Choosing the right carbon steel for your project involves considering strength, cost, and durability. This carbon steel selection guide provides an overview of low, medium, and high carbon steels:

| Steel Type | Tensile Strength (psi) | Cost & Durability Notes |

|---|---|---|

| Low-Carbon Steel | 20,300 – 347,000 | Affordable, easy to shape, but lower strength |

| Medium-Carbon Steel | 35,500 – 252,000 | Balanced strength and cost |

| High-Carbon Steel | 39,900 – 484,000 | Highest strength, higher cost, more brittle |

Selecting the appropriate steel is crucial for your application. Consider processes like quenching and metal tempering to enhance the steel’s performance. This carbon steel selection guide ensures you make informed decisions for optimal results.

Key Takeaways

- Low-carbon steel does not cost much. It is easy to shape and weld. You can find it almost everywhere. This makes it great for quick and cheap production.

- Medium-carbon steel is strong and tough. It needs careful welding and heat treatment.

- High-carbon steel is very strong and hard. It resists wearing out. But it breaks more easily. It costs more money. It is harder to weld or cut.

- Pick the right steel for your project. Think about how strong, easy to use, long-lasting, and cheap you need it to be.

- Heat treatments like quenching and tempering make steel stronger and tougher. This helps medium and high-carbon steels the most.

- Protect carbon steel from rust with coatings or treatments. This helps it last longer, especially in tough places.

- Always check the steel grade, what it is made of, and how it was treated before using it. This helps stop problems and makes sure it works well.

- Use the steel selection guide to pick the right type. Match the steel to your job. Balance cost, how easy it is to work with, and how long it lasts for the best results.

Table of Contents

Overview

What is Carbon Steel

Carbon steel is mostly made of iron and carbon. It has between 0.05% and 2.1% carbon by weight. The American Iron and Steel Institute says carbon steel does not need a set amount of alloying elements like chromium, nickel, or molybdenum. It only has small amounts of manganese, silicon, and copper. This makes carbon steel different from alloy steels. People use carbon steel because it is strong, not expensive, and easy to shape and weld.

Steel Classification

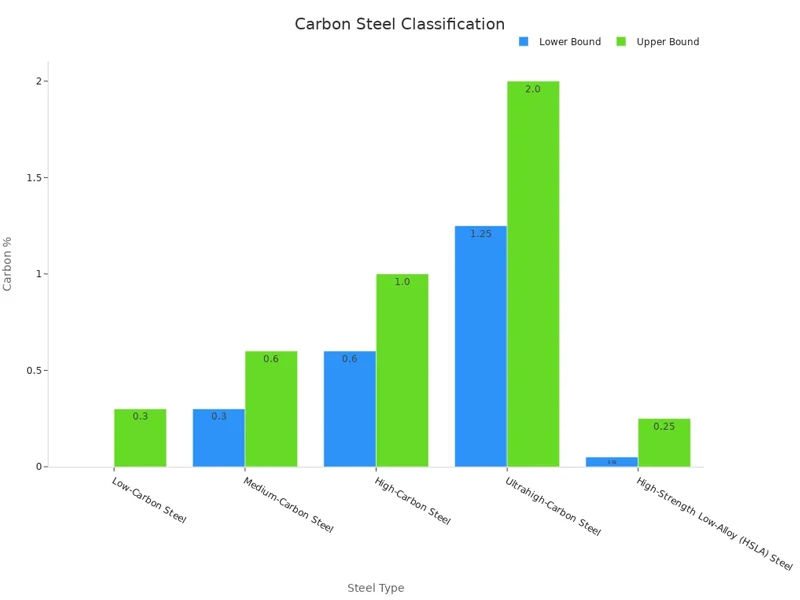

Steel can be grouped by how much carbon it has and what other elements are in it. The main types are low-carbon, medium-carbon, high-carbon, and ultra-high-carbon steel. Each type has its own features and uses. The table below shows the main types and what they are like:

| Type | Carbon Content Range (%) | Typical Alloying Elements and Limits | Typical Applications and Notes |

|---|---|---|---|

| Low-Carbon Steel | Up to 0.30 | Up to 0.4% manganese; other elements limited | Used in automobile body panels, tin plates, wire products; easy to form |

| Medium-Carbon Steel | 0.30 to 0.60 | Manganese 0.60% to 1.65% | Used for shafts, axles, gears, forgings, rails; can be quenched and tempered |

| High-Carbon Steel | 0.60 to 1.00 | Manganese 0.30% to 0.90% | Used for springs, high-strength wires |

| Ultrahigh-Carbon Steel | 1.25 to 2.00 | Experimental alloys with special processing | Used for knives, axles, punches |

You can see the carbon content range for each type in the chart below:

Low-carbon steel is the most common type. It makes up over 90% of the market’s revenue in 2024. This is because low-carbon steel costs less and is easy to shape and weld. Medium and high-carbon steels are used when you need more strength or better wear resistance.

Usage

Steel is used in many industries. You can change its properties by changing the carbon content. The main uses of carbon steel are:

- Construction: Steel is used for beams, columns, and other parts.

- Automotive: It is used for body panels, chassis, and engine mounts.

- Machinery: Steel is used for gears, shafts, and bearings.

- Pipes and Tubes It is used for oil and gas, water treatment, and chemical plants.

- Appliances: Steel is used for casings, frames, and other parts.

Steel is used in many products. The global market for steel was USD 1,017.52 billion in 2024. Low-carbon steel is used the most because it is needed in construction, cars, and ships. Asia Pacific is the biggest market, then North America and Europe.

Tip: Pick the right steel by matching its features to what you need. This helps you get the best results and save money.

Melting Point

When you pick steel, you need to know its melting point. The melting point changes with the amount of carbon and other elements. If you add more carbon, the melting point usually goes down. Some elements, like chromium and nickel, can make the melting point higher. Impurities such as sulfur and phosphorus make it lower.

Here is a table that shows melting points for different steels:

| Type | Example Grades | Melting Point Range (°C) | Explanation of Variation |

|---|---|---|---|

| Low Carbon Steel | 1018, 1020, 1030, 1040 | 1420 – 1465 | Less carbon means higher melting points. |

| Medium Carbon Steel | 1065, 1080, 1095 | 1420 – 1465 | More carbon changes melting point a little. |

| High Carbon Steel | (not specified) | 1425 – 1540 | More carbon gives a wider melting range. |

| Alloy Steels | 4140, 4150, 4340, 8620 | 1450 – 1500 | Alloying elements can make melting points higher. |

Most steels melt between 1420°C and 1540°C. Low and medium carbon steels melt from 1420°C to 1465°C. High carbon steel can melt at higher or wider ranges. If there are more impurities, the melting point drops and the quality gets worse. Always check the grade and what is in the steel before you use it.

Note: The melting point affects how you cut, weld, or shape steel. Pick the right steel grade for your needs.

Steel Density

You also need to think about the density of steel. Density tells you how heavy something is for its size. Most steels have almost the same density. Small changes in carbon make a small difference.

Here is a table with typical density values for carbon steel:

| Type | Density (kg/m³) | Density (g/cm³) | Density (lb/in³) |

|---|---|---|---|

| Low Carbon Steel | ~7850 | ~7.85 | ~0.284 |

| Medium Carbon Steel | ~7830 | ~7.83 | ~0.283 |

| High Carbon Steel | ~7810 | ~7.81 | ~0.282 |

You can see that density stays almost the same for all types. The small drop in density does not change how you use carbon steel. Use these numbers to figure out weight, shipping, and building needs.

- Low-carbon steel density: about 0.284 lb/in³

- Medium-carbon steel density: about 0.283 lb/in³

- High-carbon steel density: about 0.282 lb/in³

Chemical Element Composition

You must check what elements are in steel before you choose it. The main parts are iron and carbon. There are also small amounts of manganese, phosphorus, sulfur, silicon, and sometimes copper, chromium, or nickel. These elements change how strong and hard the steel is.

Here is a table that shows the usual chemical makeup of carbon steel:

| Element | Typical Range (%) | Purpose/Effect |

|---|---|---|

| Carbon | 0.05 – 2.1 | Makes steel stronger and harder |

| Manganese | 0.30 – 1.65 | Makes steel stronger and easier to harden |

| Phosphorus | ≤ 0.04 | Makes steel stronger, but less bendy |

| Sulfur | ≤ 0.05 | Makes steel easier to machine, but less tough |

| Silicon | ≤ 0.60 | Makes steel stronger |

| Copper | ≤ 0.60 | Helps steel resist rust |

| Chromium | ≤ 0.40 | Makes steel harder and wear less |

| Nickel | ≤ 0.40 | Makes steel tougher |

| Molybdenum | ≤ 0.10 | Makes steel strong at high heat |

Steel grades must follow strict rules for these elements. The amount of carbon decides if it is low, medium, or high carbon steel. Other elements stay in small amounts to keep the steel good. Always check the chemical makeup to make sure the steel is right for your job.

Yield and Tensile Strength

When you select steel for your project, you need to understand yield strength and tensile strength. These two properties help you decide if a material will work for your application. Yield strength tells you the point at which steel starts to bend or change shape. Tensile strength shows you the maximum force carbon steel can handle before it breaks.

You will find that different grades of steel have different strength values. The carbon content and the way you process the steel affect these numbers. For example, low carbon steel has lower yield and tensile strength. High carbon steel has higher values. You can see the differences in the table below:

| Steel Grade Category | Tensile Strength Range (MPa) | Yield Strength Range (MPa) |

|---|---|---|

| Low Carbon Steel | 400 – 550 | 250 – 350 |

| Medium Carbon Steel | 600 – 800 | 400 – 500 |

| High Carbon Steel | 900 – 1,200 | 550 – 700 |

You can also look at specific grades of steel. Each grade has its strength range. The table below shows some common grades and their properties:

| Grade | Condition | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|

| ASTM A36 | Hot Rolled | 400 – 550 | 250 |

| SAE 1018 | Cold Drawn | 440 – 640 | 370 |

| SAE 1045 | Normalized | 620 – 790 | 415 |

| SAE 4140 | Quenched + Tempered | 950 – 1,100 | 850 |

| SAE 1095 | Quenched + Tempered | 990 – 1,220 | N/A |

You should match the strength of steel to your needs. If you need to form or bend parts, you may want low carbon steel. If you need to make tools or springs, you may need high carbon steel. The way you treat carbon steel, such as quenching or tempering, can also change its strength.

Note: Always check the grade and treatment of carbon steel before you use it. This helps you avoid problems in your production.

You can use steel in many industries. For example, you can use SAE 1045 for gears and shafts. You can use SAE 4140 for axles and landing gear. You can use ASTM A36 for beams and plates. Each application needs a different balance of yield and tensile strength.

When you choose carbon steel, you make sure your parts will not fail under load. You also make sure your parts will last as long as you need. You can talk to engineers or suppliers to help you pick the right carbon steel for your job.

Low Carbon Steel

Advantages of Low Carbon

Cost

Low-carbon steel helps you save money. It has less carbon, so it costs less to make. Many companies pick it for big jobs to keep spending low. You do not need special heat treatments, which saves more money. Builders use low-carbon steel to finish work on time and under budget. For example, the Burj Khalifa used it to save money and meet deadlines.

Workability

Low-carbon steel is easy to bend and shape. You can cut, roll, or stamp it without much effort. This makes it fast to make parts with simple tools. Car makers use it in vehicles like the Ford F-150. Its easy workability lets them make many parts quickly. You can also machine and form it without special machines.

Weldability

You can weld low-carbon steel using normal methods. The low carbon keeps it from cracking when you weld. This makes it easy to join pieces and build strong parts. You do not need fancy welding skills or costly tools. Many factories have welding capabilities because welding is quick and simple.

Availability

Low-carbon steel is easy to find in stores. Many suppliers keep it ready because lots of industries use it. You can get many shapes and sizes for your needs. Its wide supply means you do not have to wait long for orders. This helps you keep your work on schedule.

Tip: Low-carbon steel is good for fast, cheap production. You can use it for many things without hard steps.

Disadvantages of Low Carbon

Strength

Low-carbon steel is not as strong as other types. It can bend or change shape if you put too much weight on it. If you need strong material, you may need something else.

Hardness

Low-carbon steel is not very hard. It scratches and dents more easily than higher carbon steels. You may need to add a coating if you want it to be harder.

Wear Resistance

Low-carbon steel wears out faster in tough places. Moving parts or tools may break sooner if you use them. You might have to replace these parts more often.

Corrosion

Low-carbon steel can rust if you do not protect it. You can use coatings like galvanizing to help stop rust. These coatings cost extra but help the steel last longer.

Note: Think about the good and bad sides of low-carbon steel before you pick it. It is cheap and easy to use, but it is not as strong or tough. Knowing both sides helps you choose the best material for your job.

Medium Carbon Steel

Advantages of Medium Carbon

Strength

Medium-carbon steel is strong. It has 0.30% to 0.60% carbon. This makes it stronger and harder than low-carbon steel. Its tensile strength can be from 400 to 2730 MPa. The strength depends on how you treat the steel. You can use it for parts that carry heavy loads. It is good for things that get hit or pushed hard. Axles, gears, and crankshafts use this steel. It does not bend or break easily.

Ductility

Medium-carbon steel is strong but still bendy. You can shape it without breaking it. This helps when you need parts that take in energy. It is good for fasteners and railway parts. Machine parts also use it. The steel does not crack much when you form or forge it.

Versatility

You can use medium-carbon steel in many ways. It works for cars, buildings, and machines. You can cut or drill it with normal tools. You can also tap it for special parts. It is good for small or big jobs. You get both strength and easy work with this steel.

Heat Treatment

You can make medium-carbon steel better with heat. Quenching and tempering make it harder. You can change its properties to fit your needs. After heat treatment, it can take on heavy use. It also resists wearing out. This makes it good for gears and shafts.

Tip: Use heat treatment to make medium-carbon steel work best for tough jobs.

Disadvantages Of Medium Carbon

Weldability

Medium-carbon steel is harder to weld. More carbon makes welding tricky. You might get cracks or weak spots if you are not careful. You need special welding methods and must check the steel mix. Tests like X-ray fluorescence help you find problems.

Cost

Medium-carbon steel costs more than low-carbon steel. More carbon and other elements raise the price. You also pay more for heat treatment and checks. This can make your project cost more.

Workability

Medium-carbon steel is not as easy to shape. It is more brittle, so it is harder to form. You may need stronger tools or more force. If you do not handle it right, it can crack or have flaws.

Corrosion

Medium-carbon steel can rust if not protected. It does not fight rust as well as some metals. You need coatings or treatments to stop rust. You also need to check and care for it often.

| Aspect | Details |

|---|---|

| Brittleness | Medium-carbon steel is more brittle than some metals. If you do not heat-treat it right, it is even harder to shape. |

| Weldability | It melts at a good point for welding, but its brittleness can make welding harder. |

| Rusting | It rusts easily, so it may not last as long without care. |

| Cost | It costs more than low-carbon steel because of extra elements. |

| Comparison | It is more brittle than low-carbon steel but less brittle than high-carbon steel. |

Note: Think about the good and bad sides before you pick medium-carbon steel. It is strong and useful, but you must watch out for welding, cost, and rust.

High Carbon Steel

Advantages Of High Carbon

Strength

You get high strength when you choose high-carbon steel. The steel forms martensite during heat treatment, which increases its strength. When you temper the steel, you create tempered martensite with finely dispersed carbides. This structure helps the steel handle heavy loads and high stress. You can use high-carbon steel for parts that need to stay strong under pressure, such as cutting tools and springs.

Hardness

High-carbon steel gives you high hardness. When you anneal the steel for longer times, larger carbide particles form. These carbides make the steel harder. Rockwell hardness tests show that samples annealed for 8 or 12 hours have higher hardness than those annealed for 4 hours. You can rely on this hardness for applications that need sharp edges or resistance to deformation.

Wear Resistance

You benefit from excellent wear resistance with high-carbon steel. The microstructure contains ferrite and cementite in plate-like shapes. This structure resists abrasive wear. In high-carbon Cr-V alloy steel, carbon combines with chromium and vanadium to form stable carbides. These carbides create a hard phase that reduces wear. When you use high-carbon steel for gears or blades, you get longer service life and less maintenance.

Tool Use

You often see high-carbon steel in tools. The steel’s hardness and wear resistance make it ideal for cutting, shaping, and drilling. You can use it for knives, saw blades, chisels, and dies. The steel holds a sharp edge and resists dulling. Many industries depend on high-carbon steel for reliable tool performance.

Tip: Use high-carbon steel when you need parts that must stay sharp, hard, and strong during tough jobs.

Disadvantages Of High Carbon

Brittleness

High-carbon steel has high strength but low ductility. When you increase the martensite content, the steel becomes more brittle. X-ray diffraction and electron back-scatter diffraction studies show that more martensite leads to less bending before breaking. You need to watch for sudden failure in parts that face impact or shock.

Machinability

You may find high-carbon steel harder to machine. The high hardness wears down cutting tools quickly. You need special equipment and slower speeds to cut or shape the steel. This can slow down your production and increase tool costs.

Weldability

High-carbon steel does not weld easily. The high carbon content causes cracks during welding. You need to use special welding techniques and preheat the steel to reduce the risk of cracking. Even with care, welding high-carbon steel takes more time and skill.

Cost

You pay more for high-carbon steel than for low or medium-carbon types. The extra processing, heat treatment, and tool wear add to the cost. You need to balance the pros and cons when you select high-carbon steel for your project.

Note: High-carbon steel gives you strength, hardness, and wear resistance, but you must manage brittleness, machinability, weldability, and cost.

Carbon Steel Selection Guide Industrial

Application Matching

You need to match the right steel to your project. The steel selection guide helps you do this by focusing on your needs. Start by looking at what your part must do. If you need high strength and durability, you may want a medium or high-carbon steel. If you need easy shaping and welding, low-carbon steel works best.

- Define your performance needs. Use steel for easy fabrication and workability. Choose alloy steel if you need more strength.

- Check the environment. Steel fits dry, controlled spaces. If you face moisture or chemicals, use coatings or pick another material.

- Look at strength and weldability. Low-carbon steel welds easily. High-carbon steel needs special welding steps.

- Match the steel to your application. Use carbon steel for pipes, beams, and machine parts. Use alloy steel for aerospace or power plants.

- Follow best practices. Set your stress, temperature, and corrosion needs. Talk to experts. Think about long-term costs.

Tip: Always match the steel’s properties to your job. This helps you avoid problems and saves money.

You also need to think about welding. Pick filler metals that match the strength of your base steel. If you weld different steels, use filler that fits the weaker one. This keeps your welds strong and safe.

Trade-Offs

You face trade-offs when you pick a steel type. The carbon steel selection guide industrial shows you how to balance cost, machinability, and performance.

- Free machining carbon steel cuts faster and saves money. It wears tools less and gives a smooth finish. You get more parts in less time.

- Additives like sulfur help with machining, but lower ductility and weldability. You must check if these changes fit your needs.

- Free machining steel works well for high-volume jobs. It costs less but does not last as long in tough spots.

- Some companies switched to lead-free free-cutting steel and saved money. They also made more parts with less tool wear.

- Use the right tools and speeds. This keeps your machines running well and your parts looking good.

- Heat treatments like annealing and case hardening change the steel’s properties. Additives can change how these treatments work.

- Watch for rules about steel lead. Some places do not allow it.

You must also weigh cost against performance. For example, 1018 carbon steel costs less and machines well. 4140 alloy steel gives more strength but costs more and is harder to cut. Stainless steel resists rust but costs the most and is hard to machine.

Research shows that plain carbon steels can match the strength and toughness of more complex steels after heat treatment. You get good performance and save money by using simpler steels. You also avoid problems like brittle phases that come with complex alloys.

Microstructure matters too. Heat treatment changes how carbon steel resists rust. You can control grain size to get the right balance of strength and corrosion resistance. Phosphorus in steel raises strength but can make the steel crack. Keep phosphorus low to avoid problems.

Note: The steel selection guide industrial helps you see these trade-offs. You can pick the best steel for your job by looking at all sides.

Industry Examples

You see steel in many industries. The steel selection guide for industry gives you real examples to help you choose.

- The construction industry uses low-carbon steel for beams, plates, and rebar. You get good weldability and strength for building frames.

- The construction industry also uses mild steel for general structures. You get enough strength and easy shaping for most jobs.

- Automotive companies use low-carbon steel for body panels. Medium-carbon steel goes into axles and crankshafts. You get a balance of formability and strength.

- Machinery makers use medium-carbon steel for gears, shafts, and bolts. You get strength and wear resistance for moving parts.

- Tool and die shops use high-carbon steel for cutting tools, dies, and springs. You get hardness and long life for tough jobs.

- One company in Canada picked a special high-carbon tool steel for stamping dies. They saw longer life and less downtime.

| Steel Grade Type | Typical Application | Yield Strength (MPa) | Tensile Strength (MPa) | Total Elongation (%) | Key Characteristics and Industrial Use |

|---|---|---|---|---|---|

| Low-Carbon Steel (IF) | Automotive body panels | 20-50 ppm C | High elongation (~50%) | Very high elongation | Ductility and weldability, good for stamping shapes |

| HSLA Steel | Automotive, construction | 300-550 | 400-620 | 16-27 | More strength and corrosion resistance |

| Mild Steel | General construction | ~296 | ~181 | ~42 | Ductility, used for moderate strength |

| Medium/High-Carbon Steel | Construction components | Higher strength | Higher tensile strength | Lower elongation | Used for strength and durability in structural applications |

You can use the steel selection guide industrial to match steel grades to your needs. For example, pick low-carbon steel for easy forming in car panels. Use medium-carbon steel for gears and shafts in machines. Choose high-carbon steel for tools that cut or stamp.

AFI Industrial Co., Ltd. supports you with custom machining and technical advice. You can get help with material selection, design, and production. Their team helps you balance cost, machinability, and performance for your applications.

Callout: Use the carbon steel selection guide industrial to make smart choices. You get better results and save time and money.

Carbon Steel Comparison

Steel Grades

You find many steel grades in the market. These grades help you pick the right material for your job. In the United States, you see standards like ASTM, AISI, and SAE. ASTM grades focus on tensile strength and what you plan to do with the steel. For example, ASTM A307 Grade A and B show different strength levels. You also see grades based on chemical composition, heat treatment, and microstructure.

You can group steel grades by:

- Carbon content and alloying elements

- Mechanical properties like tensile strength and yield strength

- Microstructure types such as ferritic, pearlitic, and martensitic

- Heat treatment methods, like annealing or tempered

- Finishing methods such as hot rolled or cold finished

Steel numbering systems like AISI and SAE use numbers to show carbon content and other elements. You see series for resulfurized or high-manganese steels. These systems help you match steel grades to your needs. You also find quality labels like commercial quality or pressure vessel quality. Each label tells you about the steel’s use and performance.

Strength

You need to know the strength of different steel types before you choose one. Strength includes yield strength and tensile strength. Yield strength shows when the steel starts to bend. Tensile strength shows the maximum force before it breaks.

Statistical studies use large datasets from mill test certificates. These studies show a strong link between yield strength and ultimate tensile strength. You see mean values and safe lower bounds for each grade. For example, ASTM A992 steel has a wide range of strength values. You also find regression models that link post-yield properties to tensile strength. These models help you predict how carbon steel grades will perform in real jobs.

You see that low-carbon steel has lower strength. Medium-carbon steel gives you more strength. High-carbon steel has the highest strength but less ductility. You must match the strength to your application. If you need more strength, you pick higher carbon steel grades. If you need to form or weld parts, you use low-carbon steel.

Cost

You see big cost differences between steel types. Low-carbon steel costs the least. It has low carbon and alloy content. You find it in many uses like construction and automotive. Medium-carbon steel costs more. It gives you a balance of strength and machinability. You use it for gears and machinery parts. High-carbon steel costs the most. It gives you high strength and hardness. You use it for cutting tools and springs.

| Steel Type | Carbon Content (%) | Cost Implication and Characteristics |

|---|---|---|

| Low-carbon steel | 0.05 – 0.32 | Most cost-effective; easy to form and weld; used in construction and automotive; lower strength but good machinability. |

| Medium-carbon steel | 0.30 – 0.60 | Moderate cost; stronger and harder; used in gears, machinery parts; balances strength and machinability. |

| High-carbon steel | 0.60 – 1.5 | Highest cost; superior hardness and strength; less ductile; used in cutting tools and springs. |

Market research shows that low-carbon steel holds the largest share. You see it in about 89% of the market. Its low cost and versatility make it popular. Medium and high-carbon steel grades have smaller shares. Their higher cost comes from better mechanical properties. You also see that raw material prices and regulations change the cost of carbon steel grades. You must check the market before you buy.

Tip: You save money by picking the right steel grades for your job. You get the best value when you match cost to your needs.

Workability

When you pick a steel grade, think about workability. Workability means how easy it is to cut, shape, weld, or machine the steel. The amount of carbon in the steel changes how easy it is to work with. If the steel has less carbon, it is easier to work with. If the steel has more carbon, it is harder to work with.

| Grade | Carbon Content (%) | Key Properties | Workability in Manufacturing Contexts | Typical Applications |

|---|---|---|---|---|

| Mild Steel (Low Carbon) | < 0.3 | Ductility, weldability, machinability | Easy welding, forming, and machining; suitable for general-purpose parts and structures. | Structural parts, general fabrication |

| Medium Carbon Steel | 0.3 – 0.6 | Strength, ductility | Moderate workability; can be heat treated; used where strength and some ductility are needed. | Shafts, gears, forging |

| High Carbon Steel | 0.6 – 1.0 | Hardness, wear resistance | Limited workability; more brittle; difficult to weld and form; requires specialized handling. | Cutting tools, springs, high-strength wire |

| Ultra-High Carbon Steel | 1.0 – 2.0 | Hardness, abrasion resistance | Very limited machinability and weldability; needs expert handling and specialized equipment. | Knives, dies, punch tools |

| 1018 Steel | ~0.18 | Machinability, stability | Performs well in CNC machining; allows high cutting speeds and precise tolerances. | CNC machined parts |

Mild steel is the easiest to work with. You can weld, cut, and shape it using simple tools. Medium carbon steel is a bit harder to work with, but is stronger. You can heat treat it to make it better. High and ultra-high carbon steels are tough to work with. You need special tools and skills for them. These types are used when you need the steel to be very hard or last a long time.

Tip: Pick low-carbon steel if you want easy manufacturing. If you need more strength or hardness, use higher carbon grades, but be ready for extra work.

Durability

You want your parts to last a long time, even in tough places. Durability means how well steel can handle wear, hits, and stress over time. The amount of carbon and other elements in the steel changes how long it lasts.

- Low carbon steel is good for most uses. It can take hits and does not break easily.

- Medium carbon steel can handle more weight and does not wear out as fast. It is good for gears and shafts that move a lot.

- High carbon steel is great for things that get scratched or used a lot. It works well for tools and springs.

- Ultra-high carbon steel is best for things that need to resist a lot of wear. It is used for knives and dies.

You can make steel last longer by adding coatings or using heat treatments. Zinc coatings help stop rust. Heat treatments like quenching and tempering make steel harder. You should pick the right steel and treatment for your job.

| Property / Feature | Description / Industrial Use |

|---|---|

| High wear resistance | Steel can handle lots of use in machines and tools. |

| Tenacity | It can take hits in buildings and vehicles. |

| Durability | It lasts a long time in hard places if you take care of it. |

Note: Always check where you will use the steel. Pick the right type and coating to get the best life from your parts.

Usage

Steel is used in almost every industry. The way you use steel depends on its grade and what it can do. Each type is good for different jobs.

- Builders use steel for beams, columns, and frames. It helps hold up buildings and bridges.

- Factories use it for machine parts, gears, and shafts. It can handle stress and movement.

- Car makers use low carbon steel for body panels and brackets. They use medium and high carbon steels for gears, axles, and crankshafts.

- Oil and gas companies use carbon steel pipes to move stuff. The steel is strong and easy to weld, so it is a top pick.

- Trains use steel for rails and crossties. It can take lot of pressure and shaking.

- Airplane and ship builders use steel because it is strong and does not wear out fast.

- Mining companies use it for tools, crushers, and drills. It can handle heavy loads and heat.

You need to protect steel from rust if it is in a harsh place. Coatings and treatments help it last longer. You can also add things like manganese or silicon to make it stronger and more bendy.

Callout:Steel is a strong and cheap material for many jobs. There is a grade for almost any industrial need.

You see that each carbon steel type fits different jobs. The table below shows the main points:

| Type | Pros | Cons |

|---|---|---|

| Low Carbon Steel | Easy to form, weld, cheap | Lower strength, wears fast |

| Medium Carbon Steel | Good strength, tough | Needs heat, less ductile |

| High Carbon Steel | Hard, resists wear | Brittle, hard to weld |

You should match your steel choice to your project needs. Use the selection guide and talk with experts at AFI Industrial to get the best results.

FAQ

You find the main difference in the content. Low-carbon steel has less carbon. Medium-carbon steel has more. High-carbon steel has the most. This changes strength, hardness, and how you use each type.

You look at your needs. If you want easy shaping, pick low-carbon steel. If you need more strength, use medium or high-carbon steel. Always match the steel to your job.

You can weld low-carbon steel easily. Medium-carbon steel needs more care. High-carbon steel needs special steps. You must check the carbon content before you start welding.

You see steel rust if you do not protect it. You can use coatings or paint to stop rust. Always keep steel dry when you store it.

You find steel in construction, automotive, machinery, and pipelines. Builders use it for beams. Car makers use it for panels and parts. Machine shops use it for gears and shafts.

You heat treat steel to change its strength and hardness. You can make it tougher. This helps you get the right properties for your part.