You might ask how to anodize steel. While this method is not common for steel, it is important to note that anodizing works better with other materials. There are better ways to treat steel surfaces. Many industries use different treatments to protect steel, including mechanical, chemical, thermal, or plasma methods. Here are some common ways to treat steel:

| Treatment Type | Description |

|---|---|

| Mechanical Treatments | Abrasive blasting, sanding, and wire brushing clean steel. |

| Chemical Treatments | Pickling, phosphating, and degreasing help protect steel. |

| Thermal Treatments | Annealing and tempering change how the metal is inside. |

| Plasma Treatment | This is a modern and eco-friendly way to treat surfaces. |

If you try to anodize steel, it is not easy, and it also does not work as well as these other methods.

Key Takeaways

- Anodizing steel does not work well. The oxide layer is weak. It does not stop rust.

- Other steel treatments work better. Passivation, electroplating, and powder coating protect steel more. They last longer.

- Passivation cleans steel. It makes a protective layer. It does not change how steel looks. Passivation saves money.

- Electroplating makes steel shiny. It protects steel from rust. It works for many uses.

- Nitriding makes steel much harder. It is good for places with lots of wear. Nitriding can cost more.

- Powder coating gives steel bright colors. It protects steel from rust and damage.

- Think about the weather, how you want steel to look, and your budget before picking a treatment.

- Always clean steel well before you treat it. This helps the treatment stick and work better.

Table of Contents

Anodizing Steel: Feasibility

Why Anodizing Works for Aluminum

You may wonder why people use anodizing for aluminum but not for steel. The reason is about chemistry and how metals react with oxygen. When aluminum is anodized, it gets a strong layer called aluminum oxide. This layer sticks to the metal and keeps it safe from rust. Steel makes iron oxides when it touches air. These oxides are weak and can fall off. They do not protect steel well.

Here’s a simple comparison:

| Material | Oxide Type | Properties | Stability |

|---|---|---|---|

| Aluminum | Aluminum oxide (Al₂O₃) | Hard, resists rust, sticks well, safe, lasts long | Stable |

| Steel | Iron oxides (Fe₂O₃, Fe₃O₄) | Has holes, breaks easily, not stable, weak, falls off | Unstable in air |

This shows why anodizing works great for aluminum. The oxide layer is strong and lasts. Steel does not have the same protection.

Steel Composition and Oxide Layer Issues

Steel has a lot of iron inside. If you try to anodize steel, iron reacts and makes rust. Rust is soft and breaks apart. It does not stick to steel. Steel also has other things like carbon. These can make the surface rough and cause problems.

Here are the main issues:

- Steel cannot handle acid used in anodizing for long.

- You need special solutions, but they are hard to use and can hurt steel.

- The oxide layer on steel is weak and can break off.

- Steel’s iron makes the oxide layer full of holes and not strong.

- Things like carbon in steel make the process hard to control.

If you want to anodize steel, you will see it is hard and does not work well. The oxide layer does not protect steel like it does for aluminum.

Lab vs. Industrial Applications

You may ask if anyone tries to anodize steel. Scientists have tested it in labs. They use special tools and watch everything closely. In these tests, they change the time and chemicals to see what happens.

Here is what they learned:

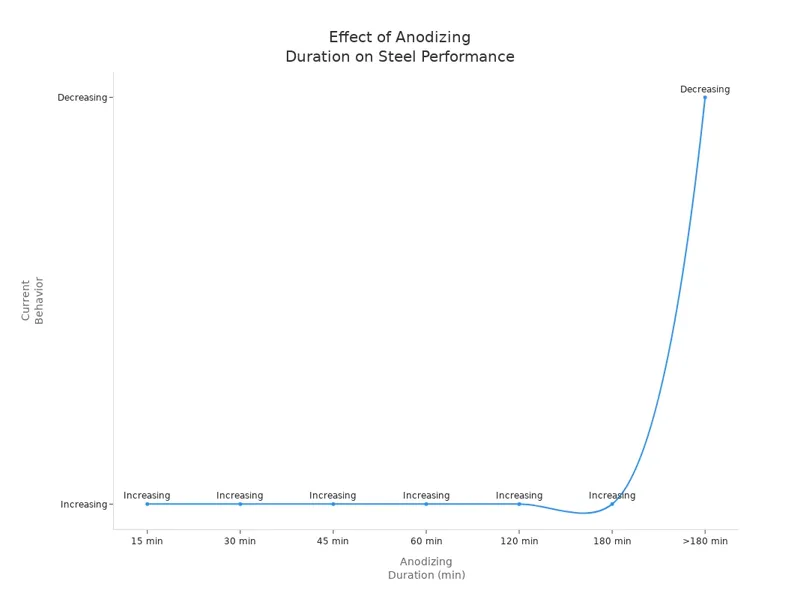

| Anodizing Duration (min) | Observed Effect on Performance | Explanation |

|---|---|---|

| 15, 30, 45, 60, 120, 180 | Currents go up | The surface grows and holds more charge |

| >180 | Currents go down | The surface gets smaller because Fe2O3 breaks down |

Steel anodizing works for a short time. After that, the surface starts to break. The oxide layer does not last long. This is why big companies do not use steel anodizing for big jobs. It costs a lot and does not protect steel well.

If you want steel to last and stay strong, you should use other methods. Anodizing steel is not a good choice for most things. You will get better results with passivation, electroplating, or powder coating.

How to Anodize Steel

Theoretical Process Steps

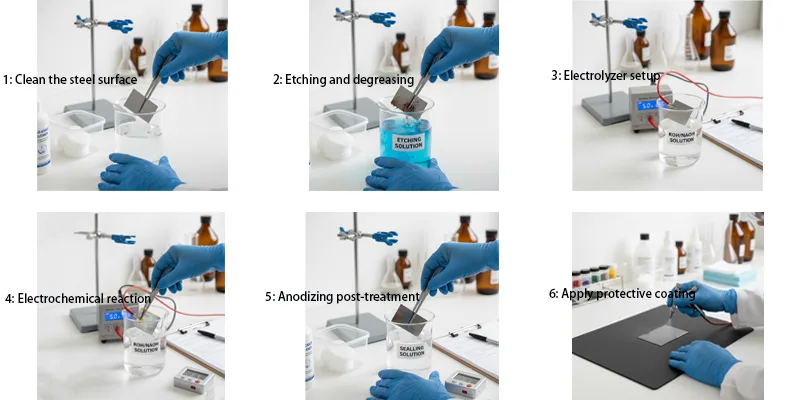

You might ask how to anodize steel in a lab. The anodizing methods for steel are harder than for aluminum. If you want to try this process, you must prepare steel the right way. Here is a simple guide for the steps:

- Clean the Steel Surface

First, wash the steel with deionized water. This gets rid of dirt and oil. The surface must be clean for the anodizing methods to work. - Etching and Degreasing

Use special chemicals to take off rust and old oxides. This makes the steel rough so the new layer can stick better. - Electrolytic Bath Setup

Put the steel in a bath with half KOH or NAOH solution. Connect the steel as the anode. This step is important for how to anodize steel. - Electrochemical Reaction

Send a high voltage current through the bath. This makes a magnetite film on the steel. You need to watch the voltage and time during steel anodizing. - Post Anodizing Treatments

Dip the steel in hot water or a chemical bath. This helps seal the surface and can add color. - Applying Protective Coatings

Use electroplating or powder coating to help the steel last longer and look nice. These anodizing methods protect the steel after the process.

Tip: For the best results, AFI Industrial Co., Ltd can give expert help with steel surface treatments.

Steel Anodizing Challenges and Limitations

You may think these steps are easy, but steel anodizing has many problems. The anodizing methods for steel are not simple or cheap. Here is a table that shows the main problems you might face:

| Challenge | Description |

|---|---|

| Technical Difficulties | Taking off the old oxide layer can make the surface uneven. |

| Increased Costs | You need special tools and skilled workers. This makes the process expensive for small jobs. |

| Surface Uniformity Issues | The finish can look blotchy or dull. Getting a smooth look is hard. |

| Corrosion Risks | If you do not control the process, the steel can rust faster, especially in tough environments. |

You will see that the anodizing process for steel is not good for big jobs. The cost goes up fast, and the results are not always great. The anodizing methods for steel do not give you a strong, stable layer like aluminum. If you want to know how to anodize steel, remember these limits. Most companies pick other treatments because steel anodizing is risky and costs a lot.

Alternatives to Anodize Steel

If you want to protect steel, you have good choices. These other treatments help stop rust and make steel last longer. You can also get the look you want for your project. Let’s look at some popular options and see how they work.

Passivation

Passivation is a simple way to treat steel. You put steel in a chemical bath to clean it. This bath takes away free iron from the surface. It helps make a thin layer that keeps rust away.

Benefits

- Passivation helps steel fight rust but does not change how it looks.

- It cleans off tiny bits of iron and dirt. This makes the steel safer and cleaner.

- You do not add anything new, so steel stays the same size and shape.

- Citric acid passivation is better for the planet than nitric acid. It makes less bad waste and helps nature.

If you need help with passivation or other coatings, AFI Industrial Co., Ltd can give you expert advice.

Applications

Passivation is used in many places. Food factories, medical tools, and chemical plants use it for steel parts. Aerospace and car parts also need passivation to stop rust.

Electroplating

Electroplating is another way to treat steel. You use electricity to cover steel with a thin metal layer. This makes steel shiny and helps stop rust.

Types

Here are some common kinds of electroplating for steel:

| Type | Main Benefit | Typical Use |

|---|---|---|

| Zinc Plating | Cheap way to stop rust | Bolts, car parts |

| Cadmium Plating | Great rust protection and slippery surface | Planes, military |

| Electroless Nickel | Even coating, hard surface, stops rust | Odd shapes, tools |

Protective Qualities

- Zinc plating puts a shield on steel. It stops rust and saves money.

- Cadmium plating works well in tough places. It is slippery and protects steel from rust.

- Electroless nickel covers every part the same. It makes steel harder and stops rust, even on tricky shapes.

Pick the electroplating type that fits your needs. Each one gives steel a special coating and helps it last longer.

Nitriding

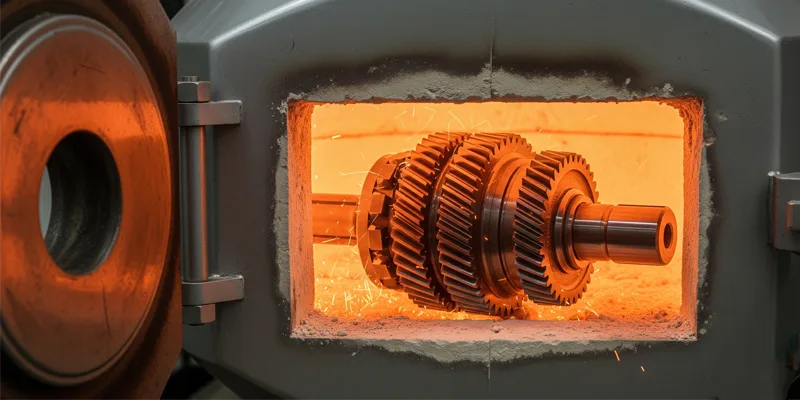

Nitriding is a heat treatment that makes steel very hard. You heat steel and let nitrogen gas touch it. Nitrogen goes into the steel and makes hard nitrides.

Process

- Put steel in a furnace and heat it up.

- Let nitrogen gas flow over the steel.

- Nitrogen atoms go into the steel and make a tough layer.

The inside of the steel stays strong. Only the outside gets super hard.

Durability

Nitriding makes steel very hard, up to 65 RC. Untreated steel is only about 45 RC. This means steel can handle more wear and stress. Nitriding also helps steel fight rust, so it lasts longer in bad places.

Nitriding is used for car and plane parts. Tool steel and stainless steel get this treatment to work better and last longer.

Tip: Nitriding is a great choice if you want steel to be very hard and fight rust for a long time.

These other ways to treat steel help protect your metal. You can pick the best one for your job. Some methods give a strong coating, some stop rust, and some make steel harder.

Powder Coating

Powder coating gives steel a bright and strong finish. This method uses dry powder that sticks to steel. The powder is baked so it stays on. You can use powder coating for many things like fences or car parts. Powder coating has some special features.

Appearance

Powder coating makes steel look smooth and even. The finish can be shiny, flat, or rough. You can choose almost any color you want. This makes powder coating good for modern and stylish steel.

Here are some types of powder coatings you may see:

- Epoxy powder coatings stick well and resist chemicals. These are best for indoor use.

- Polyester powder coatings protect steel from sun and rain. You can use these outside.

- Super-durable polyester powder coatings last longer outdoors. They keep their color and finish in bad weather.

If you want your steel to look special, powder coating lets you pick your style.

Longevity

Powder coating does more than look nice. It helps steel last longer by stopping rust, scratches, and sun damage. The coating acts like a shield against water and dirt.

Here is what you should know about how long powder coating lasts:

- Indoor powder-coated steel lasts 15 to 20 years.

- Outdoor powder-coated steel lasts 5 to 10 years. Weather and sunlight can change this.

To get the best results, you must prepare steel well. Here are the main steps:

- Cleaning: Take off dirt and oil.

- Shot-blasting: Remove rust and old coatings.

- Etching or phosphating: Make steel rough so powder sticks.

- Primer application: Help powder bond better.

A clean surface helps powder coating last longer. If you want help, AFI Industrial Co., Ltd can guide you.

Alternatives

There are many ways to protect steel besides anodizing. Each way gives different benefits. Some make steel harder, others add color or stop rust.

Here are some popular alternatives you can try:

- Brushing

- Vibratory finishing

- Sand blasting

- Shot peening

- Electropolishing

- Anodic oxidation

- Bright zinc plating

- Electroless nickel

- Burnishing

- Teflon coating

- Hard anodizing

- Enameling

- Blackening-oxidize

- Degreasing

- Pickling

- Boundary layer hardening

- Painting or liquid coating

- Case hardening (like carburizing, nitriding, or carbonitriding)

You can choose the method that fits your project. Some work better outside, others make steel shiny or strong. If you need advice, AFI Industrial Co., Ltd can help you pick the best treatment.

Comparing Alternatives

Summary Table

There are many ways to treat steel surfaces. Each way has its own good points. The table below shows the most popular choices. You can see how each one does for corrosion resistance, cost, and looks.

| Method | Corrosion Resistance | Cost | Appearance | Durability Rating |

|---|---|---|---|---|

| Passivation | Good | Low | No change | C3 |

| Electroplating | Very Good | Medium | Shiny/Matte | C4 |

| Nitriding | Excellent | High | No change | C5 |

| Powder Coating | Very Good | Medium | Colorful/Smooth | Im1 |

| Anodizing | Poor (for steel) | High | Uneven/Dull | C2 |

Anodizing does not protect steel from rust very well. The other ways work much better. Powder coating and electroplating make steel look nice and keep it safe.

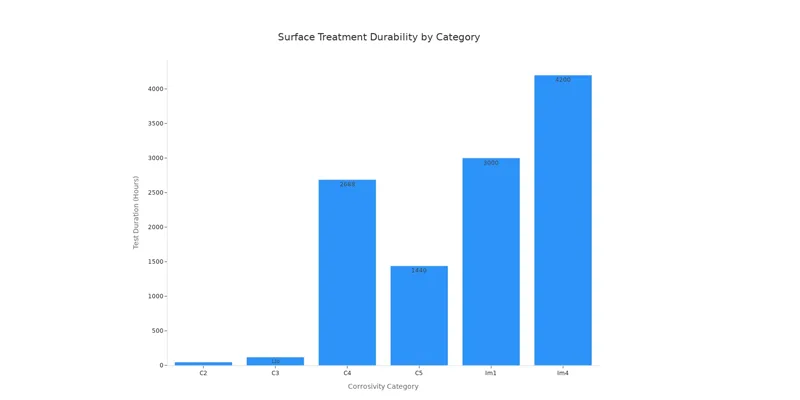

Cost and Durability

When you choose a way to treat steel, you want to know how long it lasts and how much it costs. Some ways cost more but protect steel better. Nitriding makes steel very hard and lasts a long time, but it is expensive. Passivation is cheap and good for simple jobs. Powder coating and electroplating cost a bit more but give good protection and look nice.

Here is how long each one lasts:

- Passivation can last up to 120 hours in tough tests.

- Electroplating can last for 2,688 hours.

- Nitriding can last for 1,440 hours.

- Powder coating can protect steel for up to 3,000 hours.

- Anodizing only lasts 48 hours on steel.

Powder coating and electroplating protect steel much better than anodizing.

Choosing the Best Option

You need to pick the best way to treat your steel. Here are some things to think about:

- Material type: Some ways work better on certain kinds of steel.

- Desired properties: Do you want rust protection, a hard surface, or a special look?

- Manufacturing process: Some ways fit better with how you make things.

- Environmental considerations: Some ways are safer for the planet.

If you want strong rust protection and a nice look, powder coating or electroplating are good picks. Passivation is good if you want something simple and cheap. Nitriding is best if you need steel to be very hard and last a long time.

Tip: AFI Industrial Co., Ltd can help you pick the best way to treat your steel. Their experts can give you advice on what works for your needs.

There are many choices besides anodizing. Each one has its own good points. Think about what you need and pick the best way for your steel.

Maintenance and Longevity

Care Tips

You want your steel to last as long as possible, right? Good care makes a big difference, no matter which surface treatment you choose. Each method—passivation, electroplating, nitriding, or powder coating—has its own routine. If you use passivation, you get a chemical film that blocks rust. This means you do not have to do much. Just clean the surface now and then to keep it looking good.

Electroplated steel needs a bit more attention. You should check it often for scratches or worn spots. Sometimes, you may need to reapply the coating to keep up the corrosion resistance. Nitrided steel usually does not need much care. The hard layer stays strong, but you should still keep it clean and dry. Powder-coated steel looks great and protects well, but you should inspect it for chips or cracks. If you see any, touch them up to keep the corrosion resistance high.

Here’s a quick look at what you need to do for each treatment:

| Surface Treatment | Maintenance Requirements |

|---|---|

| Passivated Steel | Low-maintenance, periodic cleaning |

| Electroplated Steel | Regular inspection, reapplication needed |

| Nitrided Steel | Varies, generally low maintenance |

| Powder-coated Steel | Requires periodic inspection and touch-ups |

Tip: Always use gloves and safety glasses when you clean or inspect steel. Work in a space with good airflow. This keeps you safe from dust or fumes.

You should also know that safety matters. Wear the right gear, like gloves and safety glasses. Make sure you work in a place with fresh air. If you use chemicals, follow the instructions and store them safely. If you ever need help, AFI Industrial Co., Ltd can guide you on safe practices for steel care.

Lifespan by Treatment

How long will your steel last? That depends on the treatment and how well you care for it. Passivation gives you a strong chemical barrier. This boosts corrosion resistance and means you do not have to worry about rust for a long time. Electroplating adds a shiny layer that fights rust, but you need to check it and sometimes redo it. Nitriding makes the surface super hard, so it stands up to wear and keeps its corrosion resistance. Powder coating gives you color and a smooth finish, plus strong protection against rust.

Let’s break it down:

- Passivated surfaces need little care. The chemical film keeps rust away, so you spend less time on maintenance.

- Electroplated surfaces need regular checks. If you see damage, fix it soon to keep up the corrosion resistance.

- Nitrided surfaces are tough. You usually do not need to do much, but always keep them clean.

- Powder-coated surfaces need you to look for chips or cracks. Touch up any damage to keep the corrosion resistance strong.

If you compare these to anodizing, you will see a big difference. Anodizing does not give steel the same corrosion resistance as these other methods. The oxide layer from anodizing breaks down fast, so you will need to do more work to keep your steel safe. That is why most people pick other treatments for steel.

Remember: Customer needs can change what you choose. If you want a certain look, like a matte-black finish, you might pick painting or powder coating. In electronics, people care about style and durability, so they often skip anodizing for steel.

If you want your steel to last, pick a treatment with strong corrosion resistance and follow the care tips. AFI Industrial Co., Ltd can help you choose the best method for your project.

When to Choose Alternatives

Decision Criteria

Choosing the right surface treatment for steel can feel tricky. You want your project to last, look good, and stay within budget. You might think anodizing is the answer, but it rarely works well for steel. Instead, you should look at other options that offer better corrosion resistance and durability.

Here are some things you should consider before making your choice:

- Material Type: Not all metals react the same way. Steel needs treatments like galvanization or powder coating. Anodizing works best for aluminum, not steel.

- Environmental Conditions: Will your steel face rain, chemicals, or salty air? You need strong corrosion resistance if your project sits outside or in a harsh place.

- Aesthetic Requirements: Do you want a shiny finish or a colorful look? Some treatments, like powder coating, let you pick colors and textures. Anodizing gives a dull finish on steel, so it’s not great for style.

- Budget: Some treatments cost more than others. Nitriding and electroplating can be expensive, but passivation is budget-friendly.

- Maintenance Needs: Think about how much time you want to spend caring for your steel. Powder coating and passivation need less upkeep. Anodizing on steel needs lots of attention and still doesn’t last long.

If you need help picking the best treatment, AFI Industrial Co., Ltd can guide you. Their experts know which method will give you the corrosion resistance and look you want.

Common Mistakes

You want your steel to last, so you need to avoid some common mistakes. Many people think anodizing will protect steel, but it does not offer strong corrosion resistance. Here are mistakes you should watch out for:

- Forgetting to include surface preparation and coating details in your plans. This can cause confusion and cost you more money. Work with coatings experts to get everything right.

- Not understanding the properties of steel. If you pick anodizing, you might get poor bonding and weak protection. Learn about your material before you choose a treatment.

- Skipping verification steps during surface prep. You need to check that the steel is ready for coating. If you miss this, the treatment may not stick well.

- Overdoing or underdoing surface preparation. Too much or too little prep can ruin adhesion. Make sure you reach the right level before you apply any treatment.

Tip: Always double-check your surface prep and talk to experts like AFI Industrial Co., Ltd. They can help you avoid mistakes and pick the best way to protect your steel.

If you keep these points in mind, you’ll get better results. Remember, anodizing is not the best choice for steel. Look for treatments that offer strong corrosion resistance and fit your needs.

You now know that anodizing is not good for steel.

The layer made by anodizing on steel is just rust. This rust falls off and makes the steel rust even more. So, anodizing does not help protect steel.

There are better ways to treat steel.

- Electroplating and chemical mechanical polishing keep steel safe and looking nice.

- These finishes can also help you spend less on repairs.

| Factor | Considerations |

|---|---|

| Environmental Conditions | Pick a treatment that works with water or chemicals. |

| Aesthetic Requirements | Use powder coating if you want your steel to have color. |

| Durability Needs | Pick a method that fits how much wear your steel will get. |

| Cost Considerations | Think about how much you pay now and what you save later. |

AFI Industrial Co., Ltd can help you choose the best way to treat your steel. If you want your steel to last, do not use anodizing. Pick a method that really works.

FAQ

Anodizing does not work well for steel. The process creates a weak rust layer that flakes off. You will not get strong protection or a nice finish.

No, you cannot get bright colors with anodizing on steel. If you want color, try powder coating. This method gives you many color choices and a smooth finish.

Powder coating and nitriding last the longest. Both protect against rust and wear. If you want advice, AFI Industrial Co., Ltd can help you pick the right treatment.

Yes, passivation is safe for food and medical tools. It removes dirt and iron from the surface. This keeps your tools clean and rust-free.

Think about where you will use the metal, how it should look, and your budget. If you feel unsure, ask experts like AFI Industrial Co., Ltd for help.

Yes, you should clean and check your treated steel. Look for chips or scratches. Fix any damage quickly to keep the protection strong.

Yes, you can combine treatments. For example, you might use passivation first, then add powder coating. This gives you extra protection and a better look.