Custom

Dryer Machine Parts

AFI Industrial Co., Ltd. professional CNC dryer machine parts customization, one piece MOQ, support mass production, 2 hours quick response, for you to reduce the failure rate of equipment, contact us immediately, get a exclusive quote.

About the Dryer Machine Parts

Element oxidation fracture, local overheating problem, AFI Industrial Co., Ltd. Nickel-chromium alloy material, diameter tolerance control ±0.02mm, surface finish Ra≤0.4μm, temperature resistance up to 1300℃, can accurately control the heat flow distribution, its heating efficiency increased by 35%.

Multi-dimensional sensor, integrated temperature and humidity dual sensing module, we monitor the chamber environment in real time, humidity detection accuracy of ±1.5% RH, temperature error ≤0.5℃, optimize the drying path through the dynamic algorithm, help you avoid fabric shrinkage and deformation, reduce energy consumption by 12%.

High-strength conveyor belt, we use carbon steel substrate nitriding treatment, tensile strength ≥600MPa, with CNC stamping of the chain structure (aperture positioning accuracy ±0.1mm), it achieves 100,000 cycles of load without deviation operation, effectively helps you prevent material stuck and belt breakage.

For the air-tight door seal system, we adopt the silicone sealing strip molded into one body, the hardness deviation is ±3 Shore A, and the radial runout of the hinge shaft core is less than 0.01mm. It realizes the opening and closing life of 150,000 times without attenuation, and the heat loss rate of the cavity is reduced to less than 3%.

AFI Industrial Co., Ltd.Dryer Machine Parts maintain consistent performance under extreme temperature and humidity conditions, key size yield ≥99.8%. It can help you shorten the equipment failure shutdown cycle by 40%, and reduce the whole machine repair cost caused by the parts matching error, helping you to achieve energy efficiency upgrade and product differentiation competition.

Consult now to get solutions!

Custom Dryer Machine Parts Service

AFI Industrial Co., Ltd. is dedicated to customizing all kinds of dryer machine parts for customers. Whether it is customized motor parts, heating elements, or customized sensor parts, we can provide you with professional customization to meet your individual needs for dryer parts, so that your dryer operation is more efficient, stable, long-term, for your life and work to bring intimate convenience.

Dryer Machine Parts Production

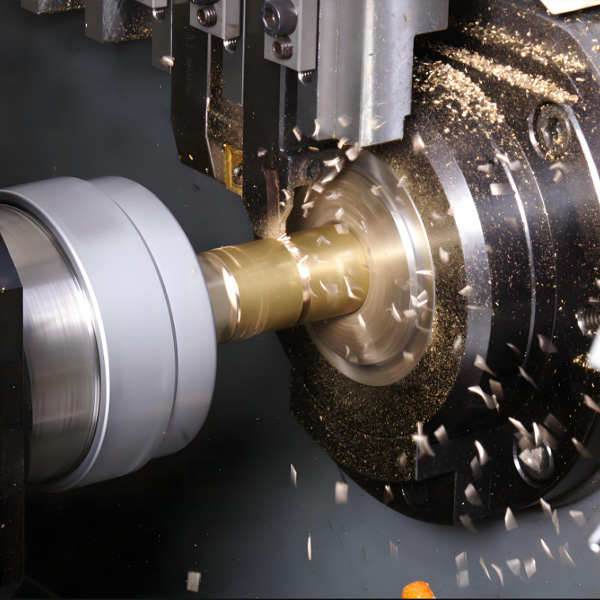

Your equipment is noisy, has a short service life, and is structurally unstable? AFI Industrial Co., Ltd. has specialized in CNC precision manufacturing for 15 years, providing you with dryer machine parts.

We use CNC turning, for the sensor housing, gear shaft and other rotating parts, multi-axis joint turning technology, the diameter tolerance is stable control within ±0.02mm, surface roughness Ra≤0.8μm, it ensures the transmission system low friction, low noise operation, extend the bearing life of more than 30%.

CNC milling, used for heating element bracket, conveyor guide rail, and other complex structural parts processing, profile accuracy of ±0.05mm, flatness ≤0.1mm/m², solves the problem of assembly dislocation caused by traditional milling, to help you improve the overall structural stability of the equipment.

Precision gear hobbing, for the dryer gear box transmission gear group, the application of full closed-loop gear hobbing process, tooth profile error ≤5μm, tooth surface roughness Ra0.4μm, reduces the transmission loss by 15%, significantly reduces abnormal vibration and noise.

Precision casting, using silica sol investment casting process to produce door sealing base and filter frame, with casting wall thickness uniformity deviation ≤±0.3mm, its surface density increased by 40%, to eliminate the risk of porosity and cracks in high temperature environment.

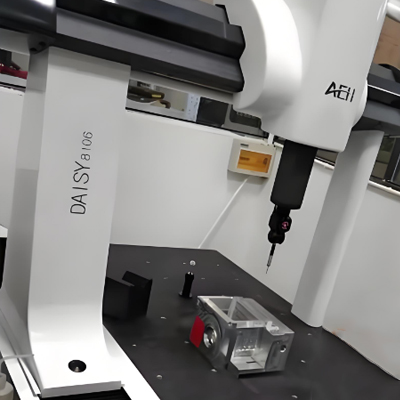

In strict accordance with the ISO 9001 certification system, we achieve 100% dimensional accuracy online monitoring, surface defect detection rate ≥99.5%. Enables your equipment to ensure the life of parts in 80℃ high humidity environment for more than 100,000 cycles.

Contact us today to shorten the production cycle of your dryer!

Dryer Machine Parts Quality

The product quality is guaranteed by AFI Industrial Co., Ltd. The fundamental basis on which a company relies for survival and development. We strictly control the quality in every link from the purchase of raw materials, the production of semi-finished products, surface treatment, to the shipment of finished products to ensure that all the products received by customers are qualified.

Materials Quality Control

Select materials from qualified suppliers for dryer machine parts processing.

Accuracy and Tolerance

In strict accordance with the customer’s drawings, the accuracy is controlled within the tolerance range.

Performance Index

The quality department to do a good job of control, and strive to meet customer performance indicators.

Durability

Do a good job of surface treatment after processing, so that the dryer machine parts have good durability.

Compatibility

Make sure the dryer machine parts are compatible with other accessories according to the drawing.

Company Strength

AFI Industrial Co., Ltd is a private investment corporation that is situated in Dongguan City, Guangdong Province of China. We provide our customers with CNC turning, CNC milling, stamping, sheet metal, bending, and other services for custom parts. Our products are widely applied in areas like mechanical equipment, aerospace, aviation, electric appliances, medical care, instruments, IT, AI products, etc. Our goal is to satisfy customers and offer them better and more convenient service.

As an integrated industrial and trade enterprise, we have no middlemen between us and foreign customers, which reduces the customer’s procurement links and the customer’s procurement costs, and truly achieves a win-win situation for both buyers and sellers.

We have professional engineering personnel to provide advanced and timely technical support, excellent production personnel and inspection personnel to control the product quality of each production link, and well-equipped inspection equipment, which is enough to enable us to produce high-quality products to meet the various needs of different customers.

We have a professional industrial product design team to help customers develop and design new products, test and proof, and help customers quickly achieve mass production of new products and occupy the market.

We have many loyal logistics companies that have opened up a smooth transportation channel between us and our customers, ensuring that each batch of goods can be delivered to customers safely, timely manner, and intact.

AFI Industrial Co., Ltd. adheres to the purpose of serving customers and always puts the interests of customers first. Customer needs are our goal.

Shipping

Packaging

We will select the appropriate packaging according to different products, and clearly mark it. So that it can be counted and used conveniently when you receive it. By sea, by air, or by land, whatever way you chase, we will prepare everything perfectly for you!

Transportation

We will choose a transportation method that saves costs and ensures timeliness for our customers based on the quantity, weight, and volume of the packaging of the transported products. No matter which mode of transportation is adopted, we will monitor the entire transportation process to ensure that the goods are delivered to our customers intact.

Our Promise

Cost

Paid production process with no markup

Quality

100% full inspection using CMM before shipment

Delivery Time

3-15 days delivery depending on quantity

Service

Fast response within 2h, fast quotation within 4h

Contact Us

Your satisfaction and trust is our eternal pursuit, let us work together to create excellent quality and service, witness every moment of success.