Metal Tempering

Explore the ultimate properties of metals, all in tempering heat treatment! AFI Industrial Co., Ltd.’s tempering and heat treatment services to inject new vitality into your products, open a new chapter in metal processing!

Metal Tempering Process

Tempering is a heat treatment process in which engineers reheat the quenched workpiece to a certain temperature below the critical temperature (usually 250℃-650℃), hold it for a period of time, and then cool it down. It can effectively reduce internal stress, enhance toughness, and adjust hardness at the same time to meet different usage requirements of customers. It includes two aspects: quenching and tempering.

Quenching

Quenching is a heat treatment method in which engineers heat metal materials above the critical temperature (usually 750℃-1200℃), hold them for a period of time to make the internal temperature of the material uniform, ensure the formation of austenite, and then quickly cool the workpiece to room temperature. Its main purpose is to obtain a high-hardness martensitic or bainitic structure, thereby enhancing the strength and hardness of the material.

Tempering

Tempering is a heat treatment process in which engineers reheat the quenched workpiece to a certain temperature below the critical temperature (usually 250℃-650℃), hold it for a period of time, and then cool it down. Its main purpose is to effectively reduce the internal stress generated during the quenching process, enhance the toughness of the workpiece and adjust its hardness.

Custom Tempering Service

AFI Industrial Co., Ltd.is dedicated to providing customers with professional customized tempering and heat treatment services. We adopt intelligent temperature control technology, which can precisely control the temperature within ±3℃, ensuring the stability and reliability of the entire heat treatment process.

For different demands, we flexibly apply various quenching media such as water-based, oil-based and aerosol to help customers precisely control the hardness of steel and stably maintain it within the ideal range of HRC50-65. Through our tempering process treatment, the material toughness can be increased by more than 30%. According to customer feedback, this treatment can effectively reduce the risk of component fracture under extreme working conditions.

From raw material analysis to finished product inspection, we have established a quality control system to ensure that the products can meet industry standards in key indicators such as hardness, metallographic structure, and dimensional accuracy.

We promise a rapid response within 2 hours, support minimum orders of 1 piece, and support either 1 piece or mass production to meet your needs and help you gain an edge in the market competition!

Metal Tempering Process

Metal tempering heat treatment is the core process for optimizing the performance of steel. By controlling the temperature (adjustable from 200 to 650℃), time (depending on the size of the workpiece), and cooling method (air cooling/oil cooling), the directional regulation of quenched martensite can be achieved.

This process, while ensuring the hardness of the steel (HRC45-60), can increase the material’s toughness by 30-50%, achieving a balance between high strength (1000-1500MPa) and high toughness (AKU≥40J).

The steel we have treated in this way has a strength retention rate of over 85%, a fatigue life increase of 2 to 3 times, and a wear resistance enhancement of 20 to 30%. It is suitable for manufacturing automotive transmission system components, precision tools and dies, and core components of construction machinery with strict performance requirements.

Modern heat treatment equipment offers a temperature control accuracy of ±5℃ and a time error control of ≤3%. It tailors suitable strength and toughness combination solutions for workpieces of different specifications, meeting the specific performance requirements of customers in various application scenarios, from micro precision parts to large mechanical structural components.

Before tempering

After tempering

Metal Tempering Equipment

AFI Industries Co., Ltd. is equipped with an intelligent tempering production line, featuring a ±5℃ precision temperature control system. By optimizing the heating curve (up to 650℃), holding time (±2% accuracy), and staged cooling process, it can stabilize the hardness of steel within the HRC45-60 range, increase the impact toughness by more than 40%, and achieve a tensile strength of 1000-1500MPa. Meet the material performance requirements of high-demand industrial fields such as aerospace and automotive manufacturing.

Automatic heating equipment

Precise control of the heating process of automatic heating equipment can ensure the consistency and repeatability of the products.

Tempering Furnace

Tempering treatment effectively eliminates quenching stress, improves material toughness and maintains the required hardness through precise temperature control (150-650℃) and holding. This process can reduce the risk of workpiece deformation and cracking, and help customers improve dimensional stability.

Cooling circulation system

Our cooling system regulates the cooling rate (0.5-50℃/s), optimizes the phase transformation of materials, enhances performance, and ensures the best mechanical properties of the products.

Metal Tempering materials

Tempering heat treatment is an important process for improving the performance of metallic materials and is applicable to a variety of common engineering materials.

After tempering treatment, medium carbon steel (such as 45 steel) and alloy steel (40Cr, 42CrMo, etc.) can achieve a balance between strength and toughness. For low-carbon alloy steel (25CrMo) and stainless steel, tempering can optimize their processing performance and service life. All kinds of engineering cast steels (such as ZG310-570) can improve their internal structure and stress distribution through tempering.

We adopt precise temperature control technology (200-650℃) and customize tempering processes based on the characteristics of different materials, which can increase impact toughness by 30-50% and reduce residual stress by 40-60% at the same time. This treatment is particularly suitable for manufacturing key mechanical components such as shafts and gears that are subjected to complex loads, ensuring that the products achieve the best overall performance.

We can provide customized solutions based on your different material properties and usage requirements to help you enhance product performance and market competitiveness.

Metal Tempering Quality

AFI Industrial Co., Ltd. adopts advanced process control technology to monitor and precisely control key parameters such as temperature and speed during the metal tempering process to ensure consistency and reliability of the metal tempering effect. After appearance inspection, hardness testing, etc., The quality problems that may occur in the process of metal tempering are comprehensively tested to ensure quality and effect and meet the quality needs of customers.

Microstructure Examination

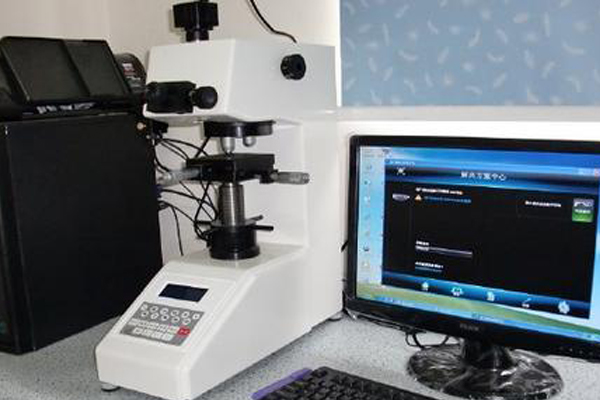

Hardness Measurement

Dimension Measurement

Appearance Inspection

How to Start Your Order

Send your drawings

Process discussion, quotation

Make a sample

Volume produce

Shipment & Payment

Frequent Asked Questions

The hardness after tempering mainly depends on the temperature and time. The higher the temperature, the lower the hardness. For instance, a medium carbon steel that has been quenched can still maintain a hardness of HRC40-45 (relatively hard) after tempering at 200-300 ℃, but if the tempering temperature rises to 500-600 ℃, the hardness will drop to HRC25-30 (becoming softer). The longer the time, the slightly the hardness will decrease, but the influence of temperature is more obvious.

Our company can adjust the most suitable tempering temperature and time for you based on the initial hardness of your material and the desired final hardness, ensuring that the products made meet your quality requirements.

Tempering treatment is applicable to forged parts, castings, stamped parts, machined parts, welded structural parts, special alloy products, etc. It optimizes hardness and toughness, eliminates stress and enhances durability by heating (150-650℃).

Low-temperature tempering (150-250℃) maintains high hardness and is used for cutting tools. Medium-temperature tempering (350-500℃) enhances elasticity and is suitable for springs. High-temperature tempering (500-650℃) achieves a combination of strength and toughness, which is suitable for structural components.

Tempering can reduce the brittleness of materials, adjust mechanical properties (hardness/toughness balance), eliminate internal stress generated by quenching or processing, and improve dimensional stability and service life.