You need consistent quality to make good metal parts every time. Quality control helps stop mistakes and makes sure each part is right. When you care about good metal parts, people trust you more and you get fewer returns. Look at how different parts of good metal parts change how happy customers are:

| Aspect | Impact on Customer Satisfaction and Return Rates |

|---|---|

| Dimensional Accuracy | Makes sure products fit right, so customers are not upset. |

| Material Strength | Makes products last longer, so customers trust you more. |

| Surface Finish | Changes how the product looks, which matters to customers. |

| Reliability Metrics | Shows how well products work and if people like your brand. |

| Recalls | Bad control can cause recalls and hurt your reputation. |

Good metal parts Quality Control helps you make great metal parts and keeps your customers happy.

Key Takeaways

- Good quality metal parts make customers trust you and buy again. Fewer returns happen when parts are made well.

- Make clear rules and steps for making parts. This helps every part match the design.

- Check parts often while making them. This finds problems early. It saves time and money.

- Teach your team how to find and fix mistakes. This makes the parts better.

- Use tools that watch for problems as you work. These tools help you fix issues fast.

- Work closely with suppliers to get good materials. This keeps parts the same each time.

- Keep good records of how parts are made. This helps you solve problems fast and keep quality high.

- Make goals you can measure for quality. This helps you see how you are doing and get better at making parts.

Table of Contents

Consistent Quality Defined

What It Means

Consistent quality means you make metal parts that are always good. You follow rules so every part is made the same way. Each part matches the design and works like it should. The ISO 9001:2015 certification is a big standard for this. It says you must use strong quality controls all the time. This helps you stop mistakes and keeps your products working well.

You need to watch some important things to keep quality steady:

- Dimensional accuracy

- Tolerance specifications

- Material specifications

- Surface finish

- Welding symbols

These things help you from the very start. They let you check if each part is the right size and shape. They also help you see if the part is strong enough. When you use these standards, you make fewer mistakes. Your work gets faster and better. You make sure parts fit and work as planned.

A set quality control process gives you steps to follow. You know what to check and when to check it. This makes your work easier to plan. You use your time and supplies better. You fix fewer problems and make more good parts. Your clients see you care about quality. Your brand gets stronger.

Why It Matters

Keeping quality steady brings many good things. Your work goes smoother and you waste less. You save money because you do not redo work or throw away bad parts. The table below shows what you can get:

| Measurable Outcome | Description |

|---|---|

| Streamlined workflows | Makes production faster and easier. |

| Reduced waste and costs | Saves money and helps you earn more. |

| Enhanced reputation and customer trust | Helps you keep customers for a long time. |

| Access to international markets | Lets you sell in more places. |

| Improved environmental performance | Helps the planet by using less. |

| Safer working conditions for employees | Keeps workers healthy and safe. |

You can set goals like lowering mistakes by 10% in a year. You can try to deliver on time 95% of the time. You can aim for 100% right material use. These goals help you see how you are doing. They show your team what to work toward.

If you let quality drop, you get big problems:

- You spend more money and waste more materials.

- Parts can break and cause accidents.

- You can get in trouble if your parts are not safe.

By keeping quality steady, you protect your business and your customers. You build trust and can sell in new places. You make work safer for everyone. Consistent quality is not just a goal. It is the base for success in making metal parts.

Metal Parts Quality Control

Quality control starts with a good plan. You need strong standards. You must watch your work and train your team. These steps help you stop mistakes. They make sure every part is made right. When you follow these steps, your products work well. Your customers stay happy.

Setting Standards

You need clear standards before you make anything. Standards tell you how each part should look. They say how strong it must be. They show how it should work. International standards help you keep quality the same everywhere. Some common standards are:

- ISO standards help keep things the same around the world.

- ASTM standards are used in the United States and North America.

- Japanese Industrial Standards (JIS) are used in Japan.

- European Norms (EN) help with safety and performance in Europe.

Using these standards gives you a strong base. You can check every part by the same rules. This helps you find mistakes early. You save money and time. It is easier to teach your team what you want.

Process Monitoring

You need to watch your work as you go. This helps you find problems fast. Process monitoring is very important. Real-time systems help you see mistakes right away. For example:

- Real-time weld monitoring can cut defects by 40%.

- These systems give you quick feedback.

- Workers can change settings to fix problems fast.

Process monitoring keeps your work smooth. You waste less and save time. Every part meets your standards. This helps you get better all the time.

Staff Training

Your team is very important for quality control. Well-trained workers find mistakes and fix them. You should give them good training. Here are some ways to train:

| Training Method | Description |

|---|---|

| On-the-job training | Workers learn from others while doing real work. |

| Classroom training | Classes teach the ideas behind quality control. |

| Online training | Staff can learn online at their own speed. |

| Coaching and mentoring | Workers get help and advice from others. |

| Cross-functional training | Staff learn about different jobs to help teamwork. |

| Six Sigma certification | Teaches ways to make work better and fix problems. |

| ISO 9001 training | Shows how to use quality systems and meet standards. |

| Lean Manufacturing workshops | Teaches how to waste less and work faster. |

Using many training methods helps your team learn well. They know what to do at every step. They learn to spot mistakes and fix them. This makes your work better and keeps your products strong.

Tip: Good planning makes your quality control better. Use root cause analysis to learn why mistakes happen. Keep records so you can track each part. Build a system that checks every step. Always try to get better at what you do.

A strong quality control system needs clear rules, careful watching, and skilled workers. When you plan well and follow your steps, you make fewer mistakes. You always deliver good metal parts.

Inspection and Testing

Inspection and testing are very important for metal parts. You need to check each part at different times. This helps you find problems early. You do not want to send out bad products. When you use good inspection steps, customers trust you more. Your brand stays safe.

In-Process Inspection

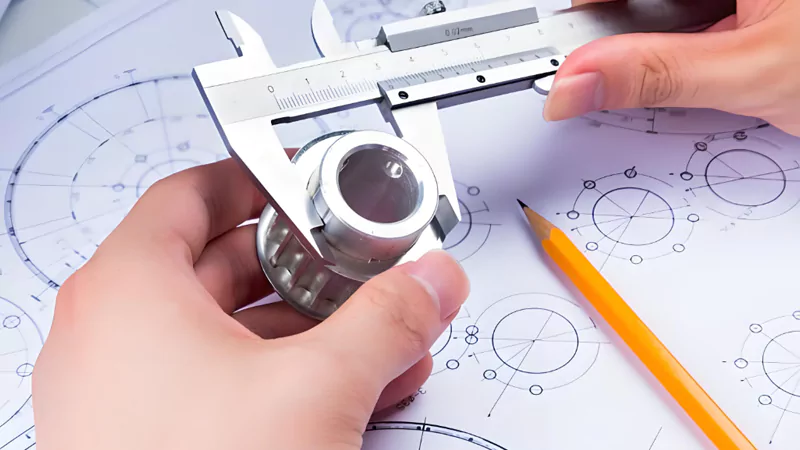

You should check parts while making them. In-process inspection means you look at parts during each step. This helps you find mistakes before they get worse. You can use calipers, gauges, and look at parts closely. You also test for hardness, thickness, and weld quality.

Here are some good things about in-process inspection:

- You find defects early and save time and money.

- You do not need to redo work or throw parts away.

- Your production line keeps moving well.

- You spot problems and fix them right away.

Tip: Put checkpoints at important steps. Teach your team to see problems and tell someone fast.

Final Inspection

Final inspection is the last check before shipping. You need to look at every part and compare it to your standards. You do visual checks, measure parts, and test how they work. You also look at the surface finish and make sure the part matches the design.

You should focus on these goals during final inspection:

- Find defects early

- Make sure parts are accurate

- Check if parts match the design

A strong final inspection helps you:

- Make sure stamped parts are good and work right.

- Find problems before shipping and protect your reputation.

- Get fewer complaints and returns from customers.

Here is what you should check in your final inspection:

| Inspection Step | What to Check |

|---|---|

| Visual appearance | Look for scratches, dents, or marks |

| Dimensional accuracy | Measure size and shape |

| Functional performance | Test if the part works as planned |

| Packaging integrity | Make sure packaging is strong and secure |

Note: Final inspection helps you feel sure your parts will work well for customers.

Packing Checks

Packing checks are important for inspection and testing. Even perfect parts can get damaged if packed badly. You need to test your packing ways and materials to keep parts safe.

Common packing mistakes that cause damage are:

- Boxes that are too big

- Packing material that does not fit your products

- Cheap or wasteful packing methods

- Packing too many products together

- Seals that are weak or hard to open

- Not enough padding in boxes

- No protective layers around items

- Weight not spread out, which can cause damage

You should test your packing by copying shipping conditions. Drop tests, vibration tests, and moisture tests help you see if your packing works. Good packing checks make sure your parts arrive safely.

Remember: Careful inspection and testing from start to finish help you give customers high-quality metal parts every time.

Implementation Steps

Planning

You need a good plan to keep quality high. First, look at how you make metal parts now. Find places where mistakes happen. See what you can make better. Work with your quality team to set clear rules. These rules show what good parts should look like. They also show how parts should work.

Next, make a plan to collect data. Use sensors and regular checks to get information. Train your team so everyone knows the new rules. When you start your plan, watch how it works. Look at what happens and see if you need changes. Keep making your process better by learning from each time.

Here are the main steps for planning quality control:

- Check your current production setup.

- Set clear quality rules and goals.

- Make a plan to collect data.

- Teach your team the new steps.

- Start and watch your quality checks.

- Study results and fix problems.

- Make your process better each time.

Tip: Good planning helps you find problems early. It keeps your work moving without trouble.

Material Checks

Material checks help stop mistakes in your parts. Pick the right material grade for each part. The grade depends on the design, how hard it is to shape, and the price. Make sure the material is thick enough for your needs. If it is too thin, it can break or get weak when shaped.

Store and handle materials the right way. This keeps them safe and clean. Bad storage can cause rust or dirt. Test and check materials often to make sure they are right. Regular checks help you find problems before they hurt your parts.

| Material Check | Description |

|---|---|

| Material Grade Selection | Pick the right grade for design, shaping, and cost. |

| Material Thickness Considerations | Make sure thickness is right to stop cracks and keep strength. |

| Material Storage and Handling | Store and handle materials well to stop problems. |

| Material Testing and Verification | Test and check materials often to meet rules. |

Note: Good material checks help you save money. They keep your parts strong and safe.

Process Control

Process controls help keep your work steady. Use heat numbers to track each batch of metal. These codes help you follow the metal’s quality from start to finish. Mill Test Reports tell you where the metal came from and its details. You can use these reports to check if the metal is good.

Check every batch and make sure it is right. If you find a problem, you can trace it and fix it fast. This system helps you follow rules and keeps your products safe.

- Use heat numbers to track metal.

- Check each batch to meet rules.

- Look at Mill Test Reports for metal details.

Tip: Good process controls help you find problems fast. They keep your work steady and safe.

Corrective Actions

If you find a quality problem, you must act fast. Corrective actions help you fix the issue. They also stop it from happening again. Quick action protects your business. It keeps your customers happy.

First, find out what caused the problem. Use tools like the Ishikawa (Fishbone) Diagram. This tool helps you look at all possible reasons for a defect. You can check if the problem comes from materials, machines, people, or methods. When you know the cause, you can plan what to do next.

A strong corrective action plan (CAP) shows you what steps to take. It lists what needs to be done, who will do it, and when it should happen. You also set ways to check if your fix works. This plan helps everyone stay on track. It makes sure you solve the problem for good.

Here are some good corrective actions you can use:

- Process Optimization: Make your work steps easier and faster. Remove steps that do not help. This helps you avoid mistakes and save time.

- Supplier Management: Work with your suppliers to fix material problems. Check incoming materials more often. Good talks with suppliers help you get better parts.

- Training and Education: Teach your team new skills. Hold training sessions to show the right way to do each job. Well-trained workers spot problems early and know how to fix them.

- Equipment Maintenance: Keep your machines working well. Set a schedule for regular checks and repairs. Well-maintained equipment makes fewer mistakes.

- Quality Control Measures: Make your inspections stronger. Add more checks at important points. Use better tools to find defects before they reach your customers.

You can see some common corrective actions and their uses in the table below:

| Corrective Action | Description |

|---|---|

| Ishikawa (Fishbone) Diagram | Helps you find the root cause of a problem. |

| Corrective Action Plan (CAP) | Lists steps, people, and checks to fix and prevent issues. |

| Employee Retraining | Gives your team new skills to avoid future mistakes. |

| Equipment Maintenance | Keeps machines accurate and reliable. |

| Process Adjustments | Changes workflows to make them more efficient. |

| Supplier Quality Checks | Tests incoming materials to catch defects early. |

| Design Modifications | Updates product designs to improve performance and reduce errors. |

Tip: Always check if your corrective action worked. Look at the results and make changes if needed. This helps you keep making your process better.

When you use these corrective actions, you build a stronger quality system. You stop problems before they get bigger. You make sure every metal part meets your standards and your customers’ needs.

Technology & Data

Real-Time Monitoring

You can use real-time monitoring to keep your process steady. This technology lets you watch important things as you work. You see problems fast and fix them before they get worse. In metal parts manufacturing, some methods help you keep quality high:

- In-process sensing methods check key things during production.

- Melt pool geometry monitoring looks at the melted metal’s shape and size. It makes sure the shape stays the same.

- Thermal distribution tracking helps you find uneven heating. Uneven heating can cause defects.

- Metal transfer behavior monitoring checks if material flows smoothly.

- Advanced control algorithms use machine learning to change settings. These help keep quality steady.

Real-time monitoring and control systems give you feedback all the time. You can make quick changes to improve your process. In Wire Arc Additive Manufacturing, these systems help you meet strict standards. You also use in-process measurement to lower changes. By watching temperature and cooling rates, you make sure each part is right.

Tip: Real-time monitoring helps you catch mistakes early. You save time and avoid costly rework.

Automated Tools

Automated tools make quality control faster and more accurate. You use machines and systems that check parts with little help from people. This lowers human error and keeps products the same.

- Automated optical inspection (AOI) systems use cameras to find defects. Only good parts move forward.

- Coordinate Measuring Machines (CMMs) measure part size very closely. You check that each part matches the design.

- Non-destructive testing (NDT) methods, like ultrasonic testing, look inside parts for problems. They do not damage the parts.

- CNC machines help you make parts with tight tolerances. You meet standards every time.

- Advanced quality control methods can be built into CNC systems. This gives you more trust in your products.

- Frequent in-process inspections use both manual and automated tools. You measure key sizes on many parts to keep quality high.

- Statistical Process Control (SPC) techniques let you watch production variables. You spot issues early.

Automated tools help you work faster and make fewer mistakes. You can trust your results and deliver better products.

Data Analytics

Data analytics helps you understand and improve your process. You collect data from sensors, machines, and inspections. Then, you use software to find patterns and spot problems.

- Process monitoring helps you find and fix issues that could cause defects.

- You use data analytics in cutting, welding, and machining to keep quality high.

- Data analytics turns numbers into useful information. You make better choices and work smarter.

- Real-time monitoring and control improve quality and save money.

- Predictive maintenance helps you fix machines before they break. You avoid downtime and waste.

- Data analytics finds defects or changes from standards early. You keep products safe and reliable.

Note: Using data analytics helps you stop problems before they happen. You build a stronger, more efficient manufacturing process.

Overcoming Challenges

Material Variability

Material variability can cause big problems in making metal parts. Even small changes in material can make flaws. These flaws can make parts weak and unsafe. In additive manufacturing, this problem is even bigger. If you do not control material variability, parts may not be safe or good quality.

You can lower risks by checking where flaws show up. When you study how flaws spread, you find patterns. This helps you make better ways to stop problems early. Both in-process and post-process checks are important. Use these checks to find issues fast and make sure every part is good. Quality assessment methods help keep your products strong and safe, especially for jobs needing perfect parts.

Tip: Always test your materials before and after making parts. This helps you find problems early and keeps your reputation safe.

Human Error

Human error is a common problem in making metal parts. Mistakes can happen at many steps, like setup or packaging. You might see errors when setting up machines, putting parts together, or measuring. Sometimes, labeling or packing mistakes cause trouble. Human mistakes and hardware failures also matter.

You can lower human error by doing these things:

- Help your team talk to each other.

- Make tasks easy and safe for everyone.

- Build a friendly work place.

- Give training often to all workers.

Training helps your team learn the right way to work. Good talking makes sure everyone knows their job. A safe and friendly place helps your team feel sure and make fewer mistakes.

Note: Small changes in training or your work place can help lower mistakes a lot.

Equipment Issues

Equipment problems can quickly cause defects and slow work. If machines do not work well, you get more bad parts and waste. Broken equipment can slow down your work and cause delays.

You can stop many equipment problems with a good maintenance plan. Here are some best ways:

- Plan regular checks, like oil testing and filtering.

- Check your machines every three to four months.

- Use the right oil to keep things smooth.

- Watch vibration, temperature, and oil levels to find problems early.

- Test oil often to lower wear and help machines last longer.

Finding problems early and fixing them fast saves money. When you keep machines working well, you make better parts and keep work moving.

| Challenge | Description |

|---|---|

| Quality Assurance | You must make sure every part meets the rules. |

| Skilled Labor | Well-trained workers help you get good results. |

| Supply Chain Disruptions | Problems in the supply chain can change material quality. |

| Equipment Issues | Machine problems can cause defects and slow work. |

| Continuous Innovation | You need to keep getting better to stay ahead. |

Remember: Solving these problems helps you make good metal parts every time.

Traceability

Traceability is very important in making metal parts. You must know where each piece of metal comes from. You also need to know how it moves through your factory. A strong traceability system keeps records for every part. You write down what the part is made of and where it started. You also keep track of its details.

Each batch or part gets a special ID. This ID stays with the metal at every step. At each checkpoint, you write down key facts. You record who worked on the part and what machine they used. You also note when each step happened. This helps you follow the whole process. It makes sure everyone does their job right.

A good traceability system helps you in many ways:

- Makes sure everyone is responsible and keeps records

- Lets you find problems fast if something goes wrong

- Helps you follow rules and do recalls quickly

- Builds trust with customers by being open

If you find a problem, you do not have to guess. You can see exactly when and where it happened. This helps you act quickly. You only remove the bad parts, not everything. You save time and money. You also waste less and avoid big recalls. Customers see you care about safety and quality.

Traceability helps you follow industry rules. Many jobs need you to show where your materials came from. You also need to show how you made each part. If you cannot do this, you might get fined or lose work. With a good system, you can show your records right away.

Here are ways traceability can help you:

- Find where problems start very fast.

- Waste less and stop big recalls.

- Make your products better and build a good name.

You can use digital tools to make traceability easier. Barcodes, RFID tags, and software help you track parts. These tools keep your data safe and easy to find.

Tip: Check your traceability system often. Make sure your records are right and up to date. This keeps your quality high and your customers happy.

Traceability gives you control over your work. You can fix problems faster and keep your business strong. When you focus on traceability, you protect your brand and make better metal parts every time.

Sustaining Quality

Quality Culture

You make a strong quality culture by setting clear goals. Everyone in your company must know what quality means. You help your team learn these goals with regular training. Good training gives workers skills to spot and fix problems fast. Teamwork gets better when people talk openly. When teams share ideas, they solve problems together.

You should listen to what customers say. Complaints and suggestions help you find ways to get better. Use quality management software to track how things are going. This keeps everyone working together. Here are the main steps to build a quality culture:

- Set clear quality goals and values.

- Give the right training to workers on time.

- Help teams talk and work together more.

- Use customer complaints and feedback to improve.

- Use good quality management software.

A strong quality culture helps every part of your quality control. It helps you make better choices and keeps your team focused on making great metal parts.

Supplier Management

You need your suppliers to give you good materials. If your supplier changes the feedstock, your parts might change too. These changes can cause problems with how well parts work. You may have to fix or redo parts, which costs money. You need to check that your suppliers use good quality control. Bad controls from suppliers can make your finished parts less steady.

Good material quality is important for getting the same results each time. When you use high-quality raw materials, your metal stamping works as planned. If the material changes, you may get more bad parts and size mistakes. Pick suppliers who have a good record. They must meet or beat industry standards to help you keep quality high.

- Changes in supplier feedstock can change your product quality.

- Good supplier management helps stop process changes.

- Reliable suppliers help you avoid costly rework and keep rejection rates low.

- Meeting industry standards makes sure your parts work as they should.

Build strong relationships with your suppliers. Regular checks and clear rules help you keep quality high.

Audits

You use audits to see if your quality control works right. Audits help you find problems and fix them before they get big. You can do audits with your own team or hire outside experts. During an audit, you look at records, check how things are done, and talk to workers. You look for ways to get better and make sure everyone follows the rules.

A good audit checks these things:

| Audit Area | What to Check |

|---|---|

| Process Compliance | Are workers following set procedures? |

| Record Accuracy | Are quality control records complete? |

| Material Traceability | Can you track each part’s history? |

| Equipment Condition | Are machines well maintained? |

| Training Records | Do workers have up-to-date training? |

Regular audits keep your quality control strong. They help you find problems early and show your customers that you care about quality.

You can keep quality steady in metal parts by using simple steps. Look at the table below for helpful advice:

| Step | Description |

|---|---|

| Material Inspection | Look for problems and make sure materials are correct. |

| Defined Processes | Make clear rules for each step in making parts. |

| Welding Inspection | Check welds by looking and using special tests. |

| Performance and Tolerance Tests | Test parts to see if they work and fit right. |

| Record Keeping | Write down each step so you know what happened. |

Checking your process often helps you find problems early. Try new tools and better ways to check your work. Always work to get better so your products stay the best.

FAQ

You must set clear standards first. Standards guide every step and help you check if each part meets your needs. When you follow these rules, you catch mistakes early and keep your products strong.

You should inspect parts at every key stage. In-process checks help you find problems early. Final inspections make sure each part meets your standards before shipping.

Traceability lets you track each part from start to finish. You can find problems fast and fix them. This system helps you avoid big recalls and keeps your customers safe.

You can use sensors, cameras, and software for real-time monitoring. These tools show you problems as they happen. You can fix issues right away and keep your process steady.

You should stop production and find the root cause. Use a corrective action plan to fix the problem. Train your team and check your process to prevent the same issue again.

Yes, automation reduces human error and speeds up inspections. Machines like CMMs and AOI systems check parts quickly and accurately. You get more reliable results and save time.

Pick suppliers with strong quality control and a good track record. Check if they meet industry standards. Reliable suppliers help you keep your parts consistent and safe.

Well-trained workers spot mistakes and fix them fast. Training gives your team the skills to follow standards and use new tools. You get better results and fewer defects.