Brushed

Delicate as silk, shiny as a mirror – drawing surface treatment, for your products to give extraordinary texture and lasting charm! AFI Industries Co., Ltd. offers a wide range of customized surface drawing services!

Brushed Process

Metal brushed is a combination of mechanical friction and chemical corrosion process, mainly used to form a layer of uniform macroscopic lines on the surface of the metal, so as to obtain a non-mirror-like metallic luster, with strong decorative effect.

Lipid Ester

Remove oil from metal surface to prepare for subsequent wire-drawing treatment.

Sandmill

The metal surface is treated using a wire drawing machine to create the desired texture and texture. Drawing methods are straight, random, corrugated, spiral and so on.

Rinse

Clean and maintain metal surfaces after wire-drawing treatment to extend their service life and keep them beautiful.

Custom Brushed service

AFI Industrial Co., Ltd. is committed to providing customers with excellent custom drawing services, through exquisite craftsmanship and personalized design, to give your product surface a unique metallic texture and beautiful appearance. Whether it is a subtle hair line or a bold straight line, we can create it precisely according to your needs and specifications, ensuring that every product shows exceptional quality and unique style.

About the brushed Surface

The metal surface before drawing is usually smooth and untextured, and may appear relatively plain and featureless; The brushed metal surface presents a fine or rough texture, which not only enhances the beauty of the metal, but also gives it a unique touch and gloss, making it more visually attractive and textured.

Before the Brushed Surface

After the Brushed Surface

Equipment for Drawing Wire

AFI Industrial Co., Ltd. has a complete range of drawing surface treatment equipment, which can be selected according to the different drawing needs of customers and the characteristics of the workpiece, to customize the best drawing results for customers.

Automatic Wire Drawing Machine

The automatic wire drawing machine continuously or intermittently forms textures on the metal surface through precisely controlled wire drawing rollers, generating beautiful wire-like textures and enhancing the decorative effect and surface texture of the metal.

Grinding and Drawing Machine

The grinding and drawing machine integrates the dual functions of grinding and wire drawing. It can conduct pre-treatment and post-treatment on the metal surface, thereby enhancing the appearance and surface quality of the product.

Brushed Surface Treatment Material

Brushing treatment is suitable for metal materials such as stainless steel, aluminum, copper (brass/bronze) and iron. It can make the metal surface present various fine stripes, which not only enhances wear resistance but also appears high-end – for example, the metal frame of a mobile phone, the stainless steel countertop of a kitchen, and vintage copper ornaments can all be treated in this way.

However, plastics or coated metals are not suitable for wire drawing as they are prone to scratches or color fading.

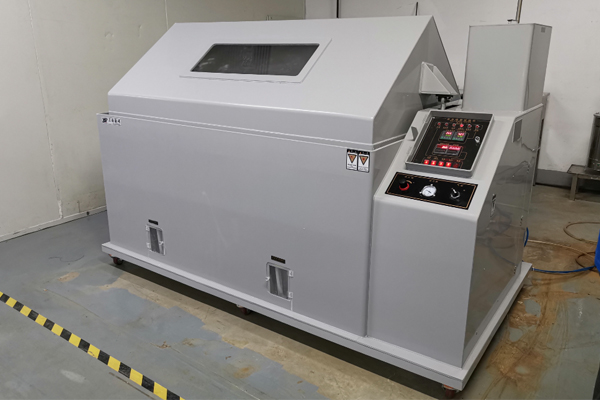

Wire Drawing Test Equipment

The quality inspection of wire drawing surface treatment process involves many aspects of inspection equipment. AFI Industrial Co., Ltd. offers comprehensive inspection solutions for wire drawing surface treatment through inspection equipment, ensuring product quality and precise process control.

Hardness tester

Tensile testing machine

Finish meter

Salt spray testing machine

How to Start Your Order

Your satisfaction and trust are our eternal pursuits. Let us work together to create excellent quality and service, and witness every moment of success.

Frequent Asked Questions

Brushing treatment is suitable for metal materials such as stainless steel, aluminum, copper (brass/bronze) and iron. It can make the metal surface present various fine stripes, which not only enhances wear resistance but also appears high-end – for example, the metal frame of a mobile phone, the stainless steel countertop of a kitchen, and vintage copper ornaments can all be treated in this way.

The brushed texture has straight lines, which are unidirectional continuous patterns and can be unidirectively sanded with a abrasive belt. Random patterns, they are irregularly interwoven patterns and can be randomly polished with a nylon wheel. Spiral patterns, their concentric circle patterns can be processed by machine tool rotation. Threads, they have spiral patterns and are processed by special rolling tools. Our company can create exclusive brushed textures for customers according to their demands.

AFI Industrial Co., Ltd. usually has a Ra of 0.4 to 3.2μm, which is finer than sandblasting (sandblasting Ra 1.6 to 12.5μm).