End milling lets you cut or shape materials with great control in the machining process. You use a spinning end mill to take away material from metals, plastics, wood, and composites. This method helps you make complex shapes, slots, and curves in any direction. AFI Industrial Co., Ltd uses end milling on aluminum alloys, stainless steel, Delrin, MDF, and carbon fiber composites. You can pick the best end mill for each job, so you get accurate results if you want a smooth edge or a detailed pocket.

Key Takeaways

- End milling uses a spinning tool to cut materials. In the milling process, it can cut in many directions. This helps make complex shapes and smooth surfaces.

- Picking the right end mill shape, size, and material is important. It helps you get accurate cuts. It also makes the tool last longer.

- Setting up the machine the right way is needed. Planning the toolpath helps you avoid mistakes. It also makes your work better.

- Different end mills do different jobs. Some are for roughing, which removes material fast. Others are for finishing, which makes surfaces smooth.

- Using the right cutting speed and feed rate is important. Coolant keeps tools cool and helps them last longer.

- Checking and taking care of tools often is needed. This stops tool wear, bad finishes, and machine shaking.

- End milling is used in many industries. These include aerospace, automotive, medical, and electronics.

- Following best practices and tips helps you work well. It makes milling efficient, accurate, and high-quality.

Table of Contents

End Milling Basics

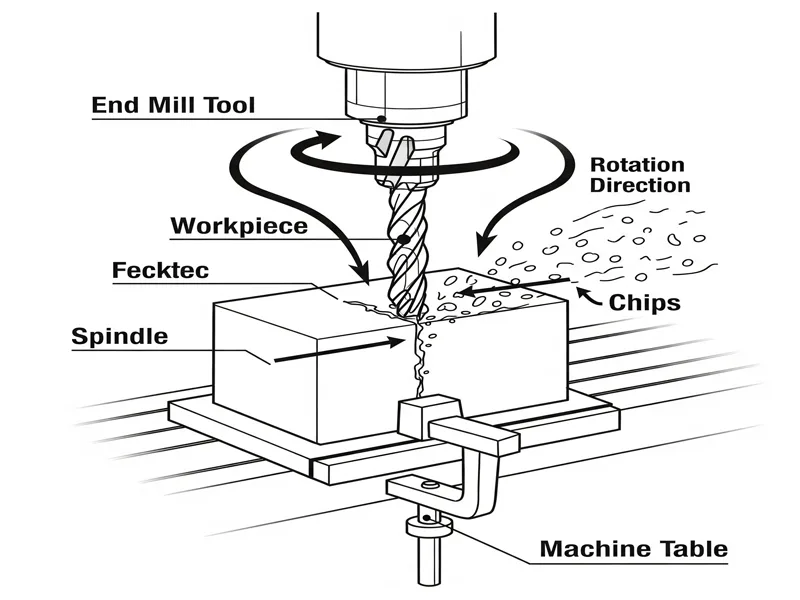

What Is End Milling

End milling helps you shape and cut materials very accurately. The process uses a spinning tool called an end mill. The end mill has sharp edges on its tip and sides. You hold the workpiece tightly in place. Then, you move it carefully against the spinning tool. CNC milling machines often control this movement. This lets you make complex shapes, slots, and curves. You can cut in more than one direction, not just straight down. This makes end milling great for making detailed parts and smooth surfaces. AFI Industrial Co., Ltd uses end milling to get accurate results on metals, plastics, and composites.

End milling is special because you use both the bottom and sides of the tool at once. The tool removes material and forms chips. You need to clear away these chips for a clean cut. You also change the speed, feed rate, and depth of cut for each job. Coolant and lubrication keep the tool cool and help it last longer. This setup lets you make precise parts again and again.

Key Features

End mills have features that make them different from other tools. Here are some main points:

- Cutting edges are on the sides and tip, so you can cut down and sideways.

- You can use end mills for both horizontal and vertical cuts.

- End mills come in many shapes, like ball-nose, square-end, and corner-radius. Each shape works best for certain jobs.

- You get very accurate cuts, so they are good for slots, grooves, pockets, and 3D shapes.

- You often use end mills on vertical milling machines. The tool stands straight up compared to the workpiece.

- End mills are smaller, so in the milling process, you can reach tight spots and make tiny details.

| Feature | End Mills | Other Cutting Tools (Face Mills) |

|---|---|---|

| Cutting Edges | On sides and bottom (axial and radial cutting) | Only on the periphery |

| Cutting Directions | Multi-directional (axial and radial) | Primarily radial (peripheral) |

| Tool Shapes | Various (ball-nose, square-end, corner-radius) | Generally larger diameter, fewer shape variations |

| Tool Orientation | Perpendicular or parallel to surface | Typically perpendicular to workpiece |

| Application Focus | Slots, grooves, pockets, 3D complex shapes | Flat surface machining |

| Precision and Size | Smaller diameter, precise cuts in tight spaces | Larger diameter, broad surface coverage |

| Cutting Depth | Deeper axial cuts possible | Shallow cuts, surface-level |

| Versatility | High, suitable for intricate and complex tasks | Focused on flat surfaces and large-scale removal |

Tip: Always pick the right end mill shape and size for your project. This helps you get the best results and keeps your tool from breaking.

End Milling vs. Other Milling Processes

You may wonder how end milling is different from other methods like face milling or drilling. End milling gives you more choices and better accuracy. You can cut in many directions and make complex shapes. Face milling is best for quickly removing lots of material from flat surfaces. It uses bigger tools with cutting edges only on the outside, so it cannot make deep or detailed cuts.

- Face milling removes material faster, so it is good for big, flat surfaces.

- End milling removes material at a medium speed but gives more detail and accuracy.

- You use end milling when you need slots, pockets, grooves, or 3D shapes.

- Face mills cover more area at once, but end mills work better in small spaces and on detailed parts.

End milling can reach tolerances of about ±0.1 mm (±0.005 inches) most of the time. With careful setup and the right tool, you can get even tighter tolerances. Because you can cut both down and sideways, end milling is useful in many industries, like aerospace, automotive, and manufacturing.

How End Mills Work

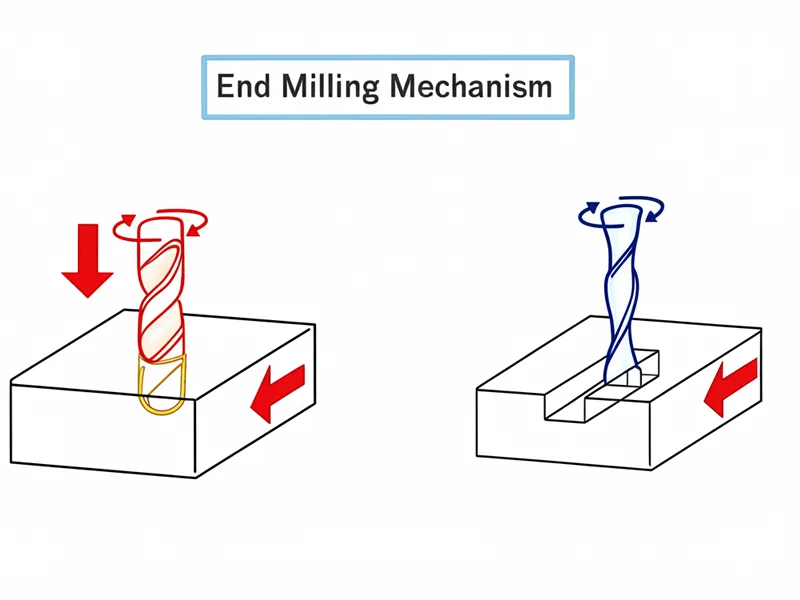

Cutting Directions

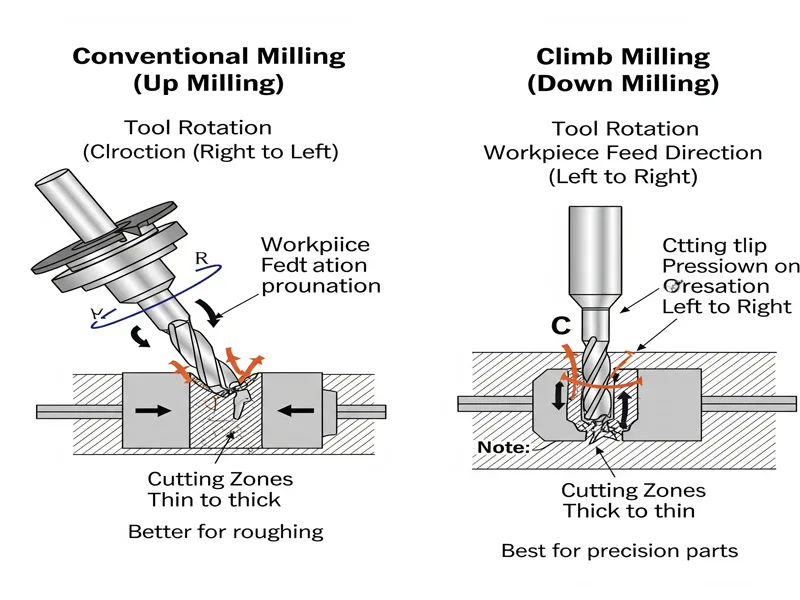

You can choose how the end mill cuts. There are two main ways: up-milling and down-milling. Each way changes how your project turns out.

Here is a table that shows how these two ways are different:

| Cutting Direction | Description | Effects on Machining Outcomes | Advantages | Disadvantages | Suitable Conditions |

|---|---|---|---|---|---|

| Up-milling (Climb Milling) | The cutter spins the same way as the feed moves. The chip starts thin and gets thicker. | You get a smoother finish and the tool lasts longer. You need a strong setup. | The surface looks better and the tool does not wear out fast. It works well on hard outsides. | You need a strong setup. It can make burrs when the tool leaves the material. | Use for parts that need to be exact, hard materials, and strong machines. |

| Down-milling (Conventional Milling) | The cutter spins against the feed. The chip starts thick and gets thinner. | You can remove material faster. It works better if your setup is not very strong. The finish is not as smooth. | It works with setups that are not very strong. Chips move away easily. It is good for rough work. | The finish is not as smooth. The tool wears out faster and there is more shaking. | Use for rough work, soft or bendy parts, and less strong machines. |

Tip: Pick the cutting direction that matches your material, how strong your machine is, and the finish you want. AFI Industrial Co., Ltd says climb milling is best for exact parts. Conventional milling is better for rough work.

Center-Cutting vs. Non-Center-Cutting

When you pick end mills, you should know about center-cutting and non-center-cutting. This choice changes how you start your cut and what shapes you can make.

- Center-cutting end mills can go straight down into the material. You use them to go down, ramp, or make spiral cuts. These end mills let you do many jobs.

- Non-center-cutting end mills cannot go straight down. You must use ramping or spiral moves to reach the bottom. These end mills often have more flutes and a strong core. They are good for deep side cuts with straight walls.

- Non-center-cutting end mills give a better finish on side walls in deep pockets. They also help stop the tool from bending.

- Most jobs use center-cutting end mills because they can plunge, ramp, and spiral.

AFI Industrial Co., Ltd uses both types to fit each project. You get the best results when you pick the right end mill for your job.

Depth and Width of Cut

You can change how deep and wide the end mill cuts. This helps you balance speed, tool life, and how smooth the surface is. If you cut deeper, the tool gets hotter. Too much heat can wear out the tool and make the surface rough. Deep cuts take away more material but can cause shaking and tool bending. Use shallow cuts for finishing to get a smooth surface and make the tool last longer.

The width of the cut changes how chips move and how the tool wears. Wider cuts can spread out the wear and help the tool last. But wide cuts can also make the tool bend and get hot. If chips do not clear out, the tool can cut them again and break.

Note: AFI Industrial Co., Ltd says to start with small depth and width settings. You can change these after you test to find what works best for your material and machine.

You should set the depth and width of cut for each job. This helps you control heat, tool wear, and bending. It also keeps your work fast and the surface nice. In cnc milling, planning these settings gives you good results and makes your tools last longer.

Milling Process Steps

Machine Setup

You must get your workspace and tools ready first. Clean the workpiece and machine table. Wipe the spindle taper and arbor. Take away chips and burrs so nothing gets damaged. Make sure the milling machines move well and have enough oil.

Put the workpiece close to the spindle for better support. Use vises or clamps to hold it tight. This stops shaking. Pick the right vise for your workpiece shape and angle. Attach the cutting tool to the arbor with the right taper and drawbolt. Check that the spindle spins the right way for your milling method.

Add cutting oil to keep things cool and help the tool last. Do not change speeds or feeds while you are working. AFI Industrial Co., Ltd says to do a test cut on a small spot to check your settings. Watch for strange shaking or sounds. When you finish, clean the machine and area. Put your tools away the right way.

Tip: Always check your setup before you start milling. A steady setup helps you avoid mistakes and makes better parts.

Tool Selection

Picking the right cutting tool is very important. Think about what material you will cut. Harder materials need stronger end mills like carbide or cobalt. Softer materials work well with high-speed steel. Choose a roughing mill if you want to remove a lot of material. Use a finishing mill for smooth surfaces.

Look at the cutting diameter, shank diameter, flute length, and total length. More flutes give finer cuts. Fewer flutes remove material faster. Pick coatings like titanium nitride or diamond-like carbon to help the tool last longer and lower friction. Make sure the cutting edge is sharp and not broken. Good chip removal stops the tool from getting stuck. AFI Industrial Co., Ltd uses top-quality end mills with tight tolerances and even flutes for accurate work.

| Criteria | What to Consider | Why It Matters |

|---|---|---|

| Material Type | Carbide for hard, HSS for soft | Matches tool to workpiece |

| Finish Type | Roughing or finishing | Controls surface quality |

| Flute Count | More for fine, fewer for fast removal | Affects speed and finish |

| Coating | TiN, TiAlN, DLC | Improves durability |

| Diameter/Length | Based on job size and detail | Ensures proper fit and reach |

Note: Always use a cutting tool that fits your job and material. This helps you stop tool breaks and get good results.

Toolpath Planning

Toolpath planning decides how your milling will go. You pick the path for the cutting tool. For tricky shapes, think about the shape and type of job—roughing, semi-finishing, or finishing. Use patterns like spiral, offset contour, or straight lines to make smooth surfaces. Set things like feed per tooth, cutting speed, stepover, and depth of cut for your tool and material. CAM software lets you see toolpaths and fix mistakes before you start. Look for places where the tool might hit the workpiece.

Good entry and exit moves help the tool last longer. Adaptive clearing and trochoidal milling keep the tool load even and stop heat from building up. AFI Industrial Co., Ltd uses smart toolpaths for nice finishes and fast work.

Tip: Plan your toolpath well. Good planning saves time and makes the surface look better.

Cutting Operation

Once you finish setup and planning, you start cutting. This step shapes your workpiece and makes the features you want. You control how the end mill moves, how fast it spins, and how quickly it moves forward. These settings should match your material and design.

Some common cutting operations are:

- Roughing: You take away a lot of material fast. Use roughing end mills with jagged edges for quick cuts and less heat.

- Finishing: You use finishing end mills to make smooth surfaces and fine details. Go slower and take shallow cuts for a clean look.

- Slotting: You cut straight slots or grooves. Pick end mills that match the width you need.

- Pocketing: You make holes or sunken areas. Plan your tool’s path to clear chips and stop the tool from getting stuck.

- Tapered Cutting: You use tapered end mills to make slanted walls or cone shapes.

You need to set the right cutting numbers for each job:

| Parameter | Typical Range (1/2″ Carbide End Mill) |

|---|---|

| Cutting Speed (SFM) | Aluminum: 600-1000 Mild Steel: 250-400 Stainless Steel: 100-300 Titanium: 50-150 |

| Feed Rate (IPM) | Change for material and tool type |

| Depth of Cut | Usually less than half the tool width |

| Width of Cut | Set by how much the tool moves over |

| Coolant | Use to keep things cool and move chips |

Watch how the chips look and clear them out often. Use coolant or oil to keep the tool cool and help it last longer. Always hold your workpiece tight so it does not move. AFI Industrial Co., Ltd says to do test cuts first to check your settings and avoid mistakes.

Tip: Begin with slow speeds and feeds. Make them faster as you get better and see steady results.

Finishing and Inspection

After the main cutting, you do finishing and inspection. Finishing makes the surface smoother and checks if your part matches the design. Use fine end mills and slow speeds for the last passes. This step takes away tiny flaws and sharp edges.

Inspection checks your work for accuracy and quality. You follow steps to find mistakes early and make sure the part is right.

- Check your setup before you start. Look at the tool and make sure the machine is lined up.

- While cutting, use simple tools like micrometers and go/no-go gauges to check important parts.

- Use automatic probes in CNC programs to measure key sizes while you work.

- After milling, do a final check with advanced tools. Coordinate Measuring Machines (CMMs) and laser scanners help you check tricky shapes and surface smoothness.

- Use sampling plans and process control to check if parts meet size limits. If you find a problem, check all parts and separate any that are not good.

AFI Industrial Co., Ltd follows ISO 9001:2015 rules for tracking and quality. You should keep inspection records and set aside any bad parts. This helps you give customers the same high quality every time.

Note: Checking your work during and after milling helps you find problems early and saves you from fixing costly mistakes later.

Types of End Mills

Flat End Mills

Flat end mills, also called square end mills, have a flat tip that creates sharp, 90-degree corners and flat surfaces. You use these tools when you need to cut simple profiles or make flat-bottomed pockets. The square end lets you produce clean, straight edges and precise corners. If you want to mill signs with raised letters or cut large letters out of wood, flat end mills work best. You get smooth, flat surfaces at the bottom of any inset shape. These end mills cut most efficiently when you use the side of the tool, not just the tip.

Milling software often ramps the tool into the material, which helps you avoid plunging straight down and damaging the tool. Flat end mills are the most common choice for general milling tasks that require flat surfaces and sharp edges. At AFI Industrial Co., Ltd, you can select flat end mills for projects that demand accuracy and clean finishes.

Tip: Choose flat end mills when you need crisp corners and flat bottoms in your workpiece.

Ball Nose End Mills

Ball nose end mills have a rounded, hemispherical tip instead of a flat one. You use these tools when you need to create curved surfaces or sculpt complex 3D shapes. Ball nose end mills perform point contact cutting, which means they touch the material at a single point. This design makes them perfect for 3D contouring and sculpting. You often see these end mills in mold making, woodworking, and engraving. They work well for finishing operations that require smooth, rounded corners and detailed features.

Ball nose end mills also excel in CNC machining centers, especially when you need to reach into narrow or deep areas. You can use them for artistic designs or industrial parts that have complex surfaces. Tapered ball nose end mills offer extra rigidity, which helps you achieve high accuracy in deep cuts.

- Ball nose end mills are ideal for:

- 3D contouring and sculpting

- Finishing operations with rounded corners

- Mold and die making

- Engraving and woodworking

- Machining complex surfaces in aerospace parts

Note: Ball nose end mills help you achieve smooth, scalloped finishes on intricate 3D shapes.

Corner Radius End Mills

Corner radius end mills combine features from both flat and ball nose end mills. The tip has a small, rounded radius instead of a sharp corner. You use these tools when you want the strength of a flat end mill but need to avoid sharp corners that can crack or chip. The rounded edge reduces tool wear and improves the life of your end mills. You get smoother transitions between surfaces and less risk of stress points in your part. Corner radius end mills work well for machining pockets, slots, and edges where durability and a clean finish matter. AFI Industrial Co., Ltd recommends corner radius end mills for jobs that need both strength and a smooth edge.

Tip: Use corner radius end mills to extend tool life and prevent chipping in your finished parts.

Roughing End Mills

Roughing end mills help you take away lots of material fast. You use these tools before you finish shaping your workpiece. The tool has many small cutting edges. Each edge takes a tiny bite from the material. This makes small chips that move away easily. Small chips lower the force needed to cut. You can use roughing end mills at higher speeds. They run about 20% faster than finishing end mills. This helps you finish roughing quickly and save time.

You get many benefits when you use roughing end mills:

- You remove material faster, so you work quicker.

- The tool makes small chips, which clear out better and help the tool last longer.

- You can take bigger cuts without too much shaking.

- The design is good for deep slots and machines that are not very strong.

- Using roughers first helps finishing end mills last longer.

- Small chips mean you need less power and your tool lasts longer.

AFI Industrial Co., Ltd uses roughing end mills to take away lots of metal and composite material. You must clear chips well, using air or lots of cooling fluid, to keep things smooth. After roughing, you switch to finishing end mills for a clean look.

Tip: Always start with roughing end mills. This saves time and keeps your finishing tools safe.

Tapered End Mills

Tapered end mills have a cutting edge that gets thinner from the shank to the tip. You use these tools to make angled walls or sloped parts. The tapered shape makes the tool stronger and stops it from bending. You often use tapered end mills for molds, dies, and deep parts. The design lets you reach tight spots and cut at an angle.

You can pick different taper angles for your project. Tapered end mills are good for engraving, 3D carving, and making tricky shapes. AFI Industrial Co., Ltd suggests tapered end mills for jobs that need exact angles and strong tools. You get better accuracy and less chance of breaking the tool if you use the right taper.

Note: Pick the right taper angle for your part. This helps you get the shape you want and keeps your tool safe.

Chamfer End Mills

Chamfer end mills help you make angled edges called chamfers on your parts. You use these tools to take away sharp edges and make your workpiece safer to touch. Chamfering also helps parts fit together better. You can use chamfer end mills on inside and outside edges, even on tricky shapes.

Here are some ways chamfer end mills help your finishing:

- You get neat, controlled cuts along edges, meeting tight size limits.

- The tool works with many part shapes and features.

- Chamfering takes away burrs and sharp edges, so you do less hand work.

- Chamfered edges help parts fit and make assembly easier.

- You save time and money by doing chamfering while machining.

- The process makes parts better and more efficient.

AFI Industrial Co., Ltd uses chamfer end mills for aerospace and medical parts that need to be very exact. You must set up your CNC machine carefully to get the right angle and size. The good things about chamfering are worth the extra work in programming.

Tip: Use chamfer end mills to make your parts safer, better, and easier to put together.

Other Specialty End Mills

You will find that not every job fits the standard end mill shapes. Specialty end mills help you solve unique machining challenges. These tools let you handle tricky features, hard-to-reach spots, or special finishes. At AFI Industrial Co., Ltd, you can choose from a wide range of specialty end mills to match your project needs.

Here are some common specialty end mills you might use:

- Thread Mills

You use thread mills to cut threads inside holes. Unlike taps, thread mills do not get stuck as easily. You can use one tool for different thread sizes. This tool works well for both right-hand and left-hand threads. - Dovetail End Mills

Dovetail end mills help you cut angled slots or grooves. You often use them for making parts that slide together, like machine ways or fixtures. The angled shape gives you strong, precise joints. - Keyseat (Woodruff) Cutters

You use keyseat cutters to make keyways or slots in shafts. These tools have a rounded profile. They help you create slots that fit keys for gears or pulleys. - Engraving End Mills

Engraving end mills let you add text, numbers, or designs to your parts. You use them for marking, labeling, or adding logos. The sharp, pointed tip gives you fine detail. - Radius End Mills

You use radius end mills to create rounded grooves or fillets. These tools help you avoid sharp corners that can crack or wear out. They also improve the strength and look of your parts. - Drill Mills

Drill mills combine the features of a drill and an end mill. You can use them to drill, chamfer, or mill slots. This tool saves you time when you need to switch between drilling and milling. - T-Slot Cutters

T-slot cutters help you make T-shaped slots in your workpiece. You often use these slots for machine tables or assembly fixtures. The unique shape lets you cut undercuts that standard end mills cannot reach.

Tip: Always match your specialty end mill to the job. The right tool helps you work faster and get better results.

| Specialty End Mill | Main Use | Key Benefit |

|---|---|---|

| Thread Mill | Internal threading | Versatile, less breakage |

| Dovetail End Mill | Angled slots, dovetails | Strong, precise joints |

| Keyseat Cutter | Keyways, slots in shafts | Accurate, rounded slots |

| Engraving End Mill | Text, logos, fine details | Sharp, detailed marks |

| Radius End Mill | Rounded grooves, fillets | Smooth, strong corners |

| Drill Mill | Drilling, chamfering, slotting | Multi-purpose, saves time |

| T-Slot Cutter | T-shaped slots, undercuts | Unique shapes, deep slots |

AFI Industrial Co., Ltd recommends you keep a few specialty end mills in your tool kit. You will find that these tools help you solve tough machining problems and improve your finished parts. When you face a new challenge, check if a specialty end mill can make the job easier and more accurate.

Note: Specialty end mills may cost more, but they save you time and reduce tool changes. You get better quality and longer tool life when you use the right tool for each task.

Materials and Coatings

Picking the right materials and coatings for your cutting tool is important. The right choice helps your end milling work better and makes your tool last longer. AFI Industrial Co., Ltd says you should learn about tool materials and coatings before you start.

Tool Materials

End mills are made from different materials. Each one has its own good points for hardness, how long it lasts, and price. You should know how these materials are different so you can pick the best one for your job.

| Tool Material | Hardness & Wear Resistance | Key Characteristics & Applications |

|---|---|---|

| High Speed Steel (HSS) | Good wear resistance; lower cost | General-purpose milling of ferrous and nonferrous materials |

| Cobalt (M-42, 8% Co) | Better wear resistance and hot hardness than HSS | Runs 10% faster than HSS; good for cast iron, steel, titanium alloys; cost-effective |

| Solid Carbide | Very high hardness (60-70 HRC); superior wear resistance and heat resistance | High rigidity; enables 2-3X faster machining than HSS; ideal for cast iron, nonferrous, plastics, tough materials |

High-Speed Steel

High-speed steel is a common choice for end mills. It gives good wear resistance and costs less. HSS works for both soft and hard metals. If you need a tool for simple jobs or softer metals, HSS is a good pick.

Carbide

Carbide end mills are very hard, between 60 and 70 HRC. This means they stay sharp longer and do not chip easily. Carbide can handle heat, so you can cut faster and work on tough metals. Carbide is best for fast jobs and when you want your tool to last.

Cobalt

Cobalt end mills have extra cobalt, so they last longer and stay hard when hot. You can use cobalt tools about 10% faster than HSS. They are good for cast iron, steel, and titanium alloys. Cobalt is a cheaper way to cut harder metals if you do not want to use carbide.

Coatings

Coatings make your cutting tool work better. They make the tool harder, lower friction, and help it last longer. You should pick a coating that fits your job and material.

Titanium Nitride

Titanium Nitride (TiN) gives your tool a hard, gold surface. TiN helps the tool last longer and makes it smoother. You get better chip removal and smoother cuts. TiN is good for most milling jobs and helps your tool last.

Titanium Aluminum Nitride

Titanium Aluminum Nitride (TiAlN) can take more heat. This coating lets you cut faster and at higher temperatures. TiAlN is best for hard metals and tough jobs. You see less tool wear and better results in dry or wet cutting.

Diamond Coatings

Diamond coatings are very hard and strong. These coatings are best for tough materials, plastics, and soft metals. Diamond-coated end mills last longer and can cut fast. You get smooth finishes and less tool damage.

Tip: Coated end mills can cut faster, handle heat, and stay sharp longer. Pick your coating based on your job and material for the best results.

Choosing Materials and Coatings

You should think about a few things when picking tool materials and coatings:

- Match the tool to what you are cutting. Harder metals need carbide or cobalt.

- Pick coatings for your workpiece. TiAlN is good for steel, and diamond is good for soft or rough materials.

- Think about your job type. Roughing needs strong tools, finishing needs sharp ones.

- Look at flute count and shape for chip removal and smooth surfaces.

- Use coated tools for faster speeds and longer tool life.

AFI Industrial Co., Ltd helps you pick the right tool for every job. You get better results and save money by choosing the best materials and coatings.

Applications and Industries

Common Operations

End mills help with many jobs in factories. Each end mill type works best for a certain task. The table below shows which end mill fits each job:

| End Mill Type | Common Machining Operations |

|---|---|

| Ball End Mills | Milling contoured surfaces, slotting, pocketing, die and mold work |

| Roughing End Mills | Rapid removal of large amounts of material, heavy-duty roughing |

| Corner Radius End Mills | Milling with a specific radius, longer tool life |

| Corner Chamfer End Mills | Chamfering edges without a specific radius |

| Finishing End Mills | Creating smooth finishes |

| Corner Rounding End Mills | Milling rounded edges, reducing edge chipping |

| Drill Mills | Spotting, drilling, countersinking, chamfering, various milling |

| Tapered End Mills | Die and mold applications with tapered edges |

Ball end mills are good for making 3D shapes and pockets. Roughing end mills help you take away material fast. Finishing end mills make parts look smooth. Drill mills let you drill and mill with one tool. You can choose the right end mill for each step.

Tip: Use roughing end mills first to remove most material. Then use finishing end mills for a smooth surface.

Industry Uses

Many industries need end milling every day. Applications of end milling are widely used. These tools help when you want things done quickly and accurately. Here are some industries and how they use end milling:

- Automotive: You make engine parts, gears, and special pieces.

- Aerospace: You build turbine blades and strong frames.

- Medical Devices: You shape surgical tools and implants that must be exact.

- Electronics: You cut circuit boards and tiny cases.

- Metal Fabrication: You form and finish metal for machines.

- Construction Equipment: You make strong parts for vehicles and tools.

- Electric Vehicle (EV) Manufacturing: You cut battery boxes and light frames.

- High-Speed Rail and Defense: You make exact parts for trains and military gear.

- Semiconductor: You create small, tricky parts for chips.

- Furniture and Precision Engineering: You make detailed wood and metal items.

Factories around the world use end milling machines. You see them in China, the USA, Europe, South Korea, Japan, and Australia-New Zealand. Companies like AFI Industrial Co., Ltd use advanced CNC machines to work fast and meet high standards.

Real-World Examples

End milling helps make many things you use. For example:

- Mold makers use end mills to shape detailed cavities for plastic molds.

- Medical companies use end mills to make implants and tools that must be very accurate.

- Electronics makers use end milling for circuit boards and tiny parts.

- Jewelry makers use end mills to carve fancy designs.

One example is machining a cast aluminum box, about 7.5″ x 4.75″ x 3″ tall. The box has slanted sides and a flat top that is exactly straight. This shows end milling can make both tricky shapes and perfect flat surfaces. At AFI Industrial Co., Ltd, you see these results in custom parts for aerospace, cars, and medical tools. You get the same good quality every time.

Note: Picking the right end mill and process helps you get smooth finishes and exact shapes, even for hard jobs.

Advantages and Disadvantages

Advantages

End milling gives you many good things for your projects. This process is flexible and very accurate. You can use it for contouring, profiling, tracing, and plunging. CNC machines help you get tight tolerances. You can work with metals, plastics, wood, and composites. End milling works fast and uses automation. This means fewer mistakes and steady production. You can make complex shapes, slots, shoulders, and housings easily.

Some main benefits of end milling are:

- You can use it for many jobs, from simple slots to tricky 3D shapes.

- CNC machines give you great accuracy and repeatable results.

- It works with hard and soft materials.

- Production is quick and needs less manual work.

- You can make detailed and tiny parts.

Tip: AFI Industrial Co., Ltd says end milling is best when you need speed and accuracy for custom parts.

Disadvantages

You should know the downsides of end milling before you start. Some problems can slow you down or cost more. You must pick tools and machines that fit your material. Fine finishing takes extra time, and tools wear out faster with hard materials. Advanced machines cost a lot at first. Programming CNC machines can be hard and needs special skills.

Some common disadvantages are:

- You need special tools and machines for each material.

- Finishing takes longer and tools wear out faster with tough materials.

- Advanced end milling machines cost a lot upfront.

- CNC programming is tricky for different jobs.

- End milling removes less material than face milling.

- You need to make several passes to reach the final shape or depth.

Note: You can make these problems smaller by planning well, picking the right tools, and keeping your equipment in good shape.

When to Use End Milling

Use end milling when you need detailed, exact, or tricky cuts. This process is best for profiling, contouring, slotting, and making complex 3D shapes. You can cut up and down or sideways, so it works well for custom jobs. End milling works for hard and soft materials, so you can use it for many workpieces. If you need tight tolerances or deep and shallow cuts (up to 20 mm), end milling gives you steady results. You can grind end mills to special angles for more accuracy.

Pick end milling if you want to:

- Make complex shapes, contours, or pockets.

- Get high accuracy and tight tolerances.

- Work with many kinds of materials.

- Do deep and shallow cuts.

- Create detailed parts for aerospace, cars, or medical devices.

Face milling is better for big, flat surfaces and quick material removal. End milling gives you more control for detailed work. AFI Industrial Co., Ltd uses end milling for jobs that need custom shapes and exact sizes.

Troubleshooting and Tips

When you use end milling, you may have some problems. Knowing how to find and fix these problems helps you work better and faster.

Common Problems

Tool Wear

Tool wear means the cutting edge is not sharp or gets damaged. You might notice the tool is dull or has chips. Sometimes, the tool can even break. This happens if you run the tool too fast or use the wrong coating. Cutting hard materials can also cause tool wear. If you do not fix tool wear, your parts will not look good and your tool will not last long.

Poor Surface Finish

A rough surface finish makes your part look bad and not fit well. This can happen if you cut too fast or use a slow spindle speed. Using a worn tool can also make the finish worse. Sometimes, chips stick to the tool or workpiece and make the surface rough.

Vibration and Chatter

Vibration and chatter make loud noises and leave marks on your part. These problems happen if your machine is not strong or the tool sticks out too far. Cutting too hard can also cause vibration. Chatter can break your tool and make your part less accurate.

Here is a table that lists common problems, what causes them, and how to fix them:

| Problem | Likely Causes | Likely Solutions |

|---|---|---|

| Tool Wear | High speed, wrong coating, hard material | Adjust speed, use coated tools, improve coolant |

| Edge Chipping | Aggressive feed/depth, poor rigidity | Reduce feed/depth, improve setup, check spindle run-out |

| Tool Breakage | Aggressive feeds, tool overhang, chip packing | Reduce feed/depth, shorten tool, improve chip evacuation |

| Poor Surface Finish | High feed, low speed, worn tool | Reduce feed, increase speed, replace or resharpen tool |

| Chatter (Vibration) | Poor rigidity, aggressive tool paths | Reduce speed/feed, improve setup, use rigid holders |

Tip: Always check your tool and setup before you start. Checking early helps you stop bigger problems later.

Solutions

You can fix most problems by making small changes. Try these steps:

- Change the cutting speed, feed rate, and depth of cut to fit your tool and material.

- Use enough coolant or cutting fluid to keep the tool cool and move chips away.

- Pick end mills with the right material and coating for your job.

- Start cutting slowly to avoid sudden shocks that can chip the tool.

- Check and change tools often to keep them sharp.

- Keep the tool short and hold it tight to stop vibration.

- Choose the right tool shape and adjust your settings for a smoother finish.

- Make sure your machine and tool setup are correct to avoid mistakes.

AFI Industrial Co., Ltd says you should check and care for your tools and machines often to keep them working well.

Best Practices

You can stop many problems by following these best practices:

- Pick the right end mill for your material and job.

- Use special tool shapes to lower chatter and help your tool last longer.

- Make sure the tool holder is tight and the cutter lines up with the spindle.

- Clamp the workpiece tight and use holders that stop vibration.

- Set speeds and feeds based on how hard your material is and what the tool maker says.

- Use the right coolant or oil to keep things cool and lower friction.

- Clean and check end mills after each use to remove chips and dirt.

- Sharpen or change tools as soon as you see they are worn.

Note: Good habits and regular checks help you stop most problems and keep your end milling running well.

End milling lets you do many different jobs with accuracy. You can make tricky shapes and smooth surfaces. You can also use it on many materials. AFI Industrial Co., Ltd says you should learn each step well. Pick the best tool for your job. Fix problems fast when they happen.

Use the tips in this guide to get better results.

If you want to learn more, try CNC machining classes or check AFI Industrial Co., Ltd’s website for expert help.

FAQ

You can machine metals, plastics, wood, and composites with end mills. AFI Industrial Co., Ltd often uses end mills on aluminum, stainless steel, Delrin, MDF, and carbon fiber. Always match your end mill to the material for the best results.

You should consider the material, the shape you need, and the finish you want. Look at the number of flutes, tool material, and coating. Use roughing end mills for fast removal and finishing end mills for smooth surfaces.

You can use the same end mill, but it is not ideal. Roughing end mills remove material quickly. Finishing end mills give you a smooth surface. Switching tools helps you get better results and extends tool life.

You should use the correct speeds and feeds. Apply coolant or cutting fluid. Choose the right tool material and coating. Keep your tool sharp and check for signs of wear often. Proper setup reduces vibration and extends tool life.

Up-milling (climb milling) moves the cutter in the same direction as the feed. Down-milling (conventional milling) moves against the feed. Up-milling gives a smoother finish. Down-milling works better for rough cuts or less rigid setups.

You can slow down the feed rate, increase spindle speed, and use a sharp finishing end mill. Apply coolant to reduce heat. Make sure your workpiece is secure. Clean chips away often for a smoother result.

Coated end mills last longer and cut faster. The coating reduces friction and heat. You get better finishes and fewer tool changes. AFI Industrial Co., Ltd uses coated end mills for high-quality, efficient machining.

Yes, you can use end mills on manual machines. You must set speeds and feeds by hand. Secure your workpiece tightly. Manual milling works well for small jobs or prototypes. CNC machines give you more precision for complex parts.