When comparing galvanized steel vs stainless steel in 2025, your choice depends on your specific needs. Stainless steel is ideal for harsh environments or coastal areas because it offers excellent rust protection and high strength. On the other hand, galvanized steel is more affordable and works well for construction or outdoor projects in typical weather conditions. Consider these factors when deciding between galvanized steel vs stainless steel:

- Corrosion resistance

- Cost

- Durability

- Strength

- Maintenance

- Application requirements

Evaluate your budget, location, and the expected lifespan of your project before making a decision.

Key Takeaways

- Stainless steel stops rust better and is very strong. It works best in places that are wet or salty.

- Galvanized steel costs less and is good for outdoor jobs. It works well when the weather is normal and you want to save money.

- Pick stainless steel for projects that need to last a long time. Use it near the ocean, in chemical plants, or where things must stay clean.

- Galvanized steel is good for building, farming, and car parts. It gives good protection and does not cost much.

- You need to check galvanized steel often and sometimes coat it again. Stainless steel needs little care and is easy to keep up.

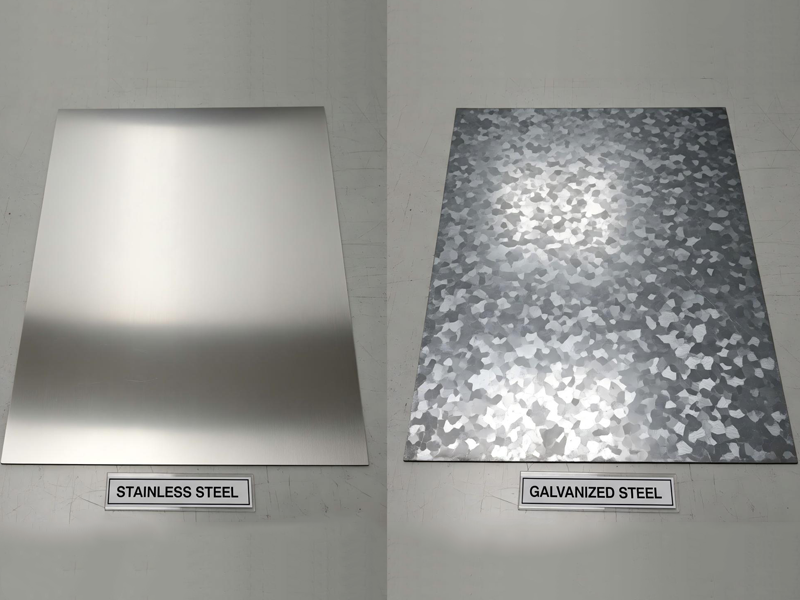

- Stainless steel looks shiny and modern. It comes in many styles. Galvanized steel looks dull or flat most of the time.

- Think about how much you pay at first and later. Stainless steel costs more at first but saves money because it lasts longer.

- Both types of steel can be recycled. Making stainless steel uses more energy. Using recycled steel helps the planet.

Table of Contents

Galvanized Steel vs Stainless Steel

Key Differences

When you look at galvanized steel vs stainless steel, you see they are not the same. Both help stop rust, but they work in different ways. Galvanized steel has a zinc layer that covers the steel. Stainless steel has chromium, which makes a layer that fixes itself and keeps out rust.

Here is a table that shows how they are different:

| Aspect | Galvanized Steel | Stainless Steel |

|---|---|---|

| Composition | Standard steel coated with zinc layer (not alloy) | Alloy containing chromium (and often nickel) |

| Protective Mechanism | Zinc coating acts as a physical barrier; sacrificial | Passive chromium oxide layer that is integral and self-healing |

| Corrosion Resistance | Good against water and chlorine; coating can be damaged and is not self-healing | Superior corrosion resistance, especially in harsh environments; self-healing oxide layer |

| Structural Strength | Depends on base steel grade; zinc coating does not affect strength | Generally stronger; tensile strength ranges from ~515 MPa to 1300 MPa depending on alloy |

| Malleability | Same as base steel; generally more malleable | Varies by grade; generally less malleable than galvanized steel |

| Product Type | Layered product (steel + zinc coating) | Fully alloyed product |

Stainless steel is better at fighting rust and is stronger. Galvanized steel bends more easily and costs less.

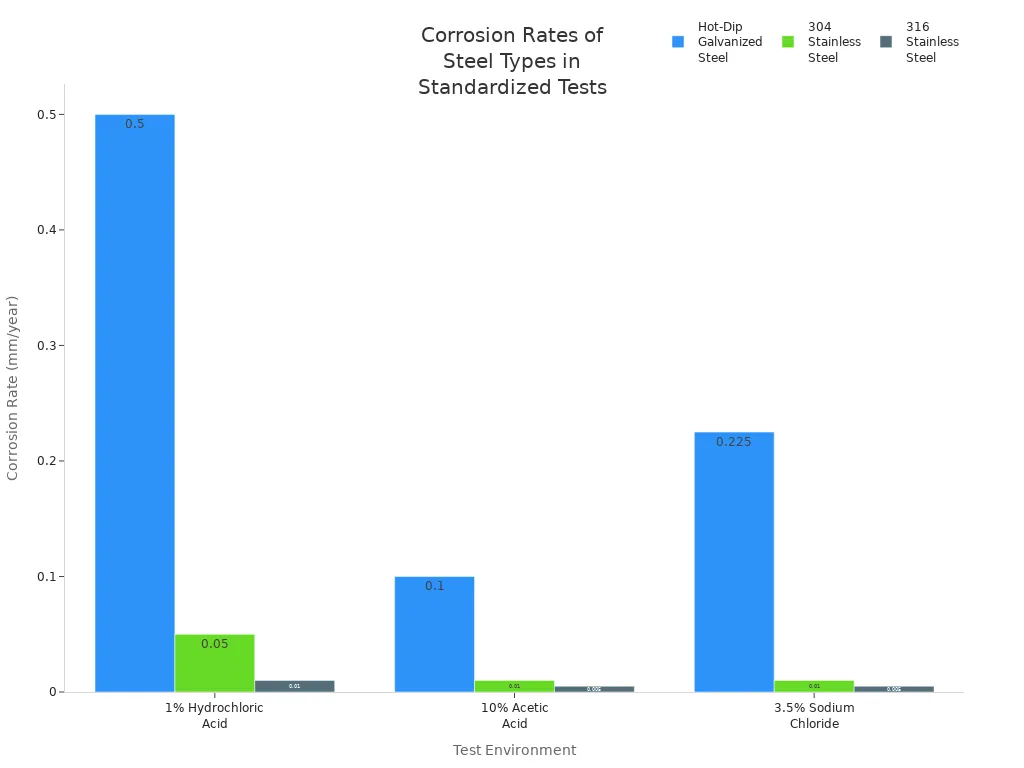

Rust protection is very important when you pick between these two. In salt spray tests, stainless steel lasts much longer before rust shows up. The chart below shows how galvanized steel, 304 stainless steel, and 316 stainless steel perform in different chemicals:

Grade 316 stainless steel works best in tough or salty places. Galvanized steel is good for normal outdoor use but does not last as long near the ocean or in factories.

Decision Factors

When you pick between galvanized steel vs stainless steel, you should think about a few things:

- Corrosion Resistance: If you need strong rust protection, especially in wet or salty places, choose stainless steel. Galvanized steel is fine for rain and normal weather, but its zinc layer can wear off.

- Cost: Galvanized steel is usually cheaper. It is a smart choice for big projects if you want to save money.

- Durability: Stainless steel lasts longer in hard places. It stays strong and looks good for many years, even if you do not take care of it much. Galvanized steel is tough in easy weather but might need fixing or replacing sooner in bad weather.

- Strength: Stainless steel is often stronger than galvanized steel. It can hold more weight and handle more stress, which is good for heavy jobs.

- Typical Applications:

- Galvanized steel is used for building, fences, ladders, and car parts. You see it where price matters and the weather is not too rough.

- Stainless steel is used in kitchens, hospitals, boats, and chemical plants. Pick it when you need strong rust protection and a shiny look.

Tip:

If your project is near the sea or in a wet place, use stainless steel for the best results. For most buildings away from saltwater, galvanized steel gives good value and works well.

Here is a quick list of where you might use each one:

| Application Category | Typical Uses of Galvanized Steel | Typical Uses of Stainless Steel |

|---|---|---|

| Structures | Balconies, staircases | Bridges, high-rise supports |

| Outdoors | Fences, walkways, sidings | Marine railings, sculptures |

| Automotive | Car body panels, frames | Exhaust pipes, trim |

| Construction | Roofing, guardrails, framing | Architectural panels, fasteners |

| Food/Medical | Not recommended | Kitchen equipment, surgical tools |

You also find galvanized steel in solar panel mounts, farm buildings, and HVAC systems. Stainless steel is best for food making, medicine, and places that need to be very clean.

When you think about galvanized steel vs stainless steel, remember your budget, the weather, and how long you want your project to last. This will help you pick the best one for your needs in 2025.

Galvanized Steel

Production

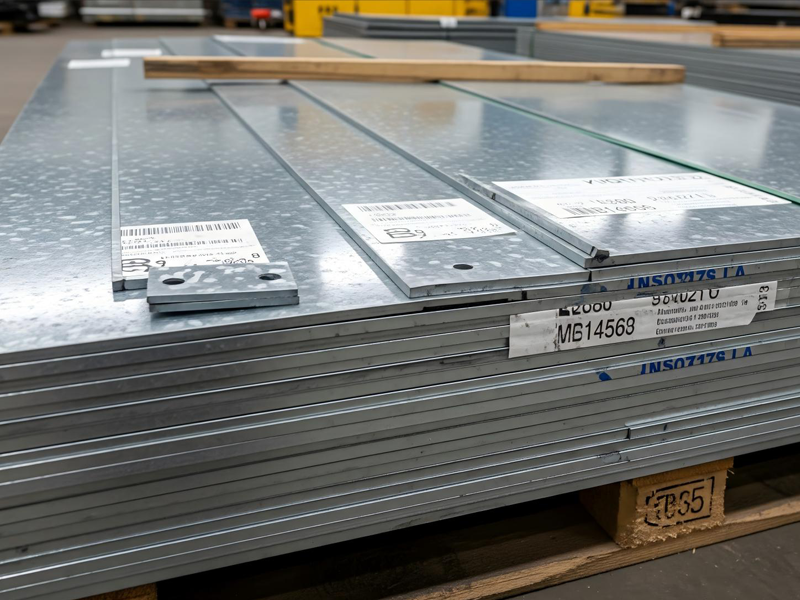

Have you ever wondered how galvanized steel gets its tough layer? First, workers clean the steel to get rid of dirt and grease. This step is needed so the zinc will stick well. Here are the main steps:

- Surface Preparation: Workers wash and treat the steel to remove anything on it.

- Immersion in Molten Zinc: The clean steel goes into very hot zinc, about 830°F. The zinc sticks to the steel.

- Alloying and Solidification: When the steel comes out, the zinc cools down. This makes a strong layer on top.

- Cooling and Inspection: The steel cools more and gets checked for how thick and good the coating is.

- Optional Post-Treatment: Sometimes, the steel gets extra steps to look better or fight rust more.

These steps help make galvanized steel strong and useful for many jobs.

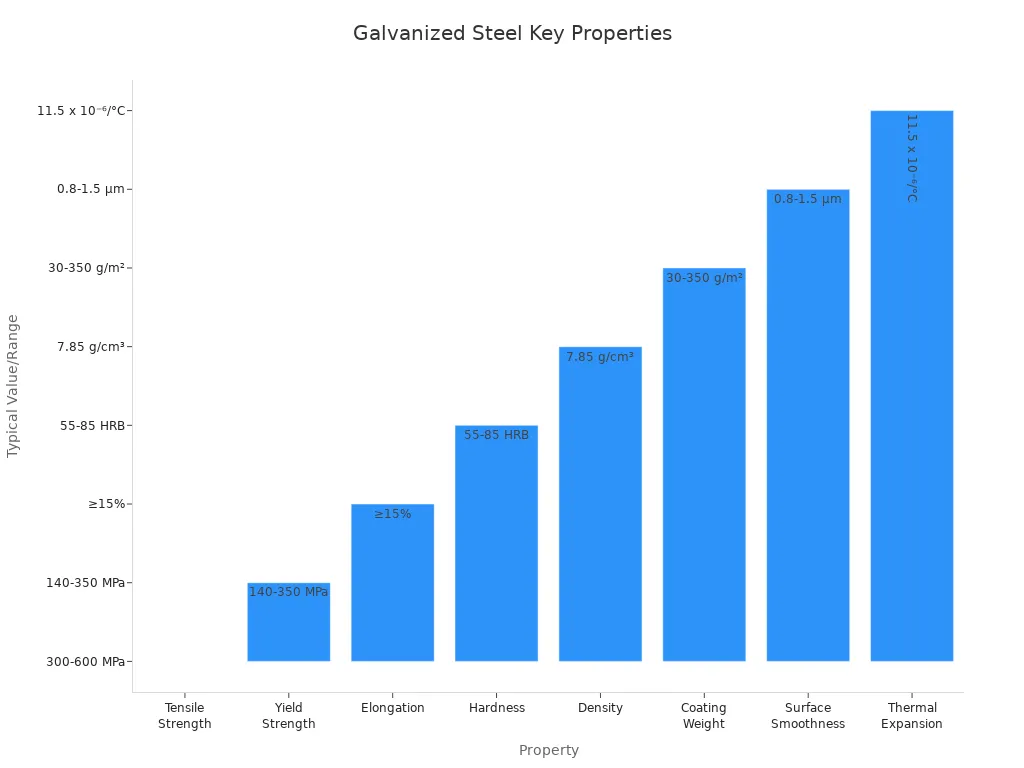

Properties

Galvanized steel gives you both strength and protection. The zinc layer keeps rust and damage away. Here are some important things to know:

- Tensile Strength: It is between 300 and 600 MPa. This means it does not bend or break easily.

- Yield Strength: It is from 140 to 350 MPa. The steel can hold heavy things before it bends.

- Ductility: The steel can bend and shape, but the zinc might crack if bent too much.

- Hardness: The top is hard enough for most jobs, but the zinc is softer than the steel.

- Abrasion Resistance: The coating stops scratches, but lots of rubbing can wear off the zinc.

- Weldability: You can weld it, but you need fresh air because zinc fumes are not safe.

Here is a table that shows these properties and what they mean:

| Property | Typical Value | What It Means for You |

|---|---|---|

| Tensile Strength | 300-600 MPa | Strong for building and auto parts |

| Yield Strength | 140-350 MPa | Handles heavy loads |

| Elongation | ≥15% | Can bend without cracking |

| Hardness | 55-85 HRB | Good balance of hard and flexible |

| Surface Coating | 30-350 g/m² | Adjustable rust protection |

Galvanized steel lasts a long time outside or in factories. The zinc layer helps stop rust, so your projects stay strong.

Tip:

If you want to save money but still need good protection, galvanized steel is a great choice.

Uses

You see galvanized steel in lots of places every day. It is cheap and fights rust, so many people use it. Here are some ways it is used:

| Industry | Uses and Benefits |

|---|---|

| Automotive | Car bodies, frames, and parts that need rust protection and good paint adhesion |

| Solar | Frames and mounts for solar panels that stay strong outdoors |

| Agriculture | Equipment and buildings that face harsh weather and chemicals |

| Construction | Fences, roofs, staircases, balconies, and outdoor structures |

| Telecommunication | Phone wiring and equipment boxes that need to last with little maintenance |

You might see galvanized steel in fences, walkways, and big building frames. Farmers use it for barns and tools. Car makers use it for body parts to stop rust. Solar companies use it for mounts that face rain and sun.

Galvanized steel is a smart pick when you want something strong, tough, and rust-proof without spending a lot. Its many uses make it popular in building, farming, and green energy.

Stainless Steel

Production

Have you ever wondered how stainless steel is made? It starts with scrap metal and raw materials like iron ore, chromium, and nickel. Workers melt these in a furnace at very high heat. The melted mix becomes a new metal with special traits. This is different from galvanized steel, which only has a zinc layer. Stainless steel has rust protection inside the metal.

Here is how workers make it:

- They gather and sort scrap metal and other materials.

- The mix goes into an electric arc furnace to melt.

- The melted steel gets cleaned to take out bad stuff.

- Chromium and other things like nickel or molybdenum are added.

- The hot mix is shaped into slabs or billets.

- The steel cools and is rolled or shaped into sheets, bars, or other items.

This way, the metal makes a layer that can fix itself. If the surface gets scratched, the chromium reacts with air and repairs the spot. This makes it last longer than just a coating.

Note:

Stainless steel keeps rust away because of what it is made of, not just a layer on top. So, it stays protected even if the surface gets scratched.

Properties

Stainless steel is special because of its great features. The most important thing is it has a lot of chromium, at least 10.5%. This chromium makes a thin layer that stops rust. Other things like nickel, molybdenum, and nitrogen help make it stronger and better against heat and chemicals.

Here are some main features:

- It fights rust about 200 times better than regular steel.

- It is very strong and can be used for tough jobs.

- Stainless steel can handle very hot or very cold places.

- It is easy to clean and does not need much care.

- It looks shiny and modern, which many people like.

- You can recycle it, so it is good for the planet.

There are four main kinds of stainless steel:

| Type | Main Features | Common Uses |

|---|---|---|

| Austenitic | Not magnetic, lots of chromium and nickel, best at stopping rust | Kitchenware, airplanes, foodservice |

| Ferritic | Magnetic, bends well, okay at stopping rust | Cars, home appliances |

| Martensitic | Magnetic, very strong and tough | Surgical tools, knives, medical |

| Duplex | Mix of austenitic and ferritic, very tough | Chemical plants, boats |

These types help you pick the right stainless steel for your job, whether you need strength, rust protection, or a certain look.

Uses

You see stainless steel in many places every day. It is strong and looks clean, so many businesses use it. In 2025, most stainless steel is used in Asia-Pacific, like China, India, Japan, and South Korea. These places use it for building, cars, and making things. North America and Europe also use a lot, mostly for cars and factories.

Here are some common ways people use stainless steel:

- Foodservice gear like sinks, counters, and fridges

- Food trays, utensils, and prep tables

- Medical tools, surgical gear, and hospital furniture

- Medical implants and devices for patient care

- Building fronts, bridges, and art

- Car parts like exhaust pipes and trim

- Chemical and boat equipment that faces tough weather

Tip:

If you need something for food, medicine, or boats, stainless steel is best for keeping things clean, strong, and lasting a long time.

Stainless steel is useful for many jobs that need to be clean, safe, and last a long time. If you work with food, medicine, or building, you get a lot of good things from using it.

Corrosion Resistance

When you pick a metal, think about how it fights rust. Both galvanized steel and stainless steel stop rust, but they do it in different ways. They also work better or worse depending on where you use them.

Galvanized Steel Performance

Outdoor

Galvanized steel is good for many things outside. The zinc layer keeps water and air away from the steel. This helps the steel last a long time outdoors. How long it lasts depends on the ground, air, and weather. For example:

- In rough soil with good air, it can last 35 to 50 years, even if the weather is bad.

- In soil that does not cause much rust, it can last more than 75 years.

- In fresh water, hard water helps make a shield on the zinc, so it rusts more slowly.

Note: If the zinc gets scratched or broken, the steel can rust faster. This happens more in hot or wet places.

Marine

The ocean is very hard on metals. Saltwater has things that make most metals rust fast. Galvanized steel helps some, but it does not last long in salty water. In cool seawater, the zinc makes a shield, but in warm seawater, the shield goes away faster. The zinc layer might last 2-3 years where waves hit it, and more than 5 years if it stays underwater. Magnesium and calcium in the water slow rust a little, but not enough for long-term use.

Stainless Steel Performance

Outdoor

Stainless steel is great at stopping rust outside. The chromium in it makes a thin layer that fixes itself if it gets scratched. This means you do not need to worry about rust, even if it gets a mark. Grade 304 stainless steel works well outside, like on buildings and benches. It fights rain, wet air, and dirty air better than galvanized steel.

Here is a table that shows how some stainless steel grades compare:

| Grade | Corrosion Resistance | Typical Use |

|---|---|---|

| 304 | Good | Outdoor furniture, kitchen equipment |

| 316 | High | Marine hardware, chemical plants |

Marine

If you need metal for the ocean, stainless steel is best. Grade 316 stainless steel has molybdenum, which helps it fight salt and other things in seawater. This makes it great for boats, docks, and buildings near the sea. Even in places with lots of waves or underwater, 316 stainless steel stays strong and looks good for many years. People use it for boat railings, medical tools, and chemical plants because it stops rust so well.

Tip: If your project is near the ocean or in salty air, always use 316 stainless steel. It will last the longest and work the best.

Strength and Durability

Galvanized Steel Strength

Galvanized steel is strong and not too expensive. The zinc coating does not make the steel stronger, but it helps protect it. This layer keeps the steel from rusting. You can look at the table below to see how strong galvanized steel is compared to other steels:

| Material Type | Yield Strength (ksi) | Ultimate Tensile Strength (ksi) |

|---|---|---|

| ASTM A653 Mild Hot Dipped Galvanized Steel | 36.3 | 58.0 – 79.8 |

| Typical Galvanized Steel (various grades) | 35 – 49 | 47 – 57 |

| Hot Rolled Steel (industry typical) | 25 – 42 | 40 – 55 |

| Cold Rolled Steel (industry typical) | 17 – 40 | 30 – 50 |

| SAE J2340 HSLA Steel (various grades) | 43.5 – 98.6 | 56.5 – 94 |

Galvanized steel is as strong or even stronger than many other steels. This makes it good for building things like frames, fences, and car parts. The zinc layer helps the steel last longer by stopping rust.

Stainless Steel Strength

Stainless steel is very strong and lasts a long time. Different types have different strengths. The table below shows how strong some stainless steel grades are:

| Stainless Steel Grade | Condition | Tensile Strength (psi) | Yield Strength (psi) |

|---|---|---|---|

| 201 | Annealed | ~115,000 | ~55,000 |

| 301 | Annealed | ~110,000 | ~40,000 |

| 304 | Annealed | ~85,000 | ~35,000 |

| 316 | Annealed | ~85,000 | ~35,000 |

Stainless steel can hold more weight before breaking than galvanized steel. Some types, like 301 when hardened, are even stronger. This is why people use stainless steel for bridges, boats, and medical tools. It is strong and lasts a long time.

Tip: Always check which type of stainless steel you need. The right type gives you the best strength and durability.

Longevity

How long your project lasts depends on where you use it and what it is made of. Galvanized steel can last 50 years or more outside if the weather is not too bad. Inside, it might last up to 100 years. In tough places, like near the sea or in factories, it may only last 20 years or less.

Stainless steel lasts even longer than galvanized steel. It has chromium, which helps stop rust. This means it stays strong and looks good for many years, even in hard places. Stainless steel costs more, but it is tough and does not need much care.

- Galvanized steel is good for most outdoor jobs and does not cost a lot.

- Stainless steel is best for wet, salty, or chemical-filled places. It is the strongest and lasts the longest.

Note: If you want your project to last a very long time, especially in a hard place, stainless steel is the best choice.

Cost

Initial Cost

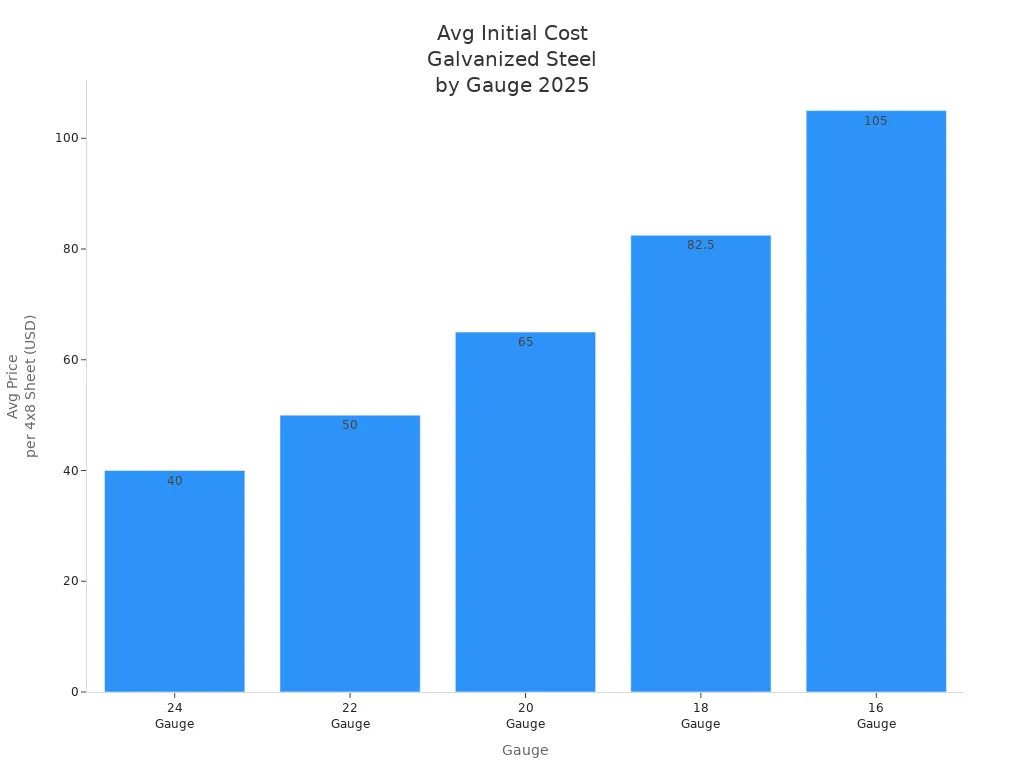

When you compare galvanized steel and stainless steel, you notice a big difference in price. Galvanized steel costs much less at the start. You can see the price for galvanized steel sheets in the table below:

| Gauge | Thickness (inches) | Approximate Price per 4×8 Sheet (USD) |

|---|---|---|

| 24 | 0.0239 | 35–45 |

| 22 | 0.0299 | 45–55 |

| 20 | 0.0359 | 60–70 |

| 18 | 0.0478 | 75–90 |

| 16 | 0.0598 | 95–115 |

You pay much more for stainless steel. In 2025, stainless steel costs about four to five times more than galvanized steel. If you have a small project or a tight budget, galvanized steel helps you save money at the beginning.

Tip: For large projects where cost matters most, galvanized steel gives you good value upfront.

Long-Term Value

You need to think about more than just the first price. Galvanized steel saves you money at first, but you may spend more later. The zinc coating on galvanized steel can wear off, especially in tough places like near the ocean or in factories. You might need to fix or replace it every 5 to 7 years. This adds to your total cost.

Stainless steel costs more at the start, but it lasts much longer. Its strong resistance to rust means you do not need to fix it often. You save money over time because you do not need to replace it or do much maintenance. Stainless steel works best in harsh or coastal areas. Its durability makes it a smart choice for projects that need to last many years.

Note: If you want your project to last a long time with little worry, stainless steel gives you better long-term value.

Maintenance Cost

Maintenance is another important cost to consider. Galvanized steel needs regular checks, cleaning, and sometimes new coating. In rough environments, you may need to repaint or re-treat it every 5 to 10 years. This means you spend more on upkeep.

Stainless steel needs very little care. You may only need to clean it sometimes. Over a 10-year period, you spend much less on maintenance for stainless steel. Galvanized steel may need touch-ups and repairs, which add up over time.

Here is a quick list to help you compare:

- Galvanized steel needs more maintenance in harsh places.

- Stainless steel lasts for decades with almost no maintenance.

- For projects near the ocean or with lots of rain, stainless steel is the best choice.

- If you want to save money now and your project is not in a tough spot, galvanized steel works well.

You should look at both the initial cost and the cost over time. Stainless steel may cost more at first, but its durability and low maintenance make it a better deal for long-term projects.

Maintenance

Galvanized Steel Care

You can keep galvanized steel strong and rust-free with the right care. Regular cleaning and inspections help you spot problems early and extend the life of your steel. Here are some best practices:

- Clean the surface with water and mild soap, like laundry soap or car shampoo. Use a soft cloth or sponge. Avoid steel brushes or anything rough that could scratch the zinc layer.

- For tough stains, use a household ammonia cleaner. Always rinse the area well after cleaning.

- Remove hardened debris, such as cement or mortar, as soon as possible. Use hand tools carefully and oxalic acid if needed, then rinse thoroughly.

- After washing, dry the surface completely. Do not let water puddle, as this can cause rust stains.

- Avoid letting galvanized steel touch copper or brass. If you cannot avoid contact, use an insulating barrier to prevent galvanic corrosion.

- If you see any damage to the zinc coating, repair it right away. Use zinc-rich paint, zinc alloy rods, or powders. Replace the part if you cannot repair it.

- Set up regular inspections, at least twice a year. Check roofs, seams, and areas where water collects.

Tip: Using a duplex system—adding paint or powder coating over galvanized steel—can make it last much longer. This extra layer protects the zinc and can double the lifespan of your steel.

You can also follow a maintenance schedule like the one below:

| Maintenance Task | Frequency | Details |

|---|---|---|

| Visual Inspection | Quarterly/Biannual | Check for rust, scratches, and coating damage |

| Cleaning | Annually | Use mild detergents, rinse, and dry thoroughly |

| Repairs | As needed | Fix cracks, holes, and damaged coatings right away |

| Paint Touch-Ups | Every 5-10 years | Apply zinc-rich paint to worn areas |

Stainless Steel Care

You can keep stainless steel looking new and prevent rust by following a few simple steps. The passive chromium oxide layer on the surface protects the metal, but you need to help maintain it.

- Always wear clean gloves when handling stainless steel. This prevents fingerprints and keeps the surface clean.

- Use only stainless steel tools and parts to avoid contamination from other metals.

- Keep stainless steel away from carbon steel and iron. Do not weld, cut, or grind carbon steel near it.

- Clean the surface every six months with a soft nylon brush and mild soap. Rinse with clean water and dry with a soft cloth.

- For stains like limescale or cement, use diluted vinegar or a phosphoric acid-based cleaner. Rinse and dry well.

- Never use steel wool or abrasive pads. These can scratch the surface and cause rust.

- For minor rust spots, apply a lubricant like WD-40, then rinse. For more serious corrosion, use a phosphoric acid-based cleaner and neutralize with an alkaline cleaner.

- If you see heat stains, use a metal polish and treat the whole surface to keep the color even.

- For severe corrosion, ask a professional about passivation. This process restores the protective layer.

Note: Always avoid cleaners with strong acids, bases, or chlorides. These can damage the protective layer and cause pitting.

By following these steps, you help stainless steel stay strong, shiny, and rust-free for many years.

Appearance

Galvanized Steel Finish

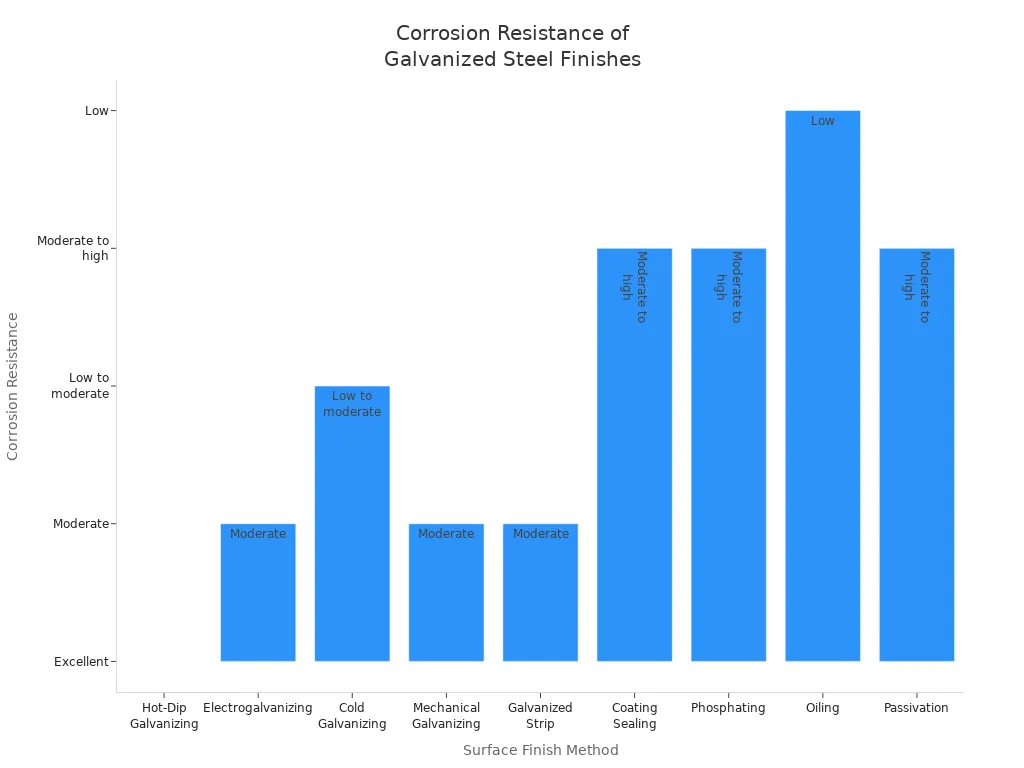

Galvanized steel can look different based on how it is made. Hot-dip galvanizing gives a dull, rough surface. Electrogalvanizing makes the steel look smooth and shiny. Cold galvanizing uses zinc-rich paint, so it can be colored and smooth. Each finish changes how the steel looks and how well it stops rust.

Here is a table that shows the main types of galvanized steel finishes and what you can expect from each:

| Method | Coating Type | Appearance | Corrosion Resistance | Typical Uses |

|---|---|---|---|---|

| Hot-Dip Galvanizing | Zinc coating | Matte, rough | Excellent | Construction, infrastructure |

| Electrogalvanizing | Zinc coating | Smooth, shiny | Moderate | Automotive, appliances |

| Cold Galvanizing | Zinc-rich paint | Smooth, colored | Low to moderate | Repairs, maintenance |

| Mechanical Galvanizing | Zinc coating | Variable | Moderate | Fasteners, hardware |

| Galvanized Strip | Continuous zinc | Smooth | Moderate | Roofing, panels |

Extra treatments like sealants, oil, or phosphating can change the look. These can make the steel glossy, matte, or clear. They also help stop rust.

How the surface looks is important for both style and use. Sometimes, you might see rough spots or stains. These can happen from sand, welding, or storage. Most of these do not stop the steel from fighting rust, but they can make it look less shiny. If you see bare spots or bumps, fix them to keep the steel strong.

Tip: Pick electrogalvanized steel if you want it smooth and shiny. For the best rust protection, hot-dip galvanizing is best, even if it looks rough.

Here is a chart that compares the corrosion resistance of different galvanized steel finishes:

Stainless Steel Finish

Stainless steel comes in many finishes. Each one changes how it looks and how easy it is to clean. Some finishes are rough and dull. Others are shiny like a mirror.

Here is a table that shows the most common finishes and what they offer:

| Finish Type | Processing Method | Surface Look | Typical Uses | Aesthetic Impact | Durability Impact |

|---|---|---|---|---|---|

| No. 0 | Hot rolled, annealed | Rough, matte | Industrial ovens, heat exchangers | Low visual appeal | Harder to clean |

| No. 1 | Hot rolled, pickled | Dull, non-reflective | Tanks, structural parts | Basic, less smooth | Moderate corrosion resistance |

| No. 2B | Cold rolled, polished | Smooth, slightly shiny | Appliances, medical equipment | Clean, modern look | Good corrosion resistance |

| No. 4 | Brushed, satin | Fine lines, satin finish | Architecture, kitchen equipment | Decorative, popular | Needs more cleaning |

| No. 8 | Mirror polished | Highly reflective, mirror | Luxury interiors, signage | Brilliant shine | Easiest to clean, best resistance |

A No. 2B finish is smooth and easy to clean. It has a soft shine and works well for kitchens and hospitals. The No. 4 finish has fine lines and looks like satin. You see it on appliances and building panels. The No. 8 finish is very shiny, like a mirror. It looks great, is easy to clean, and helps stop rust.

Note: Smoother finishes are easier to keep clean and shiny. Mirror finishes also help stop rust by removing tiny cracks.

You can pick the finish that fits your style and needs. Stainless steel gives you many choices, from tough and plain to bright and fancy.

Environmental Impact

Sustainability

You might wonder how picking galvanized steel or stainless steel affects the earth. Both have good and bad points for the environment.

Galvanized steel uses chemicals like zinc and hydrochloric acid when made. These can pollute the air and create dangerous waste if not handled properly. Dirty water from making galvanized steel can hurt fish and plants in rivers. The process can also add to smog and acid rain. Factories can help by using safer methods and cleaning water before letting it go.

Galvanized steel is strong and fights rust well. This means you fix or replace it less, so you use less energy and make less pollution over time. Corbec’s reports show that galvanized steel rebar causes less global warming than stainless steel rebar. Stainless steel needs more special metals, which produce more greenhouse gases when made. Galvanized steel parts, like hollow sections and plates, have about 15% less global warming effect than most other steel.

Stainless steel is made from iron, chromium, nickel, and other metals. Making it uses more energy and resources because of the mixing process. New electric arc furnaces help lower energy use and pollution. Stainless steel lasts a long time and does not rust, so you do not need to change it often. This long life means it is better for the earth over many years.

🌱 Tip: Pick steel made with electric arc furnaces to cut carbon pollution. Try to buy products with lots of recycled steel for a greener choice.

Recycling

Recycling steel helps save nature’s resources. You can recycle both galvanized steel and stainless steel without losing quality. The zinc on galvanized steel can also be taken off and used again.

Modern plants recycle zinc ash and dross, clean hydrochloric acid, and reuse flux. They use little water, and clean water gets used again, which keeps pollution low. Better energy use and controls make the process cleaner.

Most new structural steel, including galvanized steel, has about 93% recycled steel. When it is old, about 98% gets recycled, saving lots of iron ore, coal, and limestone. Electric arc furnaces use mostly recycled steel and electricity, which can come from green sources. This way cuts carbon pollution by up to 75% compared to old blast furnaces.

Stainless steel is also fully recyclable. You can melt it and use it again without losing strength or rust protection. Recycling stainless steel saves energy and raw materials, which helps the planet.

| Material | Recycled Content in New Products | End-of-Life Recycling Rate | Key Benefits |

|---|---|---|---|

| Galvanized Steel | ~93% | ~98% | Zinc recovery, long lifespan |

| Stainless Steel | ~60% | ~100% | No quality loss, durability |

♻️ Note: Recycling steel saves energy, cuts greenhouse gases, and protects nature. You help the earth every time you pick recycled steel for your project.

Applications

Galvanized Steel Scenarios

Galvanized steel is used when you want to save money. It works well if the weather is not too harsh. The zinc coating keeps the steel safe from rain and sun. People use galvanized steel for fences, roofs, and beams in buildings. You also see it in outdoor electrical boxes and farm tools. HVAC systems often use galvanized steel, too.

Car makers use galvanized steel for frames and body panels. It is also used for exhaust pipes. The zinc layer helps stop rust, even if the steel gets scratched. If you need something strong and cheap, galvanized steel is a good choice. It is best for places with normal weather and some wear.

Tip: Pick galvanized steel for building or car parts if you do not need the best rust protection. It saves money and works well.

| Feature | Why Choose Galvanized Steel? |

|---|---|

| Cost | Good for big jobs and repairs. |

| Durability | Stays strong in rain and snow. |

| Maintenance | Needs checks and new coating sometimes. |

| Common Uses | Fences, HVAC, outdoor boxes, farm tools, car frames, and exhaust pipes. |

| Best Environments | Works best away from salt, chemicals, or the ocean. |

Stainless Steel Scenarios

Stainless steel is great when you need strong rust protection. It lasts a long time in tough places. You see stainless steel in boats, chemical plants, and food factories. It is also used for bridges and fancy building fronts. Car makers use it for exhausts and trim that face heat or salt.

Stainless steel is good for buildings that need to last many years. Hospitals and kitchens use it because it stays clean. If you work near the sea or with chemicals, stainless steel is safest. It costs more at first, but you save money later because it does not need much fixing.

Note: Stainless steel is best for tough places, shiny looks, and where safety and cleanliness matter.

Decision Guide

You should pick galvanized steel or stainless steel based on your needs. Use this guide to help you choose:

| Decision Criteria | Choose Galvanized Steel If… | Choose Stainless Steel If… |

|---|---|---|

| Budget | You need to spend less now. | You can pay more for long-term savings. |

| Environment | The area is dry or only a little wet. | The area is near the sea, chemicals, or is very wet. |

| Maintenance | You can check and fix as needed. | You want almost no care needed. |

| Appearance | A dull, plain look is fine. | You want a shiny, smooth finish. |

| Lifespan | Short or medium use is okay. | You need it to last for many years. |

| Application Type | Building, cars, farming, or outdoor gear. | Food, medical, boats, or fancy buildings. |

- Galvanized steel is good for car parts that get scratched.

- Stainless steel is better for car parts near salt or chemicals.

- Always think about your budget, the weather, and how long you want your project to last before you choose.

You have learned how galvanized steel and stainless steel are different. Use the decision guide to help you pick the right one. Follow these steps:

- Look at your budget and where you will use the steel.

- Think about what your project needs.

- Ask suppliers for help and advice.

Choose the steel that works best for your project in 2025. Make sure it matches your goals and will last a long time.

FAQ

Galvanized steel has a zinc layer that stops rust. Stainless steel has chromium, which forms a layer that fixes itself. This layer helps stainless steel fight rust better and last longer.

Do not use galvanized steel for food or medical tools. The zinc can come off and get on surfaces. Stainless steel is safer because it stays clean and does not wear away.

Stainless steel is usually stronger than galvanized steel. Some types of stainless steel are even stronger. Galvanized steel’s strength depends on the steel underneath.

Use galvanized steel for things like fences, car frames, and outdoor buildings. It costs less and works well where the weather is not too harsh. Stainless steel is better for tough places or if you want it to look nice.

Stainless steel, especially grade 316, does not rust easily near the ocean. Chromium and molybdenum help protect it from saltwater. Galvanized steel will not last as long by the sea.

Stainless steel is used in airplanes because it is strong and fights rust. It can handle heat and stress very well. Galvanized steel is not good enough for airplane parts.