Manufacturers use casting to make parts with hard shapes. Casting helps them work fast and save money. There are many casting processes. Each one has special features. Picking the right casting process affects product quality. It also helps control costs and makes sure things work well. The Classification of Casting Processes helps companies pick the best method for their needs.

| Aspect | Casting | Forging |

|---|---|---|

| Product Quality | Good for hard shapes; may have small holes or shrinking | Stronger, lasts longer, has fewer problems |

| Cost | Lower tool cost; more waste and extra work needed | Higher tool cost; less waste and less extra work |

| Performance | Good for fancy, light, or non-strong parts | Best for parts that need to be strong and last long |

Casting processes like high-pressure die casting help make things like GPU frames and car parts. These parts are exact, light, and not too expensive. Companies perform better when they select the most effective casting process among various casting types.

Key Takeaways

- Metal casting makes strong and detailed parts fast. It saves money if you pick the right process.

- Different casting methods work for different metals and shapes. They also fit different sizes and needs.

- Low pressure, gravity die, centrifugal, vacuum, and lost-foam casting are all special. Each one is good for certain parts.

- Picking the right casting process makes products better. It also cuts down on waste and keeps costs low.

- Cast iron, steel, and non-ferrous alloys need the right casting method. This helps get the best results.

- A clear checklist helps you choose the best casting process. You look at size, shape, precision, and how many you need.

- Digital tools and green casting are changing casting. They make production faster and cleaner.

- Knowing about casting problems and new trends helps companies. It lets them make better parts and stay ahead.

Table of Contents

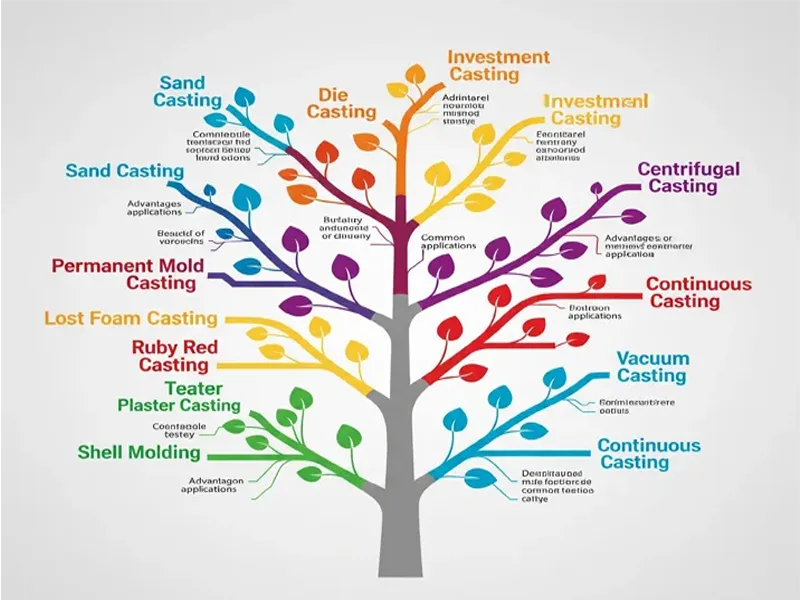

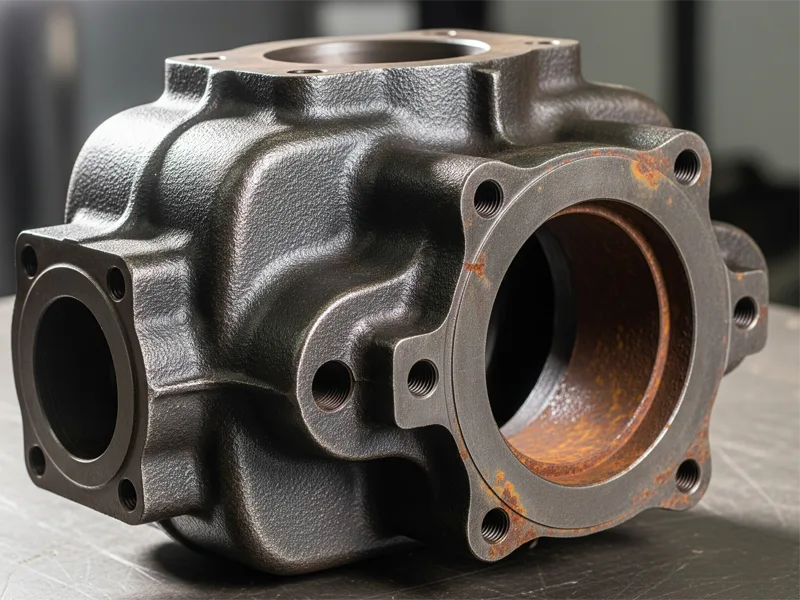

Classification of Casting Processes

Manufacturers use casting process classification to pick the best method. They check a few main things:

- The metal type matters because each metal needs special tools and melting ways.

- The mold material changes the process. It can be sand, ceramic, or metal.

- Metal goes into the mold in different ways. Some use gravity pouring, others use high-pressure injection.

- Pressure is important. Some methods use high pressure, others use gravity or low pressure.

- How many parts and how hard the shapes are matter. Permanent molds work well for lots of parts. Sand casting is good for small batches or tricky shapes.

- Cores help make inside spaces. Finishing steps are needed too.

Today, factories use at least eleven casting types. These are sand casting, investment casting, plaster mold casting, vacuum casting, shell mold casting, lost foam casting, gravity die casting, pressure die casting, centrifugal casting, continuous casting, and slush casting. Each one has special strengths for different jobs.

Picking the right casting process helps make better products. It saves money and makes things work better. The next parts talk about the most important casting processes and how they work.

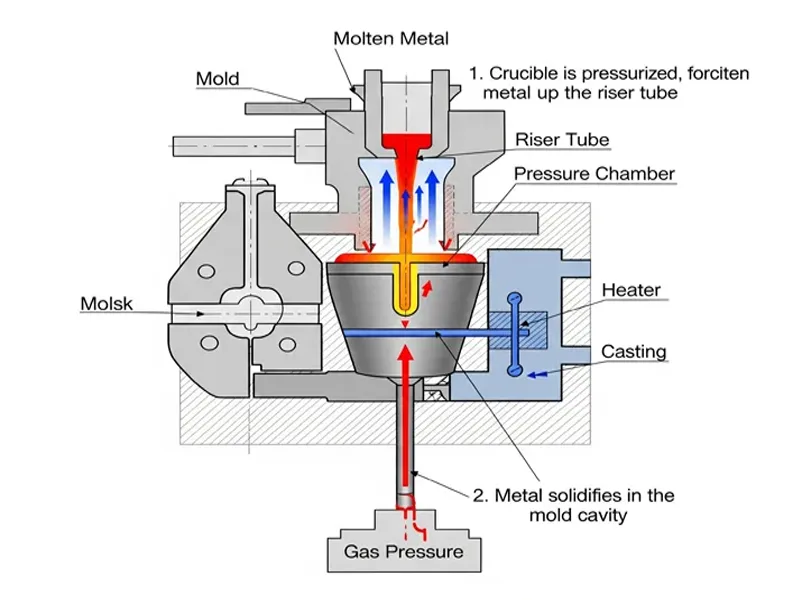

Low Pressure Casting

Low pressure casting is good for making strong metal parts. It uses gentle pressure to move melted metal into a mold. Gravity casting only uses the metal’s weight. Low pressure casting uses a soft push instead. This helps the metal fill the mold smoothly. It works well for thin or tricky shapes.

Low pressure casting makes parts that are strong and dense. There are fewer mistakes in the parts. Car wheels, engine blocks, and electronics cases use this method. It works with aluminum, magnesium, zinc, and copper alloys.

The table below shows how low pressure casting and gravity casting are different:

| Quality Aspect | Low Pressure Casting (LPC) | Gravity Casting (GC) |

|---|---|---|

| Surface Finish | Very smooth surface | Rougher surface |

| Dimensional Accuracy | More exact size | Less exact size |

| Porosity | Fewer holes, denser parts | More holes, more mistakes |

| Solidification Shrinkage | Less shrinking | More shrinking |

| Mold Filling | Smooth flow with gentle pressure | More splashing with gravity |

| Mold Orientation | Mold can be turned different ways | Mold is usually straight up and down |

Low pressure casting lets you change the mold’s position. It also lets you control how fast the metal cools. This makes the parts solid and strong. It is used for things with thin walls and detailed shapes. The table below lists what it is used for:

| Product Type / Material | Common Applications and Industries |

|---|---|

| Aluminum Alloys | Engine blocks, wheels, bike frames, electronics cases, home appliances, golf club heads, heat sinks, pump housings, cylinder heads, suspension parts |

| Zinc Alloys | Door handles, shiny decorations, hardware that does not rust |

| Magnesium Alloys | Gearbox covers, steering parts, airplane and electronics pieces |

| Copper Alloys | Heat sinks, connectors, electric parts |

Low pressure casting is a top pick for making tough, light, and detailed parts. It helps companies make good products that last.

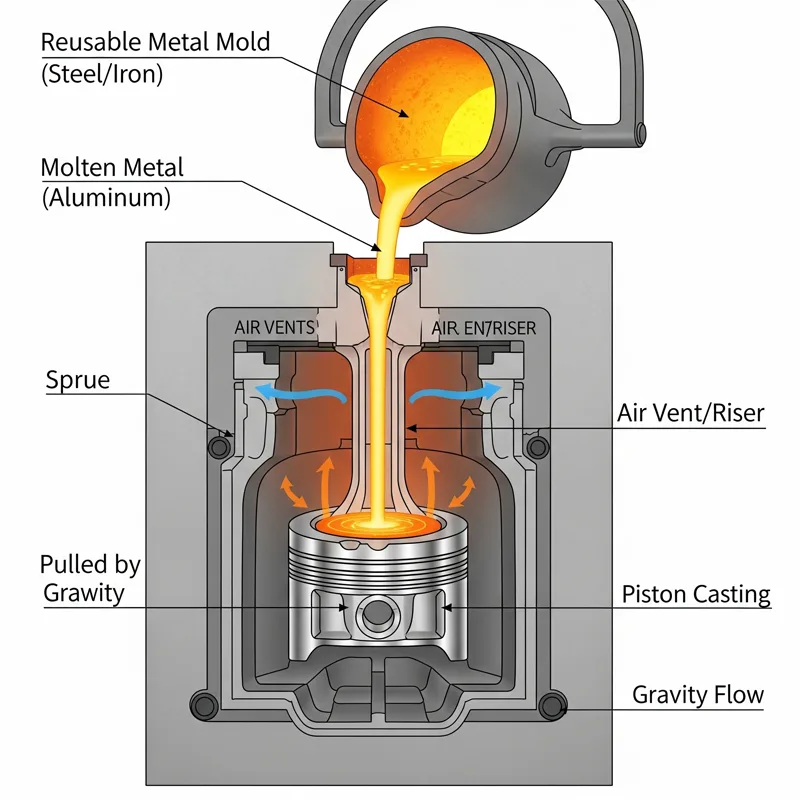

Gravity Die Casting

Gravity die casting uses metal molds that can be used again. Melted metal is poured into a steel or iron mold. Gravity pulls the metal down into the mold. This makes parts with smooth surfaces and exact sizes.

Gravity die casting makes shiny, neat parts. These parts do not need much extra work. Car pistons, valve bodies, and water pump covers are made this way.

The table below shows how gravity die casting and sand casting are different:

| Feature | Gravity Die Casting | Sand Casting |

|---|---|---|

| Mold Material | Metal mold that can be reused | Sand mold that is thrown away |

| Surface Finish | Smooth and shiny | Rough and not shiny |

| Dimensional Accuracy | Very exact size | Less exact size |

Gravity die casting makes parts that are always good and strong. The metal mold can be used many times. This saves money when making lots of parts. The cost for gravity die casting tools is between $100 and $100,000 or more. This is more than sand casting but less than pressure casting.

Gravity die casting is chosen for parts that need to be strong and fit well. It works best with aluminum, copper, and zinc alloys. It is used for engine parts, pump covers, and other things that need to work well.

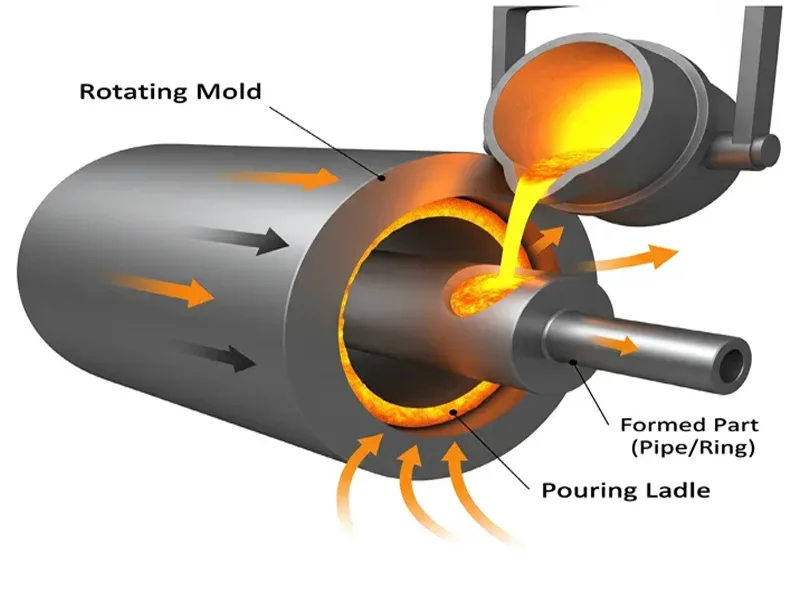

Centrifugal Casting

Centrifugal casting uses a spinning mold to shape metal. The mold turns very fast. Spinning spreads the melted metal evenly. This makes parts that are thick and have few mistakes.

Centrifugal casting is great for making round things like pipes and rings. It helps get rid of holes and makes strong parts.

Some good things about centrifugal casting are:

- Even thickness and fine texture

- Fewer holes and mistakes

- Best for round and hollow shapes

- Works with many materials, like metals and mixes

- Saves money and is quick

- Handles heat and rust well

Centrifugal casting can use many kinds of metals. It works with stainless steel, nickel, copper, cobalt, gray iron, aluminum, and steel. It can also use glass and concrete.

Centrifugal casting cools the metal in a special way. This makes the parts stronger and last longer. Spinning pushes dirt to the middle, so it is easy to clean out. Companies use centrifugal casting for airplane, military, and factory parts that must be very strong.

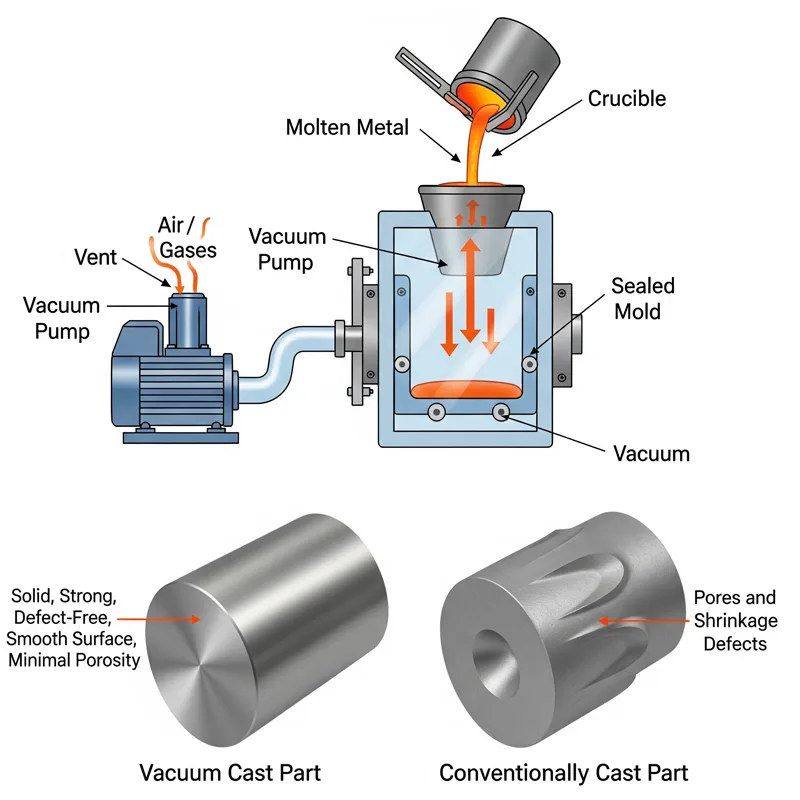

Vacuum Casting

Vacuum casting is a newer way to make parts. It makes strong parts with fewer mistakes. This process uses a vacuum to pull melted metal into the mold. The vacuum takes out air and gases from the mold space. This stops air bubbles and shrinking. The finished part is solid and strong. It has almost no tiny holes. Vacuum casting fills the mold gently. Other methods can make the metal move too fast and get too hot. This gentle way gives better strength and a smoother surface.

Vacuum casting lowers tiny holes by using a vacuum. The vacuum removes air and gases before and during metal pouring. This stops air from getting trapped. It also lowers gas bubbles and shrinking holes. Studies show that less pressure in the mold can cut holes from 4.8% to 2.8%. It also makes the holes smaller, from 8.65 μm to 5.61 μm. These changes make the part stronger and stretch more. The final product is tough and works well.

Many businesses use vacuum casting. It helps make test parts fast. It is good for making small numbers of parts and tricky shapes. The table below shows how different businesses use vacuum casting:

| Industry | Benefits and Applications |

|---|---|

| Automotive | Makes test parts for dashboards, air vents, lens covers, and cases; makes small batches of inside trims; saves money on tests before big production. |

| Medical Devices | Makes custom fake limbs and sensor cases; uses safe materials; gives steady, safe quality. |

| Aerospace | Makes light, non-strong parts like inside tubes and cabin panels; good for small amounts and testing. |

| Consumer Products | Makes test parts for wearable tech, phone cases, and easy-to-hold grips; makes small batches for market tests and demos. |

| Electronics | Makes cases and control panels; helps make test parts for handheld gadgets and smart devices. |

| Food and Beverage | Makes test pump cases, mixer parts, and easy-to-hold handles with safe materials. |

Vacuum casting lets companies make detailed, strong parts quickly. This process helps save money, work faster, and make better products.

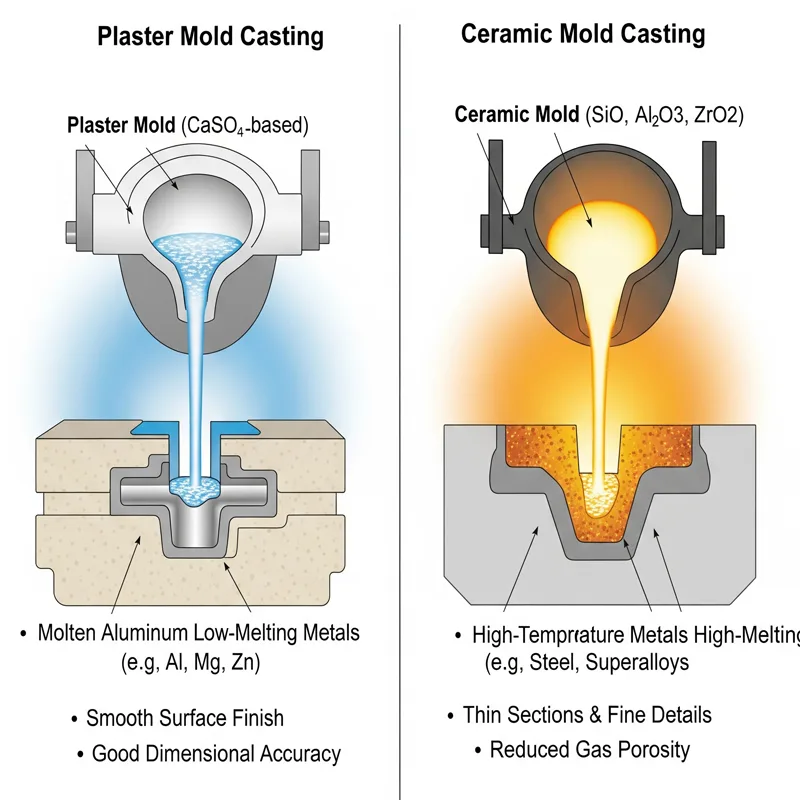

Plaster and Ceramic Mold Casting

Plaster and ceramic mold casting are special ways to make exact and tricky parts. Plaster mold casting uses plaster for the mold. It works best with metals that melt at lower heat, like aluminum, magnesium, and zinc. It gives smooth surfaces and good size accuracy. This makes it good for simple jobs that do not need much.

Ceramic mold casting uses tough ceramics like silica, alumina, or zircon. These can take much higher heat. This lets companies cast metals like stainless steel and bronze. Ceramic molds give very smooth surfaces and exact sizes. Often, you do not need extra cutting or shaping. Ceramic molds do not let much gas through. This means fewer gas problems and better parts. This method is good for thin parts and tiny details. It is used for airplane, car, and special machine parts.

The table below shows how plaster and ceramic mold casting are different:

| Aspect | Plaster Mold Casting | Ceramic Mold Casting |

|---|---|---|

| Mold Material | Plaster | Tough ceramics (silica, alumina, zircon) |

| Temperature Capability | Only for metals that melt at low heat | Can be used for metals that need high heat |

| Application Complexity | Good for simple jobs | Good for tricky shapes and thin parts |

| Dimensional Accuracy | Good | Very good, fits tightly |

| Surface Finish | Good | Very smooth, often no extra work needed |

| Mechanical Properties | Not as good with heat | Better strength because of fewer tiny holes |

| Production Volume | Simple parts, not many made | Small to medium batches with tricky shapes |

If you need tricky shapes, thin walls, or strong metals, pick ceramic mold casting. For easy, low-heat parts, plaster mold casting is cheaper.

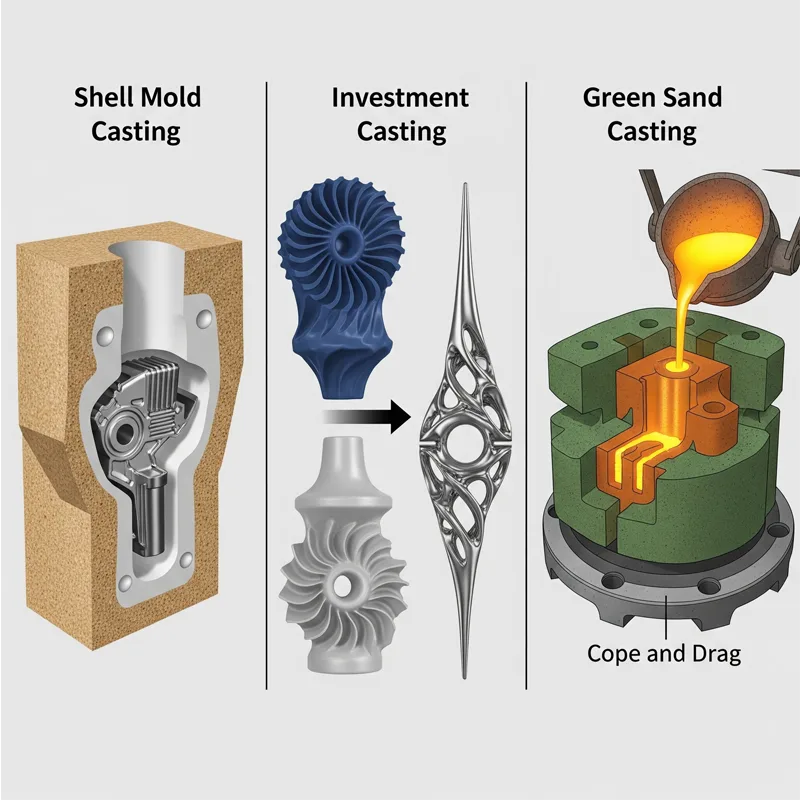

Shell Molding

Shell molding is a careful way to cast parts. It uses a thin shell made of sand and glue to make the mold. This method makes parts with smooth surfaces and exact sizes. Shell molding is good for small to medium parts. It can make lots of parts quickly.

But shell molding has some problems compared to other ways:

- Most parts weigh less than 50 lbs (about 30 kg).

- Tools cost more because metal molds must handle heat.

- Making the mold takes longer than green sand casting.

- Flat parts can swell because the mold is light.

- The glue used costs more than sand casting glue.

- Using sand cores for tricky shapes is harder.

The table below shows how shell molding is different from other casting ways:

| Feature | Shell Molding | Investment Casting | Green Sand Casting |

|---|---|---|---|

| Tolerances | +/- 0.03-0.06 in. | +/- 0.005-0.01 in. | +/- 0.06 in. |

| Surface Finish | Good | Very Good | Fair |

| Tooling Costs | High | Medium | Low |

| Labor Costs | Medium | High | Low |

| Production Volume | High | Low | High |

| Limitations | Small parts, flat parts can swell | Best for tricky, small parts | Best for big, simple parts |

Shell molding is a good choice for making exact, repeatable parts in big amounts. For bigger or trickier parts, other casting ways may be better.

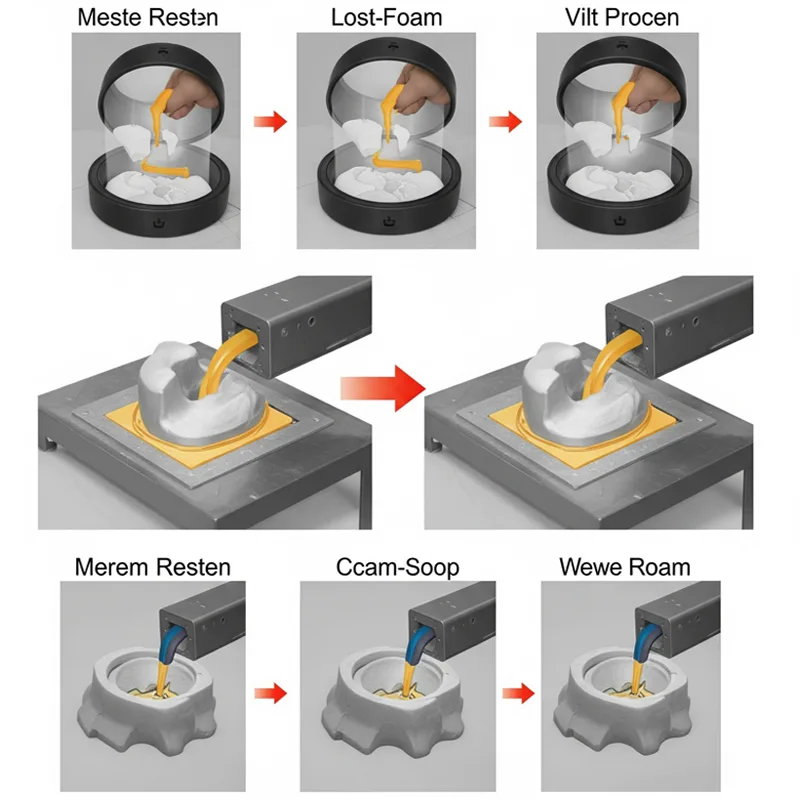

Lost-Foam Casting

Lost-foam casting is a newer way to make metal parts. It is good for making parts with hard shapes. This process uses a foam pattern that looks like the finished part. Workers put the foam in loose sand. Then, they pour hot metal into the sand. The hot metal melts the foam and takes its place. This makes the final part.

Key Steps in Lost-Foam Casting:

- Make a foam pattern that looks like the part you want.

- Put foam pieces together if the part is big or has many pieces.

- Cover the foam with a special layer so the sand keeps its shape.

- Put the covered foam in dry, loose sand inside a box.

- Pour hot metal into the mold. The foam goes away, and the metal fills the space.

- Let the metal cool. Take off the sand and clean the part.

Lost-foam casting is good for making parts with thin walls or hollow spaces. It is used for engine blocks, pump housings, and other parts with lots of details.

Advantages of Lost-Foam Casting:

- Makes hard shapes in just one step.

- Needs less extra cutting or shaping.

- Uses less metal and energy.

- Gives smooth surfaces and exact sizes.

- Good for making many parts at once.

Disadvantages:

- Foam patterns can break easily.

- Not the best for very big parts.

- Needs careful watching during casting.

Environmental Impact: Lost-foam casting is better for the environment than old sand casting. It uses dry sand with no glue, so the sand can be used again and again. This means less waste and saves money. The process makes less dust, so the work area is cleaner and safer. But, when the foam burns, it makes some bad gases. Factories use special tools to catch these gases and keep workers safe. Some companies use foam that breaks down naturally to help the environment even more.

| Aspect | Lost-Foam Casting (LFC) | Traditional Sand Casting (Green Sand) |

|---|---|---|

| Sand Type | Dry sand with no glue, loose sand | Sand with chemicals and glue |

| Sand Reuse | Sand can be used many times | Sand is harder to reuse because of chemicals |

| Waste Generation | Used sand, foam waste, scrap metal | Lots of waste sand; harder to recycle |

| Airborne Emissions | Makes bad gases; easier to catch and clean | Makes more bad gases and dust |

| Dust Generation | Little or no dust made | Makes a lot of dust |

| Environmental Equipment Investment | Needs less money for cleaning tools | Needs more money for dust and gas cleaning |

| Working Environment | Better because there is less dust and gas | Worse because of dust and bad gases |

| Maintenance | Easier, not many extra machines needed | Harder because of more machines for sand and glue |

| Overall Environmental Impact | Better for the environment, less pollution | Worse for the environment, more waste and pollution |

Applications:

- Automotive: Engine blocks, cylinder heads, intake manifolds

- Industrial: Pump housings, valve bodies, machine tool parts

- Art and Design: Sculptures, fancy metalwork

Lost-foam casting helps companies make detailed parts with less waste and lower costs. Companies that use this process can make better products, help the environment, and do well in business.

Types of Casting Processes

Principle

Casting uses different ways to shape metal parts. Each method depends on how metal moves and cools in the mold. The types of casting processes change with the mold material, pressure, and cooling. Sand casting uses sand molds that are thrown away after use. Gravity helps fill the mold with metal. Die casting pushes melted metal into metal molds using high pressure. Investment casting melts a wax pattern inside a ceramic shell to make detailed parts. Centrifugal casting spins the mold fast to spread metal evenly. These ways affect how smooth, strong, and exact each part is.

The main idea behind each casting process decides which products it makes best. Sand casting is good for big, simple shapes. Die casting makes thin, tricky parts that need to be exact. Investment casting is great for tiny details in airplane and medical parts. Centrifugal casting makes strong, round things like pipes and rings.

A table below shows how these ideas help pick the right process:

| Casting Process | Precision Level | Suitable Product Types | Key Principle |

|---|---|---|---|

| Sand Casting | Low | Big, simple parts | Gravity fills sand mold |

| Die Casting | High | Thin, tricky shapes | High-pressure injection in metal mold |

| Investment Casting | Very High | Tiny, detailed parts | Wax pattern melted in ceramic shell |

| Centrifugal Casting | Medium | Round, hollow parts | Mold spins to spread metal |

Steps

All casting processes follow steps to turn raw metal into finished parts. The steps can change with the types of casting processes, but most have these:

- Pattern Making

Workers make a pattern that looks like the final part. This pattern shapes the mold and helps with accuracy. - Core Making

Cores make hollow spaces or tricky shapes inside the part. Sand or other stuff is used for cores. - Mold Preparation

The team gets the mold ready with sand, metal, ceramic, or plaster. How they prepare the mold changes how metal moves and cools. - Melting

Workers heat the metal until it melts. They clean out bad stuff to make the metal better. - Pouring

Melted metal goes into the mold. How fast and hot they pour affects how good the part is. - Casting Cleaning

After cooling, workers take off sand, scale, and extra metal. Cleaning shows the finished part. - Finishing Treatments

The team sands, grinds, or coats the part. Finishing makes the surface smooth and gets it ready to use.

Every step in casting is important. Good pattern making and mold prep help make parts more exact. Careful melting and pouring stop mistakes. Cleaning and finishing make the part smooth and strong.

Pros

The types of casting processes give many good things to manufacturers. Companies pick casting because it is flexible, saves money, and makes hard shapes. Some main benefits are:

- Casting makes parts with tiny details and hard shapes.

- Many metals can be used, like aluminum, steel, and copper alloys.

- Casting works for both small and big parts, from little gears to huge engine blocks.

- The process gives smooth surfaces and exact sizes, especially with investment and die casting.

- Casting saves money for small and medium batches. Die casting helps save more when making lots of parts.

- Machines in casting help lower work costs and make things faster.

- Casting can use different materials needed for casting, so it works for many jobs.

Companies do better by picking the right casting process. They save money, make better parts, and finish work on time. Casting helps businesses make strong, good parts for cars, planes, and everyday products.

Cons

Every casting process has its own problems. Knowing these problems helps companies make better choices. It also helps them avoid mistakes that cost a lot of money.

- Sand casting leaves a rough surface on parts. Workers must spend more time making the surface smooth. This process is not very exact, especially for small or thin parts. Patterns and molds wear out and can change the part’s size. Sand molds are used once, so each part needs a new mold.

- Investment casting costs more and takes longer. This is because it has many steps. It is hard to make big parts with this method. The process needs careful control to stop mistakes.

- Die casting needs expensive machines and molds. It works best for metals that melt at lower heat. High-pressure injection can trap air and make small holes in the part.

- Plaster and ceramic mold casting cost more and have fewer metal choices. Plaster molds break easily and only work with metals that melt at low heat. Ceramic molds can take more heat but cost more money.

- Centrifugal casting does not work well for tricky shapes. The machines cost a lot. This process mostly makes round or hollow parts.

- Vacuum casting needs special machines and skilled workers. It is slower and costs more than other casting ways.

- Shell molding is only good for small parts. Making the shell costs more than sand casting. Flat parts can bend during making.

- Lost-foam casting uses foam patterns that can break. The process needs careful control to stop mistakes. It is not good for very big parts.

Picking the right casting process means thinking about these problems and the good things. Companies that know these limits can stop problems and make better parts.

Materials

Companies pick materials based on the casting process and what the part needs. Each casting way works best with certain metals and alloys. These are common materials used in casting.

- Sand casting works with many metals, such as:

- Aluminum alloys (360, 383, A356, A380, B390)

- Steel

- Bronze

- Iron (gray, ductile, malleable)

- Investment casting uses wax patterns and works well with:

- Stainless steel

- High-temperature alloys

- Titanium

- Aluminum

- Copper alloys

- Die casting is best for:

- Zinc alloys

- Aluminum alloys

- Magnesium alloys

- Plaster mold casting uses:

- Aluminum

- Magnesium

- Zinc

- Copper (for small, detailed parts)

- Ceramic mold casting works with:

- Stainless steel

- Bronze

- Other high-temperature alloys

- Centrifugal casting is good for:

- Iron

- Steel

- Copper alloys

- Aluminum

- Vacuum casting works with:

- Aluminum alloys

- Magnesium alloys

- Some plastics for test parts

- Shell molding uses:

- Iron

- Steel

- Aluminum

- Copper alloys

- Lost-foam casting works with:

- Aluminum alloys

- Cast iron

- Steel

Every casting process has things it cannot do. For example, sand casting cannot make very thin parts. Die casting cannot use metals that need high heat. Companies must match the material and process for the best results.

Applications

Companies use different casting ways to make many products. The choice depends on the part’s size, shape, and how exact it must be.

| Casting Process | Typical Applications |

|---|---|

| Sand Casting | Engine blocks, machine bases, pipe fittings, large valves, pump housings |

| Investment Casting | Turbine blades, medical tools, jewelry, golf club heads, aerospace parts |

| Die Casting | Car wheels, engine covers, electronic housings, appliance parts, toy components |

| Plaster Mold Casting | Decorative items, prototypes, small gears, art pieces |

| Ceramic Mold Casting | Jet engine parts, high-strength machine components, thin-walled industrial parts |

| Centrifugal Casting | Pipes, bushings, rings, cylinder liners, bearing sleeves |

| Vacuum Casting | Prototypes, dashboard panels, medical device housings, small-batch consumer products |

| Shell Molding | Gear housings, camshafts, connecting rods, small engine parts |

| Lost-Foam Casting | Engine blocks, cylinder heads, intake manifolds, pump bodies, complex housings |

Companies that pick the right casting way for each job do better. They make parts with the right strength, look, and size. This helps them make better products and keeps customers happy.

Casting Processes by Material

Casting changes when you use different metals. Each metal needs its own care. The best process depends on what the metal can do. It also depends on what the final part needs. Picking the right material helps companies make strong, good parts. Here is a quick look at how casting is different for cast iron, cast steel, and non-ferrous alloys.

Picking the right casting process for each metal makes better products. It also helps save money.

| Aspect | Cast Iron & Cast Steel (Ferrous Metals) | Non-Ferrous Alloys |

|---|---|---|

| Typical Casting Methods | Sand Casting, Die Casting, Investment Casting, Continuous Casting | Gravity Die Casting, Centrifugal Casting, Low-Pressure Casting, Vacuum Casting |

| Key Properties Considered | Strength, durability, toughness | Corrosion resistance, light weight, conductivity |

| Common Defects | Porosity, thermal cracking, shrinkage cavities | Oxidation, surface defects, warping |

| Applications | Engines, machinery, tools, railway tracks, ships | Electrical wiring, aircraft, jewelry, plumbing |

| Alloy Role | Improves strength, corrosion resistance | Enhances corrosion resistance, conductivity |

Cast Iron

Cast iron is a very common casting metal. It has lots of carbon, so it pours and shapes easily. Sand casting is used for big or tricky cast iron parts. Die casting and investment casting work for smaller, detailed pieces. Cast iron melts at lower heat than steel. It does not shrink much when it cools, so it keeps its shape.

- Types of Cast Iron:

- Gray iron: Easy to cut, but breaks easily, used for engine blocks.

- Ductile iron: Stronger, does not break as easy, used for pipes and gears.

- Malleable iron: Can bend, used for brackets and clamps.

- Key Features:

- Flows well

- Wears down slowly

- Can be brittle

- Applications:

- Engine blocks

- Pipes

- Machine bases

Cast Steel

Cast steel is strong and tough. It is good for parts that get hit or hold heavy things. Casting steel needs higher heat. It takes more care because steel does not flow as well as iron. Sand casting and investment casting are used for steel. Die casting is not used much because steel melts at high heat.

- Types of Cast Steel:

- Carbon steel: Used for tools and machines.

- Alloy steel: Has things like chromium or nickel to make it stronger.

- Stainless steel: Does not rust, used for food and medical tools.

- Key Features:

- Very strong

- Handles hits well

- Needs careful heat control

- Applications:

- Construction beams

- Gears

- Valves

Non-Ferrous Alloys

Non-ferrous alloys are metals like aluminum, copper, zinc, magnesium, and titanium. These metals are lighter and do not rust. Gravity die casting, centrifugal casting, low-pressure casting, and vacuum casting work well for these metals. Each alloy has its own good points.

- Types of Non-Ferrous Alloys:

- Aluminum alloys: Light, easy to cut, used in cars and electronics.

- Zinc alloys: Flows well, used for small, detailed parts.

- Magnesium alloys: Lightest metal, used in airplanes.

- Copper alloys: Good for pipes and electric parts.

- Titanium alloys: Strong and light, used in planes.

- Key Features:

- Does not rust

- Strong but light

- Conducts electricity well

- Applications:

- Aircraft parts

- Electrical wiring

- Jewelry

Picking the right material and casting process helps companies make better parts. They get the best mix of strength, weight, and cost.

Selection Guide for Casting Processes

Selection Factors

Picking the right casting process helps a project do well. There are many things to think about before choosing. Each thing changes how good, fast, or cheap the part will be. Companies should look at these points before they decide:

- Part Size: Big parts often use sand casting. Small or thin parts may need die casting or high precision casting.

- Shape Complexity: Easy shapes work with simple ways. Hard shapes need investment casting or lost-foam casting.

- Material Selection: The metal or alloy you pick changes the process. Some ways work better for iron, steel, or non-ferrous alloys.

- Precision Needs: High precision casting makes tight fits and smooth parts. Other ways may need more work after casting.

- Production Volume: Making lots of parts is good with die casting or gravity die casting. Small batches may use sand casting or vacuum casting.

- Cost: Tool and mold prices are different. Sand casting is cheap to start. Die casting costs more but makes parts faster.

- Mechanical Properties: Some casting ways make stronger or denser parts. Others are better for light weight or stopping rust.

- Production Efficiency: Fast ways help finish jobs on time. Some methods let you change molds quickly and make the same part again and again.

Picking the best casting way helps make better parts, saves money, and gets things done faster.

Checklist

Use this easy checklist to find the best casting process for your needs. The table below helps you pick the right way for your project.

| Requirement | Best Casting Process | Why Choose This? |

|---|---|---|

| Large, simple parts | Sand Casting | Low cost, flexible |

| Complex, detailed | Investment Casting | High precision casting, fine detail |

| Thin walls, high volume | Die Casting | Fast, high production efficiency |

| Strong, dense parts | Gravity Die Casting, Centrifugal | Good mechanical properties |

| Small batch, prototypes | Vacuum Casting, Plaster Mold | Quick setup, low tooling cost |

| Light weight, corrosion resistance | Non-Ferrous Alloy Casting | Material selection flexibility |

Tip: Check what your project needs and use this list to help you choose the best way.

Case Studies

Real examples show how picking the right casting way helps:

- Automotive Engine Block

A car company needs a big, strong part. They use sand casting because it is cheap and works for large sizes. - Turbine Blade for Aircraft

An airplane company wants high precision casting for hard shapes. Investment casting gives them the detail and strength they want. - Consumer Electronics Housing

A tech company needs many thin, light cases. Die casting helps them make lots of parts fast with smooth surfaces. - Custom Medical Device

A medical company makes a few custom parts. Vacuum casting lets them test ideas quickly and save money. - Industrial Pipe Fittings

A factory needs strong, round parts. Centrifugal casting makes dense, tough fittings for heavy work.

Companies that use this guide make better parts and do better than others.

Future Trends and Challenges

Digitalization

Digitalization is changing casting very quickly. Companies use smart tools and digital systems now. These tools help workers make better parts with less waste. Many factories use sand 3D printing to make molds and cores. This new way is faster and does not need old tools. Machine learning helps teams spot problems early. It checks for mistakes and keeps machines working well.

Robots and automation do many casting jobs today. Robots pour metal, move molds, and clean finished parts. This makes casting safer and more steady. Augmented and virtual reality help train workers. They show each step in the process. Digital twin technology lets engineers test casting on computers first. These tools help make work faster and cut down on errors.

Companies using digitalization in casting get better results. They make parts faster, save money, and keep customers happy.

Key digitalization trends in casting:

- Sand 3D printing for quick, flexible mold making

- Machine learning to find mistakes and check quality

- Robotics and automation for safer, steady casting

- Augmented and virtual reality for training and showing steps

- Digital twins for testing and improving casting

Green Casting

Green casting helps protect the earth while making strong parts. Many companies use eco-friendly binders and better sand mixes. These changes lower pollution and make casting more exact. Digital tools watch energy use and waste. Smart ideas help factories use less and follow rules.

Energy-saving ways use less power for casting. Some companies recycle sand, metal, and water to make less waste. Working with local groups and training workers also helps green casting. These steps help companies grow and care for the planet.

Green casting is good for the earth and saves money. It also helps companies work better.

Main green casting practices:

- Eco-friendly binders and better sand mixes

- Digital tools to watch resources and cut waste

- Energy-saving casting ways

- Recycling and using things again

- Training workers for green growth

New Materials

Casting keeps getting better by using new materials. Engineers use high-strength alloys, light metals, and special mixes. These help make parts lighter, stronger, and longer-lasting. Aluminum and magnesium alloys are used for cars and planes. They make things lighter and save fuel. Titanium alloys are used for medical and airplane parts because they do not rust or get too hot.

New materials let companies make parts with better shapes. Additive manufacturing, or 3D printing, makes tricky designs possible. These new ways help casting fit what modern industries need.

Companies using new materials in casting lead in new ideas. They make better products and stay ahead in business.

Challenges

Casting has many problems in today’s factories. Companies must fix these problems to do well and make good parts. Here are the biggest challenges that casting faces:

- Talent Shortage

Many factories cannot find enough skilled workers. Young people pick other jobs instead. This makes work slow and can hurt casting quality. - Environmental Pressure

Governments make strict rules about pollution and waste. Casting makes dust, gases, and scrap metal. Companies must buy cleaner machines and recycle more. - Market Competition

Companies around the world fight to sell more and spend less. They must try new ideas and better casting ways to keep up. - Rising Costs

Metal and energy prices keep going up. Casting uses a lot of both. Companies must save money but still make good parts. - Technology Upgrades

New machines and digital tools change how casting is done. Factories must teach workers and buy new tools. This can cost a lot and take time. - Quality Control

Customers want perfect parts every time. Casting can make holes, cracks, or bent parts. Companies need good checks and better control. - Material Challenges

Some metals are hard to cast. Hot alloys and new materials need special care. Factories must learn new ways to cast these metals. - Supply Chain Issues

Late deliveries of metal or tools can stop work. Companies must work closely with suppliers and plan for problems. - Changing Customer Needs

Customers want lighter, stronger, and more detailed parts. Casting must change to meet these needs. Factories need to work fast and be flexible. - Sustainability Goals

Many companies want to use less energy and make less waste. Casting must get greener. Factories use eco-friendly binders, recycled sand, and machines that save energy.

Casting companies that solve these problems will do better. They will make better parts, save money, and help the planet. Smart spending and training help fix these issues. Companies should check their casting steps and improve them when needed.

| Challenge | Impact on Casting | Solution Example |

|---|---|---|

| Talent Shortage | Less output, less skill | Training, automation |

| Environmental Pressure | Higher costs, new rules | Cleaner tech, recycling |

| Market Competition | Price wars, quality race | New ideas, process upgrades |

| Rising Costs | Profit loss | Save energy, reuse materials |

| Technology Upgrades | Disruption, expense | Digital tools, smart machines |

| Quality Control | Defects, returns | Checks, better control |

| Material Challenges | Fewer options | Research, new casting ways |

| Supply Chain Issues | Delays, shortages | Strong supplier networks |

| Changing Needs | New demands | Flexible casting processes |

| Sustainability Goals | Eco pressure | Green casting investments |

Casting is still very important for making things. Companies that fix these problems will grow and do well.

- Each casting process has its own good and bad points.

- Companies that know about casting can pick the best way for each job.

- Using the right casting process for the job makes better parts and saves money.

- Casting keeps getting better with new tools and materials.

- Readers should look at the checklist and tables to help with their next casting project.

- Learning about new casting trends helps companies do better than others.Start now. Think about what you need and pick the casting process that works best.

FAQ

Sand casting is the best choice for big parts. It saves money on tools and materials. This process works well for large shapes. Sand casting helps companies spend less and make parts faster.

Investment casting gives the most exact parts. It makes tight fits and smooth surfaces. This method is great for tricky, detailed shapes. Use investment casting for the best accuracy and less extra work.

Yes! Die casting and non-ferrous alloy casting make light, strong parts. They use metals like aluminum and magnesium. These ways lower weight but keep strength. Pick them for lighter, high-performance products.

Think about your part’s size, shape, and material. Check the checklist in this blog. Match what you need with each process’s benefits. This helps you pick the best way to save money and get good quality.

No. Each casting way works best with certain metals. For example, die casting is good for aluminum and zinc. Sand casting is better for iron and steel. Always match the metal to the right process for the best results.

Modern casting uses recycled stuff and safe binders. Companies make less waste and use less energy. Cleaner ways help protect the earth. Choose green casting to help the planet and make your brand look better.

Yes! Investment casting, lost-foam casting, and vacuum casting work for hard shapes. These ways make detailed and tricky parts. Pick them for advanced designs and fewer steps to put parts together.

Digital casting helps make work faster and better. Companies use 3D printing, robots, and smart tools. These things lower mistakes and speed up making parts. Use digital casting to stay ahead of other companies.