Metal Forging

Choose AFI Industries Ltd. to forge the key foundation parts for high-end equipment manufacturing.

Custom Metal Forging

AFI Industrial Co., Ltd. has a variety of forging equipment including forming hammers, mechanical presses, hydraulic presses, screw presses, and flat forging machines, as well as forging operators, uncoiler, straighteners, shearing machines, and other auxiliary equipment, can forge various types of key basic parts for customers.

Workshop

Professional forging technology can customize various types of forging products.

Process

Forging is a processing method that uses forging machinery to exert pressure on metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, shapes and sizes.

Parts

Forged products feature high strength, good toughness and high dimensional accuracy, and are suitable for various materials such as carbon steel, alloy steel, aluminum alloy and titanium alloy.

Inspection

Precise inspection equipment and professional personnel ensure that customers get high-quality products.

Custom Metal Forging Service

Forging is the use of forging machinery to exert pressure on the metal blank, so that it produces plastic deformation to obtain a certain mechanical property, a certain shape and size of the forging processing.

Through forging can eliminate the metal in the smelting process of the as-cast loose and other defects, optimize the microstructure, and because of the preservation of the complete metal flow line, the mechanical properties of the forgings are generally better than those of the same material.

For important parts with high load and severe working conditions in related machinery, forgings are mostly used in addition to plates, profiles or welding parts with simple shapes that can be rolled.

AFI Industries Ltd. is committed to providing customers with customized metal forging services, regardless of shape, size, material or performance requirements, we provide personalized solutions.

Precision Forging

AFI Industrial Co., Ltd. provides customers with various forging products. Under high or room temperature conditions, we refine the internal grain structure of metals through hammering, press extrusion and other methods, and form a continuous fiber flow direction, thereby enhancing the strength, toughness and fatigue life of the product. It is widely used in aerospace, automotive industry, construction, medical and other fields.

Sample Development of Forged Parts

AFI Industrial Co., Ltd. provides forging sample development services for customers. Perfect for designers and engineers, our prototyping capabilities allow you to quickly test and improve your designs, helping you get ahead by releasing new products in the shortest possible time.

Custom Precision Forged Parts

AFI Industries Ltd. is committed to providing customers with professional custom metal forging services. Our technical team of engineers uses advanced forging technology and a variety of materials to produce high-quality metal parts for the specific specifications and design requirements provided by customers while ensuring rapid response, cost-effective, and environmentally friendly production to meet customers’ needs for forged products.

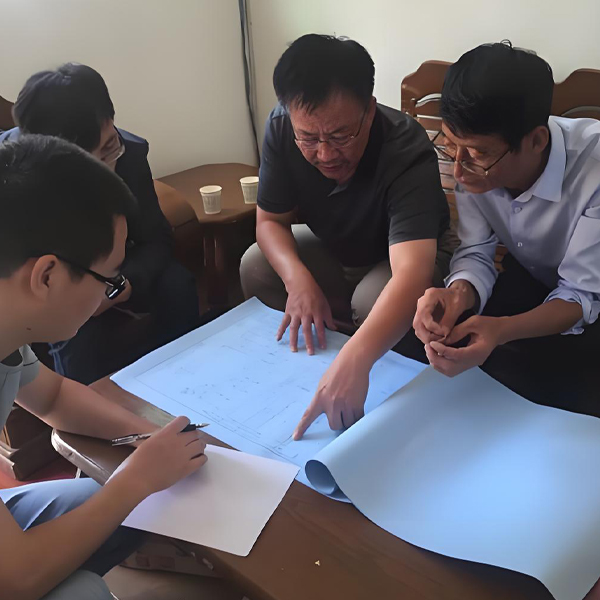

Drawings

After receiving the customer’s drawings, our technical team will conduct a drawing review and process planning to ensure that each processing link meets the requirements of the drawings, and the product size accuracy is controlled within ±0.01mm. Our quality control system ensures that the mass-produced products are consistent with the samples and meet all the technical requirements of customers.

Engineer Analysis Drawing

The engineering team carried out three-dimensional tolerance analysis based on the GD&T standard. They selected the base material in combination with the ASTM material database, optimized the technical parameters through CAM programming, and simultaneously formulated the three-coordinate inspection procedures to ensure the control of μ-level form and position tolerances.

Billet

Our technical team, relying on years of processing experience, strictly adheres to standardized process flows and uses intelligent numerical control systems to precisely control processing parameters, ensuring that each product meets the dimensional accuracy and surface finish requirements of the drawings, providing customers with stable and reliable precision parts processing services.

Inspection

From incoming material to the manufacturing process to delivery, quality inspection personnel test the products according to the drawings to ensure that the products fully meet the quality requirements of customers.

Custom Forging Materials

AFI Industrial Ltd. offers its customers a wide selection of forging materials, including steel, alloy, stainless steel, etc., to meet the needs of customers in different industries to ensure product performance and durability.

After forging, the strength of steel is increased by 20-30% compared with the cast state, the impact toughness is enhanced by 50%, and the fatigue life is extended by 3-5 times, which can significantly improve material defects. Our company can produce forged products weighing from a few grams to hundreds of tons in practical applications, with a material utilization rate of 60-80%. These products are applied to major equipment, transportation, energy equipment and other places.

- Carbon steel

- alloy steel

- spring steel

Forged aluminum parts are particularly lightweight, weighing only one-third of steel parts (about 2.7 grams per cubic centimeter), and the parts made from them can be over 60% lighter than steel parts. After being processed by forging technology, its strength can reach 300 to 500 megapascals, which is 40% to 60% stronger than that of cast aluminum parts, and its service life can be extended by 3 to 8 times. This kind of material is particularly easy to process and shape.

The surface of the aluminum forgings we produce is extremely smooth, achieving a fineness of Ra1.6-3.2 microns, and they also have inherent anti-rust properties. Nowadays, many products such as automotive parts and bicycle accessories that require both lightweight and durability are using our aluminum forgings. We can customize various high-performance aluminum alloy forgings for you according to your specific needs.

- 2000 series aluminum alloy

- 6000 series aluminum alloy

- 7000 series aluminum alloy

- 7075 aluminum alloy

- A380

- A383

- A360

- HSW-4

The forged copper alloy has good electrical and thermal conductivity, as well as anti-friction and wear resistance, beautiful color, widely used in aerospace, shipbuilding, electronic and electrical engineering, mechanical engineering, and other fields.

- orichalcum

- cupric

- bronze

- aluminium bronze

- phosphor bronze

- beryllium bronze

- pure copper

- copper-nickel alloy

- copper-aluminum alloy

Forged titanium alloy has high strength and thermal strength, good corrosion resistance, good low-temperature performance, high chemical activity, and good welding performance, and is widely used in aerospace, Marine shipbuilding, medical, and other industries.

- TA15

- TA24

- TA5

- TC4

Wrought magnesium alloys are widely used as structural materials in automotive, aerospace, and other fields because of their lightweight, high strength, good shock absorption, and excellent thermal conductivity.

- Mg-Al-Zn alloy

- Mg-Zn-Zr alloy

- WE series magnesium alloy

Forged nickel alloys have excellent corrosion resistance, high-temperature strength, and oxidation resistance, which make them widely used in aviation, aerospace, military, petrochemical, and other harsh environments.

- Incoloy alloy

- Inconel alloy

- Hastelloy alloy

- Monel alloy

Forged stainless steel parts have particularly high strength, with tensile strength reaching 800-1200 megapascals, which is 30%-50% higher than that of raw materials. Moreover, it has excellent toughness, with an elongation rate maintained at 15% to 25%, and its service life can be extended by 3 to 5 times.

The stainless steel forgings produced by our company have a very smooth surface and can achieve a fineness of Ra0.8-1.6 microns. These high-quality products are now widely used in various fields such as petrochemicals, food and medical equipment, Marine engineering equipment, etc.

We can customize various stainless steel forgings for you based on your specific usage environment and requirements.

- Austenitic stainless steel

- Martensitic stainless steel

- Ferritic stainless steel

- Precipitation hardening stainless steel

Custom Surface Treatment

AFI Industrial Co., Ltd. provides surface treatments for custom precision forging parts. Whether you need anodizing, electroplating, or surface treatment for other projects, our expertise adds value to your parts to meet the quality requirements of your products.

Anodizing: Our technicians immerse metal products in electrolytes such as sulfuric acid, chromic acid or oxalic acid. The surface of the products undergoes an oxidation reaction, forming an oxide film, thereby completing the anodic oxidation reaction of the products. This surface treatment is mainly used for aluminium and its alloys, and can also be applied to metals such as titanium and magnesium. It can enhance the corrosion resistance and wear resistance of the product. We offer customers a variety of color options to meet the diverse appearance requirements of the product. Anodizing processes are widely applied in fields such as aerospace, automotive industry, architectural decoration, consumer electronics casings, and medical devices.

Electroplating is the process of reducing metal ions in the electroplating solution and uniformly depositing them on the surface of the product to form a dense and strong metal coating. Electroplating can significantly enhance the corrosion resistance, electrical conductivity, and aesthetic appeal of metal products, and thus is often used in fields such as automobiles, electronics, and home appliances.

Spraying is a commonly used surface treatment technology, there are various spraying methods, air spraying with its flexible operation, high coating quality and low cost advantages, widely used in automobiles, air tools, electrical equipment and other areas of hardware parts.

Brushed is a surface treatment method that forms lines on the surface of the workpiece by grinding the product to play a decorative effect. Because the surface drawing treatment can reflect the texture of metal materials, it has been loved by more and more users and is more and more widely used.

Sandblasting is a process for surface treatment of workpieces. The compressed air is used as the power to form a high-speed jet beam to spray the spray material (copper ore, quartz sand, emery, iron sand, sea sand) to the surface of the workpiece to be treated at high speed so that the appearance or shape of the workpiece surface is changed.

Polishing is a process that removes microscopic protrusions on the surface of materials through physical, chemical or electrochemical methods, making them smooth, flat or even achieving a mirror-like effect. It is widely used in fields such as precision parts processing, automobiles, and medical equipment.

Mass Production

AFI Industrial Limited company has advanced forging equipment and production lines. With our professional technical team and strict quality control system, we can carry out mass production while maintaining the consistency of products. Can meet customer demand for products.

How to Start Your Order

Send your drawings

Process discussion, quotation

Make a sample

Volume produce

Shipment & Payment

Shipping

Checkout

AFI Industrial Co., Ltd. has established a quality management system for CNC parts, equipped with professional testing equipment and a senior quality inspection team. We conduct all-round inspections at every stage in accordance with the customer’s drawings and technical standards to ensure that all products meet 100% of the customer’s quality requirements and industry standards.

Shipment

AFI Industrial Co., Ltd. collaborates with many well-known logistics partners worldwide. We will carefully package your products based on their characteristics and requirements, and then select the most cost-effective and fastest transportation plan for you to ensure the safe and punctual delivery of your goods.

Our Promise

With our services, you will get a trusted supplier. In the coming days, we will continue to improve our professional degree, expand our credibility, and let you get the following harvest!

Quality Guarantee

We provide a full range of checks to ensure that the dimensions are accurate and the appearance meets customer specifications during the forging.

Quick Response

After receiving the order, we respond quickly within 2 hours, quote within 4 hours, and deliver according to quantity within 3-15 days.

Custom Material

We will according to the needs of customers, carefully select high-quality raw materials, customized to meet customer needs for all kinds of products.

Custom Surface Treatment

We can apply a variety of surface treatments to manufactured products according to customer requirements, including electroplating, anodizing, etc.

Arbitrary Size

We can produce products strictly in accordance with the dimensions on the drawings provided by customers, ensuring that every dimension is precise and error-free, fully meeting the quality standards.

Unlimited Quantity

Whether you need samples or mass production, we can precisely manufacture according to your requirements, ensuring that the quality of each product remains consistent.

Brand We Cooperated with

AFI Industrial Co., Ltd. has specialized in precision parts processing for 15 years and possesses multiple high-precision five-axis turning centers. We have passed the ISO9001 quality system certification. We have long been providing key components for the automotive and home appliance industries. We have rich mass production experience in products such as transmission valve bodies and heat dissipation components. Our product quality is stable and reliable, with a defect rate controlled below 0.05%.

Frequent Asked Questions

Forgings are formed by hammering. They have a dense structure, high strength and impact resistance, and are suitable for key components that are subjected to large forces (such as engine crankshafts and aircraft landing gears).

Castings are cast from molten iron. They have complex shapes and low costs, but they may have pores and impurities (suitable for non-load-bearing parts such as shells and brackets).

If you want it to be sturdy and durable, choose forging. If you want it to be cheap or have a complex shape, choose casting.

Forging mainly includes free forging, die forging and precision forging. Free forging is suitable for small batches of large parts. Die forging has high accuracy and is suitable for parts with complex shapes. Precision forging can achieve near-net forming and reduce the machining allowance.

Forging can refine the grain structure of metals, enhance the strength and toughness of materials, and eliminate internal defects. It is used in key components that bear high loads, such as parts of aero engines and automotive transmissions.

The common forging materials we see include carbon steel, alloy steel, stainless steel, aluminum alloy and titanium alloy, etc. The appropriate material and heat treatment process should be selected according to the performance requirements of the parts.