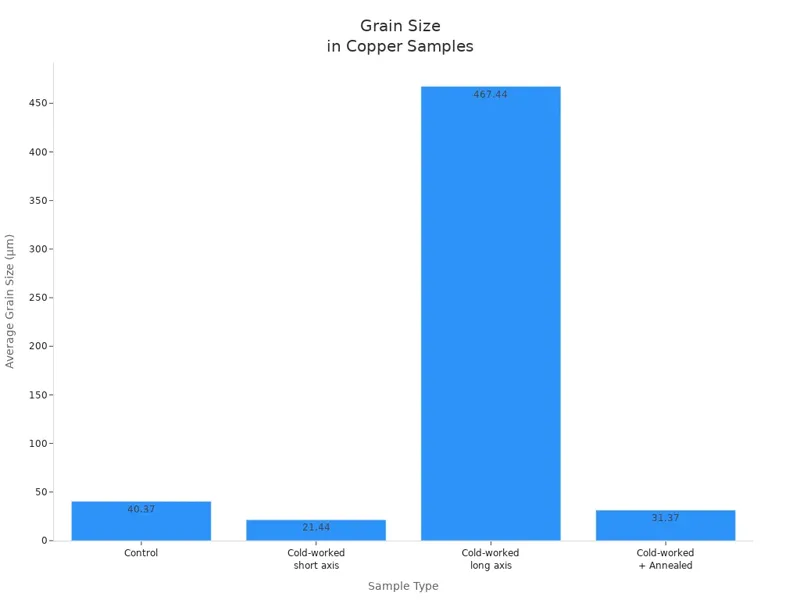

When you apply full annealing of copper, you observe significant changes. The copper becomes softer and more pliable. The grains inside the copper grow larger during the full annealing of copper process. Microhardness tests confirm that copper subjected to full annealing is less hard. This reduction in hardness occurs because the grains increase in size. The table below illustrates how full annealing of copper restores softness after the metal has been hardened by work:

| Sample Type | Hardness Trend | Average Grain Size (µm) | Interpretation |

|---|---|---|---|

| Control | Baseline hardness | 40.37 | Original grain structure and softness |

| Cold-worked | Hardness increased with cold work | 21.44 (short), 467.44 (long) | Work hardening raises dislocation density and stress |

| Cold-worked + Annealed | Hardness reduced (restored softness) | 31.37 | Full annealing of copper recovers softness and relieves stress through recrystallization |

Choosing copper that has undergone full annealing of copper makes it easier to shape, which is advantageous for manufacturing processes in factories.

Key Takeaways

- Full annealing heats copper above a certain temperature. It then cools the copper slowly. This makes copper softer and easier to shape.

- Annealing makes copper grains bigger. This lowers hardness and makes copper easier to bend and stretch.

- The process takes away stress inside the metal from cold working. This stops cracks and helps the metal stay strong.

- Annealed copper carries electricity better. This is because it has fewer defects and bigger grains. This helps conductivity.

- Manufacturers use full annealing to make copper more flexible and tough. It also helps copper be easier to machine for wires, pipes, and sheets.

- By changing the annealing temperature and time, you can control how soft copper is. You can also change the grain size for different uses.

- Fully annealed copper lasts longer and works better in electrical wiring, plumbing, and industrial parts.

- Regular annealing during making keeps copper soft. It also lowers tool wear and helps make high-quality products.

Table of Contents

Full Annealing of Copper

What Is Full Annealing

Full annealing of copper is a special heat treatment. You heat copper above its critical temperature. The copper stays hot long enough for its structure to change. Then, you cool the copper very slowly in a furnace. This slow cooling lets the grains inside grow bigger and settle. The copper becomes much softer and bends more easily. The microstructure looks even and matches what you see in the equilibrium phase diagram. Full annealing of copper makes the metal easier to shape, cut, or roll.

Tip: If copper gets hard from rolling or bending, annealing can make it soft again.

Industry standards care about the grain size after full annealing of copper. Grain size is important because it affects strength and ductility. Common grain sizes are 0.015 mm, 0.025 mm, and 0.035 mm. Sometimes, people use tensile strength when measuring grain size is hard. Annealing gives you steady results, especially after cold working makes copper thinner.

Why Anneal Copper

There are many reasons to anneal copper. First, it makes copper softer and easier to bend. You can twist or stretch copper without it breaking. Annealing also helps copper carry electricity better, which is good for wires. The process removes stress that builds up during casting, machining, or rolling. If you do not remove this stress, copper can crack or change shape. Annealing gives copper a smooth structure that stops these problems.

Manufacturers use full annealing of copper to make flexible wires, tubes, and pipes. After annealing, you can wind copper wire easily. Tubes can bend into tight shapes. Welds in pipes get stronger and last longer. Annealing helps pipes handle high pressure and rough places.

When to Use Full Annealing

You should use full annealing of copper when you want the metal to be soft and easy to work with. If you need to make thin wires or shape tubes, full annealing gives you the right properties. You also use it after copper gets hard from cold working. Full annealing brings back softness and ductility, so copper is ready for the next step.

A study on copper thin films shows that annealing raises the Young’s modulus, especially when grains grow in certain ways. This means copper is softer and has better elastic properties. You see these good changes in electronics, plumbing, and car parts. Full annealing of copper gets the metal ready for tough jobs and helps stop failures.

Annealing Process

When you start the annealing process for copper, you follow a series of careful steps. Each step helps you change the metal’s properties in a controlled way. The main stages include heating, holding, and cooling. You need to pay attention to temperature, time, and the way you cool the copper. These steps make sure you get the softness and ductility you want.

Heating Stage

The first step in the annealing process is heating. You place the copper in a furnace and raise the temperature slowly. Slow heating helps prevent thermal shock, which can damage the metal. Copper’s high thermal conductivity lets you heat it a bit faster than some other metals, but you still need to be careful. You want the temperature to reach between 200°C and 300°C. This range is important because it is where copper’s grains start to change and new grains can form.

Temperature and Time

You must hold the copper at the target temperature for a long time. This part of the annealing process is called soaking or holding. The holding time can last many hours, sometimes up to 30 hours or more. The exact time depends on how thick the copper is and what properties you want. During this time, atoms move, and the grains inside the copper grow larger. This change makes the copper softer and easier to work with. If you rush this step, you might not get the full benefits of the heat treatment process.

Tip: Always use a controlled furnace to keep the temperature steady during the annealing process. Fluctuations can lead to uneven grain growth.

Cooling Stage

After you finish holding the copper at the right temperature, you need to cool it down. The cooling stage is just as important as heating. You should cool the copper very slowly, often by letting it stay inside the furnace as it cools down. This slow cooling helps prevent new stresses from forming inside the metal.

Cooling Rate Effects

You might wonder if the cooling rate changes the final softness of the copper. In the annealing process for copper, the cooling rate does not have a big effect on how soft the metal becomes. Whether you cool it a little faster or slower, the copper will still end up soft and ductile. The main changes happen during the heating and holding stages. Slow cooling does help control grain growth and keeps the structure even, but it does not make the copper any softer than it already is after soaking.

Remember: The annealing process works best when you follow each step carefully. Heating, holding, and cooling all play a role in making copper easy to shape and use.

Property Changes

Hardness Reduction

Full annealing of copper makes the metal softer. At first, if you heat copper for just one minute, it gets harder. The yield strength can reach about 410 MPa. The tensile strength can go up to 419 MPa. If you keep heating for ten minutes or more, the hardness stops changing. The copper stays at the same hardness. This means the metal reaches a steady point and does not get any harder. Fully annealed copper keeps this constant hardness after enough time in the furnace.

This happens because the grains inside copper get bigger when heated. Bigger grains make the metal softer and easier to bend. The grains do not block movement as much. Annealing also lowers the number of defects called dislocations. Before annealing, cold-rolled copper has many dislocations, up to 10¹⁴ per square meter. After full annealing, there are many fewer dislocations. The grains become smooth and free of stress. The copper is now easier to bend and shape.

Increased Ductility

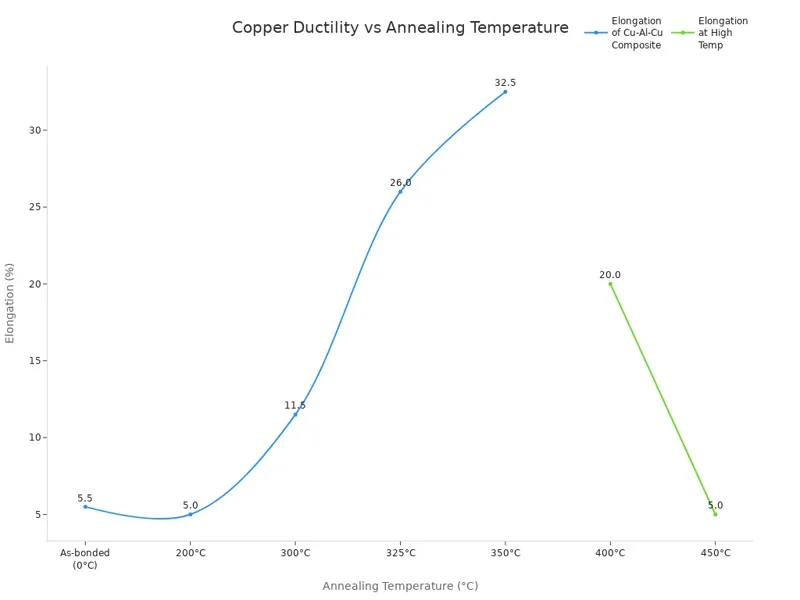

Ductility means copper can stretch without breaking. Annealing makes copper much more ductile. You can measure ductility by how much copper stretches before snapping. The table below shows how ductility changes with different annealing temperatures:

| Annealing Temperature (°C) | Elongation (%) | Observed Effect and Explanation |

|---|---|---|

| As-bonded (0 °C) | 5.5 | Baseline ductility before annealing |

| 200 | Slight decrease | Early microstructural changes cause a small drop |

| 200–350 | Increasing | Recovery and recrystallization boost ductility, peaking at 32.5% at 350 °C |

| 300–325 | Sharp increase | Elongation jumps from 11.5% to 26% |

| >350 | Decreasing | Brittle layers form, causing cracks and less ductility |

| 400 | Micro-delaminations observed | Interface damage starts, ductility drops |

| 450 | Significant decrease | Severe cracking and delamination reduce ductility |

Ductility gets better as you heat copper to 350 °C. If you go higher, ductility drops because brittle layers and cracks start to form. The chart below shows how elongation changes with temperature:

Fully annealed copper can stretch much more before breaking. This makes it great for wires, tubes, and things that need to bend or twist.

Malleability

Malleability means you can hammer or roll copper into thin sheets. Full annealing makes copper much more malleable. The grains inside get bigger, and there are fewer dislocations. The table below shows what happens inside the copper:

| Aspect | Observation after Annealing | Effect on Malleability/Ductility |

|---|---|---|

| Grain Size | Increases with annealing temperature | Larger grains reduce hardness, increase ductility |

| Dislocation Density | Decreases due to recovery and recrystallization | Lower dislocation density softens copper, improving malleability |

| Microhardness | Decreases significantly after annealing | Softening correlates with improved ductility |

| Microstrain and Crystallite Size | Microstrain decreases, crystallite size increases | Indicates recovery and recrystallization processes enhancing ductility |

| Tensile Strength vs. Elongation | Trade-off observed: strength decreases, elongation increases | Demonstrates improved malleability after annealing |

| Recrystallization Sites | High-angle grain boundaries prone to recrystallization | Facilitates softening and ductility improvement |

If you anneal copper foils with carbon nanotubes, you see even more grain growth and more twin boundaries. These changes help copper stretch and bend without cracking. The copper becomes easier to work with and can be shaped into many forms. Cracks do not spread as easily, so the metal stays strong and flexible. Fully annealed copper is perfect for rolling, stamping, or pressing into new shapes.

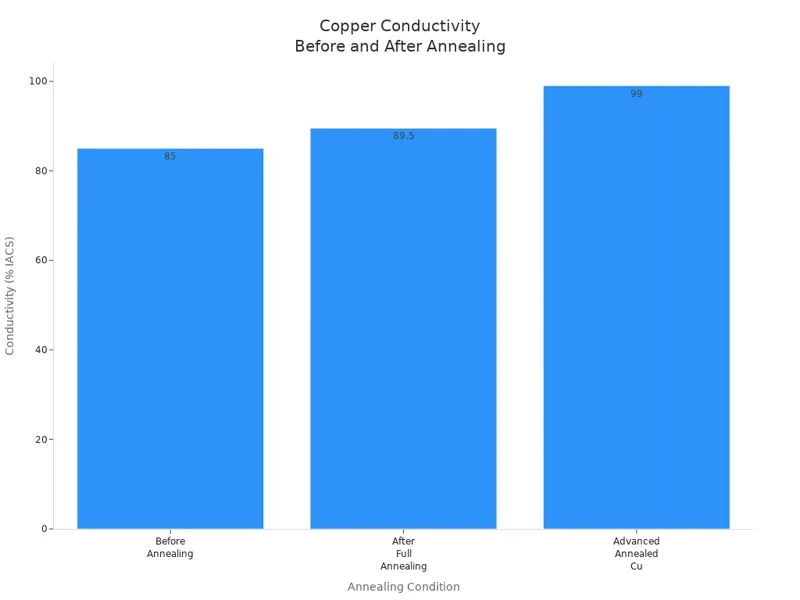

Electrical Conductivity

When you anneal copper, it carries electricity better. The process takes away defects and stress from the metal. There are fewer grain boundaries and less distortion inside. Electrons can move more easily through the copper. This means resistance goes down and conductivity goes up.

Here is a table that shows how electrical conductivity changes before and after full annealing:

| Condition | Electrical Conductivity (% IACS) | Microstructural Changes | Effect on Conductivity |

|---|---|---|---|

| Before Annealing | 84% – 86% | Many defects, small grains, lots of boundaries | High resistance, lower conductivity |

| After Full Annealing | 87% – 92% | Fewer defects, bigger grains, fewer boundaries | Lower resistance, higher conductivity |

| Advanced Annealed Cu | Up to or exceeding 99% | Twin chains, copper oxide particles | Exceptional conductivity |

You can see that annealed copper lets more electricity flow. This happens because there are fewer places for electrons to get stuck. If you use copper for wires or electrical parts, you want high conductivity. Full annealing helps you get this result.

Note: The International Annealed Copper Standard (IACS) says 100% is the best conductivity for pure copper. Annealed copper often gets close to this number.

You also see a conductivity change after different treatments. For example, copper that is deformed a lot has lower conductivity. When you anneal it, the conductivity goes up again. This is because annealing removes dislocations and fixes the crystal structure.

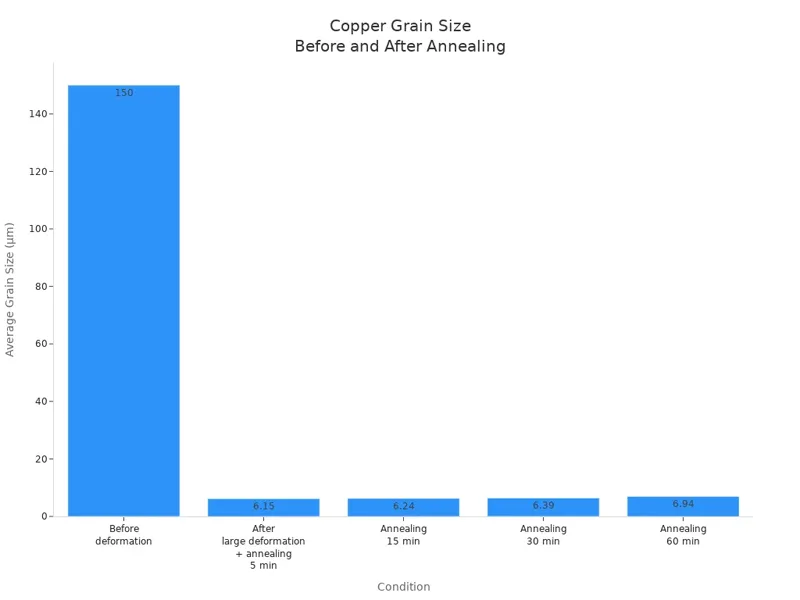

Grain Growth

Full annealing makes big changes in copper’s grain structure. Grains are tiny crystals inside the metal. When you deform copper, the grains get smaller and the metal gets harder. If you anneal copper, the grains grow larger and the metal gets softer.

Here is a table that shows how grain size changes during annealing:

| Condition | Grain Size Range (μm) | Average Grain Size (μm) |

|---|---|---|

| Before deformation | 50 – 200 | 150 |

| After large deformation + annealing at 350 °C for 5 min | N/A | 6.15 |

| After annealing for 15 min | N/A | 6.24 |

| After annealing for 30 min | N/A | 6.39 |

| After annealing for 60 min | N/A | 6.94 |

Before deformation, copper has large grains. After you deform and anneal it, the grains shrink to about 6–7 micrometers. This happens because annealing starts recrystallization. New grains form and grow, replacing the old, stressed ones.

Tip: Grain growth during annealing makes copper easier to bend and shape. You get a metal that is soft, flexible, and ready for manufacturing.

You can control grain size by changing the annealing temperature and time. If you want copper with certain properties, you can adjust these settings. Bigger grains mean softer copper. Smaller grains mean harder copper. Full annealing lets you pick the right grain structure for your needs.

Microstructural Effects

Grain Structure

When you fully anneal copper, its tiny structure changes a lot. Before annealing, copper grains are long and stretched. They have many flaws and lots of dislocations. After full annealing, grains turn round and even. You see big, equiaxed grains with clear edges. Many grains also show twin lines, which are special patterns from annealing.

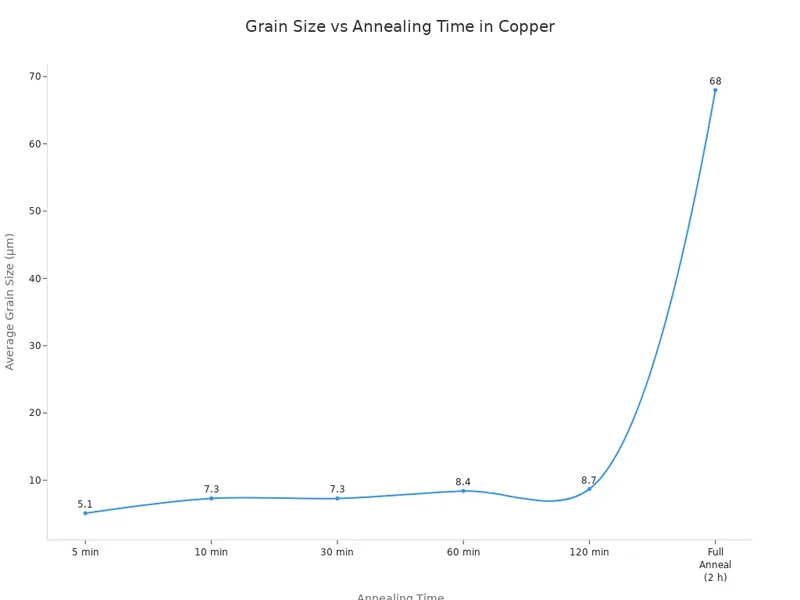

Here is a table that shows how grain structure changes with different annealing times:

| Annealing Time (min) | Grain Morphology and Features | Average Grain Size (μm) | Additional Observations |

|---|---|---|---|

| 0 (Cold Rolled) | Elongated, deformed grains with high dislocation density and shear bands | N/A | Grain elongation along rolling direction; high dislocation density (2.41 × 10^16 m−2) |

| 1 | Partial recovery; elongated grains broken into smaller grains; aspect ratio decreased | N/A | Large fraction of deformed grains remain |

| 2 | Full recrystallization; microstructure significantly changed | N/A | Formation of new equiaxed grains |

| 5 | Grain size increased; recrystallized grains present | 5.1 | Cu2O particles begin to pin grain boundaries |

| 10 | Further grain growth | 7.3 | Grain growth continues |

| 30 | Grain size stable compared to 10 min | 7.3 | Cu2O particles suppress grain boundary migration |

| 60 | Grain size increased | 8.4 | Grain coarsening limited by particle pinning |

| 120 | Bimodal grain structure: fine ( | 8.7 (mean) | Cu2O particles (~1% fraction) distributed non-homogeneously; pinning effect suppresses excessive grain growth |

| Full Annealing (1023 K, 2 h) | Equiaxed, coarse grains with numerous annealing twins; average grain size ~68 μm | 68 | Annealing twins prominent; Cu2O particles present; original elongated grains replaced by equiaxed grains |

As annealing time goes up, grains get bigger and steadier. The chart below shows grain size growing with time:

Recrystallization

Recrystallization is a main step when you change copper’s microstructure. This starts when you heat copper above its recrystallization temperature. New, strain-free grains start to form and grow. These new grains take the place of old, stretched ones. How much you worked the copper before matters for this step. If you rolled or bent copper a lot, more new grains will appear.

- Self-annealing in copper foil causes recrystallization because of stress from nanocrystals and many dislocations.

- Dislocation plasticity and twin boundaries work together, so more twin lines show up after recrystallization.

- When copper grains become equiaxed, tensile strength drops, so the metal gets softer.

- If copper started with columnar grains, it retains better strength after annealing.

You can pick the final grain size and softness by changing the annealing temperature and time. Recrystallization helps make copper easy to bend and shape.

Stress Relief

Full annealing does more than just make grains bigger. It also takes away the stress that builds up from rolling or bending. When you heat copper and cool it slowly, atoms move to a relaxed state. This lowers the stress and strain inside the metal.

Scientists use special tools like the contour method and X-rays to check these changes. These tools show that after annealing, copper has less leftover stress and a more even structure. You get copper that is less likely to crack or bend the wrong way.

When you remove stress from copper, it becomes safer for wires, tubes, and other uses. Full annealing gives copper a steady, even structure and low internal stress.

Practical Benefits

Manufacturing Uses

If you pick fully annealed copper for making things, you get many good results. Copper is special because it lets electricity flow better than most other metals that are not precious. This means copper works well for moving electricity and heat in factories. You see these good things in wires, heat exchangers, and electronic parts.

Many factories use induction annealing to heat only certain spots on copper pieces. This way, heating is faster, and more products are made quickly. You get the same good results each time, so there are fewer mistakes and better quality. Induction annealing also uses less energy and takes up less room than old gas ovens. You keep copper’s important properties and make more items at once.

Here is a table that shows the main reasons why fully annealed copper helps in factories:

| Manufacturing Benefit | Explanation |

|---|---|

| Improved Electrical Conductivity | Annealing copper enhances conductivity, critical for electrical applications. |

| Increased Toughness | Annealing increases toughness, allowing copper to be formed without cracking or breaking. |

| Improved Machinability | Softening copper reduces tool wear and improves precision in machining processes. |

| Stress Reduction | Internal stresses from manufacturing are relieved, reducing deformation and premature failure. |

| Controlled Atmosphere Annealing | Use of vacuum or inert gases prevents oxidation, maintaining copper quality during annealing. |

| Customizable Process Parameters | Temperature, holding time, and cooling rates can be adjusted to meet specific hardness and strength requirements. |

| Enhanced Flexibility | Annealed copper becomes more flexible, important for electrical and electronic components. |

Workability

You will notice that copper is much easier to work with after full annealing. The process fixes the hardening that happens when copper is bent or rolled. Copper gets softer and stretches more, so you can shape or cut it easily. You do not have to worry about cracks or the metal breaking, which makes building things simpler.

Annealing has three main steps: recovery, recrystallization, and grain growth. In recovery, heating below the melting point takes away stress and fixes some flaws. Recrystallization makes new grains, so copper shapes better. Grain growth during slow cooling makes the copper even smoother.

Usually, you heat copper to 500–700°C, keep it hot for 30 minutes to 2 hours, then cool it slowly. This makes copper soft again, removes hard spots, and brings back its ability to bend. You get better cutting, higher electrical flow, and easier welding. These changes help you make parts that fit tough rules without extra work.

Tip: When you use annealed copper, you can bend and shape it without cracks or wearing out your tools. This saves time and cuts down on wasted material.

End-Use Performance

Fully annealed copper works very well in its final jobs. Wires carry electricity better, pipes do not crack, and sheets bend without breaking. Because copper is more stretchy and tough, your products last longer and work better under pressure.

You also get better results when copper is used over and over or welded. Annealed copper can handle tough jobs and rough use. You can trust it for wiring, plumbing, and electronics. Its mix of strength and flexibility makes it great for hard work.

When you pick fully annealed copper, your finished items are safe, strong, and reliable. You can feel sure your copper parts will do their job well in real life.

Applications of Annealing Copper

Electrical Wiring

You can find annealed copper in almost all electrical wiring. This is because annealed copper wire bends easily and does not snap when twisted. You can pull it through small spaces without breaking it. Its high conductivity lets electricity move with less resistance. This keeps wires cooler and safer. Annealed copper also does not rust easily, so wires last longer in homes, schools, and factories.

Here is a table showing where you use annealed copper in electrical wiring:

| Application Area | Description |

|---|---|

| Building Wiring | Used in homes, offices, and factories for power. Copper fits better in pipes and needs less covering. |

| Motor Windings | Used in motors because it carries electricity well and bends without snapping. |

| Transformers | Used for good power transfer and long-lasting use. |

| Electrical Cables | Found in armored, mineral insulated, and main cables for safe power. |

| Busbars | Used in panels for strong, steady power. |

| Wiring Harnesses | Great for parts that must bend and twist, like car wires and appliances. |

Tip: Annealed copper is the world standard for electrical wires. You get better safety, flexibility, and performance than with other metals.

Tubing and Piping

When you use copper tubing and piping, annealing makes the work easier. The process softens copper, so you can bend, flare, or stretch pipes without cracks. This is important for plumbing and HVAC, where pipes must go around corners and through walls.

- Annealed copper tubing bends into tight shapes, like U-bends, without breaking.

- You can flare or stretch the ends for fittings, making leak-free joints.

- The process removes stress from working, so pipes stay soft and easy to shape.

- Annealed copper does not rust easily, so pipes last longer.

- You can anneal copper again if it gets hard after use.

Annealing also makes copper up to 30% more ductile. This helps pipes handle high pressure and temperature changes, which are common in air conditioning and refrigeration. Modern annealing furnaces use nitrogen to stop rust, so your copper stays clean and strong.

Note: Annealed copper pipes are safer and more reliable where pressure and shaking happen often.

Sheet and Plate

You use fully annealed copper sheet and plate in many jobs. The soft, ductile metal bends and forms into shapes without cracking. This makes it perfect for roofing, electronics, and medical tools.

- Copper sheets carry heat and electricity very well, so they work in electrical and heat products.

- They do not rust easily, so they stay strong in wet or rough places.

- Copper’s antibacterial properties help in hospitals and kitchens.

- You can recycle copper sheets, saving money and helping the planet.

- The soft metal is easy to cut, stamp, or weld.

Here are some ways annealing helps copper sheet and plate:

- You get better ductility, so the metal bends without breaking.

- The process removes stress, stopping warping or bending.

- Machining is easier, giving you smooth surfaces.

- Grain structure gets better, making the metal stronger and tougher.

- Annealing brings back softness lost during earlier work.

- Electrical conductivity goes up, which is great for circuit boards.

- The metal is less brittle, so it is safer to use.

- Welding is easier and stronger.

- Annealed copper is ready for more shaping or forming.

Tip: If you need copper parts that must bend, shape, or carry electricity, pick fully annealed copper sheet or plate.

When you pick fully annealed copper, its properties change a lot.

- The metal gets much softer and is simple to shape.

- Ductility goes up, so you can bend or pull copper and it will not break.

- The grain structure gets better, which means smoother surfaces and stronger metal.

| Benefit for You | What You Get |

|---|---|

| Easier manufacturing | Faster cutting, forming, and welding |

| Reliable end-use | Tougher, longer-lasting products |

If you know how copper becomes fully annealed, you can make smarter choices in factories. This helps your products work well every time.

FAQ

Full annealing makes copper soft. It is easier to bend. The grains inside get bigger. The process takes away stress. Copper gets back its old properties.

You look at grain size and hardness. Fully annealed copper feels soft. It bends without cracking. You can test how well it carries electricity. Conductivity goes up after annealing.

You can anneal small copper pieces at home. Use a torch or oven. Heat the copper until it glows red. Let it cool slowly. Always wear safety gear.

Yes, annealing copper helps it carry electricity better. The process removes defects and stress. Electrons move more easily. Wires and cables work better.

Bending copper makes it harder. This is called work hardening. The grains get smaller. Dislocations go up. The metal gets stiff and less flexible. Annealing fixes this problem.

You should anneal copper after each big shaping step. This keeps copper soft and easy to use. Regular annealing stops cracks. It makes products better.

Heat copper between 400°C and 700°C. Hold the temperature steady. Cool it slowly. This helps grains grow. Copper stays soft.

Yes, annealed copper is safe for plumbing and wires. The metal bends easily. It does not crack. Pipes and wires last a long time.