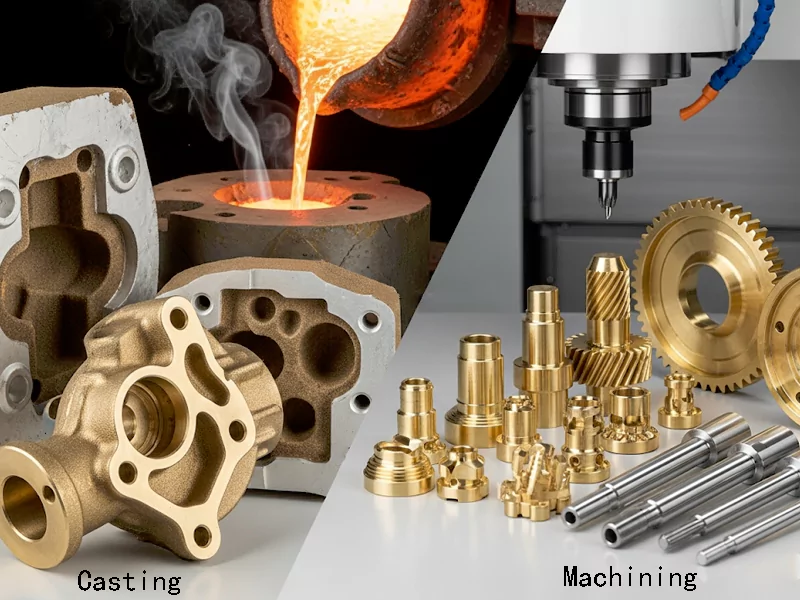

Brass casting and machining are strong tools for making things with care. You begin by casting, which shapes brass to fit your design. Machining comes next. It fixes small flaws and checks every size. This mix helps you meet high-quality rules. Turning, milling, drilling, grinding, and boring all help make parts more exact and smooth. Casting gives you many shape choices. Machining makes sure each part is just right. These steps turn your ideas into real things. Using both ways, you can make hard shapes and tight fits. You also get steady results for any design you want.

| Machining Process | Role in Improving Dimensional Accuracy and Quality |

|---|---|

| Turning | Makes exact holes for putting things together or for how parts work. It keeps hole sizes right in the cast parts. |

| Milling | Uses spinning cutters to make flat areas and tricky shapes. It does this with great care, which is needed for tight fits. |

| Drilling | Makes exact holes for putting things together or for how parts work. It keeps hole sizes right in cast parts. |

| Grinding | Makes surfaces very smooth and sizes very exact. This is important for jobs that need high accuracy. |

| Boring | Makes holes bigger and smoother. It keeps holes the right size and lined up, which is key for a good fit. |

Key Takeaways

- Brass casting makes the main part with hard shapes. Machining helps make the size and surface very exact.

- Using both casting and machining saves time and money. Machining is only done where it is needed. This helps us use less material.

- Casting lets people make hard shapes and inside spaces. Machining alone cannot make these shapes easily.

- Machining uses tools like CNC machines. These tools help parts fit tightly and look smooth. This makes sure parts are high quality.

- Many industries use both casting and machining. This helps make brass parts that are strong, exact, and not too expensive for many jobs.

Table of Contents

Brass Casting and Machining

What is Brass Casting

Brass casting is a metal forming process with a long history. Simply put, brass raw material is heated and melted into a liquid state. The liquid brass is then poured into a mold cavity. After cooling, the mold is removed to produce the finished brass casting.

Main Brass Casting Processes

Depending on the mold material and molding method, there are several common types of brass casting:

Sand casting

This is one of the oldest and most commonly used casting methods. The mold is made of sand mixed with a binder such as clay. It’s inexpensive, but the surface of the casting can be rough.

Investment casting (lost wax)

This method produces castings with higher precision. A pattern is first made of wax, which is then encased in a refractory material to form a mold. When heated, the wax melts and flows out, leaving a hollow, precision mold into which liquid brass is poured.

Die casting:

Suitable for mass-producing smaller parts. Liquid brass is injected into a metal mold under high pressure, quickly producing parts with smooth surfaces and precise dimensions.

Type of Brass Casting Materials

The primary material used in brass casting is a copper-zinc alloy, commonly known as brass. However, brass isn’t a single material; instead, it can be classified into various grades based on the ratio of copper to zinc and the presence of other elements. Each grade has distinct properties and uses.

Basic Components of Brass

Copper (Cu): The primary component of brass, responsible for its excellent electrical and thermal conductivity and corrosion resistance.

Zinc (Zn): The second-most important component. Changing the ratio of copper to zinc can adjust brass’s hardness, strength, and color.

Common Brass Casting Grades

In brass casting, brass grades with varying compositions are selected based on specific application requirements. The following are some common brass grades and their characteristics:

C83600 (Red Brass): This grade of brass typically contains approximately 85% copper and 5% zinc, with trace amounts of tin and lead. Named for its reddish color, it offers excellent casting properties and corrosion resistance and is commonly used in the manufacture of faucets, valves, pipe fittings, pump casings, and other applications.

C84400 (semi-red brass): Contains approximately 81% copper and offers excellent casting and mechanical properties. It is commonly used in general-purpose valves, plumbing fittings, and decorative components.

C85700 (yellow brass): Contains approximately 65% copper and a high zinc content, resulting in a characteristic yellow color. It exhibits good castability and machinability and is commonly used in low-pressure valves, furniture hardware, and decorative components.

Other alloys: To improve certain brass properties, other alloying elements are added during casting:

Lead (Pb): Improves machinability, making the casting easier to machine.

Tin (Sn): Improves corrosion resistance and strength.

Manganese (Mn) and aluminum (Al): Increase strength and wear resistance.

Silicon (Si): Improves casting fluidity, particularly in investment casting.

Choosing the right brass grade is crucial to casting results, as it directly affects the mechanical properties, corrosion resistance, appearance, and manufacturing cost of the final part. A professional foundry will recommend the most suitable brass material based on the customer’s specific application requirements.

Advantages of Brass Casting

Cost-Effectiveness: Brass casting is particularly suitable for high-volume production. Once the mold is made, the production cost per casting is significantly reduced, making it more economical than machining from solid bar stock. Furthermore, the casting process involves less material loss.

Design Freedom: Casting easily creates complex and unusual shapes, such as multiple flow paths, hollow cavities, and complex curves. This makes casting an ideal choice for parts with complex internal structures, such as valve bodies and pump casings.

Excellent Material Properties: Brass inherently offers excellent corrosion resistance and good electrical and thermal conductivity. The casting process preserves these properties, resulting in stable and reliable final products.

Excellent Machinability: Many cast brass grades contain a small amount of lead, which imparts excellent machinability during subsequent machining, effectively extending tool life and improving processing efficiency.

Limitations of Brass Casting

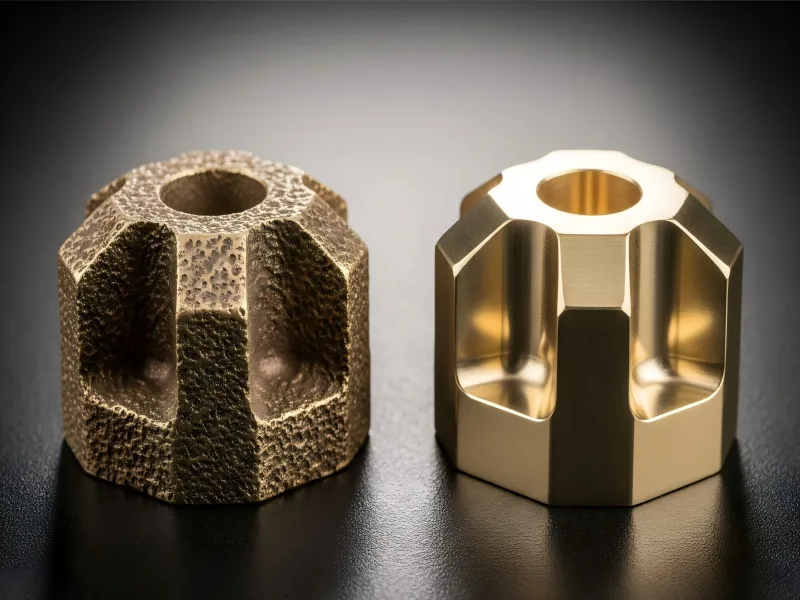

Limited Dimensional Accuracy: Compared to machined parts, castings generally offer lower dimensional accuracy. During the casting process, metal shrinkage due to cooling affects the final dimensions, resulting in wider tolerances for castings.

Rough Surface Quality: Castings typically have a rough surface with defects such as pinholes and pores. If a smooth surface or a tight fit is required, subsequent machining, grinding, or polishing are necessary.

High Initial Cost: While mass production costs are low, the design and fabrication of casting molds are relatively expensive. For small batches or single-piece production, casting is generally less economical than direct machining.

Potential Internal Defects: If the casting process is not properly controlled, defects such as pores, shrinkage, and slag inclusions may form within the casting, compromising the strength and airtightness of the part. Therefore, strict quality control and non-destructive testing are essential.

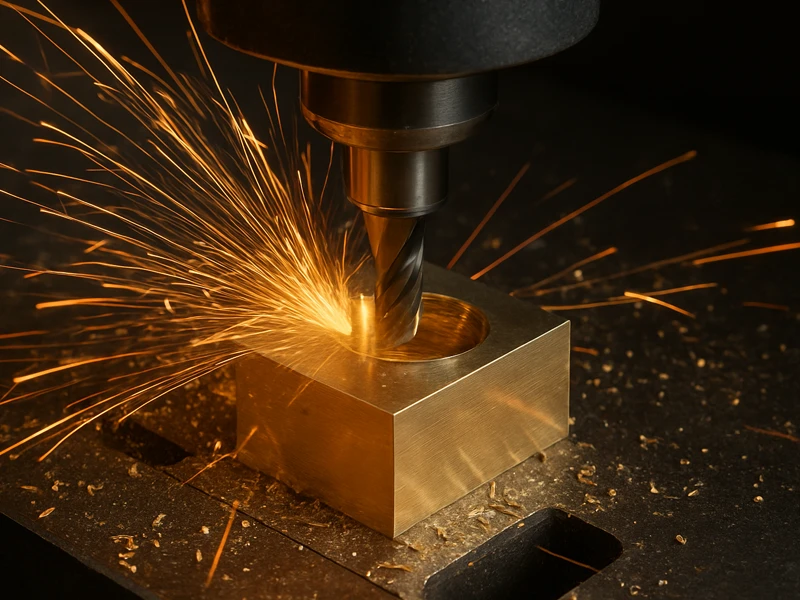

What is Machining

Machining is a manufacturing process that uses tools and machine tools to remove excess material from a workpiece (typically a solid material such as metal or plastic), thereby changing its shape, size, and surface quality to achieve the desired design.

This process is the opposite of “additive manufacturing” (such as 3D printing). While 3D printing “adds” material to build an object, machining “subtracts” material to sculpt the final product. Therefore, machining is often referred to as subtractive manufacturing.

Main Types of Machining

Machining can be categorized into several different processes, each with its unique uses and advantages. The most common include:

Turning

This process is performed on a lathe. A workpiece rotates at high speed on a spindle while a cutting tool moves along the workpiece surface, removing material. This process is typically used to create cylindrical, conical, or threaded parts, such as bolts, shafts, and pins.

Milling

This process uses a rotating cutting tool to remove material from a stationary workpiece. Milling can create flat surfaces, grooves, holes, and complex curved surfaces, making it a key process in the manufacture of various parts, such as molds, brackets, and housings.

Drilling

A rotating drill is used to create circular holes in a workpiece. This is one of the most basic and common machining operations.

Grinding

A high-speed rotating grinding wheel is used to grind the workpiece surface to achieve extremely high dimensional accuracy and surface finish. Grinding is often the final finishing step, used to meet the tightest tolerances.

Advantages of Brass Machining

Excellent Cutting Performance: This is the most prominent advantage of brass machining. Brass, especially leaded brass grades such as C360 free-cutting brass, produces short, brittle chips that don’t form long chips or wrap around the tool like other metals. This results in a very smooth machining process, enabling high feed rates and cutting speeds, significantly reducing production cycle times.

High Precision and Tolerance Control: Using CNC machine tools, brass machining can easily achieve extremely high dimensional accuracy and tight tolerance control, producing precision parts that meet exacting standards.

Excellent Surface Quality: The cutting properties of brass result in very smooth machined surfaces, often eliminating the need for additional grinding or polishing. This not only reduces post-processing steps but also enhances the aesthetics of the final product.

Extended Tool Life: Because brass is soft and easy to cut, machining generates lower cutting forces and reduces tool wear, effectively extending tool life and reducing production costs.

Good Electrical and Thermal Conductivity: Brass is an excellent conductor of both electricity and heat, making machined brass parts ideal for electronic, electrical, and heat exchange applications.

Limitations of Brass Machining

Material Cost: Compared to more common materials like aluminum and steel, brass raw material costs are relatively high. Therefore, machining large, simple parts directly from brass bar stock may be cost-prohibitive.

Material Waste: Unlike casting, machining is a subtractive manufacturing method. During the machining process, a significant amount of excess material is removed from the solid material, resulting in a high amount of scrap. While brass scrap has a high recycling value, it still increases initial material consumption.

Unsuitable for Complex Internal Structures: While machining can achieve many complex shapes, it is far less efficient and cost-effective than casting for parts with complex internal flow paths or hollow structures.

Hardness and Wear Resistance: Although brass has considerable strength, its hardness is relatively low, not as good as steel or some specialty alloys. In applications that are subject to high stress or wear, machining from brass alone may not be the best option.

Brass machining, with its high efficiency and precision, holds a significant position in precision manufacturing, particularly for parts requiring strict dimensional control and excellent surface quality. However, it has limitations in terms of cost, material utilization, and the ability to process complex structures. This is why combining brass casting with machining can leverage their respective strengths to achieve more optimized manufacturing solutions.

Synergy for Precision

After casting, you use machining to make the part better. Machining, like turning, milling, and drilling, helps you get the right size and shape. CNC machines help you make parts very exactly and the same every time. Machining takes away extra material and fixes mistakes from casting. You can get tight fits, often about ±0.05 mm, which is needed for parts that go together.

Machining also makes the surface smoother. Grinding and boring help make surfaces and holes just right. You pick the best machining method for your part’s shape and material. Quality control checks every part for size and smoothness. This makes sure your part meets tough rules.

Brass casting and machining work together for great results. Casting makes the main shape and saves material. Machining adds small details and tight fits. This mix helps you make hard shapes and very exact parts. You save time and money because you only machine where you need to.

Tip: Using both casting and machining helps you save money, design better, and get exact parts. You get strong parts with smooth surfaces.

Many industries use both casting and machining. Plumbing, automotive, and aerospace companies need parts that last and fit well. You can trust this way to give you good and steady parts every time.

Process Integration

Casting for Shape

Casting is how you make the main shape of your part. It lets you create hard shapes and inside spaces. Machining alone cannot do this easily. You pour hot metal into a mold that matches your design. The metal cools and gets hard in the mold. Now the part has the shape you want. Casting works for simple and tricky parts. You can pick different brass alloys for your needs. The casting process gives you a part close to its final form. Sometimes, you need more work for high precision.

Casting helps you save material and money. This is good when you need many parts. You can make thousands of parts with one mold. This keeps your work fast and steady. Casting wastes less metal than machining alone. You can design thin walls and special shapes. Machining these would cost more. Casting is great for making hard shapes.

Casting can cause problems. These include gas bubbles, shrinking, and bending. You must check for these before machining. You can use X-rays or sound tests to find hidden issues. You remove surface problems like flash or burrs by finishing. Heat treatments help fix bending and stress. Here is a table that shows common casting problems and how to fix them before machining:

| Defect Type | Description and Causes | Prevention and Mitigation Before Machining |

|---|---|---|

| Gas Porosity | Holes inside or on the surface from trapped gases. Poor venting and wet molds cause this. | Dry molds, better venting, control metal heat, use vacuum or flux. |

| Shrinkage Defects | Holes or pipes from metal shrinking as it cools. | Use risers, chills, control heat, allow for shrinking. |

| Mold Material Defects | Cuts, washes, swells, drops from weak or broken molds. | Make molds stronger, pack sand better, check molds before casting. |

| Pouring Metal Defects | Misruns, cold shuts, slag from cold metal or mixing problems. | Heat metal right, use flux, pour smoothly, filter metal. |

| Casting Shape Defects | Shift or mismatch from mold not lined up; flash and burrs from gaps. | Line up molds well, clamp tight, remove flash by hand. |

| Warping | Bending from uneven cooling or leftover stress. | Use heat treatment, straighten before machining. |

Note: Always check your cast parts before machining. This helps you start with good material and shape.

Machining for Accuracy

After casting, you use machining to make the part exact. Machining takes away small bits of metal. This helps you get tight sizes and smooth surfaces. You use tools like lathes, mills, drills, and grinders. CNC machines help you make parts very exactly and the same each time. You can reach tight sizes, and the tolerance range can even achieve ±0.05 mm for important parts.

Machining makes the size, surface, and shape better. You pick the right tools and set the best speeds for brass. Sharp carbide or steel tools work well. You use special milling and tool paths to keep things fast and exact. Good chip removal and cooling stop problems and keeps surfaces smooth.

Here are the best machining ways for tight sizes in brass:

- Use sharp carbide or steel tools, sometimes coated.

- Use milling with shallow cuts and high tool use.

- Make CNC tool paths smooth and steady.

- Set cutting speeds and feeds for good tool life and finish.

- Remove chips with air or coolant.

- Cool or lubricate to stop heat.

- Hold the part tight so it does not move.

- Check during machining to catch mistakes early.

- Change cutting to stop burrs and use special deburring for hard shapes.

- Program CNC machines to keep tools moving and avoid stopping.

You must check size, surface, and material strength. Checking during machining helps you keep things exact. You can get a surface finish of about 32 Ra from machining. This often means you do not need extra finishing. This keeps your work fast and your parts the same.

Tip: Only use tight sizes where you need them. Tighter sizes cost more and are harder, so use them only when needed.

Workflow Steps

You follow clear steps to mix casting and machining for the best results. This helps you save time and money and get the right size and surface.

Typical Workflow:

- Design the Part: You make a design that uses casting for shape and machining for exactness. You add features that need tight sizes and plan for extra material to machined.

- Prepare the Mold: You make a mold for casting. You think about shape and how metal will flow. You add draft angles and rounded edges to stop problems.

- Cast the Part: You pour hot metal into the mold. Casting makes the main shape and the inside spaces.

- Inspect and Finish the Casting: You check for problems using X-rays or sound tests. You remove surface flaws and use heat if needed.

- Machine the Part: You set up the part on a CNC machine. You take away extra metal, fix the shape, and get the right size and surface.

- Final Inspection: You measure the part to make sure it meets all size and surface needs. You check size, surface, and material strength.

- Quality Control: You write down the steps and results. You use checks and regular tool tests to keep your work steady.

This way lets you make parts with hard shapes and tight sizes. You save time because casting makes the basic shape. You only make what you need. This means you remove less metal and spend less money. You also get steady results, especially when making many parts.

| Aspect | Small-Scale Production (Machining) | Large-Scale Production (Casting) |

|---|---|---|

| Workflow | Fast setup, no molds needed, uses milling and turning. | Needs mold first, uses casting machines, little work after. |

| Production Volume | Good for small or medium amounts, best for samples and custom parts. | Best for big amounts, cheaper after making molds, works well for many parts. |

| Cost Considerations | Cheaper to start, costs more per part, good for small batches. | Mold costs more at first, but each part is cheaper in big runs. |

| Precision & Complexity | Very exact, can make tricky parts and change designs. | Can make hard shapes in one step, not as exact as machining but good for tricky shapes. |

| Material Waste | Not much waste, chips can be recycled. | Some waste from making molds, but casting uses metal well. |

| Design Considerations | Needs extra material for machining, easy tool access, less extra work. | Needs draft angles, rounded edges, and good mold design to stop problems like holes and shrinking. |

Note: Mixing casting and machining means you do not need lots of machining. This saves time and money. It also helps you get tight sizes and smooth surfaces for tough jobs.

Casting vs Machining

Casting Benefits

Casting gives you many good things when making brass parts. You can make tricky shapes and inside spaces in one step. Thin walls, undercuts, and small paths are easy with casting. Other ways cannot do this as well. Molds can be used again, so you save money when making lots of parts. Casting makes parts close to the right shape, so you do not waste much metal. You do not need to machine as much.

- Investment casting costs less for tools than forging or die casting, especially for small groups of parts.

- You get parts faster and need fewer workers, so you spend less money.

- Casting does not have problems like uneven stress or lines from splitting, so you get fewer mistakes and do not need to fix as much.

- You can put many parts together into one casting, which makes building things easier and stronger.

- Brass fills tiny mold spaces well, so you get smooth surfaces and good sizes.

- Casting lets you design what you want and helps you get close to sizes without much extra work.

Tip: Use casting when you need tricky shapes, want to save metal, and need to make lots of parts for less money.

Machining Benefits

Machining makes brass parts better after casting. You use machining to get very exact sizes and shapes. CNC machines follow computer plans, so every part is the same. Brass is simple to machine, so you finish faster and your tools last longer.

Here is a table that shows the main good things about machining brass:

| Benefit | Explanation |

|---|---|

| High Precision & Accuracy | CNC machines make sure every part is the right size and shape. |

| Exceptional Machinability | Brass is easy to cut, so you make tricky parts fast and tools do not wear out quickly. |

| Fast Production Times | CNC machines help you make parts quickly and do not take long to set up. |

| Surface Finish | Machining takes away marks and rough spots, so parts look and feel smooth. |

| Cost-Effectiveness | You get good parts for less money, which is great for small groups or special orders. |

| Versatility | You can change brass for special jobs or different uses. |

| Conductivity | Brass parts are good for carrying electricity or heat. |

| Corrosion Resistance | Machined brass does not rust, so it lasts longer in wet places. |

| Aesthetic Appeal | Brass looks nice and shiny, so it is good for fancy things. |

Note: You can use grinding, buffing, or electroplating to make the surface even better. This helps parts look nicer and work better.

Limitations

There are some things that casting and machining cannot do. Casting cannot make very tight sizes because brass shrinks when it cools. You often need to machine after casting to get the right size and smoothness.

- Casting sizes can be off by about 0.005 to 0.015 inches, so bigger parts are less exact.

- You need to add angles and keep walls the same thickness so the metal flows well and comes out of the mold.

- It is hard to make tricky undercuts or super shiny surfaces with just casting.

- Brass castings are not as strong as steel, so you cannot use them where you need a lot of strength.

- Machining can be hard if the brass alloy is different. Brass with lead is easier to machine, but lead-free brass needs other settings.

- You may need to change how you machine and sometimes use special coatings to stop rust and make the surface better.

Tip: You get the best parts when you use casting for the shape and machining for the exact size. This way, you save money, use less metal, and get good quality parts.

Applications

Industry Examples

Brass casting and machining are used in many fields. The marine industry uses them for valves, propellers, pumps, and heat tubing. These parts must work in tough places and have tricky shapes. Brass is good for marine hardware because it does not rust and stays strong. The marine field has lots of parts to keep prices low.

Other fields use brass for exact parts, too. Car companies use brass casting and machining for radiators and fittings. These parts need to be strong and fit just right. Robotics companies use brass for arms, joints, and frames. These parts need special shapes and must last a long time. Plumbing and electrical fields use brass for connectors, valves, and fittings. Making many parts at once helps save money and keeps quality high.

| Industry | Common Brass Parts | Why Use Brass? |

|---|---|---|

| Marine | Valves, propellers, pumps | Corrosion resistance, complex geometry |

| Automotive | Radiators, fittings | Strength, precise geometry |

| Robotics | Joints, frames, arms | Durability, custom geometry |

| Plumbing | Fittings, valves | Corrosion resistance, low cost |

| Electrical | Connectors, switches | Conductivity, high volume production |

Note: You can follow strict rules by using both casting and machining. This way, you can make tricky shapes and keep costs down.

Manufacturing process of brass valve body parts

Step 1: Casting the Brass Valve Body

The primary goal at this stage is to quickly and economically produce a near-net-shape valve body blank while preserving the complex internal structure and flow paths. Investment casting (lost wax casting) or sand casting is typically used, as both methods are well-suited to complex shapes.

1. Mold Design and Fabrication:

Based on the 3D design model of the valve body, a casting mold is designed and fabricated. For sand casting, a wooden or metal pattern is required; for investment casting, a wax pattern is required.

Mold design must take into account casting shrinkage, draft angle, and subsequent machining allowance. Machining allowance refers to the excess material thickness reserved for the casting to be removed during subsequent machining steps to achieve precise dimensions.

2. Melting and Pouring:

Select an appropriate casting brass grade (e.g., C83600) and heat it in a furnace until it is molten.

Precisely pour the liquid brass into a preheated mold.

During the pouring process, the temperature and flow rate must be strictly controlled to avoid casting defects such as porosity and slag inclusions.

3. Cooling and Solidification:

After pouring, the casting is allowed to cool and solidify naturally in the mold.

The cooling time depends on the size and shape of the casting to ensure uniform internal structure and the absence of stress cracking.

4. Demolding and Cleaning:

After the casting has completely cooled, it is demolded. For sand casting, the sand mold needs to be broken; for investment casting, the refractory shell needs to be removed.

The casting surface is cleaned of any sand, burrs, and risers (the part used for feeding and venting materials during casting).

At this point, the valve body casting blank is completed. This blank already has the general shape of the valve body and the internal flow channel, but its surface is rough and the dimensional tolerance is large, so it cannot be used directly.

Step 2: Precision Machining

This stage is the “finishing” process of the casting. CNC machining is used to cut key dimensions and functional areas of the valve body blank to achieve the strict dimensional tolerances and surface quality requirements specified in the design drawings.

1. Clamping and Positioning:

Precisely secure the casting blank to the CNC machine table.

Use a fixture to prevent the blank from moving or deforming during machining. Precise positioning is a critical first step in ensuring machining accuracy.

2. Rough Machining:

Use a large stock removal volume to quickly remove excess material from the casting surface, approaching final dimensions.

This step primarily removes hard scale and irregularities from the casting surface, preparing it for subsequent finishing.

3. Finishing:

Using sharper cutting tools and reducing cutting depth allows for precise machining of the valve body.

Key machining areas include:

Threading: Turning or milling the threads on the valve body inlet and outlet to ensure a tight connection with pipes or other components.

Sealing Surface Machining: Milling or turning mating surfaces such as the valve seat, bonnet, or seal to ensure flatness and a smooth finish to prevent leakage.

Internal Bore and Cavity Machining: Boring or reaming internal dimensions of the valve stem bore and valve core cavity to meet stringent dimensional requirements.

4. Surface Treatment and Inspection:

After machining, parts undergo surface treatment, including deburring and cleaning.

High-precision measuring tools (such as calipers, micrometers, and coordinate measuring machines (CMMs)) are used to rigorously inspect all critical dimensions of the valve body to ensure they fully conform to the design drawings.

Through the precise coordination of the above two stages, the brass valve body parts can simultaneously possess the complex internal structure brought by casting and the precise external dimensions given by machining, thus becoming a final product with complete functions and reliable performance.

Custom Components

Brass casting and machining help you make special parts for many jobs. If you need a part with a special shape, these ways help you get it. First, you cast the main shape. Then, you machine it to add small details and tight fits. This helps you make many parts fast and not spend too much.

For plumbing, you might need a fitting with a special shape. You can cast the main part and then machine the threads and flat spots. This gives you a strong part that does not cost a lot. In electrical work, you need connectors with exact shapes and good conductivity. Making many at once keeps costs low and speeds up work.

You can pick different brass alloys for your special parts. C360 brass is good for fittings and fasteners. C464 brass is best for marine hardware because it does not rust. You can choose the right alloy for your job and shape.

- Special parts you can make with this process:

- Decorative hardware with special shapes

- Exact gears for machines

- Special valves for plumbing or marine use

- Electrical connectors with tight shapes

Tip: You can save money and get the shapes you need by using both casting and machining. Making many parts at once helps you fill big orders and keep quality high.

When you use both brass casting and machining, you get many good things. You can make things faster and with more choices. You also get parts that are very exact. The table below shows how this helps you do more in making things:

| Aspect | Contribution to Design Freedom and Precision Manufacturing |

|---|---|

| Complex geometries | You can make thin walls and shapes that are hard to do with just machining. |

| Part consolidation | You can join many parts into one casting, which makes building easier. |

| Near-net-shape | You can get close to the right size, so you do not need as many extra steps. |

| Machining time reduction | You spend less time on machining, so you save money. |

| Material versatility | You can pick from many alloys for different jobs. |

| Mechanical properties control | You can make parts stronger for better results. |

There are new ways to make things now.

- 3D printing helps you spend less and work faster.

- Hybrid ways let you use old and new methods together.

- AI and machine learning help you make better parts faster.

- More companies use new ways to make tricky parts.

- Training helps you learn about new machines and tools.

- Being green is important, so you try to waste less.

- Better checking systems help keep things safe and steady.

Making things will keep changing. You will see more intelligent machines and innovative methods for producing brass parts. This helps you stay ahead in making things with care.

FAQ

You get both complex shapes and high accuracy. Casting forms the basic part. Machining makes it exact. This combination saves you time and money while giving you strong, precise parts.

You can use many brass alloys, but some work better. C360 is easy to machine. C464 resists corrosion. Always choose the alloy that fits your job best.

You inspect each part for cracks, holes, or warping. You can use x-rays or sound tests. Always remove surface flaws before machining. This step helps you avoid problems later.

Casting gives you the shape, but not the exact size. Machining removes excess metal and corrects minor errors. You get smooth surfaces and tight fits that casting alone cannot provide.