Here are the top 10 ways people use galvanized steel in 2025:

- Building structures

- Roofing and cladding

- Car bodies

- Frames and parts

- Solar mounts

- Wind towers

- Bridges and roads

- Guardrails

- Precision parts

- Fencing

Galvanized steel is highly valued because it resists rust, making it ideal for applications requiring durable materials. Nearly 70% of new cars incorporate galvanized steel. The construction sector accounts for about half of all galvanized steel usage worldwide. For manufacturers, partnering with a reliable metal parts manufacturer that specializes in cnc machining and cnc turning ensures precise, high-quality components tailored to exact specifications.

| Sector/Region | Statistic/Projection | Year/Period |

|---|---|---|

| Automotive Industry | Nearly 70% of new cars contain galvanized steel | 2025 (forecast) |

| Construction Sector | Utilizes about half of all galvanized steel | Recent data |

Table of Contents

Key Takeaways

- Galvanized steel does not rust easily and lasts a long time. This makes it great for buildings, cars, and roads. Using galvanized steel means you do not need to fix or replace things as often. This helps you save money over the years. Many businesses use galvanized steel because it is strong and tough. These include building, car, and clean energy companies. New coatings and digital tools make galvanized steel parts better and more exact. Picking galvanized steel keeps your things safe and helps make projects safer and stronger.

Construction

Building Structures

Buildings need to last a long time. Galvanized steel helps make this happen. It can handle bad weather, water, and chemicals. Builders use it for beams, columns, and frames. Hot dip galvanized reinforcement has lasted over 50 years in many places. People trust it because it stays strong and does not rust. Tests show galvanized steel bars are as strong as regular steel bars. The bond strength difference is less than 2%. This means the building stays just as safe.

When you put galvanized steel in concrete, it gets a special coating. This coating keeps the steel safe from rust. In places with lots of salt or chemicals, this is very important. Galvanized steel rebar can handle two to three times more chloride than carbon steel. This gives better protection in hard conditions. Big projects like the Mario Cuomo Bridge use a lot of galvanized reinforcement. These projects want to last 100 years. Engineers trust this material for big jobs.

Tip: Pick galvanized steel for your next building if you want it to last a long time and need less fixing.

Roofing and Cladding

Roofs and cladding need to stand up to rain, sun, and wind. Galvanized steel does this well. It does not rust and looks good for many years. Builders use it for roofs, wall panels, and ceilings. Galvanized steel studs in walls and ceilings meet fire and strength rules. You get safety and strength together.

Galvanized steel also keeps cracks smaller when under weight. This helps your building stay strong and tight. You can use it inside and outside. If you want a roof or wall that lasts, galvanized steel is a good pick.

Automotive

Car Bodies

Cars need to last a long time. Car makers use special steel coatings to stop rust and damage. This helps your car look new and stay safe. When you drive in rain or snow, the steel does not rust. You do not need to worry about rust on the panels. This means you fix your car less and save money.

Automakers pick this steel because it is strong but not heavy. Lighter cars use less gas and make less pollution. You get better gas mileage and help the planet. Most new cars in 2025 have these steel bodies. They meet tough rules for safety and strength.

Note: If you want a strong car that looks nice, check if it uses this steel in its body.

Frames and Parts

Your car’s frame keeps you safe. The frame holds up the car and helps in crashes. Engineers use coated steel for frames because it is tough and does not bend. This makes you feel safe when you drive.

Parts like bumpers, brackets, and suspension arms use this steel too. These parts get shaken and hit a lot. The steel’s coating helps them last longer, even when it is rough. You do not need to replace them as much and your ride is smoother.

| Automotive Part | Benefit of Coated Steel |

|---|---|

| Frame | High strength, impact safety |

| Bumper | Corrosion resistance |

| Suspension Arm | Long-lasting performance |

You can trust cars made with these materials to be safe, reliable, and worth your money.

Renewable Energy

Solar Mounts

You want your solar panels to last for years. The right mounting system makes a big difference. Most ground-mounted solar systems use steel with a special coating to stop rust. This keeps your panels safe from rain, wind, and sun. In 2025, the market for PV mounting systems will reach $33.9 million. Experts expect this number to grow fast, hitting $166.6 million by 2035. That means more people trust these systems for their solar projects.

| Metric | Value | Relevance to Solar Mounts |

|---|---|---|

| PV Mounting System Market Size (2025) | USD 33.9 million | Shows strong demand |

| PV Mounting System Market Size (2035) | USD 166.6 million | Rapid growth expected |

| CAGR (2025-2035) | 17.46% | High growth rate |

| Ground-Mounted Systems Market Share (2025) | 58% | Most use steel mounts |

| Fixed PV Mounting Systems Market Share (2025) | 60% | Common technology |

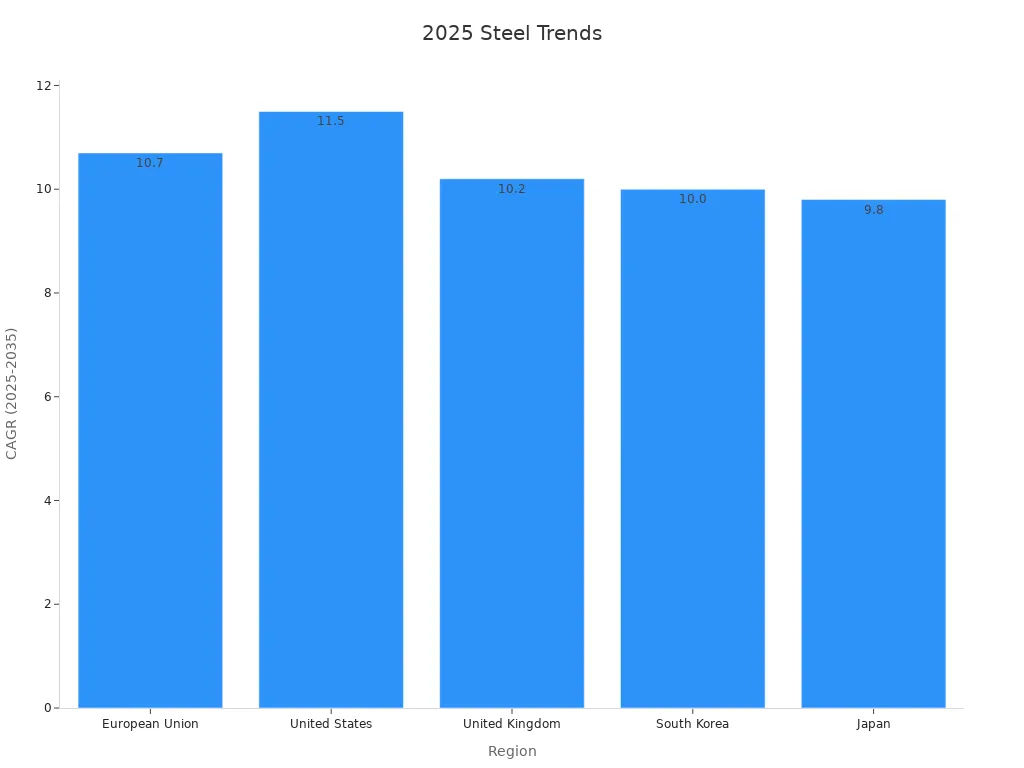

You get more value from your investment because these mounts last longer and need less fixing. Many countries, like the United States and the European Union, see over 10% yearly growth in solar projects. This growth means you can find better, more reliable mounting options for your solar panels.

Tip: Choose mounts with a rust-resistant finish to keep your solar panels secure and working for years.

Wind Towers

Wind towers face tough weather every day. You need materials that can handle rain, snow, and strong winds. Steel with a protective coating stands up to these challenges. The hot-dipped galvanizing market will grow from $88.6 billion in 2024 to $155.7 billion by 2034. This steady rise shows that more wind projects use these strong materials.

| Metric | Value | Significance |

|---|---|---|

| Hot-Dipped Galvanizing Market Size (2024) | USD 88.6 billion | Baseline for wind tower materials |

| Hot-Dipped Galvanizing Market Size (2034) | USD 155.7 billion | Strong growth ahead |

| CAGR (2024-2034) | 5.8% | Reliable increase |

You get towers that last longer and need less upkeep. This saves you money and keeps your wind turbines running. Many wind farms in North America and Europe use these towers because they trust the strength and long life of the material.

Infrastructure

Bridges and Roads

People use bridges and roads every day. These need to be strong and safe for a long time. Engineers pick steel with special coatings for these jobs. This steel can handle bad weather, lots of cars, and even big storms. Using this material means bridges last longer and need fewer repairs.

Here are some real project results:

| Project / Example | Key Outcome | Support for Durability and Cost-Effectiveness |

|---|---|---|

| Stearns Bayou Bridge, Michigan | No maintenance needed for over 50 years | Lasts long and saves money |

| Mercer County Hot-Dip Galvanized Bridge | Fast to build, fights rust, saves money | Good value and strong |

| 1994 Northridge Earthquake, California | 96% of steel bridges stayed safe | Handles disasters, less fixing needed |

| Assonet River Railroad Bridge, Massachusetts | Built in just 11 days | Quick work, less labor, strong bridge |

| Iowa County Buried Steel Plate Arch Bridge | Still working well after 82 years | Lasts a very long time |

Steel does not change shape or get smaller as time passes. This keeps bridges strong and safe. Coatings like galvanizing stop rust and damage. Groups like AASHTO and the American Galvanizers Association say these coatings help bridges last longer and cost less.

Tip: If you plan a bridge or road, use steel with a coating. You will fix it less and keep it safe for many years.

Guardrails

Guardrails keep drivers safe on the road. They must take hits, bad weather, and lots of sun and rain. Steel with a coating makes guardrails last longer and stay strong.

You see these guardrails on highways and busy roads. They do not rust fast, so cities do not replace them often. This saves money and keeps people safe. Many states use steel guardrails because they are safe and save money over time.

- Guardrails with coatings do not rust easily.

- They stay strong for many years.

- These barriers help protect people on the road.

Note: Picking steel guardrails means fewer fixes and safer roads for everyone.

Industrial Components

Precision Parts

Machines need precision parts to work well. In 2025, factories want parts that are the right size and shape. These parts must also be strong and last a long time. AFI Industrial Co., Ltd. makes custom metal parts for many uses. They use CNC turning and milling to shape metal. Their machines are run by computers for better accuracy. This lets them make parts with very small errors. Every part fits just right.

AFI Industrial checks each part many times. They look at the raw metal and the finished part. Their engineers use special tools like Coordinate Measuring Machines (CMM). These tools help them check every detail. This careful work means you get parts that work well in hard jobs.

AFI Industrial offers many services. They do sheet metal fabrication, stamping, and metal bending. You can get all these services in one place. This saves you time and money. You get your order fast and the quality stays the same, no matter how big or small.

Galvanized Steel Benefits

Galvanized steel gives you many good things for industrial parts. The hot-dip galvanizing process has steps like degreasing, pickling, and fluxing. These steps help the zinc stick to the steel. If the steel is not clean, the zinc will not bond. Problems show up right away if there are defects. This helps stop coating problems and keeps your parts strong.

New control systems make the coating even better. Digital tools check the zinc thickness with tiny mistakes, only 0.1%. You get even coatings from 0.01 mm to 4 mm. This meets tough rules used around the world. Engineers use live data to change the process. This cuts down on mistakes and keeps the quality high.

Researchers made the coating better by adding antimony to zinc-magnesium-aluminum alloys. This slows rust by 43%. Your parts last longer and fight rust and damage. You get parts that work well, even in rough places.

Tip: Pick precision galvanized steel parts for your next project. They last longer and need less fixing.

Agriculture

Equipment

Farmers need tools that work hard and last a long time. If you pick metal equipment with a zinc coating, it will not rust easily. This coating makes a shield that keeps out rain, mud, and chemicals. Your tractors, plows, and bins stay in good shape for many years. Even in bad weather, your machines keep working well.

Farmers save money because these tools do not break as much. You spend less time fixing things and more time working on your farm. The zinc layer helps your tools last over 50 years if you use them right. You buy them once and they work well every season.

Tip: Choose equipment with a zinc coating if you want it to last longer and need fewer repairs.

Fencing

It is important to keep animals safe and your land secure. Fences made from coated steel wire are strong in all kinds of weather. These fences do not sag, break, or rot like wood fences. Your animals stay inside, and wild animals stay out.

- Barbed wire fencing made from coated mild steel can stop up to 80% more escapes than wooden fences.

- High-tensile steel wire fencing is very strong, does not sag in bad weather, and needs less fixing than regular wire fences.

- Woven wire fencing keeps animals in and wild animals out, and lasts longer than wood fences.

- Hog panels made from welded coated steel do not sag and hold animals well, even in busy areas.

- Coated steel fencing needs fewer repairs, lasts longer, and works better outside than wood fences, even if it costs more at first.

You can count on these fences to keep your animals and crops safe every year. You also save money because you do not have to fix or replace them as often.

Utilities

Poles

You use utility poles for power, lights, and phones every day. These poles need to be strong in all kinds of weather and soil. Steel poles with a zinc coating do not rust easily. The coating makes a shield that keeps out water and chemicals from the ground.

How long the pole lasts depends on the soil. In rough soils, these poles last about 35 to 50 years. In better soils, they can last more than 75 years. The table below shows how soil changes the life of coated steel poles:

| Soil Condition | Corrosivity Level | Estimated Service Life (Years) | Notes |

|---|---|---|---|

| Harsh Soil | High | 35 to 50 | Coarse, textured soils with poor aeration; zinc coating thickness 3.9-5 mils |

| Less Corrosive Soil | Low | 75 or more | Better aeration and drainage; longer zinc coating durability |

Tip: If you put poles in tough soil, pick ones with a thicker zinc coating. This helps them last longer.

Water Pipes

Water pipes move drinking water, farm water, and waste. You want pipes that stay safe and strong for many years. Steel pipes with zinc coating work well in lots of water types. In freshwater, things like dirt, pH, and heat change how fast pipes rust. Hard water makes a layer on the pipe that slows down rust.

In seawater, salt can make pipes rust faster. But minerals like magnesium and calcium help protect the zinc. This means your pipes last longer, even in salty water. You do not have to fix or change them as much.

- Zinc-coated pipes work in both fresh and salty water.

- Hard water and some minerals help pipes last longer.

- You get safe water for homes, farms, and cities.

Note: For pipes that last, check your water and pick pipes with the right coating.

Appliances

Home Devices

You want your home devices to last and look nice. Makers use special metal coatings to protect appliances from water and daily use. This helps your refrigerator, washing machine, and dishwasher work longer. You feel better because these devices do not rust or get damaged.

- Many home appliances, like refrigerators, freezers, dryers, and dishwashers, have coated steel on the outside.

- This helps your devices last longer and keeps them looking new.

- More people want smart and advanced appliances now. Makers pick strong materials to meet these needs.

- The home appliance industry is growing fast. People want products that last and help save money.

You get appliances that stay strong and safe, even in busy homes. The special coating also makes cleaning easier and keeps your devices looking good.

Tip: When you buy new appliances, check if they use coated steel panels. This can help you save money on repairs and replacements.

Outdoor Units

Outdoor units face tough weather every day. You need materials that can handle rain, sun, and changing temperatures. Makers use coated steel for air conditioning units, outdoor heaters, and other equipment. This choice protects your money and keeps your equipment working.

- Coated steel fights water and damage from the weather, so it is great for outdoor use.

- More companies use this metal in outdoor appliances because it is strong and saves money.

- Buyers and makers care about how long products last and the environment. Using coated steel helps with both.

You get outdoor units that last longer and need less fixing. This means you worry less about rust or things breaking. Your outdoor spaces stay nice and work well all year.

Public Spaces

Urban Furniture

You see benches, bike racks, and trash bins in parks and cities. These pieces get used a lot and face all kinds of weather. Sometimes, people even try to damage them. If you pick metal furniture with a special coating, it lasts longer. It also keeps looking nice year after year. City planners like these materials because they do not rust or get ruined by rain or snow.

A table below shows how these materials work in public places:

| Aspect | Numerical Evidence | Context/Application |

|---|---|---|

| Load-bearing capacity | 80-1002 concentrated load | Studs in suspended ceilings supporting moving people in large public spaces |

| Lifespan of infrastructure | Designed for 100 years | Mario Cuomo Bridge using reinforced concrete structures |

| Quantity used | 30,000 bars; 6,000 precast panels; 75 tons of bars | Large-scale projects including bridge decks and abutments |

| Corrosion resistance threshold | Chloride corrosion threshold 2-3 times higher than carbon steel rebar | Concrete reinforcement exposed to coastal chloride environments |

| Protective coating duration | Over 100 years | Coatings protecting steel in corrosive environments |

You want benches and other furniture to stay safe and strong. These numbers show you can trust coated steel for city benches and fixtures. You do not have to fix or replace them as much. This helps your town save money.

Tip: Pick urban furniture with a special finish. This keeps public spaces nice and safe for everyone.

Safety Barriers

Safety barriers help protect people in busy places like sidewalks and playgrounds. You need barriers that can take hits and bad weather. Steel barriers with a coating stay strong and last a long time. They keep people safe even after many years.

When disasters happen, these barriers prove their worth. In the 1994 Northridge earthquake, 96% of steel bridges stayed safe, even with old technology. This shows that coated steel structures really keep public spaces safe.

You want to feel safe around these barriers. If you choose steel with a tough coating, you can relax. These barriers last longer and need fewer repairs. Cities and towns save money and keep people safe.

Note: For safety that lasts, pick barriers with protective coatings. They help keep everyone safe in public places.

Manufacturing

Sheet Metal

Sheet metal is used in many things you see every day. Factories pick coated steel sheets because they last longer. These sheets do not get damaged by weather or chemicals. This means your products stay strong and look nice for years. Factories now use high-strength steel grades. These grades let them make parts thinner and lighter. The parts are still strong. Lighter cars and machines use less energy.

Factories use smart technology to make sheet metal parts better. AI systems find problems fast. IoT sensors help machines work well and warn before they break. Automated systems shape metal with great accuracy. Laser tools cut and weld metal quickly and neatly. These changes help you get better products faster.

- More people want steel sheet metal for buildings, cars, and machines.

- Coated steel sheets help products last longer in tough places.

- Digital tools and machines make parts more exact and faster.

Tip: If you want good sheet metal parts, choose makers who use new technology and strong coatings.

Stamping and Fabrication

Stamping and fabrication shape metal into parts you use daily. You want parts that fit right and last long. Factories use cold rolled and coated steel for stamping now. This gives cleaner edges and tighter fits. Companies like Tenral Metal Products Ltd use these materials to make better parts.

More factories use digital tools for stamping and fabrication. AI checks each part for mistakes. IoT devices watch machine health and keep things running. Smart analytics help plan better and waste less. Laser cutting and welding make the work faster and better.

- Cold rolled and coated steel makes stamping more exact.

- AI and IoT help factories find problems early.

- Laser tools make fabrication quicker and improve quality.

You get parts that meet tough rules and last longer, whether you need them for cars, machines, or buildings.

You get lots of good things when you pick galvanized steel for your projects. This material is special because it fights rust, saves money, and works in many ways.

- Hot-dip galvanizing keeps steel safe from bad weather and chemicals.

- High-zinc coatings help steel last longer in hard places.

- Digital ordering lets you buy steel quickly and easily.

| Aspect | Details |

|---|---|

| Market Value (2024) | USD 188.8 billion |

| Projected Value (2033) | USD 268.73 billion |

| Main Use | Construction and infrastructure |

You can count on galvanized steel to work well for a long time.

FAQ

You get better rust protection with galvanized steel. The zinc coating shields the steel from water and chemicals. This means your projects last longer and need less maintenance.

Yes, you can use galvanized steel outside. The zinc layer protects it from rain, sun, and harsh weather. You will see less rust and fewer repairs.

Use mild soap and water to clean galvanized steel. Avoid harsh chemicals or wire brushes. You keep the coating strong and your parts looking new.

Yes, you can use galvanized steel for water pipes. The zinc coating keeps the water safe and prevents rust. Many cities trust it for clean water delivery.

You can order custom galvanized steel parts from trusted providers like AFI Industrial Co., Ltd. They offer precision machining services and fast delivery for your project needs.