Aluminum stamping is special because it makes parts that are strong and light. These parts also let electricity flow well and do not rust easily. The stamping process shapes flat aluminum sheets into exact shapes. When you look at aluminum, steel, and copper, you see they are used in different ways and have different results:

| Material | Key Properties | Applications |

|---|---|---|

| Aluminum | High strength-to-weight ratio, excellent conductivity, non-magnetic, recyclable | Lightweight uses, car parts, green products |

| Steel | High strength, many forms and finishes, magnetic properties | Heavy jobs, building parts, cheap solutions |

| Copper | High electrical and thermal conductivity, corrosion resistance, softness | Wires, electronics, plumbing, and heating |

You pick aluminum stamping when you want parts that bend easily, do not break, and follow strict rules for new industries.

Key Takeaways

- Aluminum stamping makes parts that are strong and light. These parts do not rust easily. They also let electricity pass through well. The stamping process uses machines to shape flat aluminum sheets. These machines use special methods to make exact shapes. Cold stamping is used most often. It makes tough parts and keeps the aluminum cool. Picking the right aluminum alloy is very important. This helps get the strength and bendiness you want in the parts. After stamping, steps like polishing and anodizing are used. These steps make the parts look better and last longer. Aluminum is light, so it is great for cars and planes. This helps save fuel. Quality control is very important in aluminum stamping. It makes sure every part is made right. Working with a trusted company like AFI Industrial Co., Ltd. is helpful. They can give you custom solutions and good stamped parts.

Table of Contents

Aluminum Stamping Basics

Definition

Aluminum stamping shapes flat aluminum sheets into useful parts. In factories, workers press aluminum sheets or bars with a stamping die and a press. This pressing bends and changes the aluminum to the size and shape needed. Most stamping happens while the aluminum is cold. People call this cold stamping. Cold stamping makes strong, light, and exact parts for many industries.

AFI Industrial Co., Ltd. is a top company in metal stamping. If you work with AFI, you use advanced machines and a team that cares about quality. AFI gives you custom or mass-produced aluminum parts that meet strict rules.

Process Overview

There are several steps in sheet metal stamping to make good aluminum parts. Here is what you do:

- Handle aluminum sheets gently. Keep them clean and dry so they do not get dents, scratches, or dirt.

- Use CNC or servo-driven stamping machines. These machines help you control the process and make parts that look the same.

- Put coatings or lubricants on the aluminum. This protects the surface and helps stamping go smoothly.

- Check the size and surface of each part. Use special tools to make sure every piece matches your plan.

- Use simulation software to plan tool paths. This helps you see how the aluminum will move and makes stamping more exact.

Tip: Sheet metal stamping gives you parts that are accurate and repeatable. This is a big benefit of sheet metal stamping.

AFI Industrial Co., Ltd. uses many advanced machines for these steps. You can find machines for turning, threading, milling, drilling, grinding, pressing, cutting, welding, and hydraulic pressing. These tools help shape, cut, and finish aluminum sheets with high accuracy.

| Process/Measure | Description |

|---|---|

| Advanced Stamping Technology | Molds and stamping tools give high precision and low waste. |

| Drawing Review and Process Planning | Every step is checked to keep size within ±0.01mm. |

| Standardized Process Flows | Strict steps and smart control systems give exact results. |

| Full-Process Quality Monitoring | Quality is watched from start to finish, with a rate over 99.8%. |

| Quality Inspection Personnel | Each product is tested to make sure it meets customer needs. |

If you choose AFI, you get a partner who can make solutions just for you. You can order one prototype or many parts, and AFI will give the same care and quality. Their team helps you design molds and processes for your project. This makes sure you get the best results from sheet metal stamping.

Sheet Metal Stamping Process

Material Prep

You begin by getting the aluminum sheets ready. The sheets must be clean and flat. This helps you get good results. You should check every sheet for dents or dirt. Dirty or bent sheets can ruin your parts.

You also need to choose the right aluminum alloy. Each alloy works best for certain jobs. Here are some alloys you might use:

- 1100: Very bendy and easy to shape, good for tricky designs.

- 3003: Stronger than 1100, does not rust easily, used in kitchens.

- 5052: Even stronger, does not wear out fast, used in planes and appliances.

- 6061: Can be heated to get stronger, used for car parts.

You may put a thin oil layer on the sheets. This helps the machine work better and keeps the sheets safe from scratches. Good prep makes the rest of the process easier.

Die Selection

Picking the right die is very important. The die shapes the aluminum and affects how your part turns out. You need to think about a few things before you choose a die. The table below shows what to look at:

| Critical Factor | Description |

|---|---|

| Material Properties | Check if the aluminum is hard or soft and if the surface is smooth. |

| Production Requirements | Think about how many parts you need to make each year. |

| Quality Specifications | Look at how exact the size must be and how smooth the part should feel. |

| Initial Investment | Add up the money needed to make and set up the die. |

| Operating Costs | Think about how much it costs to keep the die working and how fast it makes parts. |

You want a die that fits your stamping job. If you need very exact parts, pick a die that is very precise. If you need lots of parts, pick a die that lasts a long time. AFI Industrial Co., Ltd. can help you pick the best die.

Press Operation

Now you are ready for the main step. Put the aluminum sheet into the stamping machine. The machine pushes the sheet into the die. This shapes the aluminum into the part you want.

There are different stamping machines. Some press once, others press many times. CNC and servo-driven machines let you control the process better. You can change the speed and pressure for your job.

You must watch the process closely. Check each part as it comes out. If you see a problem, stop the machine and fix it. This keeps your parts good and waste low.

Tip: Always keep your stamping machine clean and oiled. This stops problems and helps your work go smoothly.

Post-Processing

After you finish the main stamping steps, you need to focus on post-processing. This stage makes your aluminum parts look better and work better. You want each part to meet high standards before it leaves the factory. Post-processing helps you remove rough spots, improve the surface, and protect the part from damage.

You can use several methods to finish your stamped parts. Each method has a special purpose. Here are some of the most effective techniques:

- Shot Blasting: You clean the surface by hitting it with tiny abrasive particles. This step removes dirt and gives the part a smooth finish.

- Deburring and Polishing: You take away sharp edges and smooth out rough areas. This makes the part safe to handle and improves how it looks.

- Anodizing: You use an electrochemical process to make the surface stronger. This step helps the part resist corrosion and wear.

- Electropolishing: You remove a thin layer of metal from the surface. This makes the part shiny and helps prevent rust.

- Cleaning: You wash away oils and residues left from the stamping process. Clean parts work better and look more appealing.

Tip: Good post-processing can make your metal stamping parts last longer and look more professional.

You should always check each part after post-processing. Use quality control tools to make sure every piece meets your needs. If you find a problem, you can fix it before the part goes to the next step. This careful approach helps you keep your metal stamping products at a high level.

When you use aluminum stamping, you get parts that are strong, light, and ready for many uses. The right post-processing steps help you get the best results from your stamping process.

Aluminum Properties

Lightweight

When you pick up aluminum parts, they feel light. Aluminum is much lighter than most other metals. This makes it a top choice for many jobs. You see aluminum in cars, planes, and electronics. It helps lower weight but still stays strong.

Here is how aluminum compares to other metals:

- Aluminum’s density is about 2.70 g/cm³.

- Iron’s density is 7.87 g/cm³.

- Copper’s density is 8.96 g/cm³.

- Steel’s density is 7.85 g/cm³.

- Titanium’s density is 4.54 g/cm³.

- Aluminum is about one-third as dense as steel and copper.

This is why aluminum is great for things that need to be light. Aluminum stamping makes parts easy to move and carry. Lighter parts save energy and cost less to ship. Cars with aluminum use less fuel. Devices with aluminum are easier to hold.

Tip: Using aluminum can help you keep things light and work better.

Ductility

Aluminum can bend and stretch without breaking. This is called ductility. You need ductile metals to make shapes that are tricky. Aluminum lets you make parts with smooth edges and cool designs.

Check out how ductile some aluminum alloys are:

| Alloy | Heat Treatment | Elongation at Break (at 77°F) |

|---|---|---|

| Aluminum 3003 | O (Annealed) | 40% |

| Aluminum 5052 | O | 30% |

| Aluminum 6061 | O | 30% |

These alloys can stretch a lot before they snap. You can stamp, bend, and shape aluminum many ways. You do not have to worry about cracks. Aluminum stamping gives you strong parts that fit your needs.

Note: Ductile aluminum lets you make thin, tough, and detailed parts for lots of jobs.

Corrosion Resistance

Aluminum does not rust like iron or steel. It stands up to water, chemicals, and salt. Aluminum makes a thin layer on its surface. This layer keeps the metal safe from damage.

This helps you in many ways. Aluminum parts last longer outside or in wet places. You use aluminum for outdoor gear, kitchen stuff, and boats. It does not get ruined by water or air. Aluminum stays strong and looks good for a long time.

You do not have to fix or replace aluminum parts as much. Aluminum stamping gives you parts that stay tough, even in hard places.

Tip: If you want parts that last and look nice, aluminum is a good pick.

Conductivity

Aluminum is a metal that lets electricity move through it. Stamped aluminum parts work well for electrical jobs. You see aluminum used in wires and connectors. Many companies pick aluminum because it helps send electricity where it is needed.

Copper is known for being very good at carrying electricity. Aluminum’s conductivity is about 60% of copper’s. This means aluminum is not as good as copper, but it still works for many uses. Aluminum is chosen when weight is more important than top conductivity.

| Metal | Relative Electrical Conductivity (%) | Common Uses in Stamping |

|---|---|---|

| Copper | 100 | Wires, connectors, busbars |

| Aluminum | 60 | Power cables, housings, contacts |

| Steel | 10 | Structural parts, brackets |

Aluminum is used in power lines because it is lighter than copper. Lighter wires are easier to put up and hold in place. Aluminum is also found in car electrical systems. Lighter parts help cars use less gas and go faster.

Aluminum does not rust easily. This keeps electrical connections safe and strong. You do not have to worry about rust stopping the flow of electricity. Stamped aluminum parts work well even in wet or salty places.

Tip: Aluminum is a smart choice if you want light parts that carry electricity.

Aluminum can be shaped into thin sheets and tricky forms. Stamping helps make connectors and shields that fit your needs. These parts work well in electronics, appliances, and cars. Aluminum’s conductivity helps send signals fast and keep power steady.

Aluminum also costs less than copper. Copper is heavier and more expensive. Aluminum gives good conductivity for less money. You can make lots of stamped parts without spending too much.

Aluminum’s conductivity helps you make products that last. Stamped aluminum parts give steady performance. You can trust aluminum to send electricity where you need it.

When you pick aluminum stamping, you get light weight, good conductivity, and strong resistance to rust. These parts help your products work better and last longer. Aluminum makes your job easier and your results more reliable.

Stamped Aluminum Parts Techniques

Flattening

Flattening makes stamped aluminum parts smooth and flat. You use this step to fix bends or curves from before. You press the part between flat dies. The pressure makes the surface straight. Parts fit together better and look nice. Flattening gets the part ready for coating or assembly. If you want parts with tight tolerances and a good finish, flattening is important.

Tip: Always check the part after flattening. Smooth parts work better and last longer.

Swaging

Swaging changes the shape of stamped aluminum parts. You squeeze or hammer the metal to make new shapes. Swaging makes ends smaller or adds grooves. You do not cut the metal. You use force to mold the aluminum. Swaging makes parts stronger. When you swage a pin or tube, it gets tougher. Cold-working makes the part resist bending and breaking. Swaged parts last longer and work well in tough places.

You use swaging for connectors, fasteners, or fancy edges. Swaging gives stamped aluminum parts more strength and longer life. You also get parts that look neat and fit tight.

Piercing

Piercing punches holes or shapes in stamped aluminum parts. You use a sharp die and a press to cut the metal. Piercing makes slots, holes, or patterns for screws, wires, or air. You need good control for clean edges and the right size. Piercing works well for thin sheets and tricky designs.

Check out the tolerances you can get with piercing:

| Material Type | Common Gauge Tolerance | Piercing Tolerance Capability |

|---|---|---|

| Aluminum | ±0.004″ | ±0.002″ |

Stamped aluminum parts can have very tight tolerances. This means your parts fit together well and work right. Piercing saves time and cuts down on waste. You can make lots of holes fast and keep each part the same.

Note: Piercing lets you change the size or shape of holes to fit your needs.

When you use flattening, swaging, and piercing, you get stamped aluminum parts that meet high standards. These steps help you make parts for cars, electronics, and appliances. Stamped aluminum parts are strong, smooth, and exact. You can trust these methods to give you good results every time.

Coining

Coining is a special technique you use when making stamped aluminum parts. You press the aluminum with very high force. This force changes the surface and makes it smoother and more detailed. You can add logos, numbers, or patterns to the metal. Coining helps you get sharp lines and clear shapes on each part.

When you use coining, you do more than just shape the metal. You also make the surface harder. The pressure from coining squeezes the aluminum and packs the atoms closer together. This process is called work hardening. You get stamped aluminum parts that last longer and resist bending or scratching.

- Coining applies high pressure to aluminum, which can enhance its surface hardness.

- The process leads to work hardening of the material, increasing its durability and resistance to deformation.

You often choose coining for stamped aluminum parts that need to look perfect. You can make coins, badges, or decorative pieces. You also use coining for parts that need to fit tightly with other pieces. The smooth surface helps you avoid problems when you assemble products.

Here is how coining works step by step:

- Place the aluminum sheet in the stamping press.

- Use a die with the design you want.

- Press the die into the aluminum with high force.

- Remove the part and check the details.

You can see the difference after coining. The stamped aluminum parts have crisp edges and a shiny finish. You do not see rough spots or blurry lines. The surface feels harder when you touch it. You get parts that look and feel better.

Coining also helps you control the thickness of stamped aluminum parts. You can make some areas thinner or thicker. This is useful when you need parts with special shapes or features. You can make raised letters or deep grooves. The technique gives you more options for design.

You should always inspect stamped aluminum parts after coining. Look for sharp details and smooth surfaces. If you see any problems, you can adjust the pressure or change the die. Good coining gives you reliable results every time.

Tip: Use coining when you want stamped aluminum parts with strong surfaces and clear designs. This technique helps your products stand out and last longer.

Stamped aluminum parts made with coining are popular in many industries. You see them in electronics, cars, and home appliances. The hard surface protects the part from wear and tear. You get parts that work well and look great.

If you want stamped aluminum parts that meet high standards, try coining. You will notice the difference in quality and durability. Coining gives you the power to create parts that fit your needs and impress your customers.

Applications

Automotive

Aluminum is used a lot in cars. Car makers stamp aluminum to make light panels and brackets. These parts help cars go faster and use less gas. You get strong bumpers, doors, and hoods. These protect you and last a long time. Aluminum does not rust, so cars look new longer. Many industries pick stamped aluminum for safety and style.

AFI Industrial Co., Ltd. makes custom aluminum parts for cars and trucks. You can order one piece or thousands of them. Their machines shape aluminum to exact sizes for each job. You get parts that fit well and meet strict rules. Aluminum stamping in cars includes engine covers, trim, and battery cases. Lighter cars work better and use less fuel.

Aerospace

Aluminum is very important in airplanes and space vehicles. You need parts that are light but strong. Airplanes use aluminum alloys for wings and panels. These alloys lower weight and help save fuel. You get safer flights and equipment that lasts longer.

Here is how aluminum stamping helps in aerospace:

| Evidence | Description |

|---|---|

| Aluminum Alloys | Special aluminum alloys are strong and light, perfect for aerospace. |

| Hot Stamping Process | Hot stamping shapes tricky parts and keeps aluminum strong. |

| Weight Savings | Using aluminum in a B-pillar saves over 3 kg compared to boron steel. |

| High-Temperature Forming | Forming aluminum at high heat makes it easier to bend and shape. |

| Material Properties | AA2198 aluminum-lithium alloy fights damage and wear, great for aerospace parts. |

AFI Industrial Co., Ltd. makes stamped aluminum parts for planes, satellites, and drones. You get parts that meet tough aerospace rules. Their team can make test pieces or big batches. Aluminum stamping in aerospace helps you build lighter and safer flying machines.

Electronics

Aluminum stamping shapes many electronics you use every day. You find aluminum in phones, laptops, and smart home devices. Aluminum keeps electronics cool and safe from harm. You get nice designs and good performance.

Common electronics made with aluminum stamping are:

- Cameras

- Computer electronics

- Smart phones

- Smartwatches

- Sensors

- Speakers

- Video doorbells

- Smart locks

- Smart hubs and controllers

- Wearable fitness trackers

- LED lighting

- Augmented reality devices

- Smart home technology

Aluminum stamping in electronics makes cases, connectors, and heat sinks. You see aluminum in cleaning robots and kitchen gadgets. AFI Industrial Co., Ltd. gives stamped aluminum parts to electronics companies. You can order one part or many. Their machines make sure every part fits and works well.

Aluminum helps electronics last longer and look better. You get light devices that are easy to carry. Many industries trust stamped aluminum for strength and style. Aluminum stamping gives you great results for all your electronics needs.

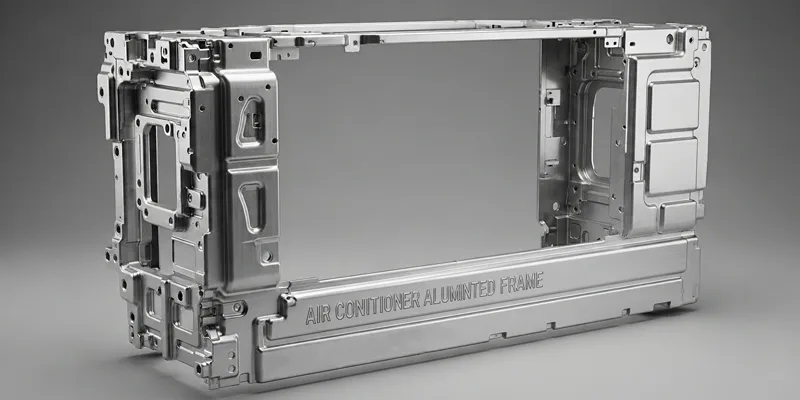

Home Appliances

Aluminum stamping helps home appliances work well and last longer. You see these aluminum parts in many things at home. They make appliances light, strong, and stop rust. Aluminum makes your devices look good and work better.

You find aluminum stamping in fridges, washers, microwaves, and air conditioners. Kitchen gadgets also use stamped aluminum. These parts are panels, brackets, covers, and frames. They help appliances run smoothly and look modern. Aluminum does not rust, so appliances stay shiny for years.

AFI Industrial Co., Ltd. gives advanced stamping for home appliances. Their team uses over 100 high-tech machines for shaping aluminum. You can order one part or thousands for big jobs. AFI helps you meet strict rules and keeps costs low.

When you work with AFI, you get more than just parts. You get a partner who knows what you need. Their engineers help design molds and pick the right aluminum alloy. You can trust AFI to deliver parts that fit and work well.

Here is how AFI’s processes help home appliance makers:

| Process Type | Benefits |

|---|---|

| Precision Stamping | Makes production faster and saves money |

| CNC Turning/Milling | Keeps size within ±0.01mm, stops gaps |

| Stamping and Sheet Metal | Uses 30% more material, saves on buying sheets |

You see these results in your finished appliances. Precision stamping makes many parts fast and keeps sizes the same. CNC turning and milling stop gaps when you put parts together. Stamping and sheet metal work save money by using more of each sheet.

Tip: Aluminum stamping helps you build appliances that are lighter, stronger, and use less energy.

You also get more choices for finishes. AFI offers anodizing and electroplating for better looks and longer life. These finishes protect against scratches and stains. You can pick colors and textures for your brand.

If you want to test a new design, AFI can make a sample for you. When you need a big order, their machines can make lots of parts fast. You get high quality whether you order one or ten thousand.

Aluminum stamping lets you make home appliances that stand out. You get products that are easy to use, safe, and stylish. With AFI Industrial Co., Ltd., you get help for every step. Your appliances work better, look better, and last longer with stamped aluminum parts.

Stamping Challenges

Material Handling

You face some problems when you work with aluminum in stamping. Aluminum acts in special ways that change how you use it. When aluminum gets older and harder, its yield strength goes up. This makes it tougher to shape the edges during stamping. You also need different dies than you use for cold-rolled sheets. Aluminum’s surface can easily get oxidized. You must use special packaging to keep it safe from air.

Here is a table that shows the main challenges:

| Challenge Description | Details |

|---|---|

| Material Properties | After aging hardening, the yield strength of aluminum sheets increases, reducing their edge-forming processability. |

| Tooling Requirements | Differences in die requirements compared to cold-rolled sheets must be considered when stamping aluminum. |

| Surface Management | The surface of aluminum is prone to oxidation and requires special packaging to prevent exposure. |

You need to watch these things closely. If you ignore them, your stamped aluminum parts may have problems. Careful handling helps you get good results every time.

Tool Wear

When you stamp aluminum, tools wear out in a different way than with other metals. Uncoated MS1 inserts get rougher after lots of use. This means they wear down fast. Coated inserts stay smoother and only get small scratches. Aluminum wears out uncoated tools more than steel does. You should pick the right coatings for your tools. This helps your stamping process work well and keeps your parts looking nice.

Tip: Use coated tools when stamping aluminum. This lowers wear and keeps your parts smooth.

Quality Control

Quality control matters a lot in metal stamping. You want every aluminum part to be high quality. There are many ways to make sure your stamped aluminum parts are always good.

- Check raw materials carefully.

- Keep your tooling exact for each job.

- Make your equipment and process better.

- Handle every part with care.

- Teach your team to care about quality.

You can use new technology to help with quality control.

- Try laser checks for automatic testing.

- Build strong systems for safety and rules.

- Find tiny problems with special tools.

Quality control is a big part of making things. You need to make sure every aluminum part works well and lasts long. Many companies buy new tech to make quality even better. These steps help you meet tough standards in today’s market. When you focus on quality, you get good stamping results and happy customers.

Aluminum stamping is special because it makes strong and light parts. The finish looks smooth and nice. New smart machines help the process go faster. They also make it more reliable.

- Hot stamping gives new facts for science.

- Adaptive manufacturing keeps parts good.

- Predictive maintenance stops long breaks.

- Making things lighter lowers CO2.

| Benefit | Aluminum Stamping | Other Metal Stamping |

|---|---|---|

| Surface Finish | Excellent | Varies |

| Strength-to-Weight | High | Varies |

| Cost-Effectiveness | High | Varies |

You will see more robots and digital tools soon. There will be more green ways to make things. Try aluminum stamping to find new ideas for your projects.

FAQ

Aluminum stamping uses a die and press to shape flat sheets. You get parts that are strong, light, and exact. This process works for cars, electronics, and home appliances.

Pick aluminum if you want lighter parts that do not rust. Aluminum bends easily and helps save energy in cars and planes. Steel is better for heavy jobs, but aluminum gives more design choices.

AFI checks every step, from start to finish. You get parts with tight sizes and smooth surfaces. Their team uses smart machines and strict checks to keep quality high.

Yes, you can order custom parts from AFI. Their engineers help you design and make what you need. You can get one sample or thousands of pieces.

Aluminum stamping is used in cars, planes, electronics, and home appliances. These industries need parts that are light, strong, and do not rust. Aluminum stamping helps products last longer and work better.

You can pick anodizing, electroplating, polishing, or shot blasting. These finishes protect your parts and make them look nice. AFI offers many choices for your project.

Handle sheets gently and use coatings or lubricants. Clean work areas and smooth dies help stop scratches. AFI uses special steps to keep your parts looking good.

Yes, aluminum stamping is great for making lots of parts. You get fast and repeatable results with high accuracy. AFI’s smart machines make thousands of parts quickly and keep quality steady.