Selecting the right CNC milling precision machining services shapes the success of your project. You need a provider with proven expertise, advanced equipment, and strong quality assurance. These factors ensure each part meets your exact specifications. Focus on providers who align their capabilities with your unique requirements. Take a practical, step-by-step approach to make your decision with confidence.

Table of Contents

Project Requirements

Materials and Tolerances

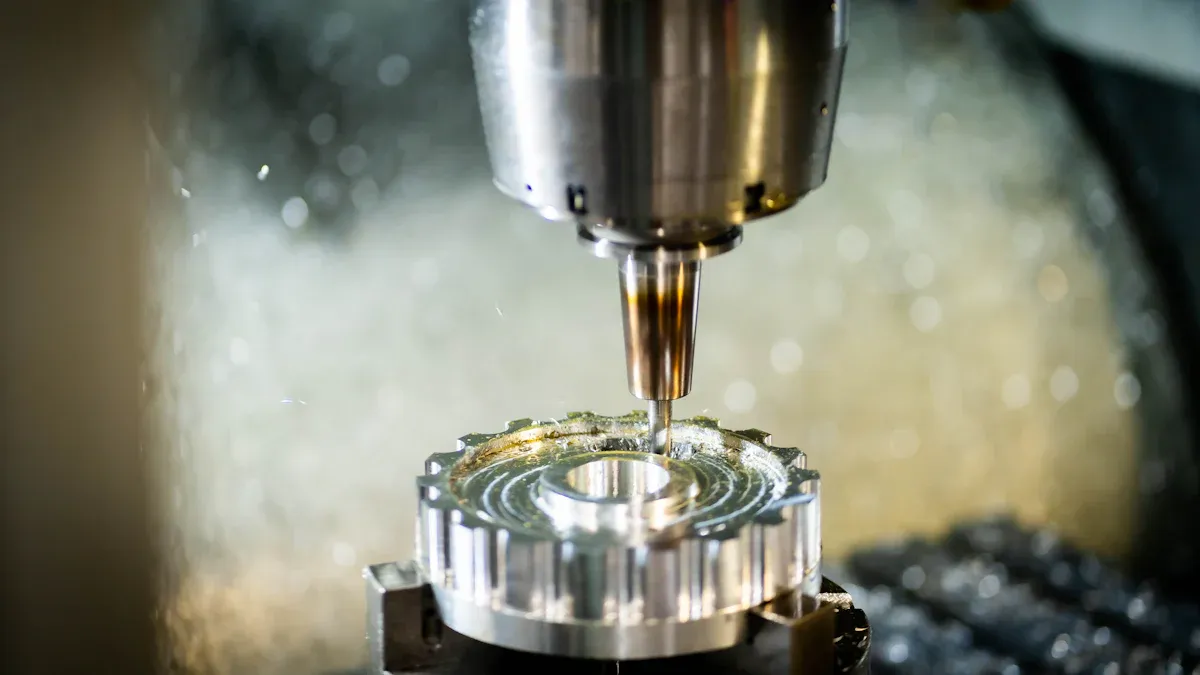

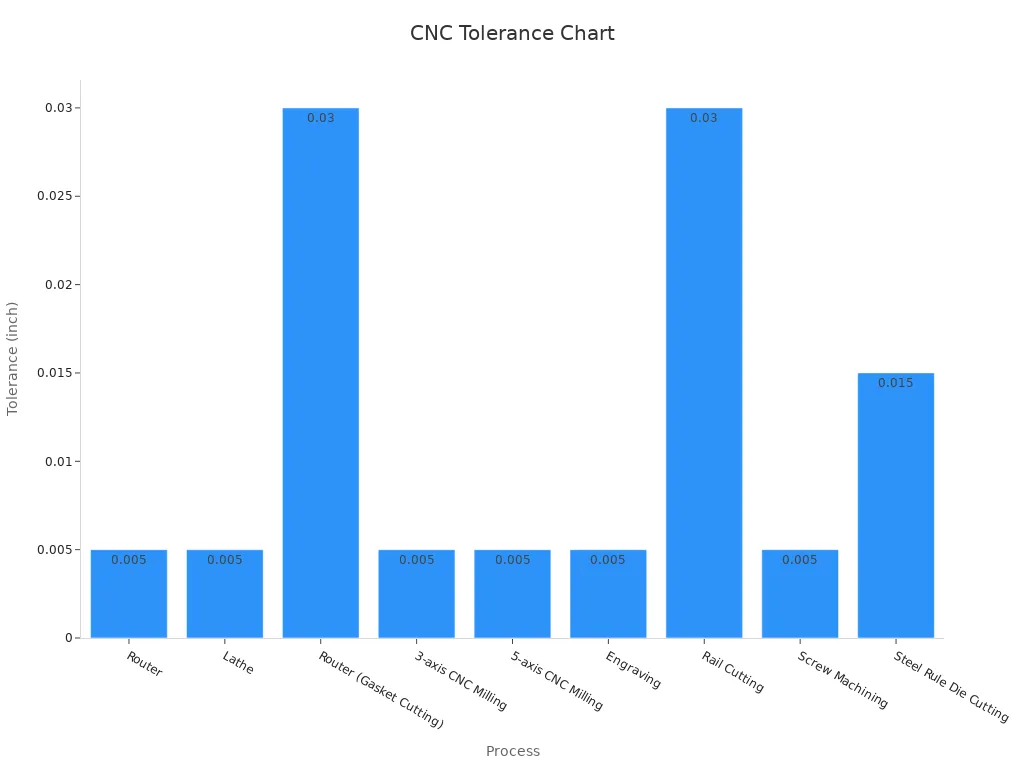

You must define the materials and tolerances for your CNC milling project before you choose a provider. Different materials, such as aluminum, stainless steel, or plastics, require specific machining processes. Tolerances determine how precise each part must be. Providers who understand your requirements can deliver parts that fit and function as intended.

| CNC Machining Process | Typical Tolerance (±) | Unit |

|---|---|---|

| Router | 0.005 | inch |

| Lathe | 0.005 | inch |

| Router (Gasket Cutting) | 0.030 | inch |

| 3-axis CNC Milling | 0.005 | inch |

| 5-axis CNC Milling | 0.005 | inch |

| Engraving | 0.005 | inch |

| Rail Cutting | 0.030 | inch |

| Screw Machining | 0.005 | inch |

| Steel Rule Die Cutting | 0.015 | inch |

| Surface Finish | 125 | RA |

Industry standards like GD&T and ISO 2768 help you communicate your expectations clearly. These standards guide providers in measuring and verifying tolerances.

Part Complexity and Volume

You should consider the complexity and volume of your parts. Complex parts often need advanced multi-axis CNC machines. High-volume orders require providers with efficient workflows and enough machine capacity. When you share these details, you help providers plan production and avoid delays.

- Tight machining tolerances maintained at ±0.01 mm

- Rapid prototyping capabilities enable fast iteration

- Advanced machines handle complex designs

- Providers offer DFM feedback, which can reduce costs by up to 30%

Deadlines and Delivery

You need to set clear deadlines and delivery expectations. Providers who understand your schedule can allocate resources and prioritize your order. Lead times vary based on project size and complexity.

| Performance Metric | Statistic / Detail |

|---|---|

| Rapid Prototyping Lead Time | 3–7 working days |

| Low-Volume Production Lead Time | 7–15 working days (10–500 pcs) |

| Mass Production Lead Time | 15–30 days or more |

Tip: Share your timeline early. Providers who commit to regular inspections and error rectification can help you avoid costly delays.

Provider Capabilities

Equipment and Technology

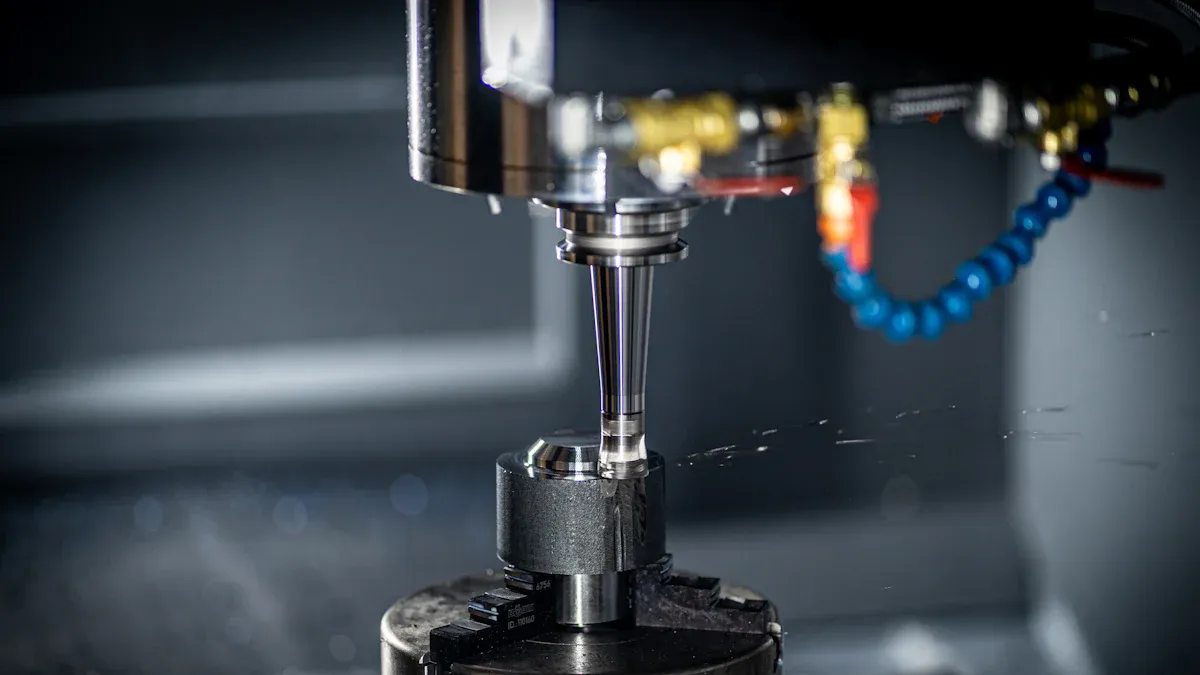

You should always check if a provider uses modern and specialized equipment. Advanced CNC machines, such as multi-axis systems, can handle complex shapes and tight tolerances. The global CNC market reached $80 billion in 2019 and is expected to grow to $115 billion by 2026. This growth shows that many providers invest in new technology. Automation in CNC machining reduces errors almost to zero. This means you get parts with high precision and less waste.

Multi-axis CNC machines, which can have three to twelve axes, allow for faster production and more complex parts. These machines also save time and lower costs. When you compare CNC machining to traditional methods, you see clear benefits:

| Performance Aspect | CNC Machining | Traditional Machining |

|---|---|---|

| Precision | High | Variable |

| Consistency | Repeatable | Operator-dependent |

| Efficiency | High | Lower |

| Labor Costs | Reduced | Higher |

| Waste | Minimal | Higher |

Tip: Ask your provider about their machine models and how often they upgrade their equipment. Future-proof technology ensures your project meets the latest standards.

Technical Expertise

You need a provider with strong technical skills. Look for teams that understand many materials and machining processes. You can measure technical expertise with several metrics:

- Positional accuracy and repeatability

- Spindle speed range and power

- Tool capacity for different tasks

- Machining time for each part

- Flexibility to handle new designs

- Ability to create complicated shapes

- Surface finish quality

- Performance scores from a QFD matrix

Providers should also use inspection tools like Coordinate Measuring Machines (CMM) and surface profilometers. These tools help check if parts meet your requirements. Statistical Process Control (SPC) helps monitor quality during production. When you choose CNC milling precision machining services, make sure the team can show you these skills and tools.

- Dimensional accuracy and tolerance keep your parts within strict limits.

- Surface finish and roughness affect how your parts look and work.

- Material hardness and strength show if the provider can handle tough jobs.

Custom and Complex Parts

Many projects need custom or complex parts. You want a provider who can deliver high precision and handle unique designs. Modern CNC milling precision machining services use advanced machines and strict quality checks. Here are some key statistics:

| Aspect | Details / Statistics |

|---|---|

| Precision Tolerances | ±0.005 mm repeatability; concentricity tolerances as tight as 0.01 mm; EDM precision ±0.005 mm |

| Machining Capabilities | Multi-axis machining (4-axis, 5-axis) for complex geometries and undercuts |

| Quality Control Measures | In-process inspections, First Article Inspection (FAI), final inspection with CMM |

| Quality Management Systems | ISO 9001, AS9100 certifications; SPC; lot traceability |

| Material Expertise | Stainless steel, titanium, copper, brass, plastics, aluminum alloys with tailored tooling and parameters |

| Surface Finish | Ultra-fine finishes with Ra < 1.6 µm |

Modern CNC technology uses microelectronics and computers to achieve micrometer-level accuracy. This makes it possible to produce parts for industries like aerospace, medical, and automotive. When you need custom solutions, choose a provider with a proven track record in complex projects.

Note: Always ask for examples of past custom work. Providers who share case studies or sample parts show confidence in their abilities.

Quality Assurance

Certifications and Standards

You should always verify the certifications of any CNC milling provider. Certifications like ISO 9001:2015, AS9100, and ISO 13485 show that a company follows strict quality management systems. These standards ensure your parts meet industry requirements and regulatory guidelines. Providers with these certifications focus on customer satisfaction, continuous improvement, and risk management.

| Certification Body / Standard | Description | Key Benchmarks | Industry Significance |

|---|---|---|---|

| ISO 9001 | Quality management for all industries | Customer satisfaction, robust processes | Consistent quality, compliance |

| AS9100 | Aerospace quality standard | Risk management, traceability | Safety, reliability in aerospace |

| ISO 13485 | Medical device quality | Documentation, regulatory compliance | Medical device safety |

| ITAR Compliance | Defense manufacturing | Export control, secure processes | National security |

| ISO 14001 | Environmental management | Pollution prevention | Environmental responsibility |

| ISO 45001 | Health and safety | Hazard prevention | Workplace safety |

Tip: Ask for copies of certifications and check their validity. Certified providers show commitment to quality and reliability.

Inspection Processes

You need to understand how a provider inspects your parts. Rigorous inspection processes catch errors early and keep defect rates low. Providers use tools like Coordinate Measuring Machines (CMM), micrometers, and surface profilometers to check dimensions and finishes. Real-time monitoring and Statistical Process Control (SPC) help detect deviations before they become costly problems.

- Continuous data collection at key points

- Real-time monitoring for immediate error detection

- Statistical analysis to find trends and root causes

- Regular machine calibration for precision

A strong inspection process reduces scrap and rework. CNC machines with skilled operators and quality programming achieve less than 1% error probability. Quality assurance programs also improve customer satisfaction by ensuring on-time, defect-free deliveries.

Company Profile and Awards

You should review a provider’s company profile and look for industry awards. A clear profile lists machine capacity, facility size, and technical capabilities. Awards like the ‘Top CNC Machining Companies’ list highlight leadership and innovation. Companies such as Mazak earn recognition for quality, sustainability, and automation. Industry benchmarking reports, like those from MachineMetrics, offer data-driven insights into machine reliability and efficiency.

Note: Providers with awards and a strong profile often deliver better results and maintain high standards. This gives you confidence in their ability to handle your project.

Choosing CNC Milling Precision Machining Services

Service Range

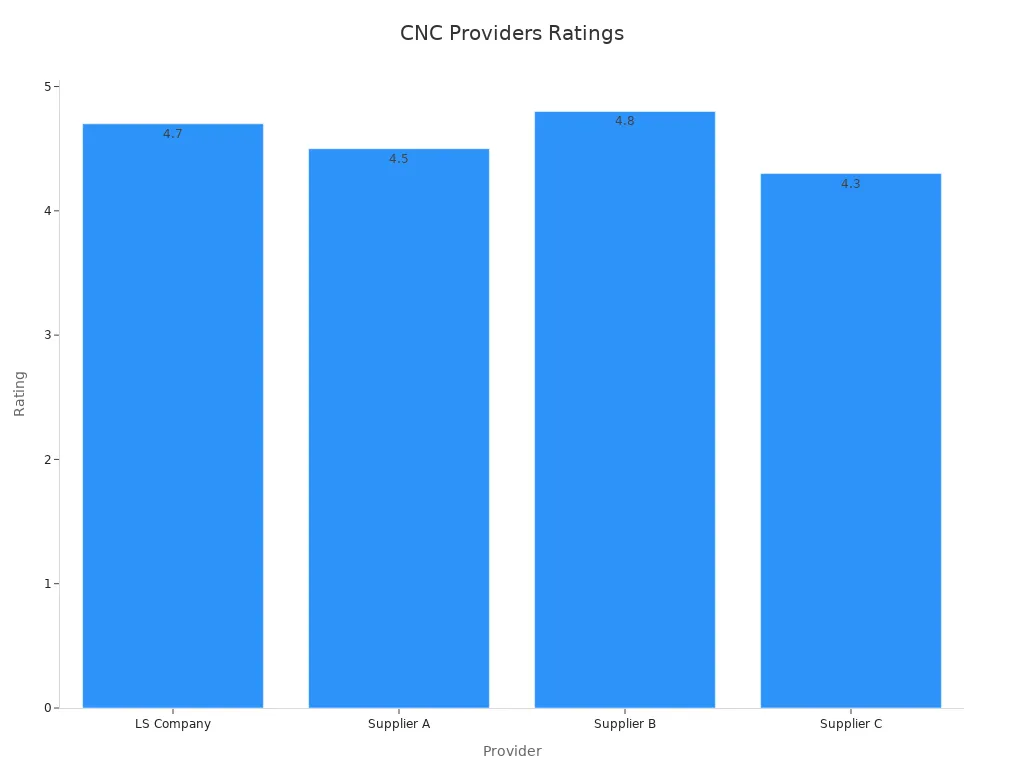

You need to check the service range of each provider before making a decision. Some companies focus on high-precision, complex parts, while others handle large batches or simple shapes. The right provider matches your project’s needs for equipment, order size, and technical support. Review comparative data to see how different providers perform:

| Provider | Overall Rating (based on reviews) | Advantages | Disadvantages | Technical Capabilities & Suitability |

|---|---|---|---|---|

| LS Company | 4.7/5 (200+ reviews) | Advanced equipment (five-axis), high precision, punctual delivery | High price, poor cost control for small batches | Strong in complex, high-precision machining; optimized for large orders; suitable for enterprises needing high volume and precision |

| Supplier A | 4.5/5 (150+ reviews) | Price transparency, supports small batch customization, wide material compatibility | Long delivery time, slow urgent order response | Good for special materials and small batches; less efficient production; may not meet tight delivery requirements |

| Supplier B | 4.8/5 (300+ reviews) | Full-process service, strong technical support, excellent after-sales | High price, suited for medium/large enterprises | High automation, capable of design to assembly; suitable for complex projects and medium to large scale production |

| Supplier C | 4.3/5 (100+ reviews) | Strong price competitiveness, supports overseas outsourcing, suitable for mass production | Low communication efficiency, slow after-sales | Mainly three-axis machines for simple shapes; suitable for cost-sensitive, high-volume production; insufficient for high precision and complexity |

Providers with advanced equipment and high ratings often deliver better results for complex CNC milling precision machining services. You should match your project’s complexity and volume to the provider’s strengths.

Lead Time and Flexibility

You must consider lead time and flexibility when choosing CNC milling precision machining services. Providers with fast turnaround and the ability to adjust schedules help you meet tight deadlines. Some companies excel at rapid prototyping, while others focus on steady, large-scale production. Ask about their capacity to handle urgent orders or changes in project scope. Providers who adapt quickly reduce the risk of delays and keep your project on track.

Tip: Choose a provider who can scale production and respond to changes without sacrificing quality.

Communication and Support

Strong communication and support play a key role in project success. Providers who keep you informed and respond quickly to questions help prevent misunderstandings. Good support teams solve problems fast and keep your project moving. Performance statistics show the impact of robust communication:

- On-time delivery rates improve with clear updates.

- Defect rates drop when providers address issues early.

- Projects stay within budget when teams share progress reports.

- Client satisfaction rises with responsive support.

- Machine utilization increases when teams coordinate schedules.

You should choose a provider who values open communication and offers reliable support throughout the process. This approach ensures your CNC milling precision machining services meet your expectations every time.

Cost and Reputation

Quotes and Pricing

You should always request detailed quotes from CNC milling providers. A clear quote helps you understand what you pay for each service. Look for itemized pricing that covers materials, machining time, finishing, and inspection. Some providers offer volume discounts for larger orders. Others may charge extra for rush jobs or complex parts. Compare quotes from several companies to see which one offers the best value for your project.

| Pricing Factor | What to Check |

|---|---|

| Material Costs | Type and grade of material |

| Machining Time | Hourly rates, setup fees |

| Finishing Services | Surface treatments, coatings |

| Inspection Fees | Quality checks, certifications |

| Delivery Charges | Shipping, handling, insurance |

Tip: The lowest price does not always mean the best value. You should balance cost with quality and reliability.

Customer Reviews

You can learn a lot from customer reviews. These reviews show how well a provider meets deadlines, solves problems, and communicates. Many CNC machining services use a 0 to 2.0 scale for customer satisfaction. Ratings include ‘It Rocks!’ (2.0), ‘It’s Okay’ (1), and ‘Not Very Happy’ (0). Most customers—about 65%—rate their experience as ‘It Rocks!’. Only a small number, around 4.7%, report negative experiences. Net Promoter Scores also show if customers would recommend the provider to others.

- High customer satisfaction scores signal reliable service.

- Strong customer service ratings mean quick responses and support.

- Positive Net Promoter Scores suggest good word-of-mouth reputation.

Note: Consistent positive feedback often means you can trust the provider with your project.

Location and Logistics

You should consider the provider’s location and logistics capabilities. Local providers can offer faster shipping and easier communication. If you work with overseas companies, check their experience with international shipping and customs. Reliable logistics ensure your parts arrive on time and in good condition. Some providers offer tracking and insurance for added peace of mind.

- Local providers may reduce lead times and shipping costs.

- International providers should have strong logistics networks.

- Always confirm delivery timelines before placing your order.

Choosing a provider with strong logistics helps you avoid delays and keeps your project on schedule.

Choosing CNC milling precision machining services requires careful planning. You should match provider strengths, quality systems, and communication to your project needs. Use the checklist from this guide to compare options. Providers with certifications like ISO 9001 deliver consistent quality, fewer defects, and faster turnaround. Strong customer support and flexible production help you adapt to changes. A thorough evaluation leads to cost savings, better delivery times, and reliable results.

FAQ

What certifications should you look for in a CNC milling provider?

You should look for ISO 9001:2015, AS9100, or ISO 13485 certifications. These show that the provider follows strict quality standards. Certified companies focus on quality, safety, and customer satisfaction.

How do you compare quotes from different CNC machining providers?

Always check if the quote includes material, machining, finishing, inspection, and delivery. Compare itemized costs. Ask about extra fees for rush jobs or complex parts. Choose the provider who offers the best value, not just the lowest price.

Why does equipment type matter for your project?

Modern CNC machines deliver higher precision and faster production. You get better results with providers who use multi-axis or automated equipment. Advanced machines also handle complex shapes and tight tolerances.

How can you check a provider’s reputation?

Read customer reviews on trusted platforms.

Ask for references or case studies.

Check for industry awards or recognition.

A strong reputation means you can trust the provider with your project.

See Also

Discovering The Incredible Strength Behind CNC Milling Processes