Choosing galvanized aluminum in 2025 requires careful consideration of several factors, especially when learning how to choose galvanized aluminum effectively. You need to evaluate how you plan to use the material and consider local weather conditions. Additionally, it’s important to factor in long-term costs. Market data shows the galvanized aluminum market is expected to grow significantly, reaching $5-7 billion USD, driven by strong demand in automotive, construction, and home appliance sectors:

| Aspect | Details |

|---|---|

| Market Size (2025) | $5-7 billion USD |

| Key Uses | Automotive, Construction, Appliances |

| Leading Region | China |

When comprehensive comparison galvanized steel and aluminum, understanding Aluminum Alloy Properties is crucial. Aluminum naturally forms a protective oxide layer that helps prevent rust, reducing maintenance needs. In contrast, galvanized steel relies on a zinc coating for protection. To avoid issues like galvanic corrosion, it’s essential to understand the interaction between different metals. Reviewing the Specifications, Performance, and Applications of each material will guide your decision. How to choose galvanized aluminum? Always align the Aluminum Metal Materials with your specific requirements. Considering the Types and Uses of Metal Materials will ensure you select the best option for your project.

Key Takeaways

- Pick galvanized aluminum by thinking about where you will use it. Think about if it is inside or outside. Check if it will touch chemicals.

- Choose the right coating type for your needs. Use aluminum-silicon in hot or rusty places. Use aluminum-zinc alloy for strong rust protection.

- Use anodizing to keep aluminum safe and add color. Galvanizing works best for steel, not aluminum.

- Pick the right aluminum grade for your project. Match it to how strong and rust-proof you need it. Use 3003 for most jobs. Use 5052 for boats or water areas.

- Always check the product quality before buying. Look for ASTM and ISO certifications. Check if the surface is smooth and has no defects.

- Think about all costs, not just the first price. Include installation, care, and how long it lasts. This helps you save money later.

- Do not make mistakes like forgetting about the environment. Do not skip taking care of the material. Do not pick only by price.

- Buy from trusted suppliers. They should give clear quality papers. They should have good customer service and strong warranties. This keeps your investment safe.

Table of Contents

Application Needs

When picking between galvanized steel and aluminum, think about where you will use it. The place and how you use the material are very important. Each one has special benefits for different jobs.

Indoor vs. Outdoor

Humidity

If you use galvanized materials outside or in wet places, you should think about how well they fight rust. Galvanized steel has a zinc coating that keeps it from rusting. This makes it good for things that get wet or are outside in the rain. Aluminum also does not rust easily because it forms a natural oxide layer. You can use aluminum in wet or seaside places without worrying about rust. For inside jobs, both galvanized steel and aluminum work well. Aluminum is lighter, so it is easier to put in place.

Chemical Exposure

Some places have chemicals that can hurt metals. Galvanized steel can handle many chemicals, but strong acids or salts can wear away its zinc coating after a while. Aluminum is good at fighting rust in most chemical environments, but it can react with some alkaline substances. You should check what chemicals are around before you pick your metal. If there are lots of chemicals, you might need a special type of coating for more safety.

Structural vs. Decorative

Load Requirements

You need to pick the right material for how strong your project must be. Galvanized steel is very strong and can take hard hits. It is great for big jobs like bridges, building frames, and machines. Aluminum is much lighter, so it costs less to move and does not weigh down your project. This makes aluminum great for planes, cars, and roofs, where being light is important.

Here is a simple comparison:

| Property | Galvanized Steel | Aluminum |

|---|---|---|

| Density | About 7.85 g/cm³ (heavier) | About 2.70 g/cm³ (lighter) |

| Tensile Strength | Higher, best for heavy loads | Lower, but strong for its weight |

| Yield Strength | Usually higher | Lower, more bendable |

| Impact Resistance | Very good | Takes hits, is light |

| Typical Applications | Bridges, machines, frames | Planes, cars, roofs |

Appearance

If you want your project to look nice, both galvanized steel and aluminum have choices. Galvanized steel’s zinc coating gives it a rough look that holds paint well. This lets you add color or extra protection. Aluminum is soft and easy to shape, so you can make many styles and designs. It can have many colors and can look like wrought iron, but needs less care. Aluminum is flexible and light, so it is great for custom looks. Galvanized steel looks strong and bold but may need more work to keep it looking new.

Tip: Always pick your material based on where you use it, how strong it needs to be, and how you want it to look. This helps your project last longer and makes you happy with the result.

How to Choose Galvanized Aluminum?

To pick the right galvanized aluminum in 2025, you need to know about coatings, ways to protect it, and grades. Match these things to your project and where you will use it. This guide will help you learn how to choose galvanized aluminum.

Coating Types

The coating on galvanized aluminum helps it last longer and keeps it from rusting. It also makes it good for different places. You should look at the main types before you choose.

Aluminum-Silicon

Aluminum-silicon coatings mix aluminum and silicon, with 5-11% silicon. This coating works well in hot places and where there is a lot of rust. Silicon helps the coating stick to the metal and helps when bending or shaping. You see this coating in exhausts, ovens, and machines. It makes a strong shield that stops oxidation, sulfidation, and carburization.

Zinc

Zinc coatings are used a lot for regular galvanized things. They protect steel by making a layer that wears away first. For aluminum, zinc is not used as much, but you might see aluminum-zinc alloy coatings. These have about 55% aluminum, 43.5% zinc, and 1.5% silicon. This mix fights rust better and lasts longer than just zinc. The aluminum-zinc alloy also bounces heat and is good for painting.

Here is a table that compares common coating types:

| Coating Type | Description | Benefits |

|---|---|---|

| Hot-dip Aluminized Coating | Aluminum and silicon mix (5-11% Si), used for hot and rusty places. | Stops oxidation, sulfidation, and carburization; protects up to 800°C. |

| Pure Aluminum Coating | Used to stop rust from air. | Makes a shield; light and strong. |

| Aluminum-Zinc Alloy Coating | 55% aluminum, 43.5% zinc, 1.5% silicon (like GALVALUME®). | Lasts 2-4 times longer than galvanized; great at stopping oxidation; easy to paint. |

| Galvanized Metal | Steel with about 99.8% zinc oxide from hot dipping. | First layer fights rust; zinc wears away in 10-15 years. |

Tip: Pick a coating that fits your place. For hot or chemical spots, aluminum-silicon is best. For outside, aluminum-zinc alloy lasts longest.

Protection Methods

You also need to choose how to protect your galvanized aluminum. The two main ways are galvanizing and anodizing.

Galvanizing vs. Anodizing

Galvanizing puts a zinc layer on metal, mostly for steel. This gives good rust protection, but is not used much for aluminum. Anodizing uses electricity to make the natural oxide layer on aluminum thicker. This makes the surface hard, tough, and better at fighting rust.

| Protection Method | Metal Type | Process Description | Longevity Impact on Aluminum Products | Environmental Suitability |

|---|---|---|---|---|

| Anodizing | Aluminum | Uses electricity to make oxide layer thicker | Makes the surface hard, tough, and better at fighting rust; lasts longer | Great for aluminum, gives color choices and tough surface |

| Galvanizing | Steel, Iron | Adds zinc by dipping or plating | Zinc protects steel and iron; not used much for aluminum | Best for steel and iron; not good for aluminum |

Anodizing lets you pick more colors and gives a smoother look. It also makes the surface harder and less likely to get scratched. If you want your aluminum to last and look nice, anodizing is the best choice.

Note: For most aluminum jobs, anodizing is the best way to make it last and look good. Use galvanizing only for steel or if you want a tough, rough look.

Grade Selection

Choosing the right grade is the last step in how to choose galvanized aluminum. Grades change how strong it is, how easy it is to shape, and how well it fights rust.

Common Grades

There are a few common grades for galvanized aluminum. Each one is good for different things:

- 3003: Good for many uses, easy to shape, and has medium strength.

- 5052: Stronger, fights rust well, used for boats and outside.

- 6061: Very strong, good for building parts, easy to cut and weld.

- Aluminum-Zinc Alloy (e.g., GALVALUME®): Mixes the good parts of aluminum and zinc, best for roofs, walls, and wet or salty places.

| Grade | Key Features | Typical Uses |

|---|---|---|

| 3003 | Easy to shape, medium strength | Ducts, panels, general jobs |

| 5052 | Fights rust well, strong | Boats, outside, chemical tanks |

| 6061 | Very strong, easy to weld and cut | Building parts, frames, supports |

| Aluminum-Zinc Alloy | Fights rust best, lasts long | Roofs, walls, places near water |

Callout: Always pick the grade that fits your job. For outside or boats, choose a grade that fights rust well. For building, pick a grade that is strong.

If you follow these steps, you will know how to choose galvanized aluminum. Start by looking at your place, then pick the right coating, protection way, and grade. This helps your project last longer and work better.

Quality Check

When you pick galvanized aluminum, you need to check its quality first. This helps you avoid mistakes and makes sure your project lasts a long time. You can use these steps to get the best material.

Standards

ASTM

Look for products that follow ASTM rules. ASTM International makes rules for how metals should work. These rules cover how thick the coating is, how well it sticks, and how it fights rust. If your galvanized aluminum meets ASTM rules, it will work well in tough places. Always ask your supplier for ASTM papers.

ISO

ISO rules are known all over the world. They focus on making good products and caring for the environment. ISO 9001 means the supplier checks quality very carefully. ISO 14001 means they care about making things in a green way. If you see ISO papers, you can trust the supplier and their products.

Tip: Ask your supplier for both ASTM and ISO papers. This makes sure your material is safe and strong.

Visual Inspection

Surface Finish

You should look at the surface of galvanized aluminum closely. A smooth and even surface means the coating was put on right. Check for even color and texture. If you see rough spots or shiny patches, the coating may not protect the metal well.

Defects

Looking at the metal helps you find problems fast. Here are things you should look for:

- Brown stains or wet storage marks

- Welds that leak and bare spots

- Lines from oxide and rough areas

- Dross bits (zinc-iron pieces)

- Black marks from too much aluminum

- Places where water sits or metals touch

Check for cracks and places that were fixed before. These spots can rust faster and need extra care. If you see big dross or bare spots, ask for repairs or say no to the product. Always check before painting or coating to make sure the surface is ready.

Note: The same checks work for galvanized steel and aluminum because both use zinc coatings and can rust in the same way.

Supplier Reputation

Reviews

You need to check if the supplier is good before you buy. Use these ideas to help you choose:

- Read reviews from many places to get a fair idea.

- Pick suppliers with lots of experience and the right papers.

- Look for clear talk and easy access to rule papers.

- Check if they have strong quality checks and know a lot.

- See if they offer many products and can make special ones for you.

- Ask for names and stories from other buyers.

- Make sure they ship well and manage orders quickly.

- Choose suppliers who care about the planet and help you fast.

Callout: Treat your supplier like a partner. Good suppliers help you avoid problems, get good products, and fix issues quickly.

If you follow these steps, your galvanized aluminum will meet high standards and fit your project well. Checking quality saves your money and helps you feel sure about your choice.

Compare Options

When you look at galvanized aluminum choices, check specs, cost, and warranty. Doing this helps you pick the best one for your project. Comparing everything gives you clear answers about what fits your needs.

Specs

Technical Data

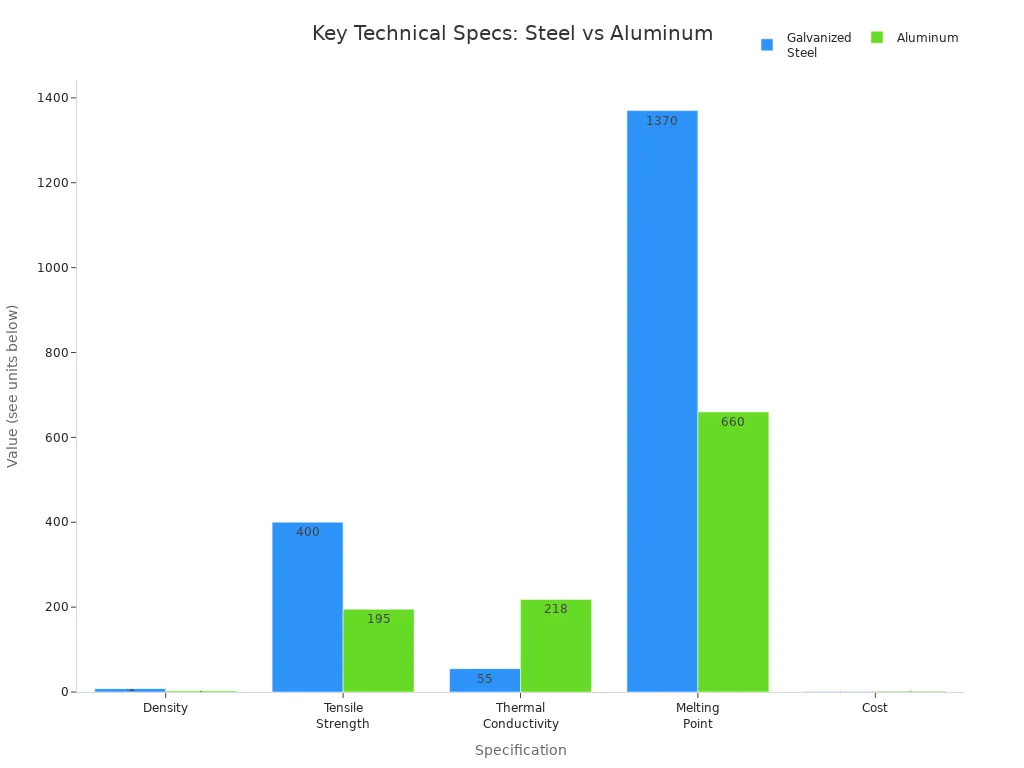

Start by looking at the technical data for each material. This lets you see how galvanized aluminum and galvanized steel are different. Use the table below to compare important things:

| Specification | Galvanized Steel | Aluminum |

|---|---|---|

| Density | ~7.85 g/cm³ (heavier) | ~2.7 g/cm³ (about 1/3 the weight of steel) |

| Tensile Strength | Higher (~250-550 MPa) | Lower (~90-300 MPa) |

| Yield Strength | Generally higher | Lower but more flexible |

| Corrosion Resistance | Zinc coating provides sacrificial protection; can degrade if coating is damaged | Natural oxide layer provides excellent, self-repairing corrosion resistance |

| Thermal Conductivity | Lower (~50-60 W/m·K) | High (~200-235 W/m·K) |

| Electrical Conductivity | Low | High (about 60% of copper’s conductivity) |

| Magnetic Properties | Magnetic (due to iron content) | Non-magnetic |

| Melting Point | ~1,370°C (steel core), zinc melts at ~420°C | ~660°C |

| Protective Coating | Thickness of zinc coating critical for durability | Natural oxide layer thickness important but self-forming |

| Machinability | Harder to machine, requires special tools | Easier to machine and fabricate |

| Weight Considerations | Heavier, less suitable where weight is critical | Lightweight, ideal for weight-sensitive applications |

| Impact Resistance | Excellent | Good, but less than galvanized steel |

| Cost | Generally lower initial cost | Higher initial cost but lower maintenance costs |

Tip: Always check specs for your job. If you need something strong, galvanized steel is best. If you want something light and easy to shape, pick aluminum. For wet or salty places, aluminum lasts longer.

Cost

Initial vs. Lifetime

You should think about more than just the first price. Galvanized steel usually costs less at the start. For example, a steel roof for a 3,000-3,500 sq ft house might be $65,000. An aluminum roof could be $69,000. Both can last about 50 years. Aluminum does not rust as fast, so you pay less for repairs. Over time, you might save money with aluminum.

Aluminum cable trays show the same thing. You pay more at first, but they are lighter and faster to put in. You need fewer workers, and you do not have to fix cut edges. Galvanized steel trays need extra paint, which adds to the cost if skipped. Aluminum fights rust on its own, so you save money as you use it.

Note: Always look at the total cost, not just the first price. The cheapest choice today may not save you money later. Think about how much it costs to install, fix, and keep up before you choose.

Warranty

Support

Check the warranty before you buy. Warranties protect your money and show that the maker trusts their product. Here is a table with common warranty types for galvanized aluminum:

| Warranty Type | Description | Typical Coverage / Notes |

|---|---|---|

| Substrate Warranty | Usually not offered for galvanized steel or aluminum substrates. Galvalume steel may have up to 45 years warranty. | Galvanized aluminum typically lacks substrate warranty; important to verify with manufacturer. |

| Paint/Finish Warranty | Covers color fade, chalking, and paint degradation with specified coverage length and acceptable color change. | Warranty length varies; critical to review allowed color fade and chalking levels. |

| Workmanship Warranty | Provided by installers, covering installation quality such as clips, fasteners, and trims. | Typically lasts 5 to 10 years; covers defects in installation workmanship. |

| Weathertightness Warranty | Guarantees no leaks for a specified period, often around 20 years. | Rare for residential projects; more common in commercial or architectural projects. |

| Environmental Considerations | Some manufacturers offer specialized warranties for aluminum in coastal or harsh environments. | Warranty applicability can depend on environmental exposure; maintenance and transferability are important. |

Paint and finish warranties cover things like cracking, peeling, fading, and chalking. If you live near the ocean or in a tough climate, ask about special warranties. Always read the details and ask about care rules, and if you can give the warranty to someone else.

Callout: Good warranty support helps you worry less. Ask your supplier for all the details and keep your warranty papers safe.

Mistakes to Avoid

When you pick galvanized aluminum, you should avoid common mistakes. These mistakes can cause big problems and cost you more money. If you pay attention, your project will last longer and work better.

Ignoring Environment

Some people forget to think about where they will use the material. If you do not look at the place, you might choose the wrong product. Here are some mistakes people make:

- Mixing up galvanized steel and aluminum, so you use the wrong one.

- Not thinking about salty air near the ocean, which makes rust happen faster.

- Forgetting about galvanic corrosion when using different metals together.

- Not picking the right alloy or coating for the place you use it.

- Not knowing that bare aluminum can change color outside.

Tip: Always pick the right material and coating for your area. For places near the sea or factories, choose products made for tough spots.

Overlooking Maintenance

You may think galvanized aluminum does not need care, but it does. Taking care of it helps it last longer. If you skip maintenance, you can get rust, damage, and high repair bills. The table below shows how long it lasts in different places and why care is important:

| Environment Type | Lifespan Without Maintenance | Effect of Neglecting Maintenance | Maintenance Benefits and Recommendations |

|---|---|---|---|

| Normal Outdoor | 20 to 50 years | Coating wears faster; corrosion increases | Inspect every 5 years; clean as needed |

| Coastal Area | 5 to 15 years | Salt spray removes coating quickly | Inspect twice a year; clean quarterly |

| Industrial Pollution | 10 years or less | Acidic gases speed up coating loss | Use thicker coatings; inspect and clean often |

If the coating gets scratched or damaged, water can get in. This makes rust spread much faster, especially in wet places. Cleaning and fixing problems early can help your project last many more years and save you money.

Note: It costs less to take care of your material than to replace it. Make a plan to check and clean it often to keep it safe.

Price-Only Decisions

If you only look at the price, you might spend more later. Here are some problems with picking just by cost:

- Galvanized steel is cheaper at first, but it needs more care, especially in wet or salty places.

- Aluminum costs more at the start, but it saves money later because it does not rust as fast and needs less work.

- If you pick just by price, you might pay more for repairs, care, and replacing things early.

- Heavy materials like galvanized steel also cost more to put in.

Callout: Do not just look at the first price. Think about all the costs, like putting it in, taking care of it, and how long it will last where you use it.

Selection Checklist

Define Needs

First, think about what you want your galvanized aluminum to do. Decide if your project needs to be strong or just look nice. Write down what you want to build. Do you need the material to be light or have a special style? If you are making a roof, frame, or sign, list these things. Knowing what you need helps you make better choices.

- Make a list of what you want your project to do.

- Decide if you want it strong, light, or with a certain look.

- Think about how long you want it to last.

- Write down if you want it easy to paint or shape.

Tip: Clear goals help you pick the right product and save time.

Assess Environment

Check where you will use the galvanized aluminum. The place can change how long it lasts. Some places can make it rust or break faster.

- Check if you are near the ocean, where salt is in the air.

- Test the pH. Aluminum works best between pH 5 and 9. An acid or a base can hurt it.

- Measure how wet and hot it gets. More heat and water can cause more rust.

- See if there are salts, like from roads, in the area.

- Check if it will touch other metals. Touching galvanized steel or copper can cause problems.

- Think about pollution. Cities and factories may have chemicals that hurt metals.

- Find out if there are strong acids or bases. Some acids can damage it fast.

- Think about what kind of rust can happen, like pitting or waterline rust.

- Use good design and coatings to protect it in tough places.

Note: Real projects, like the National City Aluminum Bridge, show aluminum lasts longer near the sea if you keep it away from other metals and use smart design.

Pick Grade and Coating

Pick the grade and coating that fit your needs and where you will use it. Grades change how strong it is and how well it fights rust. Coatings give extra safety.

| Grade | Best For | Key Benefit |

|---|---|---|

| 3003 | General use, easy forming | Good for shaping |

| 5052 | Marine, outdoor, chemical tanks | High corrosion resistance |

| 6061 | Structural, frames, supports | Strong and weldable |

| Aluminum-Zinc Alloy | Roofs, walls, coastal areas | Superior rust protection |

- Choose a grade that matches your strength and shaping needs.

- Pick a coating for your area. Aluminum-zinc alloy is good for salty or wet places.

- For hot or chemical spots, use aluminum-silicon coatings.

- Use anodizing if you want a hard surface or more color choices.

Callout: The right grade and coating keep your project safe and looking nice for a long time. Always match your choice to your project and where you will use it.

Check Quality

You must check the quality of galvanized aluminum before you buy it. First, look for products that follow rules like ASTM and ISO. These rules mean the metal passed tough tests for thickness and coating. Ask your supplier for papers that prove this. Look at the surface to see if the coating is even and smooth. Make sure there are no cracks, stains, or bare spots.

Use this checklist to help you check:

- Find ASTM and ISO certificates.

- Look at the color and texture to see if they match.

- Watch for rough spots or dross on the surface.

- Make sure the coating is thick enough for your job.

- Ask for new test results and quality records.

Tip: Good galvanized aluminum lasts longer and works better in hard places. Always check the rules and look at the metal before you use it.

Compare Costs

You should look at all costs to get the best deal. Do not just look at the first price you pay. Think about how much it costs to put in, fix, and keep up. Aluminum is lighter, so it is easier and cheaper to install. Galvanized steel is heavier and may need more work and a new coating later, which costs more over time.

Here is a table to help you compare gutter costs:

| Factor | Galvanized Steel Gutters | Aluminum Gutters |

|---|---|---|

| Installation Weight | Heavier, needs more work | Lighter, faster and cheaper to install |

| Installation Cost Range | $980 – $1,680 (for 140 ft., installed) | $840 – $1,400 (for 140 ft., installed) |

| Maintenance | May need new coating or repairs | Usually costs less to keep up |

| Environmental Suitability | Works with all roof types | Not good with algae shingles or copper |

| Durability | Strong, can go almost anywhere | Light and fights rust but has limits |

Think about how the metal holds up over time. Aluminum does not rust much and needs less fixing, so you save money later. Galvanized steel is strong and works in more places, but you must think about fixing and weather risks.

Note: Always look at the full cost, not just the first price. This helps you pick the best choice for your project.

Review Supplier

You need to check your supplier to make sure you get good galvanized aluminum. First, see if the supplier follows ASTM and ISO rules. Pick suppliers with good reviews and a strong name. Make sure they can give you quality papers and have done jobs like yours before.

Think about these things when you check a supplier:

- Check the metal quality and make sure it meets the rules.

- Ask how they coat the metal; hot-dip is best for lasting longer.

- See if the metal can hold the weight you need, and ask for help if needed.

- Check if they can make special shapes or sizes for you.

- Look at their reviews, papers, and how they treat customers.

- Make sure they can deliver on time, even for big or far orders.

- See if they have many products to fit your project.

Callout: A good supplier helps you finish your project on time and gives you strong materials. Always ask questions and get proof before you buy.

Confirm Warranty

When you pick galvanized aluminum, checking the warranty is very important. A good warranty keeps your money safe and helps you feel calm. You should know what the warranty covers, how long it lasts, and what you must do to keep it.

Ask your supplier for the warranty papers in writing. Look at what is covered, like normal use, mistakes in making it, and problems with the finish, such as chipping or peeling. Many companies give lifetime limited warranties. These last for the product’s whole life, not just for the first owner. This kind of warranty gives you more safety and helps you avoid surprise costs.

Check how long the warranty lasts and what it covers. Some warranties last 45 to 50 years, especially for Galvalume® from steel mills. These can cover rust that goes all the way through, not just on the top. Products with lots of zinc, like G100 grade, fight rust better and last longer.

Read all the small details in the warranty. Some things are not covered. Common things not covered are:

- Damage from big storms or floods

- Wind damage

- Bad installation

- Harm from strong chemicals

- Corrosion from mixing metals

- Not following the right way to install

You must use the right way to put it in and hire trained workers. If you do not, you might lose your warranty. Companies often want you to take care of the product their way. For example, if you live near the ocean, you may need to wash it with fresh water two times a year to stop salt from hurting it.

Here is a table to help you look at warranty features:

| Warranty Feature | What to Look For | Why It Matters |

|---|---|---|

| Length | Lifetime or 45-50 years | Long-term protection |

| Coverage | Wear, defects, finish, substrate | Broad coverage reduces risk |

| Exclusions | Acts of God, installation errors, chemicals | Know what is not covered |

| Maintenance Requirements | Regular cleaning, inspections | Keeps warranty valid |

| Transferability | Can warranty transfer to new owner? | Adds resale value |

| Service Procedures | Clear steps for repair or replacement | Fast support when issues arise |

Tip: Always get the warranty papers before you buy. Check what is covered, what is not, and how to care for it. If you live by the sea, look for special coastal warranties and follow all care rules.

Strong coatings like Kynar 500® (PVDF) give extra safety from fading, chalking, and film loss. These coatings can make your warranty better. Pick products from companies that care about quality and have clear ways to fix or replace things.

Checking the warranty helps you avoid problems and makes sure your galvanized aluminum works well for a long time. Take time to read the rules, follow care steps, and keep your warranty papers safe. This protects your money and helps you feel happy with your choice.

You can pick galvanized aluminum easily if you follow the steps. First, choose trusted manufacturers and check how they make it. Make sure the product fits your job and where you use it. Use a checklist to check grades, certifications, and if it works with other things. Check and clean it often to keep it strong.

Remember: Taking care of your material and picking carefully saves money and keeps you happy for a long time.

FAQ

Galvanized aluminum is aluminum with a special coating. The coating is usually made from aluminum and zinc mixed together. This layer helps stop rust. It also makes your project last longer in hard places.

Pick the grade that fits your project best. Use 3003 for most jobs. Choose 5052 for things outside or near water. Pick 6061 if you need something strong. Always ask your supplier about the grade.

Yes, you can use it by the sea. Pick aluminum-zinc alloy coatings for more safety from salt. Clean the surface often to stop rust. This also helps keep your warranty good.

Check the surface once a year. Wash it with gentle soap and water. Fix any scratches or damage right away. Follow the maker’s care steps to keep your warranty and make it last longer.

Only use food-grade aluminum for touching food. Regular galvanized aluminum may have coatings not safe for food. Always ask your supplier for proof before using it in kitchens or food factories.

Always look for ASTM and ISO certificates.

Check the surface for any problems.

Compare different grades and coatings.

Read all the warranty rules.

Look at supplier reviews and how they deliver.

Yes, you can paint it. Clean the surface first. Use a primer made for aluminum. Put on thin coats of paint for the best look. Painted aluminum fights rust and stays nicer longer.