If you want your metal to last longer, copper plating is a great choice. Copper makes a shield that stops rust and keeps metal safe. It also helps electricity flow better and makes machines last longer. Here is how copper plating compares to other coatings:

| Benefit | Description |

|---|---|

| Corrosion Resistance | Stops metal from rusting and adds a strong shield. |

| Enhanced Conductivity | Makes metal better for carrying electricity. |

| Extended Equipment Life | Helps machines work longer and stay strong. |

| Low Friction | Smooth surface helps parts slide and not wear out. |

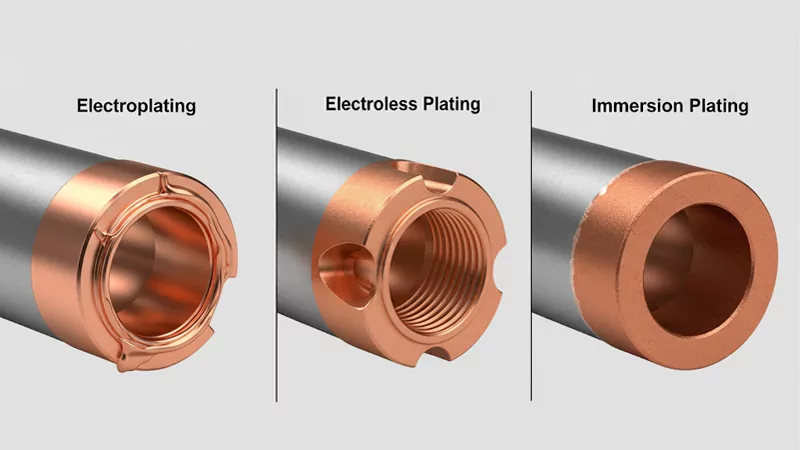

Want to know how to copper plate metal? There are different ways to do it. Each way works best for certain jobs.

Key Takeaways

- Copper plating helps stop metal from rusting and makes it last longer. Electroplating sticks copper to metal best and gives a strong, smooth layer. Electroless plating works well for things that are not metal or have tricky shapes. Immersion plating is fast and simple but only gives a thin copper layer. Think about what kind of metal you have and how you want it to look before picking a plating method. Always clean your metal parts very well before plating to get better results. Safety is very important; wear safety gear and make sure you work where air moves well. Plan how much money you can spend and how big your project is to pick the best plating method.

Table of Contents

Best Copper Plating Method

Quick Comparison

You may wonder which method is best for your project. Let’s check out the main metal plating methods together. Each method has its own good points and works for different jobs. Here’s a table that shows how these methods stack up:

| Method | Description |

|---|---|

| Electroplating | Uses electricity and a special liquid to put copper on metal. It gives even coverage. |

| Electroless Copper Plating | Adds copper without using electricity. It works well for non-metal surfaces and tricky shapes. |

| Thermal Spray Copper Coating | Melts copper and sprays it onto big surfaces. It is good for fixing large equipment. |

| Brush Plating | Lets you plate small spots by hand. It is useful for repairs or touch-ups. |

There are also different types of copper plating. Some examples are acid copper plating, sulfate copper plating, ethylenediamine copper plating, and cyanide copper plating. Each type gives a slightly different look and works better for certain jobs.

If stopping rust is most important to you, recent studies can help:

“To fix this problem, we added a 1 µm Cu plating layer on the front silver grid. This makes a shield that really lowers the chance of corrosion.”

“After testing, we found the plated-Cu layer can stop NaCl damage under DH conditions and make the device last longer.”

Electroplating is great for making a strong, even copper layer. Electroless plating helps when you need to coat plastic or weird shapes. Brush plating is best for small fixes. Thermal spray works well for big repairs.

Key Factors

Picking the right method depends on a few things. You want the copper layer to last and look nice. Here are the main things that matter:

| Key Factor | Description |

|---|---|

| Current Density and Distribution | Controls how fast copper builds up and how tough the layer is. |

| Temperature of the Electroplating Bath | Higher heat makes plating faster but can change the solution. |

| Electrolyte Composition and Concentration | Changes how shiny or hard the copper gets. |

| Anode-Cathode Area Ratio and Positioning | Makes sure copper spreads out evenly. |

| Bath pH | Affects how well copper sticks and how smooth the finish looks. |

| Agitation Speed | Keeps the solution moving so copper coats evenly. |

Think about what metal you want to plate, how smooth you want the finish, and how much money you want to spend. Some methods cost more but give better results. Others work faster or fit special shapes. If you need the best protection from rust, electroplating and electroless plating are the top choices.

When you choose a method, ask yourself these questions:

- What kind of metal or surface do you have?

- Do you want a shiny finish or just protection?

- How big is the area you want to plate?

- Is your budget small, or can you spend more for better quality?

If you remember these things, you’ll pick the method that works best for your project.

Metal Plating Overview

What Is Metal Plating

You might wonder what metal plating is. Metal plating means putting a thin metal layer on another metal. This makes the surface stronger and shinier. It also helps stop damage. Many industries use metal plating. You can find it in electronics, cars, and jewelry. Metal plating protects metal from rust. It also makes things look better and last longer.

To do metal plating, you add a thin metal layer to another metal. There are different ways to do this. Some ways are electroplating and electroless plating. Metal plating helps you get the features you want. If you need a surface that does not rust, metal plating is a good idea. It can also help metal carry electricity better. Sometimes, it gets a surface ready for another metal layer.

Metal plating is not just for big companies. You can use it for small fixes or to make things look nice. Metal plating lets you change how your metal parts look and feel. You can pick the type of metal plating that works best for you.

Why Use Copper Plating

Copper plating is a very common kind of metal plating. You may wonder why people pick copper so often. Copper plating has many good points. Copper is easy to shape and bend. It does not break when you press on it. Copper plating also keeps metal from rusting.

Copper plating is great at moving heat and electricity. If you work with electronics, copper plating helps your devices work better. Copper plating gives a smooth finish. It also works well as a base for other metal layers. You can use copper plating to make a part thicker. This helps with heat treatment.

Manufacturers like copper plating for many reasons:

- Copper plating is easy to shape and does not peel off.

- It stops rust, especially if you add nickel.

- Copper plating is good for custom designs.

- It gives a smooth and even finish.

- Copper plating costs less than gold or silver.

Here is a quick table to compare copper plating with other metals:

| Plating Material | Cost Efficiency | Conductivity |

|---|---|---|

| Copper | High | High |

| Gold | Low | Very High |

| Silver | Low | High |

Copper plating is special because it works well and does not cost a lot. Using copper for metal plating is a smart choice for many jobs.

The copper plating market keeps getting bigger. Copper plating chemicals could reach USD 1.29 billion in 2025. By 2034, the market might be USD 1.88 billion. The growth rate is about 4.32% each year. Using copper for metal plating is not just popular. It is also a big business.

Applications

You can find metal plating in many fields. Copper plating is used in lots of places. Metal plating helps products last longer and work better. Here are some ways copper plating is used:

| Industry | Application Description |

|---|---|

| Electronics and Electrical | Used for connectors and printed circuit boards. It helps electricity move well. |

| Semiconductor | Used to make connections in semiconductor devices. |

| Telecommunications | Used in connectors for strong electrical links. |

| Aerospace | Used in connectors and antennas for planes and spacecraft. |

| Automotive | Used in car electrical systems and connectors. |

| Decorative Finishes | Used to make things look nice in buildings and jewelry. |

| Anti-Microbial Applications | Used in healthcare and food to stop germs. |

| Heat Exchangers | Used in cooling systems because it moves heat well. |

| ATMs and Cash Handling | Used in parts that need good electrical flow. |

| Underplating for Other Metals | Used as a base for other metal layers. |

You also see metal plating in oil, gas, medical, and aviation fields. It helps you get the right finish and protect your tools. It also helps meet safety rules. Copper plating is good for heat exchangers, connectors, and decorations.

Metal plating is not just for looks. It helps products work well and last longer. Copper plating is a top pick for many makers. It gives a good mix of price, strength, and how well it works.

How to Copper Plate Metal

If you want to learn how to copper plate metal, you are in the right place. This process can look tricky, but you can do it at home or in a workshop if you follow the right steps. Let’s break down how to copper plate metal so you get a smooth, shiny finish every time.

Preparation Steps

Getting ready is the most important part of how to copper plate metal. If you skip these steps, your copper layer might not stick well or look good. Here’s what you need to do:

- Choose the right electrolyte. Pick a copper salt solution. This helps the copper move onto your metal.

- Clean the electrode. Wash your metal with an alkaline cleaner or a strong acid. Dirt or oil will stop the copper from sticking.

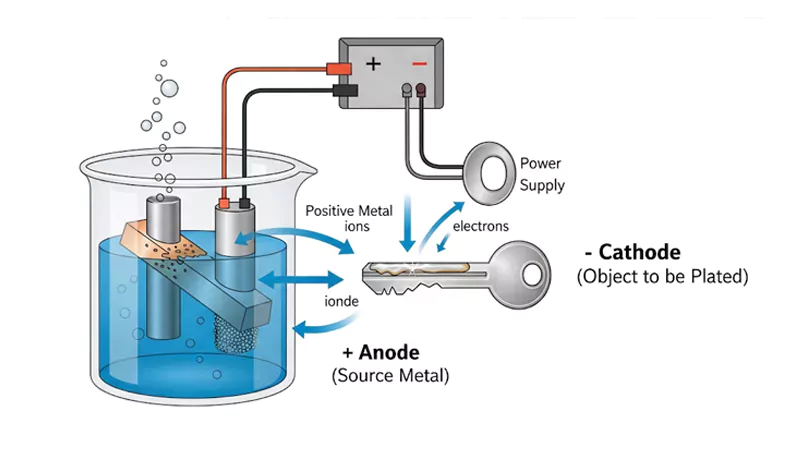

- Set up your electroplating process. Place two electrodes made from different metals into the copper salt solution.

- Connect to electricity. Attach wires to the electrodes and turn on the power. This starts the copper plating process.

Tip: Always double-check that your metal is clean. Even a tiny bit of grease can ruin your results.

Copper Plating Process

Now you are ready for the main event. The copper plating process is where you see the magic happen. Here’s how to copper plate metal step by step:

- Place your cleaned metal (the item you want to plate) as the cathode in the copper salt bath.

- Use a piece of pure copper as the anode.

- Make sure both electrodes are fully covered by the solution.

- Turn on the power supply. The copper will start to move from the anode and stick to your metal.

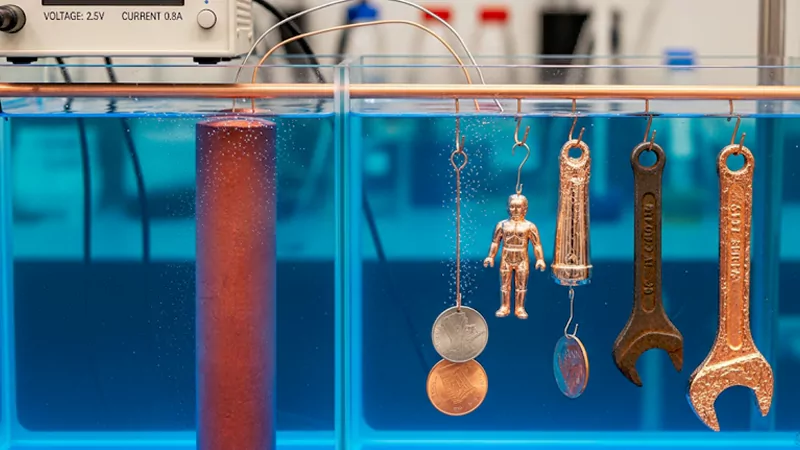

- Watch the process. The longer you leave it, the thicker the copper layer gets.

- When you are happy with the thickness, turn off the power and remove your item.

- Rinse your plated metal with clean water and dry it.

The copper plating process works best when you keep the solution at the right temperature and stir it gently. This helps the copper coat your metal evenly.

Safety Tips

Safety matters every time you learn how to copper plate metal. The chemicals and electricity can be dangerous if you are not careful. Here are some safety tips to keep you safe:

- Wear heavy-duty gloves, safety glasses, and a mask.

- Put on long sleeves and pants to protect your skin.

- Work in a space with good airflow. Open a window or use a fan.

- Keep kids and pets away from your setup. Lock the room if you can.

- Add chemicals slowly. Start with half the amount and test the solution before adding more.

- Be careful with brighteners and leveling agents. Add them a little at a time.

Note: Never touch the solution with bare hands. If you spill anything, clean it up right away.

Now you know how to copper plate metal safely and correctly. Take your time, follow each step, and you will get a great copper finish.

Copper Electroplating

Process

Copper electroplating is a common way to cover metal with copper. You use electricity to move copper ions onto your metal. First, you put two electrodes in a bath with copper salt. The metal you want to plate is the cathode. A piece of copper is the anode. When you turn on the power, copper ions move through the bath. They stick to your metal and make a new layer.

You might wonder what happens in the bath. Here is a simple table that shows the main chemical reactions:

| Reaction Type | Reaction |

|---|---|

| Oxidation | Cu → Cu²⁺ + 2e⁻ |

| Reduction | Cu²⁺ + 2e⁻ → Cu |

Copper atoms leave the anode and become ions. These ions travel in the solution and turn back into copper on your metal. You can change how thick the copper gets by changing the time or electricity. There are different types of copper electroplating. Some examples are acid copper plating and cyanide copper plating. Each type works best for certain jobs and gives a different look.

Advantages

Copper electroplating has many good points. It gives a smooth and shiny surface that lasts longer. Here are some reasons to pick copper electroplating:

- Excellent conductivity helps parts carry electricity better. This is great for circuit boards and cables.

- Malleability means you can bend or shape your parts. The copper layer will not crack.

- Great thermal and corrosion resistance keeps parts safe in tough places. This helps near the ocean or in hot machines.

- Antibacterial properties make it good for medical tools and devices.

- Friction reduction helps moving parts slide easily. This is important for military and machine parts.

You can choose from different types of copper electroplating. Some types are better for thick layers. Others give a brighter finish. You get to pick what works best for your project.

Limitations

Copper electroplating is strong, but it has some limits. You need to watch out for problems like uneven coating or poor sticking. If you do not clean your metal well, the copper can peel off. Sometimes, the solution gets dirty. This can cause rough spots or weak layers.

You also need to think about the types of copper electroplating you use. Some types need special chemicals that can be dangerous if not handled right. Problems can include pitting, burning, or dull finishes. Too much electricity can make the layer brittle. Too little can make the coating thin and patchy.

Copper electroplating works best if you follow each step carefully. Keep the bath clean, watch the temperature, and check the current. If you have problems, you can fix most by cleaning your parts or changing your setup. Picking the right type of copper electroplating helps you avoid many issues and get the results you want.

Use Cases

You may wonder where copper electroplating is used. You can find it in many things you use every day. It helps your phone work well and your car last longer. Copper electroplating makes things stronger and look nice. Here are some common ways people use it.

1. Electronics Manufacturing

Copper electroplating is very important in electronics. It is used in circuit boards, connectors, and microchips. Copper is chosen for these jobs for many reasons.

- Exceptional Electrical Conductivity: Copper lets electricity move fast and easy. This is important for devices to work quickly.

- Superior Corrosion Resistance: Copper makes a shield that keeps out water and air. This helps electronics last longer and not rust.

- Improves Solderability for Electronic Assembly: Solder sticks to copper well. This gives strong and steady connections in devices.

- Surface Smoothing and Precision Enhancement: Copper plating makes rough spots smooth. This helps small parts fit together just right.

Tip: If you want your electronics to last, copper electroplating is a good idea.

2. Automotive Industry

Copper electroplating is also used in cars and trucks. It covers engine parts, connectors, and shiny trims. Copper helps car parts handle heat and not wear out. It also helps the car’s electrical system work right. When you start your car, copper-plated connectors help it turn on.

3. Aerospace and Aviation

Planes and spaceships need strong parts. Copper electroplating protects these parts from rust and high heat. It also helps with electrical parts in control systems. When safety is important, copper plating helps keep things safe.

4. Decorative Finishes

Copper is not just useful—it looks nice, too! You see copper-plated jewelry, home decorations, and musical instruments. The shiny color makes things pretty. Copper plating also stops rust and tarnish, so things last longer.

5. Industrial Machinery

Factories use copper electroplating on gears, rollers, and molds. Copper’s smooth surface lowers friction. Machines work better and break less often. If you want your machines to last, copper plating is a smart choice.

| Industry | Common Use Cases | Why Use Copper Electroplating? |

|---|---|---|

| Electronics | Circuit boards, connectors, microchips | Conductivity, corrosion resistance, soldering |

| Automotive | Engine parts, connectors, trims | Heat resistance, durability |

| Aerospace | Navigation systems, connectors | Corrosion protection, reliability |

| Decorative | Jewelry, décor, instruments | Appearance, tarnish resistance |

| Industrial | Gears, rollers, molds | Low friction, long life |

Copper electroplating is part of your daily life. It helps make electronics better and cars safer. It also makes jewelry and decorations look great. Next time you use your phone or ride in a car, remember copper is helping things work well.

Electroless Plating

Process

If you want to plate metal without electricity, try electroless plating. You use a chemical bath to make copper stick to your part. The steps for electroless copper plating are easy. First, mix special chemicals with water. Next, dip your item into the solution. A reaction starts right away. Copper ions move onto your part and form a thin layer. You do not need wires or a power supply. The chemicals do all the work for you.

Let’s see how electroless plating and electroplating are different:

| Feature | Electroplating | Electroless Plating |

|---|---|---|

| Power Source | Needs electricity | No electricity needed |

| Mechanism | Uses electric current | Uses chemical reaction |

| Substrate Compatibility | Only works on metals | Works on metals and plastics |

You can use electroless copper plating on many things. It works on metal, plastic, and glass. Just make sure your part is clean before you start. If your part has lots of corners or holes, electroless plating can reach them better than other ways.

Tip: You do not need fancy tools for electroless plating. A clean container and the right chemicals are enough.

Advantages

Electroless plating has many good points. You get a smooth copper layer, even on hard shapes. You do not have to worry about missing spots. Electroless copper plating works well for parts with curves or holes. You can use it on metal and non-metal surfaces. That means you can plate plastic, ceramics, or glass.

Here are some reasons electroless plating is special:

- You can plate almost any material, not just metal.

- The coating is even, even on tricky shapes.

- You do not need electricity, so it is safer and easier.

- Electroless copper plating is good for electronics, jewelry, and machine parts.

If your part has lots of detail, electroless plating is a smart pick. You get a nice finish every time.

Limitations

Electroless plating is good, but it has some limits. Sometimes, the shape of your part makes it hard for chemicals to reach every spot. If you have deep holes or tight corners, copper might not coat those areas well. Dead-end holes can stop the solution from moving, so you get thin or no plating inside.

Here are some things to watch out for with electroless copper plating:

- Parts with tricky shapes can block the chemical flow.

- Deep holes may not get enough copper.

- You need to design your part so the coating goes where you want it.

If you want a thick copper layer, electroless plating might take longer than other ways. You need to check your part after plating to make sure the coating is even. Design engineers should think about these limits when planning a project.

Note: Always check your part for thin spots after electroless plating. This helps you get the best results.

Use Cases

You may wonder where electroless copper plating is most useful. This method is used in many industries. It works on metal and non-metal surfaces. Let’s see some common places where you find it.

1. Printed Circuit Boards (PCBs)

If you look inside a phone or computer, you see a printed circuit board. Electroless copper plating is important for making these boards work. Here is how it helps in PCB manufacturing:

- Metallizing Insulating Dielectric Materials: You start with a board that cannot carry electricity. Electroless copper plating changes those parts into paths for electrical signals.

- Preparation of Substrate: Before plating, you treat the board with chemicals. This step gets the surface ready so copper will stick.

- Uniform Copper Film Growth: The plating covers every part of the board. It even coats tiny holes and corners. This even layer is very important for electronics.

Tip: Electroless copper plating lets you make smaller and stronger devices. It covers every small space on the board.

2. Electronics and Microelectronics

You find electroless copper plating in many gadgets. It helps make connectors, switches, and sensors. The copper layer is even, so devices work better and last longer. You can use this method on plastics, ceramics, or glass. This gives you more ways to design your products.

3. Automotive Industry

Car makers use electroless copper plating for parts that must not rust or wear out. You see it on fuel system parts, connectors, and sensors. The copper layer keeps these parts safe from tough conditions. Your car works better and needs fewer repairs.

4. Aerospace and Defense

Planes and satellites need strong parts for hard places. Electroless copper plating gives these parts a tough, even layer. It helps with electrical connections and stops corrosion. This means safer flights and better equipment.

5. Decorative and Functional Coatings

You can use electroless copper plating for jewelry, watches, and home decorations. The copper layer makes things shiny and stops tarnish. You also see it on machine parts that need a smooth surface.

| Industry | Common Use Cases | Why Use Electroless Copper Plating? |

|---|---|---|

| Electronics | PCBs, connectors, sensors | Uniform coating, works on non-metals |

| Automotive | Fuel parts, connectors, sensors | Corrosion resistance, durability |

| Aerospace | Electrical parts, connectors | Even coverage, reliability |

| Decorative | Jewelry, watches, home décor | Smooth finish, tarnish protection |

| Industrial | Machine parts, molds | Low friction, long-lasting surface |

Electroless copper plating gives you many choices. You can coat almost any shape or material. If you want strong and even copper layers, this method is a good choice for your project.

Immersion Plating

Process

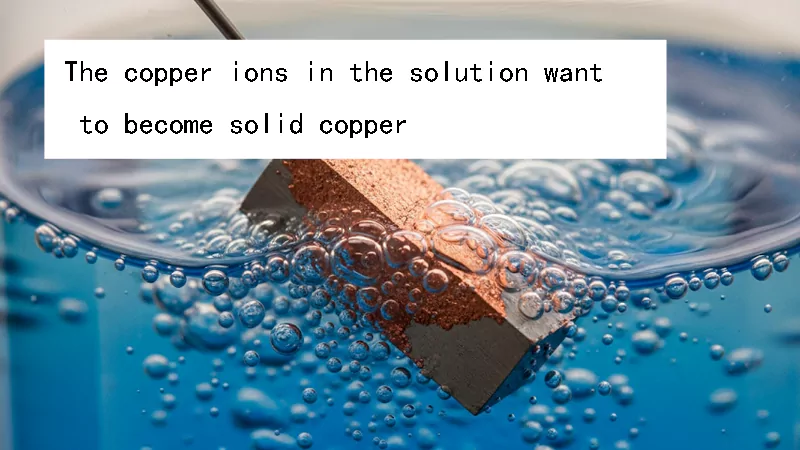

Immersion plating gives you a way to coat metal with copper without using electricity. Instead, you rely on a chemical reaction. When you dip your metal part, like steel, into a special copper solution, something interesting happens. The copper ions in the solution want to become solid copper. At the same time, the surface of your metal starts to dissolve just a little. This is called a displacement reaction.

Here’s what goes on:

- Copper ions in the solution get reduced and turn into metallic copper.

- Your base metal, such as iron from steel, gets oxidized and dissolves a bit.

- For every atom of iron that leaves the surface, one atom of copper takes its place.

- The copper forms a thin, even layer right on top of your metal.

You don’t need to hook up wires or use a power supply. The process happens at the open circuit potential of your metal. The chemistry of the copper solution controls how fast and how well the copper sticks. You just need to make sure your part is clean before you start. If you want a thicker layer, you may need to repeat the process or use another method after.

Tip: Immersion plating works best for a thin, even copper layer. If you need a thick coating, you might want to try electroplating next.

Advantages

Immersion plating has some cool benefits, especially if you want a quick and easy copper coat. You don’t need fancy equipment or electricity. The process is simple and safe for beginners. Here are some reasons you might choose immersion plating:

- It gives you a uniform, thin copper layer.

- The process is gentle and doesn’t damage delicate parts.

- You can use it on metals that are hard to plate with electricity.

- It’s great for small jobs or when you just need a base layer.

You can use immersion plating to get your part ready for more plating steps. Sometimes, you need a thin copper layer before you add nickel or gold. Immersion plating makes that possible.

Limitations

While immersion plating is handy, it does have some limits. The copper layer you get is usually very thin. If you want a thick, strong coating, this method won’t give you that. The process stops once your base metal is covered. After that, copper won’t keep building up.

Here are a few things to watch out for:

- The coating is thin and may wear off if you use the part a lot.

- You can’t use immersion plating on every type of metal.

- The process depends on the chemistry of your solution and the type of metal you’re plating.

- If your part isn’t clean, the copper won’t stick well.

Note: Immersion plating is perfect for a quick, even copper layer, but not for heavy-duty protection. If you need a thicker or tougher finish, try electroplating or electroless plating after your immersion step.

Use Cases

You might wonder where immersion copper plating really shines. This method works best when you need a thin, even copper layer and want a simple process. You do not need fancy equipment or electricity. You just need the right solution and a clean metal part. Let’s look at some places where you can use immersion plating.

1. Electronics Manufacturing

You often see immersion copper plating in electronics. If you work with printed circuit boards (PCBs), you might use this method to add a thin copper layer to holes or pads. This first layer helps other plating steps stick better. It also makes sure the copper covers every spot, even tiny ones.

2. Surface Preparation for Further Plating

Sometimes, you want to plate a metal that does not bond well with copper. Immersion plating gives you a base layer. After that, you can use electroplating or electroless plating to build up a thicker, stronger copper coat. This step helps you get better results and a smoother finish.

3. Jewelry and Decorative Items

If you make jewelry or small decorative pieces, immersion plating can help. You can add a thin copper layer to silver, gold, or even steel. This layer makes the final finish look brighter and more even. It also helps other metals stick if you want to add more layers.

4. Laboratory and Prototyping Work

When you test new ideas or make prototypes, you might not want to set up a big plating system. Immersion plating lets you try things out quickly. You can coat small parts or test how copper sticks to different metals. This saves you time and money.

5. Repair and Touch-Up Jobs

Sometimes, you need to fix a small spot on a metal part. Immersion plating is perfect for touch-ups. You can dip just the area you want to repair. The process is gentle, so you do not damage the rest of your part.

Here’s a quick table to show where you might use immersion copper plating:

| Use Case | Why Choose Immersion Plating? |

|---|---|

| PCBs and Electronics | Thin, even layer for good conductivity |

| Jewelry and Décor | Smooth, shiny finish for small items |

| Surface Prep | Easy base layer before thicker plating |

| Prototyping | Fast, simple coating for testing |

| Repairs | Gentle touch-up for small areas |

Tip: If you want a thicker or tougher copper layer, try electroplating after immersion plating. This combo gives you the best of both worlds.

Immersion plating gives you a quick, easy way to add copper to many metal parts. You can use it for small jobs, repairs, or as a first step before other plating methods. If you want a simple process with good results, immersion copper plating is a smart choice.

Comparing Methods

Performance

When you look at copper plating, you want to know how well each method works. Performance means how the copper sticks to your metal and how smooth the layer looks. Let’s break it down.

Adhesion

Adhesion tells you how well the copper layer grabs onto your metal. If the copper does not stick, it can peel off or flake. You want a strong bond, especially if your part moves or gets bumped.

- Electroplating gives you the best adhesion. The copper layer forms a tight grip because electricity helps the copper ions stick to the metal. You get a tough finish that lasts.

- Electroless plating also gives good adhesion. The chemical reaction helps copper cover the whole surface, even if your part has curves or holes. You can use it on plastics and metals.

- Immersion plating gives fair adhesion. The copper layer is thin, so it might wear off faster. This method works best for quick jobs or as a base layer.

Here’s a table to help you compare:

| Plating Method | Adhesion Strength | Notes |

|---|---|---|

| Electroplating | Excellent | Strong bond, best for moving parts |

| Electroless Plating | Good | Works on tricky shapes and plastics |

| Immersion Plating | Fair | Thin layer, good for base coating |

Tip: If you need a copper layer that will not peel, choose electroplating.

Uniformity

Uniformity means how even and smooth the copper layer looks. You want the copper to cover every spot, even tiny corners.

- Electroplating gives you a very smooth and even layer. You can control the thickness and get a shiny finish. This method works best if you clean your part well before starting.

- Electroless plating is great for uniformity. The chemical bath covers every part, even deep holes and sharp edges. You do not need electricity, so it works on plastics too.

- Immersion plating gives a thin, even layer. It works fast, but the coating is not as thick or smooth as the other methods.

Check out this table:

| Plating Method | Uniformity | Best Use |

|---|---|---|

| Electroplating | Excellent | Shiny, even finish for visible parts |

| Electroless Plating | Excellent | Covers complex shapes and small details |

| Immersion Plating | Good | Quick, thin layer for simple jobs |

If you want a perfect finish, electroplating and electroless plating are your best choices.

Durability

Durability means how long your copper layer will last. You want your metal to stay safe from rust and wear.

Electroplating gives you a tough copper layer. You can make it thick or thin, depending on your needs. If you add nickel or gold on top, you get even better protection. Electroplating is used in cars, electronics, and tools because it lasts a long time.

Electroless plating also gives good durability. The copper layer is even and covers every spot. You can use it on parts that need to resist rust or wear. If you add another metal layer, like nickel, you get even more protection.

Immersion plating gives you a thin layer. It works for quick jobs or as a base coat. The copper might wear off if you use the part a lot. You can add more layers with electroplating or electroless plating to make it last longer.

Here’s a table that shows how different copper layers hold up:

| Plating Method | Typical Durability | Corrosion Protection | Notes |

|---|---|---|---|

| Electroplating | High | Strong, lasts for years | Best for tough jobs and moving parts |

| Electroless | Good | Even protection | Great for complex shapes |

| Immersion | Fair | Thin, wears off faster | Use as base layer or for quick fixes |

Note: If you want your copper layer to last, electroplating is the top choice.

Cost

Cost matters when you pick a copper plating method. You want good results without spending too much.

Electroplating costs more because you need special equipment and electricity. You also need to clean your parts very well. The results are worth it if you need a strong, shiny finish.

Electroless plating costs less than electroplating. You do not need electricity, so you save money on equipment. The chemicals can cost more, but you get a smooth finish on many shapes.

Immersion plating is the cheapest. You only need a simple chemical bath. The process is quick, but the copper layer is thin. This method works best for small jobs or as a first step before other plating.

Here’s a quick cost comparison:

| Plating Method | Cost | Best For |

|---|---|---|

| Electroplating | High | Strong, shiny, long-lasting jobs |

| Electroless Plating | Moderate | Complex shapes, plastics, saving |

| Immersion Plating | Low | Quick fixes, base layers |

If you want the best finish and do not mind spending more, go with electroplating. If you need to save money, electroless or immersion plating can help.

You can see that each method has its own strengths. Electroplating gives you the best adhesion, uniformity, and durability. Electroless plating works well for tricky shapes and saves money. Immersion plating is fast and cheap, but the layer is thin. Pick the method that fits your project and budget.

Application Fit

When you pick a copper plating method, you want it to fit your project. Each method works best for certain jobs and shapes. Let’s see where each one is most useful.

If you have lots of small metal parts, you need to save time and money. Electroplating is best for big groups of parts. Barrel plating lets you plate many pieces at once. This way is fast and gives a strong, even layer.

Barrel plating is a very good way to electroplate many small parts at the same time.

Electroless plating is good for parts with hard shapes or made from plastic. You do not need electricity for this method. It can coat items with holes, curves, or strange angles. This works well for electronics, sensors, and jewelry.

Immersion plating is best for quick jobs or thin copper layers. You can use it for touch-ups, test pieces, or as a first step before more layers. It is simple and does not need special tools.

Here is a table to help you pick the right method:

| Method | Best Fit For | Why Choose It? |

|---|---|---|

| Electroplating | High-volume, metal parts | Fast, strong, even finish |

| Electroless Plating | Complex shapes, plastics, ceramics | Uniform coating, works on non-metals |

| Immersion Plating | Small jobs, base layers, repairs | Quick, easy, gentle process |

If you want shiny jewelry, try electroplating or electroless plating. For car parts or electronics, electroplating lasts the longest. If you need to coat plastic or odd shapes, electroless plating is best. Immersion plating is good for quick fixes or thin layers.

Tip: Always think about your part’s shape, size, and what it is made of before you pick a copper plating method. The right choice makes your project easier and gives better results.

Environmental Impact

If you care about the planet, you should think about how copper plating affects nature. Each method uses different chemicals and makes different waste.

Electroplating needs electricity and special liquids. These liquids can make waste that must be cleaned up. If you use barrel plating for many parts, you get more waste, but you save energy by working faster.

Electroless plating uses chemicals like formaldehyde. These can be harmful and make extra waste. You must handle these chemicals safely and follow the rules.

Immersion plating usually uses fewer harsh chemicals. It is a softer process, so it is safer for you and the earth. You still need to clean up, but the waste is less dangerous.

Here is a table that shows how each method affects the environment:

| Plating Method | Environmental Impact |

|---|---|

| Copper Electroplating | Makes waste from special liquids and needs careful waste treatment. |

| Electroless Plating | Uses harmful chemicals like formaldehyde and makes extra waste from copper removal. |

| Immersion Plating | Not much detail, but usually uses fewer harmful chemicals than electroless plating. |

If you want to help the earth, pick immersion plating for small jobs. For big projects, always treat waste from electroplating and electroless plating the right way. Wear safety gear and follow local rules for throwing away chemicals.

🌱 Tip: You can help nature by recycling copper waste and using safer chemicals when you can. Even small changes help a lot!

Choosing the Right Method

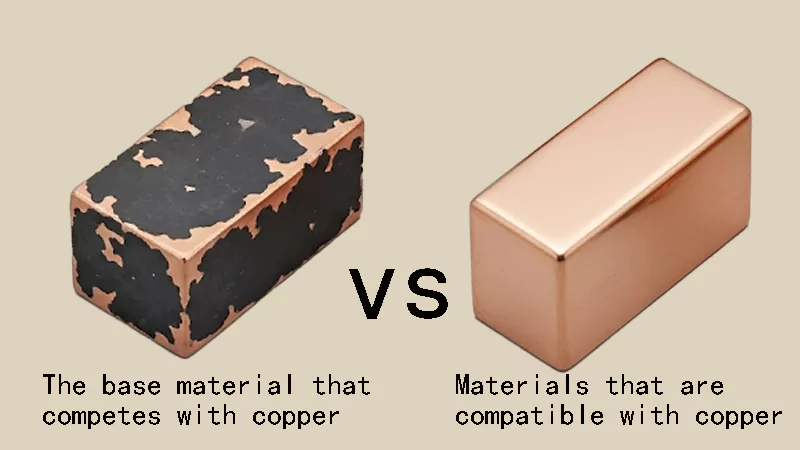

Substrate Compatibility

When you pick a copper plating method, you need to think about what your base material is. Not every metal or surface works the same way. Some metals love copper. Others fight it. You want your copper layer to stick tight and last long.

Here are some things you should look at:

- Substrate materials change how the plating process works and how good the finish looks.

- Electrical conductivity matters. Metals like steel and brass work well with electroplating. Plastics need electroless plating.

- Thermal expansion coefficients can cause trouble. If copper and your base metal expand at different rates, you might see cracks or peeling when things heat up or cool down.

- Chemical reactivity is important. Some metals react with copper or the chemicals in the bath. This can mess up adhesion and durability.

- Environmental rules and costs also matter. Some methods use chemicals that are not allowed for certain materials. You want to follow the rules and keep costs down.

If you have a metal part, electroplating is usually your best bet. If you want to plate plastic or ceramics, electroless plating works better. Always check if your base material matches the method you want to use. This saves you time and helps you get a strong, smooth finish.

Tip: Test a small piece first if you’re not sure how your material will react. This helps you avoid surprises later.

Desired Finish

Do you want your copper layer to look shiny, thick, or just protect your part? The finish you want changes which method you should use. Some jobs need a smooth, glossy look. Others just need a tough layer that stops rust.

Here’s a table to help you see what matters for your finish:

| Factor | Description |

|---|---|

| Thickness of Plating | Thicker layers last longer and carry electricity better. |

| Adhesion | Strong sticking keeps the copper from peeling off. |

| Uniformity | Even coverage means no weak spots or bumps. |

| Surface Preparation | Clean surfaces help copper stick and look smooth. |

| Choice of Plating Material | Copper is great for conductivity and durability. |

| Plating Process Control | Careful control gives you the finish you want. |

| Design Considerations | The shape of your part affects how well copper covers it. |

| Quality Control and Inspection | Checking your work makes sure the finish meets your needs. |

| Environmental Compliance | Following rules keeps your process safe and responsible. |

| Process Documentation | Good records help you fix problems and keep quality high. |

If you want a shiny, even finish for jewelry or electronics, electroplating is a good choice. For tricky shapes or plastics, electroless plating gives you a smooth, even coat. Immersion plating works for quick jobs or thin layers.

Note: Always clean your part before plating. Dirt and oil can ruin your finish.

Budget

Money matters when you choose a copper plating method. Some ways cost more but give better results. Others save you cash but might not last as long.

- Electroplating needs special equipment and electricity. It costs more up front but gives you a strong, shiny finish.

- Electroless plating uses chemical baths. You don’t need electricity, so you save on equipment. The chemicals can cost more, but you get a smooth finish on many shapes.

- Immersion plating is the cheapest. You only need a simple bath and basic supplies. The copper layer is thin, so it works best for small jobs or as a base coat.

Think about how much you want to spend and what results you need. If you’re working on a big project or need a tough finish, spending more on electroplating makes sense. For small jobs or repairs, immersion plating saves money.

💡 Tip: Plan your budget before you start. This helps you pick the method that fits your needs and keeps your project on track.

Scale

When you pick a copper plating method, you need to think about the size of your project. Scale means how big or small your job is. Are you working on a single piece of jewelry? Do you need to plate hundreds of car parts? The answer changes which method works best for you.

If you have a small project, like fixing a broken connector or making a custom ring, you want a method that is quick and easy. Brush plating and immersion plating work well for these jobs. You do not need fancy machines. You can set up at your kitchen table or in a small workshop. The process is simple, and you get results fast.

For medium-sized projects, like plating a batch of tools or making parts for a science fair, you might want to try electroless plating. This method lets you coat many items at once. You do not need electricity. You just need a big enough container for your parts and the chemical bath. Electroless plating gives you an even layer, even if your items have strange shapes.

Big projects need a different approach. If you work in a factory or need to plate thousands of pieces, electroplating is the way to go. You can use barrel plating to coat lots of small parts at the same time. This saves you time and money. Electroplating works best when you need a strong, thick copper layer that lasts for years.

Here’s a table to help you match your project scale with the right method:

| Project Scale | Best Method(s) | Why Choose It? |

|---|---|---|

| Small (1–5 items) | Brush, Immersion | Quick, simple, no big equipment |

| Medium (5–100) | Electroless, Immersion | Uniform coating, easy setup |

| Large (100+) | Electroplating | Fast, strong, good for mass production |

Tip: Always plan your setup before you start. If you have a big job, make sure you have enough space and supplies.

You should also think about your time. Small jobs take minutes. Big jobs can take hours or days. If you rush, you might get a weak copper layer. Take your time and check your work as you go.

Do you want to save money? Small projects cost less. You can use simple tools and small amounts of chemicals. Large projects need more supplies and bigger machines. You might need help from experts or special training.

Here are some questions to ask yourself:

- How many items do you need to plate?

- How much time do you have?

- Do you want a thick or thin copper layer?

- Can you set up at home, or do you need a workshop?

If you answer these questions, you will know which copper plating method fits your project scale. You will get better results and save time and money.

🛠️ Remember: The right method for your project scale makes copper plating easier and more fun!

Practical Tips

Best Practices

You want your copper plating project to turn out great, right? Let’s talk about some best practices that make a big difference. When you use metal plating techniques, you get better results if you follow a few simple steps.

- Clean your parts well. Dirt and oil stop copper from sticking. Wash your metal with soap and water. Use a brush if you see tough spots.

- Pick the right method. Not every job needs the same metal plating techniques. Electroplating works best for strong, thick layers. Electroless plating helps with plastics or odd shapes. Immersion plating is good for quick fixes.

- Control your process. Watch the temperature and time. If you rush, the copper layer might be thin or patchy. Take your time for a smooth finish.

- Use fresh chemicals. Old solutions can cause problems. Fresh chemicals help you get the benefits of copper plating, like a shiny and even coat.

- Check your work. Look at your plated part under a light. If you see dull spots or bumps, you might need to try again.

Tip: Write down what you do each time. If you find a trick that works, you can use it again. This helps you get all the benefits every time you plate metal.

Here’s a quick table to help you remember:

| Best Practice | Why It Matters |

|---|---|

| Clean parts | Better adhesion |

| Pick right technique | Fits your project needs |

| Control process | Smooth, even finish |

| Fresh chemicals | Reliable results |

| Check work | Spot problems early |

Common Mistakes

You might run into trouble if you skip steps or rush. Let’s look at some common mistakes people make with metal plating techniques. If you know what to watch for, you can avoid problems and enjoy the benefits of copper plating.

- Skipping cleaning. If you don’t clean your metal, the copper layer can peel off. Always start with a clean surface.

- Using the wrong method. Some metal plating techniques work better for certain jobs. If you use immersion plating for a thick layer, it won’t last.

- Ignoring safety. Chemicals and electricity can be dangerous. Wear gloves and goggles. Work in a space with good airflow.

- Not checking thickness. If your copper layer is too thin, you lose the benefits. Too thick, and it might crack.

- Forgetting to test. Try plating a small piece first. This helps you see if your process works before you do a big job.

Note: If you see rough spots or the copper flakes off, stop and check your steps. Fixing mistakes early saves you time and money.

You get more benefits when you avoid these mistakes. Good habits help you enjoy all the benefits of copper plating, like corrosion resistance and a smooth finish.

You now know the main copper plating methods and when to use each one. Electroplating works best for strong, shiny finishes. Electroless plating helps with tricky shapes or plastics. Immersion plating is great for quick jobs. Think about your project size, budget, and copper plating applications before you decide. If you feel unsure, talk to an expert or review your needs. The right choice helps your metal last longer and look better!

FAQ

You can try immersion plating. You just dip your clean metal part in a copper solution. No electricity or fancy tools needed. This method works well for small projects or quick fixes.

Yes, you can! Electroless copper plating lets you coat plastics, ceramics, or glass. The chemical bath covers every surface. Just make sure your item is clean before you start.

You control the thickness by how long you plate. Electroplating gives you thicker layers, sometimes up to several microns. Immersion plating only makes a thin layer, usually less than 1 micron.

Always wear gloves, goggles, and work in a well-ventilated area. Some chemicals can be dangerous. Read all safety instructions before you start. Keep kids and pets away from your workspace.

Look for a shiny, even copper color. The layer should not peel or flake when you touch it. If you see dull spots or bumps, you may need to clean your part better and try again.

No, you should not. Rust or dirt stops copper from sticking. Always clean and polish your metal before plating. This helps the copper layer last longer and look better.

Accordion content.

| Step | What to Do |

|---|---|

| Store safely | Use sealed containers |

| Dispose | Follow local rules |

| Recycle | Ask your waste center |

Never pour chemicals down the drain. Always protect the environment!