Quenching

AFI Industrial Co., Ltd. has experienced technicians to provide customers with metal quenching services, which can improve the hardness and wear resistance of metal parts, extend the service life of products, and bring greater economic benefits to customers.

Quenching Process

AFI Industrial Co., Ltd. uses advanced equipment and technology to change metal materials’ organizational structure and properties by heating and rapid cooling. Heat treatment can make the material obtain excellent properties such as high hardness, high strength, low toughness, and high wear resistance. The quenching process mainly includes four stages: preheating, heating, heat preservation, and cooling. In the quenching process, according to the characteristics of the material, we choose the appropriate coolant and control the temperature so that customers get high-quality products.

Preheating

Engineers put metal parts into the furnace for preheating, allowing the temperature of the metal material to rise uniformly to a certain level. This can reduce the internal stress of the material and prevent it from cracking easilyT.

Heating

The metal parts are fed into the quenching furnace and heated to a certain temperature. Different metal materials and required hardness require different heating temperatures.

Heat Preservation

After reaching the required heating temperature, it is necessary to maintain thermal insulation for a period of time, so that the organization inside the material reaches thermal balance.

Cooling

Rapid cooling after holding can achieve quenching. We commonly use water quenching or oil quenching and other methods to reduce the risk of deformation and cracking. It can achieve the required material properties.

Custom Quenching Service

AFI Industrial Co., Ltd. specializes in providing customized metal heat treatment services. It adopts an intelligent temperature control system and multi-media quenching equipment, which can precisely control the heat treatment process parameters according to the material properties, improving key indicators such as the wear resistance and fatigue strength of the workpiece. We serve all kinds of components, ranging from precision instrument parts to heavy machinery components, providing reliable customized solutions to help customers enhance product performance and market competitiveness, and ensure quality requirements.

Quenching Process

Quenching is a kind of metal heat treatment process. Engineers use heating furnaces to heat metal workpieces to a certain temperature to obtain a uniform austenite structure, and then quickly immerse them in water, oil or other cooling media for rapid cooling, forming a harder martensite or other hardened structure, thereby completing the quenching heat treatment of the workpieces. The hardness and wear resistance of quenched workpieces can both be enhanced, which can meet the quality requirements of customers.

before heat treatment

after heat treatment

Quenching Equipment

AFI Industrial Co., Ltd.is equipped with an intelligent quenching system, which adopts a ±5℃ high-precision temperature control module. Through multi-medium cooling processes such as water quenching, oil quenching, and gas quenching, the surface hardness of the workpiece reaches HRC50-65(ISO6508), and the tensile strength is increased by more than 30% compared to the annealed state, meeting the customers’ requirements for product quality.

Automatic Heating Equipment

Precise control of the heating process of automatic heating equipment can ensure the consistency and repeatability of the products.

Cooling Circulation System

The stability of temperature and flow rate in the cooling circulation system can ensure that the product is uniformly cooled during the processing, eliminating the problems of deformation and hardness fluctuation caused by uneven cooling.

Quenching Materials

Quenching process is mainly used to enhance the hardness and wear resistance of steel metal parts. The types of these steels include medium carbon steel, low-carbon tempered high-strength steel, medium carbon tempered high-strength steel, heat-resistant steel and low-temperature steel, stainless steel, carbon structural steel, cast iron and some alloy steels, etc. Each material has its specific process requirements and purposes for quenching treatment. Our engineers will select the appropriate quenching method based on the customer’s requirements, thereby significantly improving the performance of the workpiece and meeting the customer’s quality demands for the workpiece.

Quenching Quality Detection

AFI Industrial Co., Ltd. adopts a comprehensive quality inspection system to ensure that the performance of quenched parts meets the standards.

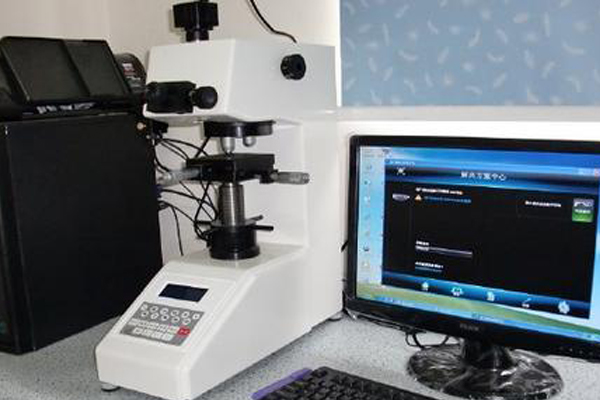

We use microscopes for microstructure examination to ensure that the uniformity of the tissue is above 95%. We measure hardness using a digital Rockwell hardness tester, precisely controlling it within the range of HRC58-62. Equipped with a high-precision three-coordinate measuring machine (with an accuracy of 0.01mm) for full-size inspection, the key dimensional tolerances are controlled within ±0.02mm. At the same time, 100% visual inspection (EN10204 standard) is carried out, combined with surface roughness detection (Ra≤0.4μm) and magnetic particle inspection to ensure that surface defects are completely eliminated.

Through this rigorous inspection process, we provide high-quality heat treatment products with zero defects for industries such as aviation and automobiles, with all indicators reaching the highest industry standards.

Microstructure Examination

Hardness Measurement

Dimension Measurement

Appearance Inspection

How to Start Your Order

Send your drawings

Process discussion, quotation

Make a sample

Volume produce

Shipment & Payment

Frequent Asked Questions

The hardness and strength of the parts after quenching can be achieved depends on the material itself, the medium used, as well as the process parameters of temperature and cooling rate. For instance, the HRC of common low-carbon steel after quenching is approximately 40-50, while that of alloy steel like 4140 can reach 50-60. However, these are all general ranges. For your specific requirements, our company can customize solutions for your products to meet your quality requirements for the products.

Metals can warp or crack during rapid cooling, as well as develop internal stresses that can affect the final shape and strength of the metal. It is important to carefully control and monitor the quenching process to avoid these problems.

The most feared thing during the quenching process is that the cooling is too fast, causing the product to crack or deform. Our company has a complete set of solutions for this problem.

How exactly should it be done? First, we will preheat it slowly like boiling eggs to allow the materials to adapt. Then, select the method based on the condition of the parts: For relatively simple small parts, water quenching is adopted, which is fast and cost-effective. For more complex precision parts, oil quenching is recommended. Although it is more costly, it is more reliable. After tempering, temper immediately, just like people do stretching after exercising, to release all the internal pressure.

If you have any special requirements, please contact us. We guarantee to make everything clear for you!