Machining tolerances are important for quality and cost. Tight tolerances can make parts better, but they cost more. Loose tolerances can save money, but quality may drop. You should learn about the types of tolerances. You also need to know what changes them. Industry standards help you pick the right ones. Tolerancing is important when making or checking a part. It is important to talk clearly with your team.

Key Takeaways

- Machining tolerances show how much a part can change in size or shape. This affects how good the part is and how much it costs.

- There are three main types of tolerances. These are dimensional, geometric, and surface. Each one controls a different part feature.

- Picking the right tolerance helps balance how well the part works and how much it costs. Tight tolerances make parts fit better but cost more money.

- The material, what the design needs, and how you make the part all affect which tolerances you can use.

- Fit types like clearance, interference, and transition help decide how parts go together. They also help you pick the right tolerance.

- Tolerance stack-up happens when small changes add up in a group of parts. Planning ahead is important so parts fit together well.

- Industry standards like ISO 2768 and ASME Y14.5 help you pick tolerances. They also help stop mistakes from happening.

- Good talking and teamwork between designers, machinists, and quality teams help make the best tolerance choices.

Table of Contents

Machining Tolerances Overview

Definition of Machining Tolerances

You must know what machining tolerances are to make good parts. Machining tolerances show how much a part’s size or shape can change from the plan. ISO 2768 gives clear rules for how much a part can be different from the drawing. This standard helps you and your team avoid mistakes. It also stops confusion.

| ISO 2768 Tolerance Classes | Description |

|---|---|

| Fine (f) | Smallest permissible deviations for high-precision parts |

| Medium (m) | Standard for most machined parts |

| Coarse (c) | Larger deviations allowed for less critical parts |

| Very Coarse (v) | Largest permissible deviations, used for rough or non-critical features |

You use these classes to pick the right accuracy for your part. This makes your job easier. It also helps you meet what customers want.

Types of Machining Tolerances

Machining tolerances have different types. Each type controls a certain part feature.

Dimensional

Dimensional tolerances are the most common type of tolerance and specify the maximum and minimum variations allowed in part dimensions. For example, a shaft might need to be 10.00 mm with a tolerance of ±0.02 mm. These limits help parts fit together.

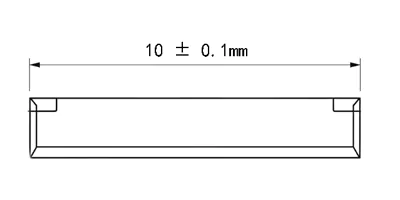

Bilateral Tolerance

- A dimension is permitted to vary in both positive and negative directions from the basic dimension.

- For example, 10 ± 0.1 mm means the actual dimension of the part can be between 9.9 mm and 10.1 mm.

- This tolerance is often used for external dimensions where fit requirements are less critical.

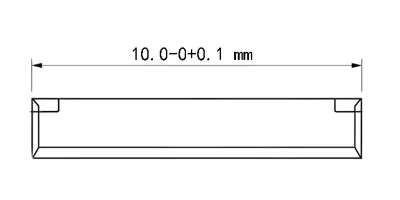

Unilateral Tolerance

- A dimension is allowed to vary in only one direction, either positive or negative.

- For example: 10−0.0+0.1 mm

- mm. This means the actual dimension of the part can only be between 10 mm and 10.1 mm.

- This tolerance is often used for parts that require a tight fit, such as shafts and holes, to ensure only one interference or clearance fit during assembly.

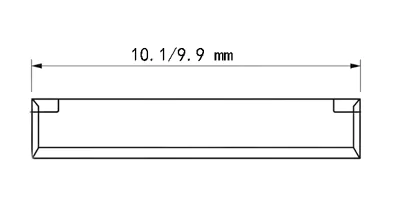

Limit Tolerance

- The upper and lower limits of a part’s size are given directly, without a positive or negative sign.

- For example: 10.1/9.9 mm. This has the same meaning as the bidirectional tolerance of 10 ± 0.1 mm; it’s just expressed differently.

Geometric

Geometric tolerances control the shape and position of features. Form tolerances keep shapes like flatness or roundness correct. Profile tolerances help you control the outline or surface. Orientation tolerances make sure holes or slots point the right way. Location tolerances tell you where features must go on the part. These controls help you avoid problems when putting parts together.

Form Tolerances

- Controls the shape of a single feature, regardless of its relationship to other features.

- These include:

- Straightness: Controls the curvature of a line.

- Flatness: Controls the flatness of a surface.

- Circularity: Controls the shape of a circular cross-section.

- Cylindricity: Controls the shape of a cylindrical surface.

Location Tolerances

- Controls the position of one or more features relative to a datum.

- These include:

- Position: Controls the deviation between the actual and ideal positions of features such as holes and slots.

- Concentricity: Controls the degree to which the center axis of a circle or cylinder is aligned with another datum axis.

- Symmetry: Controls the degree of symmetry of a feature relative to its center plane.

Orientation Tolerances

- Controls the orientation of one or more features relative to a datum.

- These include:

- Parallelism: Controls the degree of parallelism between a plane or axis and another datum plane or axis.

- Perpendicularity: Controls the degree of perpendicularity between a plane or axis and another datum plane or axis.

- Angularity: Controls the angle between a plane or axis and another datum plane or axis.

Runout Tolerances

- Controls the fluctuation of a rotating part’s surface or features during rotation.

- Includes:

- Circular Runout: Controls the circular runout of a single section.

- Total Runout: Controls the runout of the entire surface.

Surface

Surface tolerances set how smooth or rough a part’s surface should be. If you need a smooth finish, you must use tighter surface tolerances. This can change how well parts slide or seal.

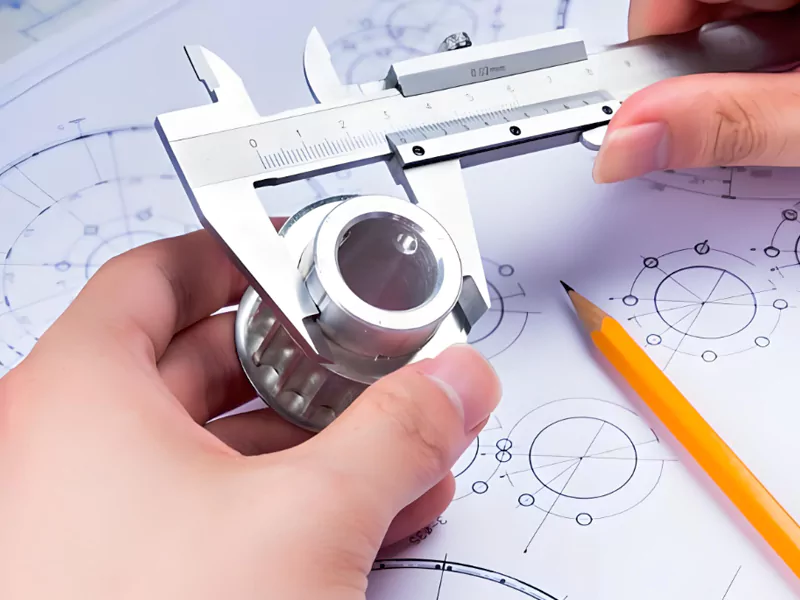

Tip: Different tolerances need different inspection tools. You might use calipers for size. You use a coordinate measuring machine for geometric features. You use a surface tester for roughness.

Why Tolerances Matter

Tolerances are important for how your parts work and how long they last. Tight tolerances help parts fit better and last longer. But you may spend more time and money making and checking them. Loose tolerances cost less. But they can cause problems like rattling or wearing out early.

| Tolerance Type | Impact on Reliability and Lifecycle |

|---|---|

| Tight Tolerances | Parts fit well, last longer, but cost more to make and inspect. |

| Loose Tolerances | Parts are cheaper and easier to make, but may not work as well or last as long. |

| Poorly Specified | Can cause assembly problems and failures. |

| Well-Balanced | Meet needs for function, cost, and customer satisfaction. |

You should always pick tolerances that match your part’s job. Good choices help you save money. They also help you make reliable products.

- Different types of machining tolerances change how you check your parts:

- Dimensional tolerances need tools like calipers or micrometers.

- Geometric tolerances may need advanced machines.

- Surface tolerances require special testers.

- Tighter tolerances mean more checks and higher costs.

- You must keep your tools accurate and follow quality rules.

- Skilled machinists and engineers help you get the best results.

Factors Influencing Machining Tolerances

Material

You need to think about the material when picking tolerances. Harder materials, like stainless steel or titanium, help you get tighter tolerances. These materials do not bend much during machining. They keep their shape well. They also do not change size much when it gets hot or cold. This makes your part more accurate. Softer materials, like aluminum or plastics, can bend or change shape more easily. You may need looser tolerances for these materials. This helps you avoid problems. Always match the material to what your project needs. This choice helps your part fit and work better.

Design Requirements

Your design goals help you decide on tolerances. If your part must fit with another part, you need tight tolerances for important features. For example, a shaft that fits in a bearing needs a close size match. If your part does not need to fit with others, you can use looser tolerances. This saves time and money. Think about how your part will be used. Ask if your part needs high accuracy or if some change is okay. Clear design rules help you avoid mistakes. They make sure your parts work as planned.

Tip: Always check your design and talk with your machinist. This helps you pick the right tolerances for each part.

Manufacturing Process

How you make your part changes what tolerances you can get. Different machining processes have their own limits.

- CNC milling, turning, and grinding give different levels of precision.

- Turning and milling make different surface finishes. This can change how accurate your part is.

- Multi-axis CNC machines can reach tighter tolerances. They move in more ways.

- The process you pick changes the surface and size of your part.

- Tool condition, machinist skill, and finishing steps also matter for tolerances.

- Using sharp tools and the right coolant helps keep your part within tolerance.

- Tool bending, especially in long or thin parts, can cause mistakes in accuracy.

- Working with a CNC machining expert helps you choose the best process.

- Always say your tolerances clearly when you order parts. This saves time and helps you get the precision you want.

Picking the right process and tools helps you meet your tolerance goals. Your parts will fit well and last longer.

Fit Types

When you design parts that fit together, you need to choose the right type of fit. The fit type tells you how much space or tightness exists between two parts. This choice affects how you set tolerances for your parts. The three main fit types are clearance, interference, and transition.

Clearance

Clearance fits give you space between two parts. You use this fit when you want parts to move easily or assemble without force. For example, a shaft that spins inside a bearing needs a clearance fit. You set tolerances so the shaft is always a little smaller than the hole. This makes assembly simple and quick. You do not need special tools. Clearance fits work well for moving parts or when you need to take things apart often. If you use too much clearance, parts may rattle or wear out faster. You must balance the tolerances to keep the fit loose enough for movement but tight enough for good performance.

Interference

Interference fits do the opposite. They make parts fit tightly together. You use this fit when you want two parts to stay joined without slipping. For example, you might press a gear onto a shaft. The shaft is a little bigger than the hole. You need to use force or heat to put the parts together. The tolerances must be very tight. This fit keeps parts from moving, even under heavy loads. Interference fits work well for permanent assemblies. If you need to take the parts apart, it can be hard. You must set tolerances carefully to avoid damaging the parts during assembly.

Transition

Transition fits give you a mix of clearance and interference. Sometimes the parts have a tiny gap, and sometimes they fit tightly. You use this fit when you want parts to line up exactly but still allow for easy assembly.

For example, you might use a transition fit for gears that need to be replaced but must stay in place during use. The tolerances for transition fits are set so you can use a small tool, like a mallet, to put the parts together. This fit helps you get high accuracy without making assembly too hard. Transition fits help you avoid problems like vibration or difficult repairs. You get the benefits of both clearance and interference fits by choosing the right tolerances

Tip: Always match your fit type to your application. The right fit helps you control how parts move, how easy they are to assemble, and how long they last.

| Fit Type | Typical Use | Assembly Method | Tolerance Range |

|---|---|---|---|

| Clearance | Moving parts, easy removal | Hand assembly | Loose |

| Interference | Permanent joints | Press or heat | Tight |

| Transition | Precise, replaceable parts | Light force or mallet | Medium (tight/loose) |

Choosing the right fit type helps you set tolerances that match your needs. You improve part quality and make assembly easier when you understand how fit types work.

Different Machining Tolerances and Their Impact

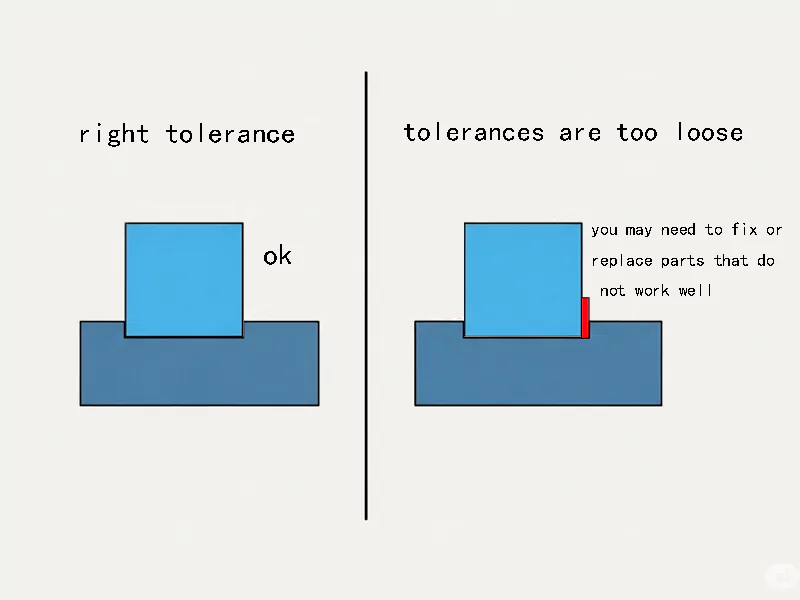

Tight vs. Loose Tolerances

You face a big choice when you set tolerances for your parts. Tight tolerances mean you want parts to be very close to the exact size or shape you planned. Loose tolerances let parts be a little bigger or smaller. Each choice changes how your part works and how much it costs to make.

If you use tight tolerances, you get high accuracy. Your parts fit together better and work smoothly. For example, if you make gears for a watch, you need tight tolerances so the gears turn without slipping. Tight tolerances help you reach high quality, but they also raise the cost. You need better machines, more skilled workers, and more time to check each part.

Loose tolerances give you more freedom. You can make parts faster and with less waste. For example, if you make a bracket that holds a sign, you do not need every bracket to be exactly the same size. Loose tolerances lower your cost, but you may lose some quality. Parts may not fit as well or last as long.

Tip: Always match your tolerance to what your part needs to do. Do not make tolerances tighter than needed, or you will spend more money for no reason.

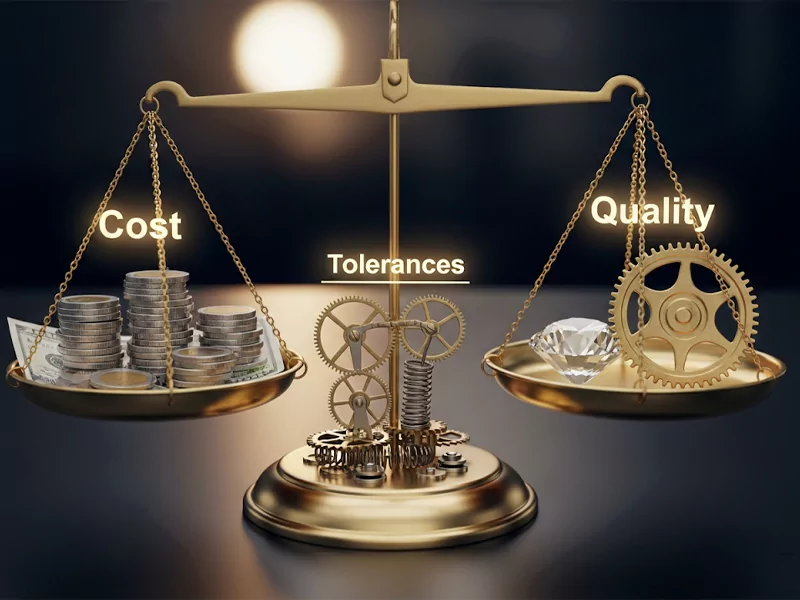

Impact Cost and Quality

Cost Drivers

The tolerances you choose have a direct effect on cost. Tight tolerances need high precision machines and careful inspection. You may need to throw away parts that do not meet the exact size. This raises your scrap rate and increases your cost. In high-volume manufacturing, even a small change in tolerance can make a big difference in how many parts you must scrap or rework.

Loose tolerances let you make parts faster and with less waste. You do not need to check every part as closely. This saves you money on inspection and reduces the number of parts you throw away. However, if your tolerances are too loose, you may need to fix or replace parts that do not work well. This can also raise your cost in the long run.

A study on clutch assemblies showed that picking the right tolerance can lower both scrap and rework costs. When you use the best process and set tolerances wisely, you get more good parts and spend less money.

Quality Risks

Quality depends on how well your parts fit and work together. Tight tolerances help you reach high quality because your parts match the design closely. You get better function and longer life. But if you set tolerances too tight, you may waste good parts that are just a little off. This does not always improve quality.

Loose tolerances can lead to problems. Parts may not fit well, or they may wear out faster. If you use loose tolerances in the wrong place, your product may not work as planned. You may need to fix or replace parts, which hurts your quality and your reputation.

You must balance cost and quality. The best choice is to use tight tolerances only where you need high accuracy. Use looser tolerances where small changes do not hurt the function.

Tolerance Stack-Up

When you put many parts together, each part’s tolerance adds up. This is called tolerance stack-up. If you do not plan for stack-up, your final assembly may not fit or work right.

Imagine you build a box with four sides. Each side can be a little bigger or smaller because of the tolerance. If all sides are a bit too big, the box may not close. If all are too small, you get gaps. You must check how all the tolerances add together before you make the parts.

Engineers use stack-up analysis to predict problems before they happen. You can use math or computer tools to see how much the sizes might change. This helps you set the right tolerances for each part. You avoid costly mistakes and make sure your assembly works every time.

Note: Always talk with your team about stack-up. Good planning helps you keep both cost and quality under control.

Standards That Define Machining Tolerances

Industry Standards

There are many rules that tell you how to set machining tolerances. ISO and ASME are two big groups that make these rules. ISO 2768 gives basic rules for how big or what shape a part can be. ASME Y14.5 explains Geometric Dimensioning and Tolerancing, also called GD&T. These standards help everyone on your team understand each other. If you follow them, you make fewer mistakes. Some industries, like aerospace and automotive, say you must use these standards. They make sure your parts fit and work the way they should.

| Standard | Organization | Focus Area |

|---|---|---|

| ISO 2768 | ISO | General tolerances for size/shape |

| ASME Y14.5 | ASME | GD&T, symbols, and definitions |

| ISO 1101 | ISO | Geometric tolerances |

Note: Always check which standard your project or customer wants. This helps you avoid expensive mistakes.

Common Guidelines

There are some easy rules to follow when you pick tolerances. First, think about what your part needs to do. If a part is very important, use a tighter tolerance. If it is not as important, you can use a looser tolerance. Always look at the standards for your industry. Use the right symbols and notes on your drawings. This helps machinists and inspectors know what you want. Also, think about how your parts will fit together. If you forget this, you might have trouble later.

Tip: Use GD&T symbols to show where you need high accuracy. This helps you keep costs down and quality up.

Selecting Appropriate Tolerances

You should pick tolerances that fit your part’s job and your budget. Here are some tips to help you:

- Think about tolerance stacking. Each part’s tolerance adds up in an assembly. Make sure the total does not cause problems.

- Do not pick the tightest tolerance for every feature. This raises cost and scrap rates. Use the loosest tolerance that still works.

- Use GD&T to show where tight tolerances matter most. This lets you relax tolerances in less critical areas.

- Balance function and manufacturability. Tolerances must be tight enough for good performance but not so tight that they slow down production or raise costs.

- Talk with your machinist or manufacturing team. They can help you find the best balance for your needs.

If you follow these steps, you can save time and money. Your parts will fit and work the way you planned.

Balancing Tolerances for Cost and Quality

Strategies

You can use smart strategies to balance tolerances for both cost and quality. Start by looking at which tolerances matter most. Some features have a big effect on how your part works or fits. Focus on these first. Use tools and data to find out which tolerances have the biggest impact on surface shape or function. This helps you avoid wasting time on less important details.

- Check which tolerances affect the part’s main job.

- Use numbers and tests to see which features are most sensitive.

- Adjust the tightness of each tolerance based on its importance.

- Think about all the limits, like size, shape, and material, at the same time.

- Use computer models or simulations to test your choices before making parts.

You can also use advanced methods, like deep learning or Monte Carlo simulations, to help you find the best balance. These tools let you see how changes in one tolerance affect the whole part. They help you keep your parts strong and working well, while also keeping costs down.

Tip: Focus your efforts on the tolerances that matter most. This saves money and keeps your parts working as they should.

Communication

Good communication helps you reach the right balance between cost and quality. You should talk with your engineers, machinists, and quality teams early in the process. Share your goals and listen to their advice. They know what is possible with their machines and tools.

- Hold meetings to review drawings and tolerance needs.

- Ask questions if you do not understand a tolerance or a process.

- Use clear notes and symbols on your drawings.

- Make sure everyone knows which features need tight control.

When you work together, you avoid mistakes and surprises. You also make it easier to solve problems if they come up.

Best Practices

You can follow some best practices to get the most from your tolerance choices.

| Practice | Why It Helps |

|---|---|

| Review tolerances often | Keeps your parts up to date and cost-effective |

| Use standards | Makes sure everyone understands your needs |

| Test with prototypes | Finds problems before full production |

| Document changes | Helps your team stay on the same page |

| Train your team | Improves skills and reduces errors |

Always check your tolerances before you start making parts. Use industry standards to guide your choices. Build and test a few parts first to see if your tolerances work in real life. Keep good records of any changes. Teach your team about new tools and methods. These steps help you keep quality high and costs low.

Picking the right machining tolerances helps you make good parts and control costs. You should always choose tolerances that fit what your part needs to do. Use industry standards to guide you. Think about the material, the design, and how you will make the part. Talk with your team so everyone understands and you do not make mistakes.

- Check your tolerance choices often.

- Change your plans if your needs are different.

Remember: Good tolerance choices save money and help you make parts that work well every time.

FAQ

You use tight tolerances when your parts must fit together perfectly or work in high-precision jobs. Tight tolerances help you avoid gaps, leaks, or movement that can cause problems.

You look at how your part will be used. You check if it needs to fit with other parts or handle stress. You also talk with your machinist or engineer for advice.

Yes, loose tolerances often lower your costs. You spend less time on machining and inspection. You also waste fewer parts. Use loose tolerances when your part does not need high accuracy.

If you ignore stack-up, your assembly may not fit or work right. Small errors in each part can add up. You may see gaps, tight spots, or parts that do not fit at all.

No, different materials behave in different ways. Hard metals like steel can hold tight tolerances. Soft materials like plastic may need looser tolerances because they bend or change shape more easily.

Industry standards help everyone understand what you want. They reduce mistakes and make sure your parts fit with others. Standards also help you meet customer or legal rules.

You use tools like calipers, micrometers, or special machines. You measure your part and size tolerances, then machinistscompare it to the drawing. If your part is within the limits, it passes inspection.