Custom

Telescope Parts

AFI Industrial Co., Ltd. manufactures telescope parts,Ensure component stability and durability to help you increase observation accuracy and equipment life. Focus on your core R&D and deliver reliable support.

About the Telescope Parts

We specialize in the production of telescope parts, providing manufacturers with core parts. Our tube connectors are made of aero-grade materials and an integrated molding process to ensure that the coefficient of thermal expansion is close to zero, avoid the focus shift caused by temperature fluctuations, and ensure the continuity of observation.

In response to the common “fine tuning stuck” problem in high-magnification observation, the gear mesh accuracy of our focusing mechanism gear group is controlled within ±2μm, and the friction coefficient is reduced by 30%, so that the celestial tracking is both delicate and silent, and can withstand the test of tens of thousands of repeated operations.

Traditional shaft bearings for a long time, been easy to produce return difference, which affects the tracking accuracy. Through the multi-axis linkage compensation design, the idling return difference is controlled within 0.001°, even bearing a large aperture mirror body, it can still achieve smooth celestial body following without lag. Helps you improve the fatigue resistance and durability of your telescope parts.

Have you ever experienced image jitter due to insufficient base rigidity? We strengthen the support surface with a honeycomb topology with a flatness of 0.005mm/m² and a 40% increase in vibration attenuation efficiency, providing a “zero interference” environment for ultra-long exposure observations.

You don’t have to compromise between “precision and cost” and “efficiency and durability” – we lower the threshold of customization through modular design, the same tolerance standard can be adapted to multiple types of equipment, helping you shorten the development cycle, reduce the frequency of equipment maintenance, and reduce long-term operating costs.

Custom Telescope Parts service

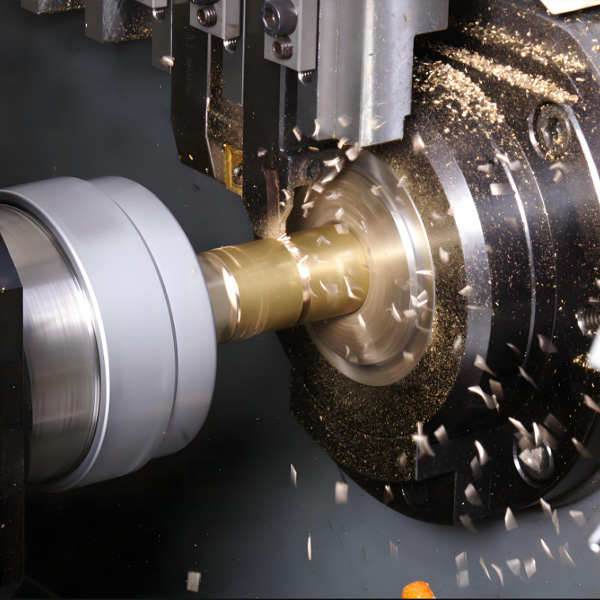

AFI Industrial Co., Ltd. has experience in cnc machining of telescope parts and can be customized according to your drawings or samples to meet your individual needs for special specifications, materials and processes.

We have a sound production process and efficient supply chain management, support the minimum order or mass production, 3-15 days delivery, to provide your telescope with lasting and stable operation guarantee, to help you seize the market opportunity.

Telescope Parts Production

Do you often encounter these troubles? The distortion of the mirror tube in extremely cold weather causes focusing failure, the gear is stuck for a long time, affects the observation efficiency, and the rotating shaft rusts in high humidity environment… These problems can be solved in advance from the telescope parts process!

To “X-ray” complex parts, such as the special-shaped structure of the mirror tube connector, we use five-axis dynamic milling to carve a “skeleton” with a ±0.008mm accuracy, which reduces the assembly gap by 60% than the traditional process. Given the problem that the slender mirror barrel is easy to bend, we use liquid nitrogen to cool the processing and shape the parts, so that the deformation of the parts is only 1/5 of the conventional process under the crazy temperature difference of -80℃ to 120℃. The feedback of the Antarctic research team is two words: worry!

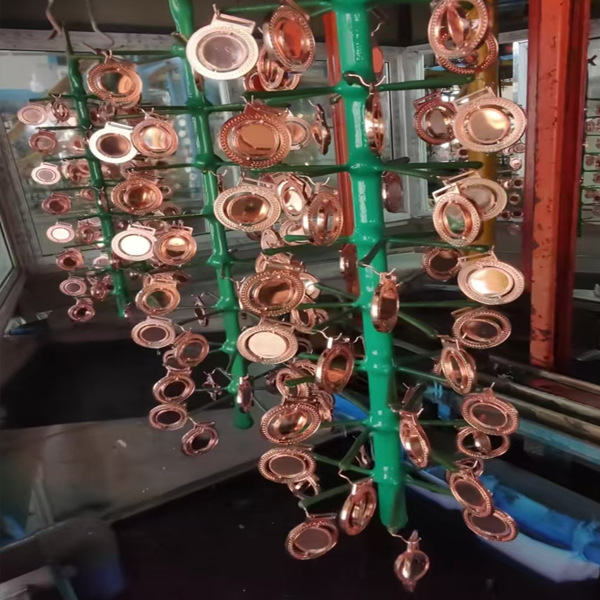

The focusing gear group is the most prone to “premature aging”. We put three layers of “protective clothing” on it. The bottom layer is rust-proof, the middle shock absorber, and the surface layer is embedded with silicon carbide particles. Measured after 100,000 cycles, the feel is smoother than the new gear, the observatory teacher said that this is “anti-common sense” durable.

The steel rotating shaft of the South Pole telescope used to freeze and crack, and now it has been cryogenically quenched at -196 ° C, and the grain is as fine as nano ceramics. Last year, the polar night of minus 89 °C still flexible rotation, and the service life was directly pulled up to 10 years.

Contact us immediately to obtain more production processes, allowing you to use them with peace of mind before installation and saving 30% of the time for commissioning and rework.

Telescope Parts Quality

The product quality is guaranteed by AFI Industrial Co., Ltd. The fundamental basis on which a company relies for survival and development. We strictly control the quality in every link from the purchase of raw materials, the production of semi-finished products, surface treatment, to the shipment of finished products to ensure that all the products received by customers are qualified.

Materials Quality Control

Select materials from qualified suppliers for telescope parts processing.

Accuracy and Tolerance

In strict accordance with the customer’s drawings, the accuracy is controlled within the tolerance range.

Performance Index

The quality department to do a good job of control, and strive to meet customer performance indicators.

Durability

Do a good job of surface treatment after processing, so that the telescope parts have good durability.

Compatibility

Make sure the telescope parts are compatible with other accessories according to the drawing.

Company Strength

AFI Industrial Co., Ltd is a private investment corporation that is situated in Dongguan City, Guangdong Province of China. We provide our customers with CNC turning, CNC milling, stamping, sheet metal, bending, and other services for custom parts. Our products are widely applied in areas like mechanical equipment, aerospace, aviation, electric appliances, medical care, instruments, IT, AI products, etc. Our goal is to satisfy customers and offer them better and more convenient service.

As an integrated industrial and trade enterprise, we have no middlemen between us and foreign customers, which reduces the customer’s procurement links and the customer’s procurement costs, and truly achieves a win-win situation for both buyers and sellers.

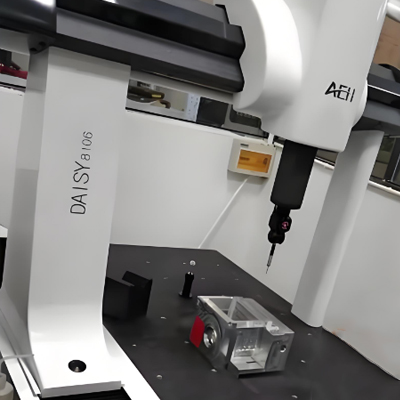

We have professional engineering personnel to provide advanced and timely technical support, excellent production personnel and inspection personnel to control the product quality of each production link, and well-equipped inspection equipment, which is enough to enable us to produce high-quality products to meet the various needs of different customers.

We have a professional industrial product design team to help customers develop and design new products, test and proof, and help customers quickly achieve mass production of new products and occupy the market.

We have many loyal logistics companies, that have opened up a smooth transportation channel between us and our customers, ensuring that each batch of goods can be delivered to customers safely, timely, and intact.

AFI Industrial Co., Ltd. adheres to the purpose of serving customers and always puts the interests of customers first. Customer needs are our goal.

Shipping

Packaging

We will select the appropriate packaging according to different products, and clearly mark it. So that it can be counted and used conveniently when you receive it. By sea, by air, or by land, whatever way you chase, we will prepare everything perfectly for you!

Transportation

We will choose a transportation method that saves costs and ensures timeliness for our customers based on the quantity, weight, and volume of the packaging of the transported products. No matter which mode of transportation is adopted, we will monitor the entire transportation process to ensure that the goods are delivered to our customers intact.

Our Promise

Cost

Paid production process with no markup

Quality

100% full inspection using CMM before shipment

Delivery Time

3-15 days delivery depending on quantity

Service

Fast response within 2h, fast quotation within 4h

Contact Us

Your satisfaction and trust is our eternal pursuit, let us work together to create excellent quality and service, witness every moment of success.