Custom

Train Parts

AFI Industrial Co., Ltd. produces train parts, through strict quality testing, support customized requirements, stable delivery cycle, help you improve train operation safety and efficiency.

Consult now to get a free sample!

About the Train Parts

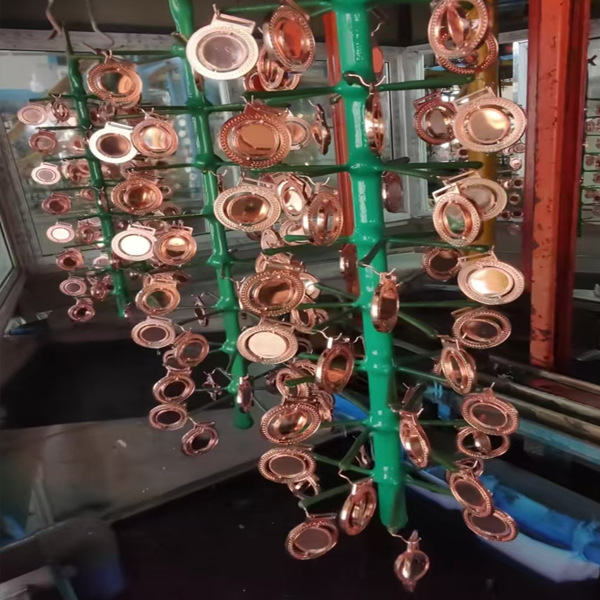

We specialize in manufacturing a full range of railway accessories such as train wheels, axles, bogies, brake discs, buffers, connecting hooks, etc. We adopt high-quality alloy steel (such as AAR M-101, EN 13262 standards) and high-strength cast iron, and go through advanced processes such as precision forging, heat treatment, and ultrasonic flaw detection. Ensure that the product features ultra-high strength, wear resistance, impact resistance, fatigue resistance, and other characteristics.

Our components comply with international railway industry standards (IRIS, ISO 9001, AAR), and are widely used in high-speed railways, subways, freight trains, and locomotive vehicles. The products undergo strict quality inspections, and the defect rate is controlled below 0.2% to ensure the safety and reliability of train operation.

Contact us immediately to get a free sample or a customized solution!

Custom Train Parts Service

AFI Industrial Co., Ltd. supports you to provide drawings or samples, fast proofing, sample delivery cycle of 3-7 days.The minimum order quantity (MOQ) is flexible to meet your small batch trial production needs.

Our monthly production capacity can reach 100,000 pieces, the delivery cycle is generally 3 to 15 days, support urgent order production.

Train Parts Production

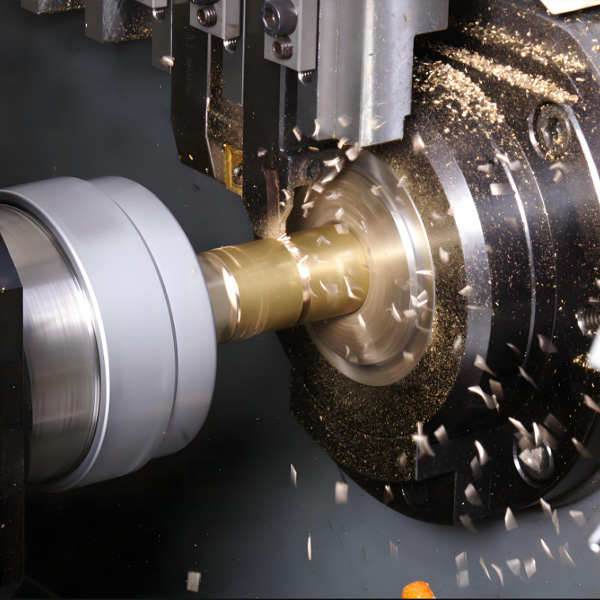

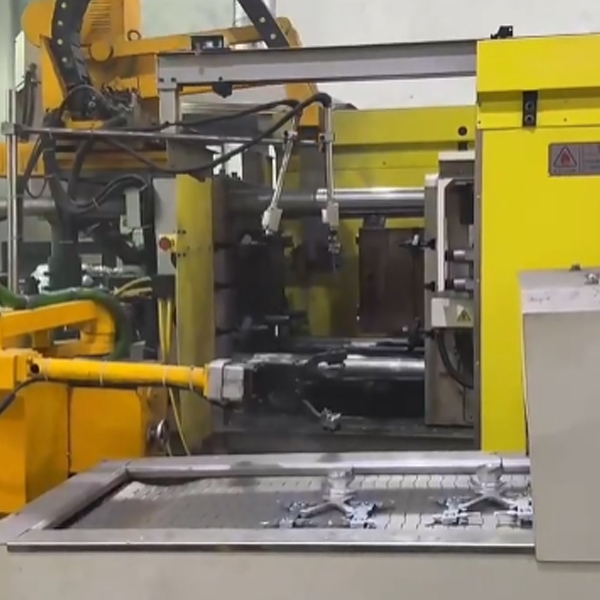

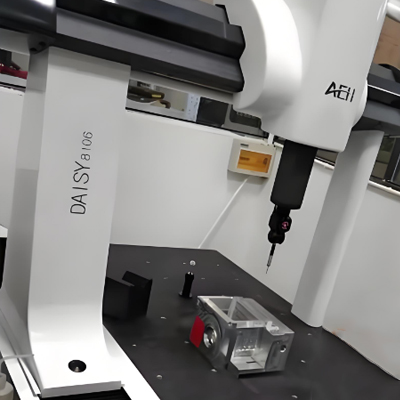

AFI Industrial Co., Ltd. has advanced machining equipment, equipped with five-axis CNC machine tools, turn-milling complex centers, and other high-precision equipment to meet your complex geometry machining needs.

We are very strict in quality control, using a coordinate measuring instrument (CMM) to detect dimensional accuracy, and tolerance can be controlled within ±0.01mm. It will also do salt spray testing, fatigue testing, impact testing, etc., to ensure that parts are reliable in extreme environments.

Our high-quality materials and advanced processes not only extend the service life of train parts but also reduce your maintenance costs. Efficient production and stable lead times also reduce your inventory pressure.

Contact us today to find out more technical parameters of train parts or get a quote!

Train Parts Quality

The product quality is guaranteed by AFI Industrial Co., Ltd. The fundamental basis on which a company relies for survival and development. We strictly control the quality in every link from the purchase of raw materials, the production of semi-finished products, surface treatment, to the shipment of finished products to ensure that all the products received by customers are qualified.

Materials Quality Control

Select materials from qualified suppliers for train parts processing.

Accuracy and Tolerance

In strict accordance with the customer’s drawings, the accuracy is controlled within the tolerance range.

Performance Index

The quality department to do a good job of control, and strive to meet customer performance indicators.

Durability

Do a good job of surface treatment after processing, so that the train parts have good durability.

Compatibility

Make sure the train parts are compatible with other accessories according to the drawing.

Company Strength

AFI Industrial Co., Ltd is a private investment corporation that is situated in Dongguan City, Guangdong Province of China. We provide our customers with CNC turning, CNC milling, stamping, sheet metal, bending, and other services for custom parts. Our products are widely applied in areas like mechanical equipment, aerospace, aviation, electric appliances, medical care, instruments, IT, AI products, etc. Our goal is to satisfy customers and offer them better and more convenient service.

As an integrated industrial and trade enterprise, we have no middlemen between us and foreign customers, which reduces the customer’s procurement links and the customer’s procurement costs, and truly achieves a win-win situation for both buyers and sellers.

We have professional engineering personnel to provide advanced and timely technical support, excellent production personnel and inspection personnel to control the product quality of each production link, and well-equipped inspection equipment, which is enough to enable us to produce high-quality products to meet the various needs of different customers.

We have a professional industrial product design team to help customers develop and design new products, test and proof, and help customers quickly achieve mass production of new products and occupy the market.

We have many loyal logistics companies that have opened up a smooth transportation channel between us and our customers, ensuring that each batch of goods can be delivered to customers safely, timely, and intact.

AFI Industrial Co., Ltd. adheres to the purpose of serving customers and always puts the interests of customers first. Customer needs are our goal.

Shipping

Packaging

We will select the appropriate packaging according to different products, and clearly mark it. So that it can be counted and used conveniently when you receive it. By sea, by air, or by land, whatever way you chase, we will prepare everything perfectly for you!

Transportation

We will choose a transportation method that saves costs and ensures timeliness for our customers based on the quantity, weight, and volume of the packaging of the transported products. No matter which mode of transportation is adopted, we will monitor the entire transportation process to ensure that the goods are delivered to our customers intact.

Our Promise

Cost

Paid production process with no markup

Quality

100% full inspection using CMM before shipment

Delivery Time

3-15 days delivery depending on quantity

Service

Fast response within 2h, fast quotation within 4h

Contact Us

Your satisfaction and trust is our eternal pursuit, let us work together to create excellent quality and service, witness every moment of success.