Anodizing

The revolution in metal surface treatment, anodizing technology, provides a strong protective coating for your products. AFI Industrial Co., Ltd. provides superior surface treatment solutions for titanium and other metal materials using advanced oxidation processes.

Anodizing Process

Anodizing is a metal surface treatment technique that forms an oxide film on the surface of a metal by electrochemical oxidation. This process is usually carried out in an electrolyte solution, with a metal or alloy acting as the anode, on which an oxide film is formed by the action of an impressed current. This oxidation technology is widely used in aluminum alloy, magnesium, titanium, and other metals, among which sulfuric acid anodized is the most common treatment method.

Rinse

Clean impurities such as oil and dust on the metal surface to ensure that the surface is clean, to ensure the quality of the anodized effect.

Acid pickling

The metal is soaked in an acidic solution for pickling treatment to remove the oxide, oxide, etc., on the surface of the metal to improve the anodic oxidation effect.

Anodizing

Select the appropriate electrolyte and DC power supply, control the electrolytic time, and obtain the required thickness of the oxide film.

Put Colour On

The coloring of the anodic oxide film can be divided into electrolytic and chemical coloring, by coloring to obtain the customer’s required color.

Hole Sealing

The anodized or colored aluminum plate is put into the sealing solution to seal the micro holes in the oxidation layer, improving its corrosion resistance and sealing performance.

Custom Anodizing Service

AFI Industrial Co., Ltd. provides anodizing services to its customers. We use advanced anodizing technology to provide customized anodize solutions and can perform specified anodizing services according to customers’ specific color plate requirements to meet the quality control acceptance standards of anodized processes. Our anodizing services are widely used in the construction, automotive, aerospace, electronics, and consumer goods industries to meet the quality needs of our customers.

About Anodizing

Before anodizing, the surface of the metal is prone to scratches and rust, and the color is only the monotonous original color of the metal. After anodize, the hardness of the metal increases, it is less prone to corrosion, and can be dyed in various colors.

Preanodize

Post-anodized

Anodizing Equipment

AFI Industrial Co., Ltd. has a complete range of anodized equipment and multiple automated production lines, which can not only provide customers with high-quality surface treatment for their products, but also handle the anodize work of large quantities of products at the same time to ensure the consistency of color of the entire batch of customers’ products.

Automatic Production Line

We have automatic production lines specifically for large-scale anodizing of materials such as aluminum, magnesium, and titanium, which can achieve fully automatic operation from pre-treatment to post-anodizing treatment, quickly and in large quantities, meeting the product demands of customers.

Ultrasonic Cleaning and Drying Equipment

Ultrasonic cleaning utilizes the tiny bubbles generated by high-frequency vibration to efficiently remove oil stains, dust, oxide layers, or other contaminants from complex structures, micro-pores, and crevices. After cleaning, the drying equipment needs to thoroughly dry the residual moisture or chemical reagents on the surface of the workpiece.

Anodizing Materials

Aluminum and aluminum alloys are the most suitable materials for anodizing. They are naturally prone to oxidation, and anodizing can form a thicker and harder oxide layer, which is widely used in mobile phones, notebook casings, automotive parts, and some household electrical appliances.

Magnesium and magnesium alloys, due to their high reactivity during anodized, require micro-arc oxidation before conventional anodizing. They are also frequently used in aerospace, electronics, and electrical fields.

After anodized titanium and titanium alloys, the oxide film can show rainbow colors, has good biocompatibility, and is often used in medical equipment.

Zinc and zinc alloys can also undergo anodized, but the effect is not very good, and it is usually only used for temporary rust prevention.

Our company can customize the anodizing effect for you based on the specific requirements of your materials, meeting the quality requirements of your products.

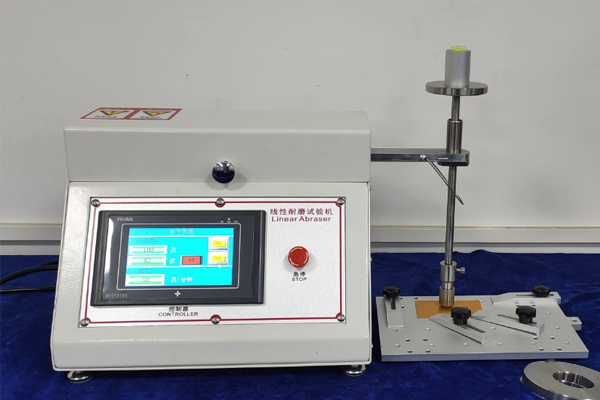

Anodizing Test Equipment

The quality testing of the anodize process involves many aspects of the testing equipment, AFI Industrial Co., Ltd. through the testing equipment to ensure the quality and stability of the anodize process, through the accurate measurement of oxide film thickness, wear resistance, density, and other key parameters to meet the quality requirements of the product.

Coating Thickness Gauge

Hardness Testing Equipment

Falling Sand Wear Tester

Admittance Tester

How to Start Your Order

Your satisfaction and trust are our eternal pursuits. Let us work together to create excellent quality and service, and witness every moment of success.

Frequent Asked Questions

Its main function is to resist corrosion and abrasion. So that metal parts are not easy to oxidize and corrode in the atmosphere, seawater, and other environments. At the same time, the oxidized film can make the original metal surface hardness increase by 5 times, which greatly improves the wear resistance of the parts. Secondly, it can make the surface of the parts into different colors, and play a decorative, beautiful effect.

The time required for anodizing depends on the size, structure, thickness of the oxide layer, and the type of anodizing agent used for metal products. Our company usually completes the anodized of samples and small batches within one day. The anodizing time for large quantities is 2 to 3 days.

Both common anodized and hard anodized can play a role in corrosion resistance. Hard anodized has higher hardness and wear resistance than ordinary anodized. Therefore, hard anodized is used for highly wear-resistant components such as engine cylinders, pistons, bearings, and gears. In addition, the hard anode also has excellent insulation performance and is suitable for electronic components that require good insulation. Ordinary anodes can be made in various colors, and thus are often used in architectural decoration, furniture hardware, car wheels, etc. Our company can select different anodizing methods according to the functions that customers need to achieve.

From the preparation work before oxidation to the post-oxidation treatment, we will follow industry standards and strictly control the quality of every link. For the finished products, we will inspect the appearance, film thickness, hardness, and corrosion resistance of the anodized products through visual inspection, instrument inspection, and salt spray test to ensure that every product received by the customer is qualified.

Not all metals can be anodized; it is usually only used for aluminum, titanium, and magnesium finishes. This is because the properties of these metals combine easily with oxygen, which allows the anodized process to take place.

It is a complex process that requires specialized equipment and chemicals. It is best done by professionals to ensure that the process is performed safely and correctly. Attempts by non-professionals to do it on their own can be dangerous and result in poor quality.