Descaling methods are essential in many industries. They help determine the quality of products and the cost of things. Chemical steel descaling is fast and is used a lot. It is common in food processing, healthcare, and textiles. It is used more where there are strict environmental rules. Mechanical steel descaling is used in steel rolling for building and cars. It is best for taking off thick scale, but can damage the surface. Picking the right steel descaling method changes the surface look, safety, and future care. Each job should use the best method for the steel type, how much is made, and what is needed.

Table of Contents

Key Takeaways

- Steel descaling takes off a tough oxide layer. This gets steel ready for painting, coating, or welding.

- Chemical steel descaling uses acids to clean steel. It makes the surface smooth. This is good for steel with tricky shapes.

- Mechanical steel descaling uses tools like shot blasting. It removes thick scale fast and at a low cost.

- Chemical methods need strict safety steps. They also need rules for acid use and waste.

- Mechanical methods produce less harmful waste. They also reuse abrasives, which helps the environment.

- Picking the best steel descaling method depends on the steel type. It also depends on how thick the scale is, the shape, and the job size.

- After steel descaling, steel needs protective coatings. This stops rust and helps steel last longer.

- Factories think about cost, speed, safety, and finish quality. They use these to choose the best descaling method.

Steel Descaling Methods

What Is Steel Descaling

Steel Descaling means taking off a hard layer called scale. This layer forms when steel gets very hot. It happens during rolling, forging, or heat treatment. There are three main ways to descale steel:

- Mechanical steel descaling uses things like shot blasting, grinding, or wire brushing. These tools scrape the scale off the steel.

- Chemical steel descaling uses acids, such as hydrochloric or sulfuric acid. The acid melts the scale away.

- Thermal descaling uses high heat in furnaces. The heat makes the scale break and fall off.

Each method works best for certain steel types and jobs. Taking off the scale is important. It gets the steel ready for more work and makes the final product better.

Why Steel Descaling Is Needed

Steel Descaling is very important for many reasons. The scale blocks paint, coatings, and welds from sticking. If you leave the scale on, coatings can peel off, and rust can form. Scale can trap gases and dirt during welding. This makes welds weak and can cause sparks. Scale also wears out tools and machines faster. This costs more money and slows down work. Removing scale helps:

- Make the surface smoother and better.

- Help coatings and paints stick well.

- Stop tools and machines from wearing out fast.

- Keep rust and corrosion away.

- Make welds strong and clean.

Note: Car and building companies need good descaling. It helps steel parts last longer and look nice.

Types of Scale

Different kinds of scales form on steel. It depends on how the steel is made and what is in it. Most scale is made of iron oxides like FeO, Fe2O3, and Fe3O4. These form when steel is hot rolled, annealed, or heat-treated. The scale can be thick or thin and stick tight or loose. This changes which descaling method works best. Some scales are hard to remove and need strong tools or chemicals. The other scale comes off easily after heating.

| Aspect | Details |

|---|---|

| Scale Types | Iron oxides: FeO, Fe2O3, Fe3O4 |

| Formation Conditions | High-temperature processes: continuous casting, reheating, hot rolling |

| Influencing Factors | Steel chemistry (Mn, Si, Al), impurities (Cu, Ni, Cr), surface condition |

| Scale Properties | Adhesion strength, complexity (root penetrations), thickness |

| Effect on Descaling | Strongly adherent scale may need special methods; complex shapes require chemical descaling |

| Scale Thickness Range | Up to 50 micrometers in hot rolled steel |

Picking the right steel descaling method depends on the scale’s type and thickness. It also depends on the steel’s shape and the finish you want. Steel descaling methods help get steel ready for the next steps in making things.

Chemical Steel Descaling

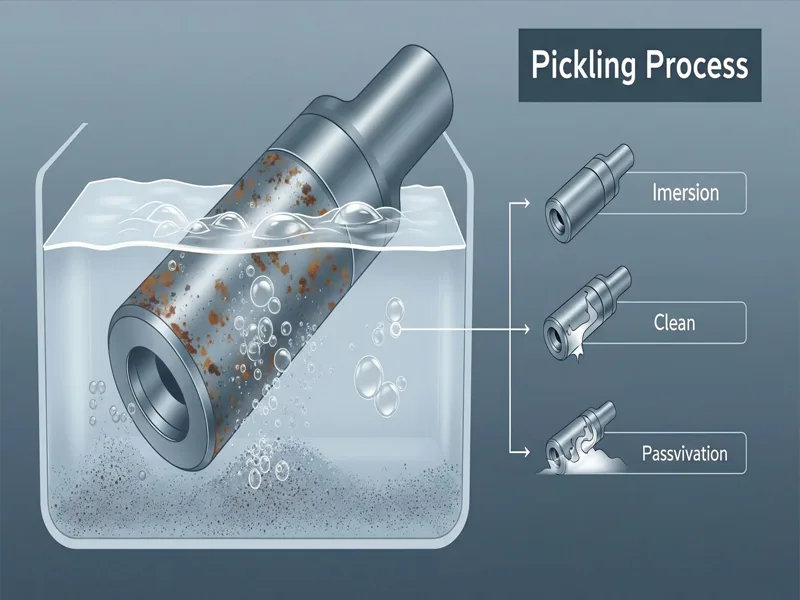

Chemical Process

Chemical steel descaling is also called pickling. It uses acids to clean steel. This process takes off rust, scale, and dirt. Workers put the steel in a bath with acid. The acid eats away the unwanted layers. This gets the steel ready for painting or shaping. Chemical oxide scale removal works on many steel types. It is good when you need a smooth, clean finish.

Chemicals Used

Factories use hydrochloric acid and sulfuric acid for chemical descaling. Hydrochloric acid works at room temperature. It removes scale fast and does not hurt the steel much. Sulfuric acid needs heat to work well. It is cheaper and easier to recycle. For stainless steel, companies use nitric acid and hydrofluoric acid together. These chemicals can be dangerous. Safer choices like citric acid with ammonium bifluoride are used more now. Citric acid is less harmful and stops over-pickling. Ammonium bifluoride is easier to use than hydrofluoric acid.

Steps Involved

- Workers clean the steel to take off oil and dirt.

- They dip the steel in the acid bath for a set time.

- The acid melts away the scale and rust.

- After pickling, they rinse the steel with water.

- Sometimes, they add a step to stop the acid from working more.

- The steel dries and is ready for the next job.

Tip: Always wear safety gear and use good airflow when working with acids to stay safe.

Pros of Chemical Steel Descaling

Precision and Finish

- Chemical steel descaling makes steel very clean and smooth.

- The process removes even tiny bits of scale.

- This helps the steel get ready for painting or coating.

- It does not scratch or dent the steel.

- The shape and size stay the same.

- Chemical oxide scale removal keeps tight tolerances.

- This is important for parts that need to fit just right.

Effectiveness for Complex Parts

- Chemical steel descaling works well on steel with tricky shapes.

- The acid can reach small spaces that brushes cannot.

- This method makes the steel very clean.

- It helps the steel last longer and stops rust.

Cons of Chemical Steel Descaling

Safety and Environmental Risks

- Many acids used in chemical descaling can hurt skin, eyes, and lungs.

- Some chemicals make fumes that pollute the air.

- These fumes can cause breathing problems.

- If acids are not thrown away properly, they can hurt soil and water.

- This can harm plants and animals.

- Workers must wear safety gear and follow strict rules.

Surface Damage Potential

| Risk Type | Description |

|---|---|

| Over-pickling | Acid can eat too much steel if left too long. This can damage the surface. |

| Material Compatibility | Some acids can hurt metals like copper or zinc in the steel. |

| Staining and Sensitivity | Some chemicals may stain the steel or cause allergies. |

Note: Always watch the pickling time and use the right acid for each steel type to stop damage.

When to Use Chemical

Chemical steel descaling is best for some jobs. Factories use it when steel has lots of scale or rust. This method is very helpful for stainless steel. Stainless steel can get a hard oxide layer when heated. Taking off this layer is needed before more treatments. These treatments include pickling or passivation. Chemical descaling removes the scale without scratching the steel.

Some steel parts have tricky shapes or tiny spaces. Brushes and blasting tools cannot clean every spot. Chemical descaling uses acids that move into small gaps and corners. This makes it good for things like heat exchangers, pipes, and machine parts with holes. The acid also gets rid of dirt or oil mixed with the scale.

Factories use chemical descaling for steel that needs a smooth finish. Types 304 and 316 stainless steel need careful cleaning. These types are used in food factories, medical tools, and chemical plants. A clean surface helps paint and coatings stick better. It also helps the steel fight rust and last longer.

The acid used depends on the job. Strong acids like hydrochloric acid work fast but can hurt steel if not used correctly. Weaker acids, like citric or acetic acid, are safer for the steel. Factories use weaker acids to protect thin or delicate parts.

Tip: Chemical descaling is good when steel cannot take rough cleaning. It is also best when the scale is thick or mixed with other stuff.

Chemical steel descaling is not always the best choice. Workers must think about safety and the environment. Acids can be dangerous and need special care. Factories must follow rules for storing and throwing away acids. In places with strict laws, companies may use safer acids or extra cleaning steps.

Mechanical Steel Descaling

Mechanical Process

Mechanical steel descaling uses force to remove scale from steel. Workers use tools and machines to break the hard layer. This works well for big steel pieces and thick scale.

Shot Blasting

Shot blasting is a common way to clean steel. Machines throw small steel shots or grit very fast at the steel. The shots hit the steel and knock off the scale. This makes the surface clean. Factories use dry and wet shot blasting. Dry blasting uses blast wheels or air. Wet blasting mixes water with sand or other rough stuff. Shot blasting is quick and good for big jobs. It also gets steel ready for paint or coating.

Wire Brushing

Wire brushing uses brushes with strong metal wires. Workers or machines move the brushes over the steel. The wires scrape off loose scale and dirt. This way is simple and good for small spots or fixing mistakes. Wire brushing does not work well on thick or hard scale.

Scraping and Bending

Scraping and bending use tools to break the scale. Bending the steel rod makes the scale crack and fall off. Scraping uses sharp tools to peel away the scale. These ways remove most of the rough scale. Air or water can wash away any fine scale left.

| Mechanical Descaling Process | Description | Key Details |

|---|---|---|

| Reverse Bending Deformation | Bend steel rods to break scale | Removes most rough scale; works best with some rod bending |

| Shot Blasting Process | Abrasive media cleans steel | Fast, cheap, uses steel shots or grit, good for big areas |

| Combination Method | Uses bending and blasting together | Cleans better, often used for rods |

| Abrasive Materials | Different abrasives for different jobs | Steel shots, grit, sand, glass beads; can be used again |

Pros of Mechanical Steel Descaling

Cost and Safety

Mechanical steel descaling works fast and does not use strong chemicals. It often costs less for big jobs than chemical methods. Workers can see the clean steel right away. It helps water flow in pipes and removes hard scale that chemicals may miss. However, it requires further refinement and precise tool use.

Environmental Benefits

Mechanical steel descaling does not make chemical waste. Factories can use the shot blasting materials again. This is better for the environment. There is less chance of hurting the soil or water.

Surface Quality

Mechanical steel descaling can clean steel well. It gets steel ready for paint, coating, or welding. This works best on flat or simple shapes. It takes off most of the scale and leaves steel ready for the next step.

Cons of Mechanical Steel Descaling

Labor and Time

Mechanical steel descaling often needs more handwork. Workers must reach the steel surface. This can take more time and cost more for the work. It is not as good for very big or nonstop jobs.

Limits on Complex Shapes

Mechanical steel descaling has trouble with tricky shapes or tight spots. Brushes and blasting tools cannot reach every place. Thin or shiny steel can get scratched. Some rough bits may stay and need more cleaning. Sometimes, pits or laps hide under the scale and are hard to see.

Note: Factories must pick the right abrasive and way to stop damage and get the best results.

When to Use Mechanical

Factories use this way for big steel parts. It works well when thick scale covers the steel. Shot blasting and wire brushing take off tough layers. Chemical methods may not work on these thick spots. These tools clean steel fast. They get it ready for painting or welding.

Many factories use mechanical steel descaling for large amounts of steel. Steel mills and car plants use it every day. Construction companies also use it for many steel pieces. Mechanical ways keep up with fast work lines. Workers can clean long beams and rods without stopping. This saves both time and money.

Mechanical steel descaling is good for simple steel shapes. Flat plates, pipes, and rods are easy to clean this way. The tools reach all parts and leave a rough surface. This roughness helps paint and coatings stick better. Factories often use this before galvanizing or powder coating.

Some steel gets a very hard scale from hot rolling or forging. Chemical baths may not take off this tough scale. Mechanical ways break and strip away these hard layers. This makes it good for carbon steel and alloy steel in heavy machines.

Mechanical steel descaling is also good when factories want less waste. Shot blasting and wire brushing do not produce dangerous byproducts. Many companies use abrasive materials again. This saves money and helps the environment.

New machines have made mechanical steel descaling better. Modern shot blasting uses computers to control speed and pressure. This gives a smoother finish and keeps the steel safe. New abrasives like glass beads and ceramic grit clean steel without deep scratches. Some factories use bending and blasting together for even better cleaning.

| Situation | Why Mechanical Descaling Works Well |

|---|---|

| Large steel surfaces | Fast cleaning, handles bulk production |

| Heavy or stubborn scale | Breaks up thick layers |

| Simple shapes (plates, rods) | Tools reach all areas |

| Environmental concerns | No chemical waste, recyclable abrasives |

| Need for rough surface finish | Improves coating and paint adhesion |

Mechanical steel descaling is best when speed, cost, and safety matter. Factories should use this method for big jobs, tough scale, and when they want to skip chemicals.

Steel Descaling Process Comparison

Side-by-Side Table

It is important to compare steel descaling methods. This helps people pick the best way for their needs. The table below shows how mechanical and chemical methods are different. Each way uses its tools and steps. They also give different results.

| Criterion | Mechanical Descaling | Chemical Descaling |

|---|---|---|

| Oxide Removal Mechanism | Physical abrasion (blasting, grinding, brushing) | Chemical dissolution (acid pickling) |

| Surface Roughness (Ra) | Higher roughness (> 3 μm) | Smoother surface (< 1 μm) |

| Process Parameters | Projectile speed, size, impact angle, duration | Acid concentration, temperature, immersion time, agitation |

| Equipment | Blasting machines, grinding wheels, wire brushes | Acid tanks, immersion baths, agitation systems |

| Pre-treatment Requirements | Cleaning to remove lubricants and dirt | Cleaning and degreasing to ensure acid contact |

| Post-treatment Considerations | Dust/fume extraction needed | Rinsing and neutralization to avoid contamination |

| Impact on Subsequent Processes | Creates micro-roughness beneficial for coatings | Produces chemically clean, smooth surfaces suitable for coatings |

| Selection Criteria | Based on steel type, scale severity, downstream requirements | Based on steel type, scale severity, downstream requirements |

Mechanical descaling uses force to remove off scale. Chemical descaling uses acids to melt the scale away. Mechanical cleaning makes the steel rougher. This roughness helps paint or coatings stick better. Chemical cleaning makes the steel smoother. This smooth finish is good for special jobs.

Cost and Efficiency

Factories care about how much money and time each method takes. Mechanical and chemical methods have different prices and speeds.

- Mechanical descaling is cheaper for each ton of steel. It usually costs between €5 and €10 per ton.

- Chemical descaling is more expensive. It can cost between €50 and €120 per ton.

- Mechanical ways need less fixing. Machines like shot blasters and brushes do not break often.

- Chemical ways need workers to add new chemicals and check the system frequently.

- Mechanical cleaning is faster. Factories can clean more steel without stopping much.

- Chemical cleaning takes longer. Workers must be careful and wait for the acid to work.

- Mechanical ways help factories finish big orders quickly. They can clean lots of steel fast.

- Chemical ways can slow down work. Workers must plan cleaning times and have enough people.

Factories often pick mechanical ways to save money and work faster. Chemical ways are best when steel needs to be very smooth or has a tricky shape.

Environmental Impact

Steel descaling can affect nature and people. Factories want to use safe ways for everyone.

- Mechanical ways do not use strong chemicals. They make less waste and are easier to recycle.

- Chemical ways use acids that can hurt water and soil if not handled properly.

- Mechanical cleaning needs dust and fume control. But it does not make chemical waste.

- Chemical cleaning needs special tanks and steps to clean up used acids.

- New machines help both ways. High-pressure water jets clean steel without chemicals and produce less waste. Laser descaling uses light to take off scale and does not make waste. Electrolytic descaling uses less acid and saves energy. Induction heating cleans steel faster and uses less power.

Many factories now use new machines to make steel cleaning safer and better for the earth. These changes help keep workers and nature safe.

Surface Quality

Surface quality is very important when cleaning steel. Both chemical and mechanical ways take off scale and get the steel ready for the next steps. But each way makes the steel look and feel different. This changes how well paint or coatings stick.

- Mechanical descaling uses blasting or brushing tools. These tools scrape off thick scale. This way is good for hard jobs in steel plants. It often leaves the steel rough. A rough surface helps paint or coatings stick better. Sometimes, not all the scale comes off. Small bits can stay and hurt how the steel looks or works.

- Chemical descaling, called pickling, uses acid to melt away the scale. This way makes the steel smooth and shiny. It is good for steel with tricky shapes or small spaces. A clean, smooth surface helps coatings last longer and look nice.

Both ways make steel look better and stop rust. They also get steel ready for welding or other jobs. If cleaning is not finished, some scale can remain. Leftover scale can cause weak spots or make paint not stick well.

A clean steel surface is very important for cars and buildings. These jobs need steel that looks good and stays strong.

There are three classes for how clean the steel is after descaling:

| Surface Class | Description | Effect on Surface Quality |

|---|---|---|

| Class A | All outside and inside oxides are gone | Best finish, almost no scale, great for more work |

| Class B | Outside layer gone, some inside scale left | Some scale left, not as smooth |

| Class C | Only outside layer gone, deep oxides still there | Poor finish, lots of scale, can hurt looks and strength |

How well descaling works depends on how much scale is removed. Class A means the steel is very clean and has the best finish. This is needed for parts that must look good and last long.

How scale sticks to steel depends on what is in the steel and how it was heated. Some scale comes off easily. The other scale needs stronger cleaning. Mechanical descaling is good for thick, hard scale. Chemical descaling is better for thin or hidden scale.

- Both ways help paint and coatings stick and make steel last longer.

- Rough steel from mechanical cleaning helps paint grip better.

- Smooth steel from chemical cleaning looks nicer and is good for special jobs.

Tip: Always check the steel after cleaning. Good cleaning means better steel that lasts longer.

After Steel Descaling

Corrosion Risks

Taking off the oxide layer leaves fresh steel open to the air. This new steel can rust fast if not covered. How the steel is cleaned changes how fast it rusts:

- Chemical descaling uses strong acids that break the oxide layer. Acids with very low pH, below 2, start rusting right away.

- Chloride ions in acids or cleaners make tiny holes called pits. These pits get deeper and make the steel weak.

- High heat during chemical cleaning makes rust form faster.

- Mechanical descaling, like shot blasting or wire brushing, can scratch the steel. If workers use rough pads the wrong way, the steel rusts more easily.

- Only using mechanical polishing, with no chemicals, can make rust worse. It makes the steel rough and easier to damage.

- Stainless steel can handle weak acids, but strong acids and chlorides can still hurt it.

A smooth oxide layer helps stop rust. Some new ways, like chemical mechanical polishing, can rebuild this layer and lower the risk of rust.

Protective Coatings

After descaling, workers put a coating on the steel. This keeps water, air, and chemicals away from the steel. There are many kinds of coatings. Some new ones use tannic acid and graphene. Tannic acid reacts with iron oxides to make a tough layer. Graphene makes the coating stronger and keeps water and salt out. These coatings work well, even near the ocean.

| Type of Protective Coating | Description | Corrosion Resistance Mechanism |

|---|---|---|

| Metallic Coatings (zinc, chromium, nickel, cadmium, aluminum) | Put on by electroplating, hot dipping, or spraying | Make a strong barrier; zinc rusts first to protect steel |

| Polymer Coatings | Thick layers put on as sheets or powders | Stop water and air; protect from scratches |

| Vitreous Enamels | Melted glass on steel at high heat | Hard, resists chemicals |

| Conversion Coatings (phosphate, chromate) | Chemical layers on steel | Help paint stick and add more protection |

| Paint Films | Paint with special chemicals | Slow down rust; need a good base coat |

Tip: Pick the right coating for where the steel will be used and how much protection is needed.

Cleaning Steps

Cleaning steel the right way after descaling helps coatings stick. It also keeps the steel strong. ASTM A380-17 gives steps for cleaning:

- Wash new steel with soap or mild cleaner and hot water. Dry it with a soft cloth.

- For old steel, use a non-metal brush and a cleaning compound.

- Do not use rough pads on new steel. Only use them if soap does not clean the dirt.

- Fix deep scratches or pits by welding, grinding, or polishing.

- Rinse the steel with clean water before adding any passivating solution.

- Put on the passivating solution with a soft brush. Let it sit for about 15 minutes.

- Rinse again with clean, hot water to wash off all chemicals.

- Handle and store the clean steel carefully so it does not get scratched or dirty.

Note: Good cleaning helps coatings last longer and keeps steel strong.

Choosing a Steel Descaling Method

Factors to Consider

Picking the right descaling method is important. Many things can change how well the process works and how good the steel looks.

Steel Type

Different steels need different ways to remove scale. Carbon, alloy, and stainless steels have their own oxide layers. Some acids work on carbon steel but can hurt stainless steel. For example, hydrochloric acid takes off scale fast but can cause stainless steel to rust. Factories must pick the right method for the steel and the finish they want.

Production Scale

How much steel you need to clean matters. Big factories use machines to clean lots of steel at once. Mechanical descaling is good for large jobs and long work lines. Chemical descaling is better for small batches or tricky shapes. Using machines and controls helps maintain high quality and prevent mistakes.

Environmental Rules

Factories must follow safety and environmental rules. Chemical descaling makes waste that needs special care. Workers must control fumes and clean up used acids before throwing them away. Mechanical descaling makes less dangerous waste, but can make dust. Companies must follow standards like ISO 8501 and ASTM A967. Good machines, dust collectors, and safe waste handling keep workers and nature safe.

Budget

How much money you have is important. Mechanical descaling usually costs less for big jobs. Chemical descaling can cost more because of chemicals and waste cleanup. Factories also need to think about machine costs, safety gear, and repairs. Picking the right way saves money and keeps work running well.

Tip: Always check local laws and safety rules before starting any descaling job.

Steel Decision Guide

Factories can follow steps to pick the best descaling method. Many use special tools to compare their choices.

- List all needs and goals. Decide what kind of surface, speed, and finish you want.

- Check the steel type and part shape. Some ways work better for certain steels or tricky parts.

- Estimate production volume. Big jobs may need machines for fast cleaning.

- Review environmental and safety rules. Make sure the way you pick follows all laws and keeps people safe.

- Compare costs. Look at prices for machines, workers, chemicals, and waste cleanup.

- Use decision tools. Tools like Analytical Hierarchical Process (AHP) or TOPSIS help rank your choices.

| Step | What to Consider |

|---|---|

| Define requirements | Surface finish, speed, part complexity |

| Identify constraints | Steel type, shape, production scale |

| Evaluate options | Mechanical vs. chemical, cost, safety, rules |

| Rank alternatives | Use decision tools for a clear comparison |

| Make a choice | Pick the method that fits all needs best |

Note: Quality checks like looking at the steel and testing roughness help make sure the method works well.

Looking at all these things helps factories pick the safest and best way to descale steel for their work.

Steel descaling methods are not all the same. Each way has its steps, good points, and best times to use it. The table below shows the main ideas:

| Aspect | Mechanical Descaling | Chemical Descaling |

|---|---|---|

| Pros | Safe, saves money, can be used many ways | Very exact, works well for tricky shapes |

| Cons | Picking the right tool is important, does not always work on every scale | Costs more, makes dangerous waste |

| Best Use | Good for on-site jobs, tough build-up, regular cleaning | Good for batches, scales that acids can remove |

You need to think about the steel type, how much money you have, and how safe it is before picking a method. People who know a lot about steel can help you choose the best way. After cleaning, steps like passivation help keep steel strong and make it last longer.

FAQ

Steel descaling takes off the hard oxide layer on steel. This helps paint, coatings, and welds stick better. Clean steel looks nicer and lasts longer.

Yes, chemical descaling can hurt steel if left in acid too long. Over-pickling can eat away the steel’s surface. Workers need to watch the process carefully.

Mechanical descaling works best on flat or simple shapes. Brushes and blasting tools cannot reach tiny corners or holes. Complex parts often need chemical descaling instead.

Mechanical descaling makes less dangerous waste. Factories can use abrasive materials again. Chemical descaling uses acids that must be thrown away safely to protect soil and water.

Workers put on coatings like paint, zinc, or special chemicals. These coatings keep water and air away from the steel. This helps stop rust and corrosion.

Workers wear gloves, goggles, and masks. They use good airflow and follow safety rules. Factories teach workers how to use acids and machines safely.

Yes. Chemical descaling gives a smooth and shiny finish. Mechanical descaling leaves the steel rougher. The method picked changes how the steel looks and how coatings stick.