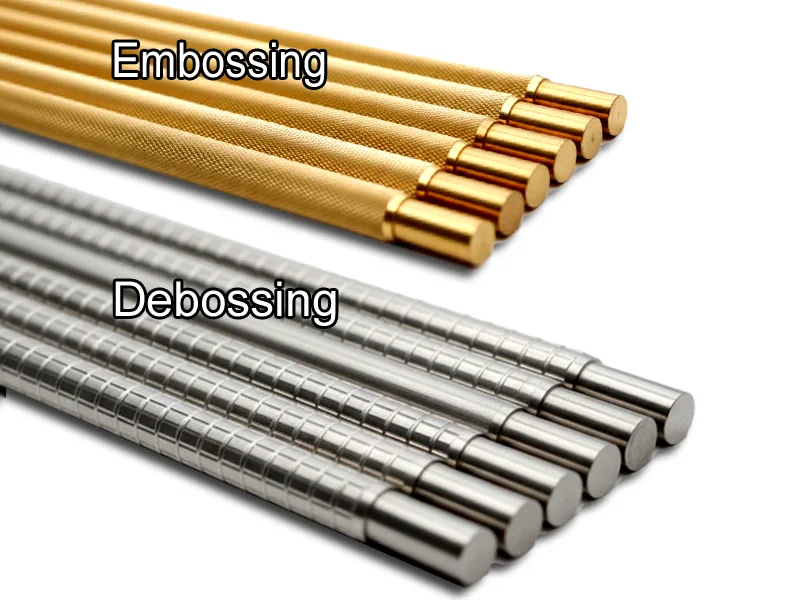

Embossing and debossing are two strong ways to make designs better in printing and packaging. Embossing makes a raised pattern on the top of the material. Debossing makes a sunken pattern instead. These methods change plain materials and help products look and feel special, and achieve the purpose of enhancing product packaging.

Recent numbers show embossing and debossing requests for company gift packages went up by 65%. This indicates that the applications for embossing and debossing are increasing. This shows they are becoming more important for branding. Companies pick embossing when they want a bold and fancy look. They use debossing for a smooth and gentle style.

Both methods help people think that products are high quality and last longer. Picking the right one is important for anyone who cares about great design.

- Embossing gives a raised look that stands out and is great for achieving a refined branding effect.

- Debossing gives a simple and classy look that top brands like.

What is embossing? This method uses strong pressure and two plates to make tough, raised designs. These designs are often found on thicker materials.

Key Takeaways

- Embossing makes designs stick out from the surface. This creates bold and noticeable effects. The design feels bumpy and looks fancy.

- Debossing pushes designs down into the material. This gives a smooth and soft look. It feels classic and elegant.

- You should pick the right technique for your project. Think about your goals, the material, your budget, and the style you want.

- Embossing works best on soft and thick materials. It is good for things like leather and cardstock. Debossing is better for hard and thin materials. It works well on metal and wood.

- Applications for embossing and debossing bring a special feel you can touch. This helps customers create a dimensional branding and connect with people.

- Embossing often costs more money. It needs two dies and extra steps. Debossing is usually cheaper. It is good for big orders.

- Try your design on the material before making many copies. This helps you get the best look and feel.

- Good teamwork between designers and printers is important. Checking quality also helps make embossing or debossing projects successful.

Table of Contents

What is Embossing?

Definition

Many designers want to know, what is embossing? Embossing makes a raised design on a material’s surface. The process pushes from below to form a 3D pattern. You can see and feel this pattern, it will bring you unique tactile experience. Embossing helps brands and artists make products look fancy. When people ask about embossing, they learn it can turn plain things into something special.

Process

Embossing uses two plates called dies. One is male and the other is female. The material goes between these dies. A machine presses them together with some heat. This heat is less than what debossing needs. The dies push the material up to make the raised design. Thicker materials work best for embossing. But skilled workers can emboss many surfaces. People often see embossing on fancy invites or nice packages. The process needs careful steps and attention to detail.

Common materials for embossing are:

- Paper (like cardstock, textured, or handmade paper)

- Metals (such as aluminum, brass, copper, stainless steel)

- Leather (cowhide, sheepskin, suede)

- Vinyl (used in car and boat trims)

- Poly-based materials (polyethylene, polypropylene, polystyrene)

- Fabric (cotton, linen, silk, polyester, nylon)

Each material reacts differently to embossing. Designers pick the best one for their project.

Typical Results

Embossing gives a look and feel that stands out. The raised parts catch light and make logos pop. You can feel the design with your fingers. There are different embossing styles like dome, flat, rim, and custom shapes. These styles help people find buttons, enjoy packaging, or notice details on book covers.

Tip: Embossing on metal tins can be light or deep. Light embossing gives a soft texture. Deep embossing makes a bold, strong look. Designers can change the depth to fit their ideas.

The table below shows how embossing looks and feels on different materials:

| Substrate Type | Visual Result | Tactile Result | Notes and Recommendations |

|---|---|---|---|

| Cardstock (300-400gsm) | Clear, attractive raised design | Pleasant, noticeable texture | Good for folding cartons, display boxes, sleeves |

| Corrugated Materials | Subtle, inconsistent effect | Barely felt | Not a good choice; embossing flattens on wavy surfaces |

| Rigid Boxes (chipboard + thin substrate) | Less prominent visually | Slightly raised feel | Use light embossing for small details; deep embossing for big designs; not much visual impact |

Embossing makes materials look and feel more special. When people ask, “what is embossing,” they find out it opens up many creative options.

What is Debossing?

Definition

Debossing makes a design that sinks into the material. This method creates an image or words below the surface, forming a unique texture. Designers pick debossing for a quiet and fancy look. It turns normal things into stylish items. You can see debossing on book covers and wallets. It is also used on special packaging. Debossing helps brands add style and make products unique.

Process

Debossing uses one die that presses down from the top. The die pushes the material in to make a lasting mark. This method often needs more heat than embossing. Heat makes the material softer for a deeper design. After pressing, the material cools and keeps its new shape. Debossing works with hot or cold methods. Hot debossing gives a sharper look. Cold debossing uses only pressure.

Here is a simple table that shows how debossing and embossing are different:

| Aspect | Embossing | Debossing |

|---|---|---|

| Die Usage | Two dies (male and female) | Single die |

| Heat | Less heat needed | More heat often used |

| Pressure | Material pressed from below | Material pressed from above |

| Result | Raised design | Recessed design |

Debossing needs careful control of heat and pressure. Skilled workers change these settings for each material and design.

Typical Results

Debossing leaves a sunken mark that feels smooth. The look is less bright than embossing but feels fancy. Many top brands use debossing for a quiet, high-quality style. This method works on many materials, so it is very useful.

Common materials for debossing are:

- Paper: Used for cards, invites, and packaging with texture.

- Cardstock: Thick paper feels special.

- Leather: Used for wallets, belts, and bags.

- Vinyl: Adds feel to wall art and decorations.

- Fabric: Used for patterns on clothes and furniture.

- Metal: Aluminum and brass for signs and accents.

Debossing can even be used on food like pastries and chocolates. It makes pretty designs. Designers enjoy the many ways they can use debossing. The finished product always feels unique and easy to remember.

Tip: Debossing on leather can last a long time. The mark stays clear even with lots of use.

Debossing helps brands make products that people notice by touch and sight. The sunken design makes people want to feel the surface and admire the work.

Embossing and Debossing Processes

Tools and Materials

Every project needs the right tools and materials. Embossing and debossing need careful work and good quality. Skilled workers use engraved dies made from wood, copper, or steel. These dies shape how the design will look and feel. The male die makes the raised part for embossing. The female die holds the material in place. For debossing, only one die pushes the design into the surface.

Key tools and materials are:

- Metal dies or plates made by engraving, hand-tooling, or photo-etching.

- Feeding systems like feed racks and rollers guide the material.

- Ink roller systems and impression rollers help when using ink.

- Drying systems, such as hot air or infrared, set the design.

- Control systems help run the machine.

Materials must be strong to handle the pressure. Heavy paper, usually 300 gsm or more, works best. Other good choices are leather, fabric, plastic, wood, and thin metal sheets. Each material gives a different texture and finish to the project.

Tip: Picking the right material can make a simple design look amazing.

Step-by-Step Overview

Embossing and debossing follow clear steps. Each step leads to a great result.

- Make the dies by engraving or etching.

- Put the material between the dies for embossing or under one die for debossing.

- Set the machine for the right pressure and heat if needed.

- Press the dies together to shape the material.

- Take out the finished piece and let it cool or dry.

This process turns plain materials into art. The look and feel inspire designers and brands to try new ideas.

Variations

Embossing and debossing have many creative choices. Blind embossing and debossing use no ink or foil. They focus on touch and a soft look. Foil embossing and debossing add shiny or colored foil for extra pop. Photographic embossing and debossing use images to make real 3D effects with different depths. Multi-level embossing and debossing use dies with more than one height. This adds layers and texture.

Different die types, like bevel-edge, chisel, textured, rounded, and sculptured, make special results. These styles show up in branding, packaging, and print. Designers use them on paper, leather, wood, acrylic, and metal. Every project is a chance to create something new and fun.

Note: Trying new debossing styles can help a brand stand out and be remembered.

Key Differences

Visual Effect

Embossing and debossing look very different. Embossing makes the design stick up from the surface. This makes it easy to see and bold. Light hits the raised parts and makes shadows. These shadows help the design stand out more. Debossing pushes the design down into the material. This gives a sunken look that is soft and fancy. Some designers use ink or foil on debossed spots. This makes them easier to notice.

The table below shows how embossing and debossing look different:

| Feature | Embossing | Debossing |

|---|---|---|

| Visual Effect | Raised design above the surface, smooth and elevated, visually prominent | Recessed design pressed into the surface, indented and subtle |

| Depth | Up to 1/16″ raised | Up to 1/8″ or more deep indentation |

| Visual Impact | Bold, makes designs ‘pop’ for branding and decoration | Understated, refined, often requiring ink fills for visibility |

| Shadows and Legibility | Shadows cast by raised design enhance legibility | Depth provides subtlety but may need ink to improve visibility |

Designers pick embossing when they want a logo to stand out. Debossing is good for brands that want a quiet and fancy look. Both ways use depth and texture to make a strong look.

Tactile Effect

Touch is important for how people remember things. Embossing and debossing both give a special tactile depth feel. Embossing feels smooth and raised under your fingers. Debossing feels deep and pressed in. These touches make packages, books, and labels more fun to hold.

- Embossing and debossing add depth and make things feel cool.

- Both ways make people want to touch and look at the design.

- Studies show that textures like these help people remember brands.

- People think a special feel means better quality and more happiness.

- Designers sometimes mix embossing or debossing with other textures for even cooler products.

The feel is not just about looks. It helps people connect with a brand in a special way. A raised or deep feel can make something simple feel amazing.

Material Suitability

Picking the right material is very important. Embossing works best on soft and bendy materials. These are things like leather, thick cotton, polyester blends, denim, and heavy canvas. The raised design shows up well on these. Debossing is better for hard and stiff materials. Real leather, suede, thick cotton canvas, cork fabric, and heavy felt are good for debossing. The deep mark gives a cool texture that lasts.

| Technique | Recommended Materials |

|---|---|

| Embossing | Leather/faux leather, Heavy cotton (10oz+), Polyester-blend fleece, Denim, Thick canvas |

| Debossing | Genuine leather, Suede/microsuede, Thick cotton canvas, Cork fabric, Heavy felt materials |

Designers also think about color and feel. Embossing looks best on solid colors. Debossing looks cool on two-tone or textured stuff. How long it lasts matters too. Leather looks fancy but costs more. Cotton blends are cheaper and still good. The best choice depends on what the project needs and how you want it to look and feel.

Tip: Always test your material before starting a big job. This makes sure the design will have the right look, feel, and quality.

Durability

Durability is important when picking embossing or debossing. Embossed designs last longer on thick materials. The raised part does not wear out fast if the material is strong. Many brands use embossing for packaging that needs to look bold for a long time. Embossed logos on metal or leather keep their shape after lots of use.

Debossed designs are also very tough. The sunken pattern keeps the design safe from rubbing off. People see debossed logos on wallets and book covers that last many years. The deep mark stays clear, even if the surface gets scratched. Debossing works well for things people touch a lot. The feel stays strong because the design is below the surface.

Tip: If a product gets handled a lot, debossing can help the design look new for longer.

Both ways give a lasting feel you can touch. The best choice depends on the material and how much use the item gets. Embossing works well on strong surfaces. Debossing is great for things that need to keep their texture and depth every day.

Cost

Cost is a big factor when choosing a technique. Embossing usually costs more because it needs two dies. The process takes more time and skill. Brands use embossing for special projects or fancy packaging. The extra cost gives a bold, raised design that feels special.

Debossing often costs less. It uses one die and sometimes needs less setup. Many companies pick debossing for big orders or a simple look. The savings add up for large runs. Debossing still looks high-quality without costing more.

Here is a quick comparison:

| Technique | Die Requirement | Typical Cost | Best For |

|---|---|---|---|

| Embossing | Two dies | Higher | Luxury, standout design |

| Debossing | One die | Lower | Subtle, large runs |

Note: The final cost depends on the material, how hard the design is, and how many items you order.

Design Flexibility

Design flexibility helps designers be creative. Embossing lets designers change height, shape, and add foil or color. The raised effect works well for logos and patterns that need to stand out. Designers can use different depths for a layered look. Embossing works best on thick materials, but skilled teams can emboss many surfaces.

Debossing lets designers make deep, touchable effects. The sunken design can hold ink, foil, or paint. This adds color and shine to the lower areas. Debossing techniques work on many materials, like leather and paper. Designers like how debossing adds depth and texture without making the surface thick.

Both ways give a special feel you can touch. Designers can mix embossing and debossing for more creative choices. The best way depends on the project and the feeling the brand wants to share.

Designers who try both embossing and debossing find new ways to connect with people through touch and sight.

Embossing Application

brass parts

Brass parts look shiny and special when embossing is used. Many companies pick brass because it is strong and pretty. Embossing makes raised effect designs on brass that last a long time. These designs do not wear off or peel away. They stay clear even if the part is used a lot. Brass nameplates, badges, and trims often have embossed patterns. This makes each item feel fancy and classic.

Factories use embossing to put logos, serial numbers, or art on brass parts. These details help people know the brand and keep track of items. The raised parts shine in the light and get noticed. You can find embossed brass in musical instruments, awards, and building decorations. Each use gives a classy look that stands out anywhere.

Tip: Embossed brass parts do not tarnish or wear out fast, so they are great for things you want to keep for a long time.

Steel parts

Steel parts get better with embossing. This method uses strong tools and lots of pressure to press patterns into steel. The result is a clear design that lasts in tough places. Steel embossing tools are strong and can be used many times. Factories can make thousands of the same part without losing quality. This helps brands keep their look for many years.

Embossing in steel makes both raised and sunken patterns. These patterns make steel parts look good and work better. For example, embossed textures help people grip handles and footplates. Logos and labels become part of the steel, not just printed on top. This way, the steel gets stiffer without getting thicker. It also does not wear out, fade, or peel. Steel sheets from 0.3 mm to 3.0 mm are best for this.

- Embossing in steel:

- Makes strong, professional logos for brands.

- Adds grip and safety to parts used in factories.

- Helps brands make a lasting mark.

- Saves money when making lots of parts.

Car, plane, and electrical companies use these benefits. Embossed steel parts help products work better and look nicer.

Aluminum parts

Aluminum parts get stronger and better looking with embossing. This process uses hard tools and lots of pressure. The result is detailed patterns with smooth surfaces. Embossing controls how the metal moves and stops it from springing back. This makes sure every part is made just right.

Embossing aluminum sheets makes them stronger and harder. The process lets thin sheets act like thick ones. This saves material and makes things lighter. Embossed aluminum is also easier to shape into tricky forms. Companies use this for both looks and how things work.

- Embossed aluminum parts:

- Show cool patterns for buildings and machines.

- Make surfaces less slippery, like diamond plates for safety.

- Last longer and do not get damaged easily.

- Help brands by adding logos and special designs.

Embossing and debossing in aluminum are used for building panels and electronics. Every embossed part shows new ideas and good quality.

Stainless steel parts

Stainless steel is strong and shiny. Many companies use it because it looks nice and lasts long. Embossing puts raised designs on stainless steel. These designs stay clear for years. They do not fade or rub off. Even after lots of use, the patterns look sharp.

Factories emboss logos, numbers, or safety marks on stainless steel. These marks help people know what the product is. They also show that the product is good quality. You can find embossed stainless steel in kitchens, cars, and buildings. Each piece shows careful work and skill.

Embossing makes stainless steel look even better. It turns plain metal into art.

Designers like how light shines on embossed steel. The patterns catch your eye and make you want to touch them. This helps brands get noticed by more people. Embossed stainless steel often means luxury and trust.

Branding

Good branding makes people believe in a product. Embossing helps brands look strong and special. Raised logos and patterns feel nice and show pride. People remember touching a logo on a card or label. This helps them trust and like the brand.

Big brands use embossing to make their logos stand out. Raised designs make names and logos pop. The effect is bold and exciting. Customers see the difference right away. Embossed branding works on paper, leather, metal, and plastic.

- Embossed business cards show strength.

- Embossed labels make products look fancy.

- Embossed logos on packages show care.

A strong brand uses every detail to connect with people. Embossing helps brands share their story in a special way.

Packaging

Embossing makes packaging look and feel better. Raised designs add depth and make boxes or bags exciting. Shoppers notice embossed packaging in stores. Touching a raised logo or pattern feels special.

Embossed packaging keeps the brand looking good. It shows the company cares about quality. People often keep embossed boxes because they look nice. This helps customers remember the brand.

Tip: Embossed packaging can make a simple box a keepsake.

Embossing lets designers try new shapes and textures. Every embossed package is a chance to surprise people.

Stationery

Stationery is important in everyday life. People use it for notes and invitations. Embossing makes these items look nicer. Raised designs on paper shine in the light. They feel cool when you touch them. Each embossed card or letter feels special.

Designers pick embossing for wedding invitations. The raised patterns look fancy and stand out. Guests see the care put into each invitation. Embossed business cards are easy to notice. They show that someone cares about quality. Giving out an embossed card leaves a strong mark.

Students and teachers like embossed notebooks and journals. The covers feel different and spark new ideas. People want to write more when their stationery looks good. Embossed logos or names on school supplies make students proud. These details help students stay neat and work hard.

Companies use embossed letterheads and envelopes to build trust. Clients see the raised logo and think the company is great. Embossed stationery helps brands share their story. It shows that small things matter.

Here are some stationery items that look better with embossing:

- Wedding invitations

- Business cards

- Thank-you notes

- Journals and diaries

- Letterheads

- Envelopes

- Certificates

Tip: Embossed stationery makes every message feel special. People remember how a raised design looks and feels.

The table below shows how embossing helps different stationery:

| Stationery Item | Embossing Benefit | Emotional Impact |

|---|---|---|

| Invitations | Adds style and texture | Makes people excited |

| Business Cards | Shows you are professional | Builds confidence |

| Journals | Sparks creativity | Makes you want to write |

| Certificates | Shows you did something great | Makes you proud |

Embossing makes regular stationery stand out. It helps people connect and celebrate. Every embossed item shows care and creativity.

Debossing Applications

Book Covers

Debossing can turn book covers into art. Designers use a metal die to press down into the cover. This makes a deep, sunken shape you can feel. It looks fancy and smooth. Debossing works best on hardcovers with thick paper. Sometimes, foil is added for shine. Blind stamping is used for a soft, simple look.

When readers touch the cover, they feel the title or logo. Publishers pick debossing for special books and art editions. The sunken design makes important parts stand out. It also adds value to the book. Debossing gives each book a rich feel and helps it get noticed. This method works with spot UV or layers, so every cover is different.

Tip: Debossed covers make people want to pick up the book and read.

Leather Goods

Debossing makes leather goods look their best. Workers press designs deep into the leather. This mark stays clear for many years. No heat is needed, so it is safe for soft leathers. The result is a sharp, clean design that does not wear off. Brands use debossing for logos, patterns, or names on wallets, belts, and bags. This gives each item a classic look and old-fashioned style. People like the deep feel and timeless look. Debossed clothes stand out in fashion and show good work.

Here is a table showing why debossing is good for leather goods:

| Benefit | Details |

|---|---|

| High Durability | The design stays clear and strong, even after years of use. |

| Timeless Aesthetic | Debossing adds a classic look that never goes out of style. |

| No Heat Required | Pressure alone creates the design, protecting delicate leathers. |

| Versatility | Works on soft and hard leathers, making it perfect for many products. |

Debossed jackets, shoes, and accessories use this method for lasting style. The sunken design feels smooth and looks fancy. Every piece is easy to remember.

Labels and Tags

Debossing makes labels and tags look neat and last long. Factories use a die to press into metal or leather. This makes a deep mark that does not scratch or fade. Many industries use debossed tags for clear names and numbers. The sunken words or logos are easy to see and read. Designers use debossing for packaging, ads, and fancy goods. The deep design adds texture and shows care. Debossed clothes often have custom tags that show the brand.

- Debossed labels last longer and look nice.

- The deep design adds feel and style.

- Brands use debossing for special tags on clothes, cars, and health items.

Debossing is a cheap way to get a fancy look without extra coatings. You can pick different fonts and shapes, so it works for many jobs. More brands use embossing and debossing to impress customers and try new ideas.

Embossing and Debossing in Industry

The print industry uses new ideas to get noticed. Embossing and debossing help printed things stand out. Companies use these methods for packaging, cards, invites, certificates, and business cards. These products grab people’s attention. In 2023, the market for embossed and debossed print was worth $81.51 billion. Experts think it will grow to $149.3 billion by 2032. This means it will grow almost 7% each year. Flatbed embossing is the most popular type. It makes up more than 40% of the market. Plastic is the top material, used in over 35% of products.

| Aspect | Details |

|---|---|

| Market Size (2023) | USD 81.51 billion |

| Projected Market Size (2032) | USD 149.3 billion |

| CAGR (2024-2032) | 6.95% |

| Key Growth Drivers | Customized packaging, laser and digital embossing, e-commerce tamper-proof packaging |

| Leading Embossing Type | Flatbed embossing (>40% market share) |

| Leading Material Segment | Plastic (>35% share) |

| Major Applications | Packaging, greeting cards, invitations, certificates, business cards, decorative items |

| Industry Importance | Product differentiation, brand recognition, sustainable packaging |

| Technological Trends | Automation, robotics, laser and digital embossing, eco-friendly solutions |

Debossing is also important in printing. Companies use debossed labels for safety and security. These special labels show if someone has opened a package. This helps keep products safe and builds trust. Embossing is used more, but debossing is still needed for security and realness.

Fashion

Fashion designers use embossing and debossing to make cool products. These methods add texture and depth to leather, wallets, bags, clothes, and packaging. Embossed clothes have raised logos and patterns. These catch your eye and feel fun to touch. Debossed clothes have smooth, pressed-in designs. They look fancy and feel nice.

- Embossing and debossing help people notice brands.

- Embossing is used on hang tags, patches, and packaging to make brands look better.

- Debossed clothes use soft, pressed designs on leather for a fancy feel.

- Both ways make products seem high quality and well made.

Fashion brands emboss designs onto wallets, belts, and bags. This makes the leather strong and nice. Debossed clothes use pressed-in designs for a simple, rich look. Designers mix these methods with others to make special items. The final products help people feel confident and unique.

Luxury Goods

Luxury brands use embossing and debossing to make products feel special. These methods make packaging look fancy and expensive. Embossed and debossed boxes stand out in stores. The raised or pressed designs make people want to touch them. This makes the products seem even better.

- Embossing and debossing show off brand names and logos.

- These finishes help brands use eco-friendly materials and still look great.

- Good embossing and debossing keep the brand looking real and high quality.

Luxury packaging turns plain boxes into something amazing. Embossed logos and details show what the brand stands for. Debossed clothes and accessories look elegant and rare. Brands use these methods to make people feel special and loyal. Customers remember how luxury goods look and feel. They think of quality and style.

Tip: Embossing and debossing help luxury brands make a strong impression and connect with customers.

Choosing the Right Technique

Project Goals

Every project starts with an idea. Designers want their products to stand out. They hope people will remember them. Picking embossing or debossing depends on what they want. Embossing makes a raised design that gets noticed. Debossing gives a sunken look that feels fancy.

Think about these things when you choose:

- Embossing looks bold and feels raised. Debossing feels gentle and pressed in.

- Embossing is good for detailed patterns. Debossing works for simple styles.

- Embossing grabs attention and invites touch. Debossing is quiet and elegant.

- Debossed designs last longer, especially on things people use a lot.

A brand wanting to stand out may pick embossing. A company wanting a classic look may pick debossing. The project goal helps designers choose the best way.

Tip: Clear goals help you make better choices. Think about how you want people to feel when they see and touch your product.

Material

The material you pick matters a lot. Each technique works best with certain materials. Embossing works well on soft, bendy things like paper or leather. Debossing is better for hard, stiff things like steel or wood.

Here is a table showing how material affects each technique:

| Aspect | Embossing | Debossing |

|---|---|---|

| Suitable Materials | Softer, bendy (paper, leather, vellum) | Harder, stiff (stainless steel, wood, thick plastics) |

| Durability | Raised parts can flatten over time | Sunken marks last longer |

| Visibility | Raised design stands out without ink | May need ink to show up |

| Cost | Costs more because of special steps | Cheaper on thin papers |

| Material Thickness & Flexibility | Best with bendy materials | Easier on thin, stiff materials |

How thick and textured the material is also matters. Embossing changes both sides, so thick paper or leather is best. Debossing works on thin or tough surfaces, like metal tags or wood plaques. Designers should match the technique to the material for the best results.

Note: Always test your design on the material before making a lot. This makes sure your product looks and feels right.

Budget

Budget is important when picking embossing or debossing. Embossing costs more because it needs two dies and extra steps. Debossing is usually cheaper, especially for big orders or simple designs.

Think about these things when planning your budget:

- Embossing needs special tools and skilled workers.

- Debossing uses fewer tools and saves money on materials.

- Hard designs cost more with embossing than simple debossing.

- The material you pick also changes the price. Soft materials for embossing may cost more than stiff ones for debossing.

Smart budgeting helps brands reach their goals without spending too much. Knowing the costs helps designers pick the best way for their project.

Tip: A good budget lets you be creative and get quality. Pick the method that fits your project and your budget.

Aesthetic

Aesthetic choices help people feel something about a product. Designers use embossing and debossing to make things look cool. Each way gives a different style. Embossing makes designs stick up from the surface. This raised part shines in the light and gets noticed. Debossing pushes designs down into the material. The sunken look feels smooth and quiet.

People see and feel these details. A raised logo on a card feels strong. A debossed pattern on a wallet feels fancy. These touches help products get noticed in busy stores. Designers think about color, texture, and shape. They use embossing for bold looks. They use debossing for a calm style.

Tip: The right finish can make a simple thing special.

Aesthetic choices are more than just looks. They help people feel close to a brand. Customers remember how a package feels in their hands. They think of the shine of a raised design or the soft feel of a pressed one. These memories help people trust and like a brand.

Here is a table that shows how each way changes the look:

| Technique | Visual Impact | Tactile Experience | Best For |

|---|---|---|---|

| Embossing | Bold, eye-catching | Raised, textured | Luxury, standout branding |

| Debossing | Subtle, understated | Smooth, indented | Classic, refined products |

Designers use embossing to add sparkle and depth. They use debossing to make things feel calm and neat. Both ways can use foil, ink, or color. These extras can make designs stand out or blend in.

Aesthetic choices also show what a brand stands for. A luxury brand may use embossing to look strong and proud. A brand with history may use debossing to show tradition and style. Each finish tells a story. It makes people want to touch and remember.

People feel happy when they see good design. They want to own things that look and feel nice. Embossing and debossing help designers make beautiful products. Every choice is important. Every detail matters.

Designers who care about looks make products that bring joy and stay in people’s minds.

Common Mistakes

Design

Designers want to make products that people love. But sometimes, mistakes happen when planning the design. These mistakes can change how embossing or debossing looks and feels. Designers might forget to check the pressure settings. If the pressure is too low, the design will look flat or unfinished. If it is too high, the material can rip or get bent. Using the wrong tools can scratch or ruin the surface. If the tool is not lined up right, the pattern will look uneven. Sometimes, designers pick the wrong method for the material. This can make the project fail. Planning carefully and paying attention helps stop these problems.

Tip: Always check the tool’s position and pressure before you start. Even small changes can help a lot.

Material Choice

Picking the right material helps your idea work. Some people choose materials without testing them first. If the material is not the same all over, the results can be random. Some materials do not work well with embossing or debossing. Thin paper can rip, and thick metal may need special tools. If you do not get the material ready, the finish will look bad. Designers should match the material to the method they use. Testing a small piece first can save money and time.

- Pick materials that are the same thickness for best results.

- Clean and smooth the surface before you start.

- Do not mix different materials in one project.

Choosing the right material helps you do a great job. Every good product starts with a smart choice.

Production

Production turns ideas into real things. Mistakes here can ruin even the best design. If you do not set up the machines right, the results will not match. Not checking and changing the process for each material can cause problems. Sometimes, workers hurry and skip steps. If you do not get ready, the design can look weak or uneven. Using the wrong debossing method for the material can make it look bad. Checking and fixing things often keeps the work going well.

Note: Take time to set up machines and look at each piece. Checking your work makes sure every product looks great.

A good project needs careful design, the right material, and careful work. Every step is important. When people learn from mistakes, they make products that last and make people happy.

Best Practices

Working with Designers

Good teamwork helps projects succeed. Designers think of new ideas for each job. They listen to others and change their plans if needed. They learn about the brand to see what makes it special. Designers draw pictures and make samples to show their thoughts. Clear goals help them pick embossing or debossing. They ask questions and give updates often. They try out materials before making lots of items. They feel happy about small wins and learn from mistakes. Designers make others excited about good design.

Tip: Tell your ideas early. Designers do their best work when they know what you want.

Communicating with Printers

Printers are important for every project. They use special machines to make raised or sunken designs. Printers follow what designers ask and check all the details. They need clear files and samples to do a good job. Printers say which materials work best. They give advice to make the product better. Printers tell clients how things are going. They fix problems fast and keep the work moving. Printers like teamwork and respect everyone’s ideas.

A simple checklist helps everyone do their part:

- Give clear design files.

- Make sure you pick the right material.

- Look at samples before making everything.

- Set deadlines and check in often.

- Ask for feedback after each step.

Printers and designers work together to do great work. They trust each other and make brands look good.

Quality Control

Quality control keeps projects safe from mistakes. Teams check every piece for errors. They look for neat lines and smooth surfaces. They test if the raised or sunken parts are strong. They match samples to the first design. They fix problems before sending out products. Teams use checklists to watch their progress. They feel proud when every item is perfect.

| Step | What to Check | Why It Matters |

|---|---|---|

| Visual Inspection | Lines, shapes, and colors | Matches the design |

| Tactile Testing | Raised or sunken feel | Ensures quality |

| Material Strength | No cracks or tears | Lasts longer |

| Final Review | Compare to sample | Consistency |

Note: Quality control helps people trust your work. People remember things that look and feel nice.

Teams who care about quality set a good example. They help brands get better and stronger. Every detail is important. Each project is a chance to do great work.

Embossing makes designs stick up so you can see and feel them. Debossing pushes patterns down, making them smooth and fancy. Both ways help brands and projects in special ways. Before picking one, think about what you want, what you will use, and how you want it to look.

Quick Checklist for Success:

- Know what your project is for

- Pick the best material

- Choose if you want a bold or soft look

- Try a test piece first

Tell us your embossing or debossing stories below! Your ideas can help others.

FAQ

Embossing makes a design stick up. Debossing makes a design sink down. Both ways add texture and style. Designers pick the one that fits their idea.

Most materials like paper, leather, and metal work well. Some thin or weak materials may not hold the design. Testing helps you find what works best for your project.

Tip: Always test a sample before you start a big job!

Embossing costs more because it needs two dies. It also takes extra steps to finish. Debossing uses one die and saves money for big orders. Both ways give great results.

Debossed designs last longer because the mark is deep. The sunken part stays clear after lots of use. Embossed designs stay strong on thick materials. Both ways help products look new for years.

Yes! Designers often mix both methods. This makes cool textures and special effects. Brands use both to stand out and get noticed.

Special machines and dies are needed for these designs. Skilled workers use these tools for the best results. Good equipment helps every project look great.

| Technique | Equipment Needed | Skill Level |

|---|---|---|

| Embossing | Two dies, press | Skilled worker |

| Debossing | One die, press | Skilled worker |

Embossing makes logos bold and easy to remember. Debossing gives a classic and fancy look. Both ways help brands connect with people and build trust.

Success Story: Many top brands use these methods to make customers feel proud and loyal.