start.

- Pick the right steel grade and finish.

- Ask experts for advice if you feel unsure.

Ready to begin? Reach out to AFI Industrial Co., Ltd. and share your ideas. Your next project can be strong and long-lasting with the right plan.

FAQ

Mild steel rusts easily and costs less. Stainless steel resists rust and lasts longer. You use mild steel for projects where cost matters. You pick stainless steel for wet or harsh places.

Yes, you can weld mild steel at home. You need basic welding tools like a MIG or stick welder. Always wear safety gear. Practice on scrap pieces before you start your main project.

You protect mild steel by painting, powder coating, or galvanizing it. These finishes block water and air. Always clean the steel before you add any finish for the best results.

Mild steel works outdoors if you protect it from rust. Use paint, powder coating, or galvanizing. Check your project often for signs of rust and fix any damage quickly.

You need cutting tools like shears or saws, bending tools like press brakes, and welding equipment. For finishing, use paint sprayers or powder coating machines. Always use safety gear.

Yes, you can recycle mild steel. Scrap yards accept mild steel. Recycling saves energy and reduces waste. You help the environment when you recycle your steel parts.

Builders pick mild steel because it is strong, easy to shape, and costs less. You can cut, weld, and join it quickly. Mild steel works well for frames, beams, and supports.

You choose the grade based on strength, weldability, and corrosion resistance. Check your project needs. Ask your supplier for advice or a grade certificate if you feel unsure.