When you ask, “what is bead blasting,” you discover that it involves using small beads to clean and smooth surfaces. People utilize bead blasting to remove rust, dirt, or old paint without damaging the underlying material. Many industries rely on bead blasting for critical tasks:

- Aerospace: It is used to finish turbine blades and compressors.

- Automotive: It helps protect engine parts and brake components from rust.

- Medical: It ensures that surgical tools and implants have a smoother feel.

Key Takeaways

- Bead blasting uses tiny beads to clean and smooth surfaces. It does not harm the material underneath. It is safer and less rough than sandblasting. This makes it good for fragile materials. Many industries use bead blasting for different jobs. These include aerospace, automotive, and medical fields. The bead blasting process needs preparation and picking the right media. It also needs careful work to get an even finish. Safety is very important. Always wear safety gear and make sure there is fresh air. Picking the right media, like glass beads or steel shot, changes the finish and cleaning power. Bead blasting removes rust, dirt, and old paint well. It gets surfaces ready for painting or coating. Bead blasting can also make parts look smooth and neat.

Table of Contents

What Is Bead Blasting

Definition

Bead blasting is a way to clean or finish surfaces. It uses small, round beads for this job. Bead blasting looks like sandblasting, but they are not the same. The table below shows how bead blasting and sandblasting are different:

| Characteristic | Bead Blasting | Sand blasting |

|---|---|---|

| Media Used | Spherical beads | Silica sand |

| Abrasiveness | Less | More |

| Surface Finish | Smooth | Rough |

| Material Removal | Minimal | More |

| Safety | Safe | More hazardous due to silica dust |

Bead blasting uses beads that are less rough. It gives a smoother finish than sandblasting. It is also safer because it does not make dangerous dust.

Surface Finishing

Bead blasting cleans and finishes surfaces gently. It removes light marks, old paint, or dirt. People like bead blasting because it makes surfaces look even and matte. This helps parts look nice and feel smooth. The shape and size of the parts stay the same, which is important for careful work.

Tip: Bead blasting is good for fragile materials. You do not have to worry about getting dirt stuck in the surface. It is a smart choice before you paint or anodize.

Some main benefits of bead blasting are:

- You get a more even surface than with sandblasting.

- You keep the size and shape of small or detailed parts.

- You do not push unwanted bits into the surface.

- You can remove small marks and make parts look better.

Industry Uses

Bead blasting is used in many industries. It works on lots of different materials. Some common things you can use bead blasting on are:

- Glass

- Ceramic

- Plastic

- Steel shot

You should not use bead blasting with things like silica sand, aluminum oxide, or silicon carbide. These are better for other blasting methods.

In cars, bead blasting cleans engine parts and brakes. In airplanes, it finishes turbine blades and other important parts. In medicine, bead blasting makes tools and implants smooth and clean. No matter the job, bead blasting helps you get a clean, even finish without hurting the material.

Bead Blasting Process

How It Works

You might wonder what happens during the bead blasting process. This method uses small beads and high-pressure air to clean or finish a surface. You can follow these main steps to understand how the process works:

- Preparation: Clean the workpiece to remove loose dirt. Mask off any areas you want to protect from the beads.

- Abrasive Media Selection: Choose the right type of bead for your material and the finish you want.

- Surface Preparation: Make sure the surface is free from oil or grease. This helps the beads work better.

- Blasting Operation: Use a nozzle to direct the beads at the surface. Control the air pressure and the distance from the nozzle to the part.

- Execution: Move the nozzle in even strokes. Keep the flow steady for a uniform finish.

- Inspection and Post-Processing: Check the surface for the desired look. Remove any masking and clean the part again if needed.

Tip: Always inspect your work after the bead blasting process. This helps you catch any missed spots or uneven areas.

Equipment Used

You need the right equipment to carry out the bead blasting process safely and effectively. Here are the main items you will use:

- Blasting Cabinet or Booth: This contains the beads and keeps dust from spreading.

- Air Compressor: Supplies the high-pressure air needed to propel the beads.

- Nozzle: Directs the flow of beads onto the workpiece.

- Abrasive Media Hopper: Holds the beads and feeds them into the air stream.

- Personal Protective Equipment (PPE): Includes safety glasses, gloves, respirators, and protective clothing.

The table below shows the main equipment and its purpose:

| Equipment | Purpose |

|---|---|

| Blasting Cabinet/Booth | Contains beads and dust |

| Air Compressor | Provides high-pressure air |

| Nozzle | Directs beads onto the surface |

| Media Hopper | Stores and feeds abrasive beads |

| PPE | Protects you from dust and flying particles |

Safety

Safety is a key part of the bead blasting process. You must protect yourself and your workspace. Here are some important safety tips:

- Wear safety glasses, gloves, and a respirator to protect your eyes, skin, and lungs.

- Use ear protection if the equipment is loud.

- Make sure your workspace has good ventilation. This keeps dust levels low.

- Keep the floor clean to prevent slips and falls.

- Only trained people should operate bead blasting equipment.

- Check all equipment before use. Look for leaks or damage.

- Keep flammable materials away from the bead blasting area.

- Have a fire extinguisher nearby in case of emergency.

Note: Following these safety steps helps you avoid accidents and keeps the bead blasting process running smoothly.

When you follow these steps and use the right equipment, you can achieve a clean, even finish. The bead blasting process gives you control over the final look and feel of your parts. If you ever ask yourself what is bead blasting, remember that it is a safe and effective way to clean and finish many surfaces.

Bead Blasting Media

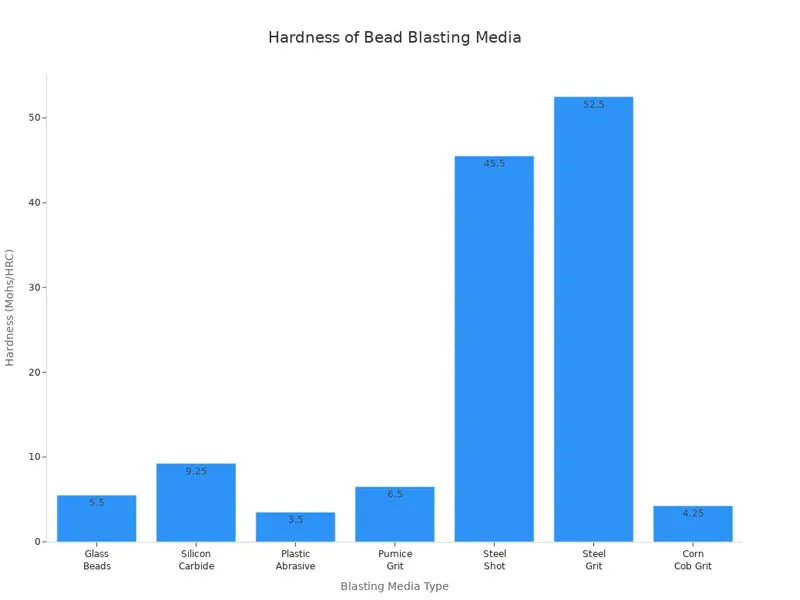

When you learn about bead blasting, you see that the type of media you pick changes your results. Each media type has special features and uses. The table below shows how the main types are different in what they are made of, how hard they are, their grit size, and their shape.

| Blasting Media Type | Material Composition | Hardness | Grit Size Range | Shape |

|---|---|---|---|---|

| Glass Beads | Lead-free, soda lime-type glass | 5-6 | 50-325 | Round |

| Steel Shot | Steel | 40-51 HRC | S-110 to S-780 | Spherical |

| Aluminum Oxide | Virgin brown fused alumina | 9 | Fine-Coarse | Angular |

Glass Beads

Properties

Glass beads are round and made from soda lime glass. They do not have lead. These beads are not very hard, so they clean gently. You can pick from many sizes to match your project. Glass bead blasting makes surfaces smooth and even. The round beads help stop sharp scratches or deep marks.

- Safe for people and the planet

- Medium hardness (5-6 Mohs)

- Many grit sizes from 50 to 325

- Round beads keep the surface safe

Tip: Glass beads are good if you want to keep your part’s shape and size.

Uses

You use glass bead blasting for lots of jobs. It is best when you want a clean, smooth surface but do not want to take off too much material. Here are some common ways people use it:

- Car work: Take off paint, rust, and old stuff from car parts. Get parts ready for painting or coating.

- Cleaning molds and tools: Clean factory molds and tools. Remove leftover bits without hurting the tool.

- Making designs: Put patterns on glass, metal, or stone for decoration.

- Airplane parts: Clean and smooth small electronic parts. Do not damage sensitive surfaces.

Glass bead blasting is gentle, so you can use it on fragile things. You get a finish that looks nice and feels smooth.

Steel Shot

Properties

Steel shot is made from steel and shaped like tiny balls. It is much harder than glass beads. Steel shot is tough and can change metal surfaces. It makes the metal stronger and helps it handle stress better.

- Very hard (40-51 HRC)

- Ball shape gives even hits

- Can be used many times

- More powerful than glass beads

Steel shot blasting is great for big jobs. You use it when you need to clean, make metal stronger, or get metal ready for something else.

Uses

Steel shot is used in many places. It is good for jobs that need strong cleaning or making surfaces tougher.

| Industry/Application | Use of Steel Shot | Purpose/Benefit |

|---|---|---|

| Automotive | Make parts stronger with shot peening | Parts last longer and resist breaking |

| Shipbuilding and Maintenance | Clean ship hulls of rust, paint, and sea stuff | Keep ships strong and ready for new paint |

| Foundries | Clean and smooth castings | Make final products look and feel better |

| Steel Structures Maintenance | Remove rust and old paint from bridges and buildings | Help buildings and bridges last longer |

| Surface Preparation | Get metal ready for coating or painting | Coatings stick better and last longer |

| General Industrial Use | Used as weights or ballast | Helps keep things steady in different jobs |

- Peening makes metal surfaces stronger and helps them last longer.

- Cleans and smooths surfaces by removing dirt.

- You can use steel shot again and again, which saves money.

Steel shot blasting is stronger than glass bead blasting. You use it when you want to change how metal acts or remove tough coatings.

Aluminum Oxide

Properties

Aluminum oxide is tough and has sharp edges. It is very hard and cuts well. The grains come in many sizes, from tiny powder to big grit. Aluminum oxide lasts a long time and can be used more than once. The sharp shape makes deep marks, which helps coatings stick better.

| Property/Benefit | Description |

|---|---|

| Aggressiveness | Cuts fast and works on wood, glass, and metal |

| Durability | Can be used many times and lasts long |

| Grain Variability | Many sizes for different jobs |

| Cost-Effectiveness | Costs less than other media |

| Strength and Endurance | Works well on tough materials like titanium and stainless steel |

| Angular Shape | Makes deep marks for coatings |

| Long Shelf Life | Stays good for a long time |

| Surface Preparation Capability | Makes rough surfaces for coatings |

One good thing about aluminum oxide is you can pick from many sizes. You can use it for frosting glass or getting metal ready for chrome plating.

Uses

You use aluminum oxide bead blasting when you need strong cleaning or want to get a surface ready for something else. It is good for taking off rust, making surfaces rough for coatings, and making fine finishes.

- Rust removal: Cuts through rust fast and can be used again.

- Surface preparation: Makes rough surfaces so coatings stick well.

- Finer finishes: Etches surfaces evenly for big and small jobs.

Aluminum oxide is stronger than glass bead blasting. You pick it when you need deep cleaning or want to get a surface ready for painting or coating.

Garnet

Properties

Garnet is a mineral with sharp, pointy pieces. It is very hard, with a rating of 7 to 8 on the Mohs scale. Garnet is harder than glass beads but softer than aluminum oxide. It cuts fast and does not make much dust. You can use garnet media more than once. This saves money and helps the environment. Garnet is tough and lasts a long time, so people use it for many blasting jobs.

Note: Garnet stays good longer than crushed glass. It makes less dust, so your workspace stays cleaner.

Uses

Garnet cleans surfaces and takes off rust, oil, and old paint. You can use it for wet or dry blasting. It is safe for you and nature because it does not make harmful dust. Garnet gets surfaces ready for painting or coating. This helps paint stick better and last longer. People use garnet to blast steel, clean ship hulls, and get things ready for waterjet cutting. Garnet gives a rougher finish than glass beads but does not use metal abrasives.

Plastic Beads

Properties

Plastic beads are soft and light. They are good for gentle bead blasting. Plastic beads do not change the size or shape of parts. They make surfaces look even and smooth. They do not make dangerous silica dust, so you stay safe.

| Advantage | Description |

|---|---|

| Gentle | Does not change the part’s shape or size. |

| Uniform Finish | Makes the surface look polished and even. |

| Safety | No harmful silica dust, so it is safer for you. |

Plastic beads work well for delicate plastics and composite materials. You can clean these without hurting them.

Uses

Plastic beads are used in many jobs. They help get surfaces ready for painting, coating, welding, or machining. Plastic beads are great for taking off coatings and rust from sensitive parts.

- Automotive: Get car parts ready for paint or coating.

- Aerospace: Clean airplane parts and remove coatings and rust.

- Medical: Prepare surgical tools and implants, take off coatings.

- Marine: Clean boat hulls and remove rust and corrosion.

- Electronics: Get parts ready for bonding or coating.

- Metal Fabrication: Prepare parts before welding or machining.

Plastic beads give you a safe and gentle way to clean and finish delicate surfaces.

Other Media

Ceramic

Ceramic beads are very hard and strong. You can use them to clean metal parts, molds, engine pieces, and turbine machines. Ceramic beads clean well and take off rust, sand, and scale. Their hardness means you get good cleaning without hurting the main material.

- Clean metal surfaces

- Remove rust, scale, and sand

- Good for industrial parts like molds and engines

Organic Media

Organic media are things like walnut shells and corn cob. You use these when you need a very soft touch. Organic media are good for cleaning soft metals, plastics, and wood. They do not scratch or hurt the surface. You can use organic media for cleaning jewelry, antiques, and delicate machine parts.

- Clean soft metals and plastics

- Polish wood and jewelry

- Safe for fragile items

There are many bead blasting media choices. Each type has special benefits for different jobs. You can pick the best media for your material and the finish you want.

Applications

Corrosion Removal

Metal surfaces can get rusty, especially in tough places. Bead blasting is a strong way to remove corrosion. You shoot small beads at the metal. The beads knock off rust and oxides. They also take away scale. The base metal does not get hurt. This works better than using chemicals or scrubbing by hand. You end up with a cleaner and smoother part. Your parts last longer because of this.

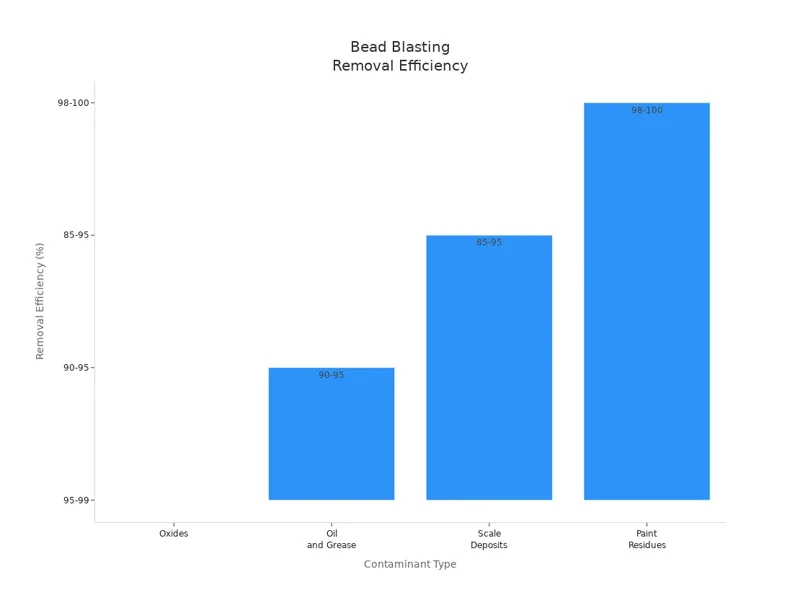

Here is a table that shows how bead blasting removes different things and helps stop corrosion:

| Contaminant Type | Removal Efficiency | Impact on Corrosion Resistance |

|---|---|---|

| Oxides | 95-99% | High |

| Oil and Grease | 90-95% | Significant |

| Scale Deposits | 85-95% | Moderate to High |

| Paint Residues | 98-100% | Substantial |

Bead blasting takes off almost all oxides and paint. This means your parts resist rust better. You do not need harsh chemicals. This keeps you and nature safer.

Cleaning

Bead blasting is great for cleaning many things. You can use it on metal and non-metal parts. It removes lots of dirt and grime. Your parts are ready for painting or putting together. Here are some things bead blasting can clean:

- Oil

- Rust

- Dust

- Paint

- Oxide

- Grease

- Coatings

- Lubricants

- Pathogens

- Metal particles

- Electrolyte residues

Bead blasting cleans surfaces well. It gets into spots you cannot reach by hand. You save time and get cleaner parts.

Tip: Try bead blasting when you need to clean tough dirt or coatings. Your parts will look and feel much cleaner.

Cosmetic Finishing

You want your products to look nice. Bead blasting helps make surfaces smooth and pretty. You can use different bead sizes for special textures. Scratches and marks get hidden. Your parts look even and neat.

Some good things about bead blasting for looks are:

- Pick bead sizes to change the texture.

- Hide small scratches and marks.

- Make products look better so they stand out.

Bead blasting makes your products look and feel smooth. You get a matte or satin finish. This can help your products beat others in the market.

Surface Preparation

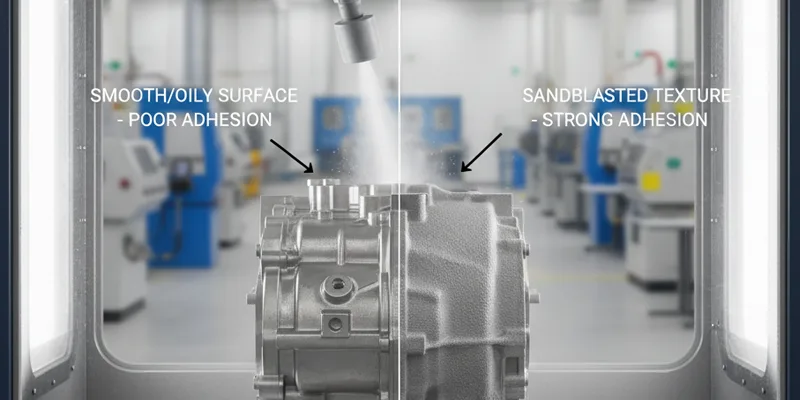

Bead blasting helps get surfaces ready for painting or coating. You can use it on many different things. This process helps your projects turn out better.

Bead blasting makes the surface feel even and rough. This roughness helps paint or glue stick well. Smooth or oily surfaces make paint peel off. Bead blasting fixes this by making the surface rough enough to hold coatings.

Bead blasting works better than cleaning by hand. Hand cleaning can miss small dirt or oil. Chemicals can leave stuff behind you do not want. Bead blasting takes away all the tiny bits and marks. You get a clean and even surface every time.

Here are some reasons why bead blasting is a good choice for getting surfaces ready:

- It makes the surface rough and even, so paint or glue sticks better.

- It takes off oil, grease, and old paint.

- It removes marks from machines that can make bonds weak.

- It makes the surface rougher, so coatings grip more.

- It does not leave any chemicals behind.

Tip: If you want your paint or coating to last, start with bead blasting.

You can use bead blasting before painting car parts or getting metal ready for powder coating. It also helps plastic parts stick better with glue. In each case, bead blasting gives a better finish and stronger results.

Bead blasting is gentle if you use soft media. This means you can use it on plastics or soft metals. You do not hurt the part, but you still get a surface ready for the next step.

Here is a table that compares bead blasting to other ways of getting surfaces ready:

| Method | Removes Contaminants | Leaves Residue | Improves Adhesion | Good for Many Applications |

|---|---|---|---|---|

| Bead Blasting | Yes | No | Yes | Yes |

| Manual Cleaning | Sometimes | No | No | Few |

| Chemical Cleaning | Yes | Yes | Sometimes | Some |

Bead blasting stands out because it gives a clean, rough surface. You do not need extra steps. You save time and get better results for your projects.

Comparing Media Types

Surface Finish

When you choose a bead blasting media, you want to know what kind of surface finish you will get. Each media type creates a different look and feel. Some give you a smooth, bright bead blast finish, while others leave a rougher texture. You can use the table below to compare how each media affects the surface finish:

| Media Type | Description | Hardness | Shape | Surface Profile |

|---|---|---|---|---|

| Glass beads | Smooth and bright finish | 5.5 Mohs | Round | Satin finish |

| Aluminum oxide | Etching and paint removal | 9 Mohs | Angular | High etch |

| Silicon carbide | Prepares hard surfaces | 9.5 Mohs | Angular | Very high etch |

| Stainless steel shot | Polishing and smoothing | 8 Mohs | Round | No etch |

| Steel shot | Polishing and smoothing | 8 Mohs | Round | No etch |

| Steel grit | Fast paint removal | 8 Mohs | Angular | Medium etch |

If you want a high-quality finish, glass beads and stainless steel shot are great choices. They give you a smooth bead blast finish that looks clean and even. Aluminum oxide and silicon carbide create a rougher surface finish, which helps when you need a strong bond for a coating. Steel grit sits in the middle, giving you a medium etch that works well for both cleaning and preparing for a coating. You can use these options for deburring, too, as they remove sharp edges and leave the surface ready for the next step.

Tip: For a decorative bead blast finish, glass beads give you the best results. If you need a surface ready for a tough coating, pick aluminum oxide or silicon carbide.

Aggressiveness

Aggressiveness tells you how much the media will change the surface. Some media types, like aluminum oxide and silicon carbide, are very aggressive. They cut into the material fast and remove coatings, rust, or paint quickly. This makes them perfect for heavy-duty jobs, but you need to be careful with delicate parts. These aggressive types can damage soft metals or thin surfaces.

- Aluminum oxide is sharp and hard. You use it for tough stripping and deburring jobs.

- Silicon carbide works even faster. It is best for high-intensity tasks and hard materials.

- Glass beads are gentle. They give you a smooth bead blast finish without harming the part.

- Steel shot and stainless steel shot polish and smooth surfaces. They do not etch or change the shape much.

You should avoid glass bead media on titanium or parts with small oil passageways. The beads can get stuck or cause problems inside the part. Always match the aggressiveness of the media to your material and the bead blast finish you want.

Note: If you need to keep the original shape and size, pick a less aggressive media. This helps you get a high-quality finish without risking damage.

Cost

Cost is an important factor when you pick a surface finishing technique. You need to think about more than just the price of the media. The total cost includes labor, energy, equipment wear, and how often you need to replace the media. Some media, like steel grit, can be recycled many times. This lowers your long-term costs. Others, like glass beads, may cost less at first but need to be replaced more often.

When you use a bead blast finish for deburring or preparing for a coating, you also need to think about the efficiency of your system. A good reclamation system lets you reuse media and save money. If you use single-use media, your material expenses go up. Equipment and plant depreciation add to your costs over time, too.

- Steel grit and steel shot last longer and can be recycled. This gives you cost advantages for big jobs.

- Glass beads and aluminum oxide are cheaper to buy but wear out faster. You spend more on replacements.

- Labor, energy, and maintenance also affect your total cost. A more efficient surface finishing technique saves you money in the long run.

Tip: Always look at both the purchase price and how long the media lasts. Sometimes, a higher-priced media gives you more advantages because you use it longer and get a better bead blast finish.

Choosing Media

Picking the right bead blasting media is important. It helps you get the finish you want. You need to match the media to your material. Each media type works best for certain jobs. If you choose well, your finish will last longer and look better.

There are several things to think about when you pick bead blasting media:

- Hardness: Hard media remove rust and coatings quickly. Soft media are better for gentle cleaning.

- Density: Dense media hit harder. This is good for tough cleaning.

- Shape of the abrasive: Round beads make surfaces smooth. Sharp shapes cut deeper and make rough textures.

- Type of profile the abrasive will leave: Some media give a matte or satin look. Others make the surface rough so paint sticks better.

- Friability: This means how easily the media breaks apart. Media that do not break easily last longer and make less dust.

- Number of recycles: Some media, like steel shot, can be used many times. Others, like glass beads, wear out fast and need to be replaced.

- Overall cost: Think about the price and how long the media lasts. Sometimes, spending more saves money because you can reuse the media.

Tip: Test a small spot first. This shows how the media will work on your material.

You also need to think about what you are blasting. Glass beads work well on aluminum and stainless steel. They make the surface bright and smooth. Aluminum oxide is better for hard metals or thick coatings. Plastic beads are gentle and safe for soft plastics or thin metals.

Here is a table to help you pick the right media:

| Media Type | Best For | Finish Type | Reusability |

|---|---|---|---|

| Glass Beads | Aluminum, stainless, soft metals | Smooth, satin | Moderate |

| Steel Shot | Hard metals, heavy rust | Polished, peened | High |

| Aluminum Oxide | Tough coatings, hard metals | Rough, etched | Moderate |

| Plastic Beads | Plastics, delicate parts | Smooth, gentle | Low |

| Garnet | Steel, surface prep | Matte, rough | Moderate |

Always think about safety and the environment. Some media make more dust or can be harmful. Wear protective gear and work where air moves well.

If you are not sure, ask a bead blasting expert. They can help you pick the best media for your job. By thinking about these things, you can get the results you want and make your project work.

There are lots of bead blasting media to pick from. Each kind is best for certain tasks. The table below shows which jobs fit glass beads, steel shot, ceramic beads, and plastic media. If you choose the right media, you get a good finish and clean off dirt. For coating prep, use the media that makes the right surface. If you are not sure what to use, ask an expert or check more guides.

| Media Type | Composition | Applications | Reusability |

|---|---|---|---|

| Glass Beads | Lead-free sodalime glass | Light surface cleaning, semi-polishing | 20-30 times |

| Steel Shot | High-carbon or alloy steel | Rust removal, deburring, shot peening | Hundreds to thousands |

| Ceramic Bead | Aluminum oxide, zirconium oxide | Controlled surface finishes | 50-150 cycles |

| Plastic Media | Acrylic, nylon, polyester | Surface cleaning of soft materials, deburring | Highly reusable |

FAQ

You can bead blast metals like steel, aluminum, and brass. You can also use bead blasting on glass, plastic, and some ceramics. Always check if your material can handle the process before you start.

Yes, bead blasting works well for delicate parts if you use gentle media like glass or plastic beads. You should test a small area first to make sure you get the finish you want.

You should match the media to your material and the finish you want. Harder media remove coatings faster. Softer media give a smooth finish. Use this table for quick reference:

| Media Type | Best Use |

|---|---|

| Glass Beads | Smooth finish |

| Steel Shot | Heavy cleaning |

| Plastic Beads | Delicate surfaces |

You can reuse many types of media, like steel shot and ceramic beads, several times. Glass and plastic beads wear out faster. Always check your media for wear before reusing.

Yes, bead blasting removes rust, scale, and old paint from metal surfaces. You get a clean, smooth part ready for painting or coating.

You should wear safety glasses, gloves, and a dust mask or respirator. Use ear protection if the equipment is loud. Always work in a well-ventilated area.

Bead blasting usually does not change the size of your part. It removes only a thin layer. If you use aggressive media, you might see more material removed.

You should brush or blow off loose media. Wash the part if needed. Always check for leftover beads in small holes or corners.