You want very exact shapes and close measurements? Pick drawing aluminum. Need tricky shapes, fast work, or to save money? Pick extrusion. Think about these main things:

- Strength

- Tolerances

- Surface finish

- Cost

- Application

Connect what your project needs to these strong points. This helps you get the best outcome for your needs.

Key Takeaways

- Pick drawn aluminum for easy shapes that need to be very exact and smooth.

- Use extruded aluminum if you want more complex shapes made quickly and for less money.

- Drawn aluminum has tighter tolerances, so it is best for jobs that need exact sizes.

- Extruded aluminum works better for making lots of parts at once, which saves time and money.

- Drawn aluminum is usually stronger because it is stretched during the process.

- Think about what your project needs: if you need many parts fast, choose extrusion.

- Drawn aluminum usually costs more for each part, especially if you only need a few.

- Always talk to your supplier to make sure you pick the best aluminum forming method for your design.

Table of Contents

Aluminum Forming Methods

Drawing Aluminum Overview

Drawing aluminum is good for simple shapes. It makes items with exact sizes. The process pulls aluminum through a die. This makes things like tubes or cans. Drawing aluminum uses lower temperatures. You do not need to heat the metal much. The metal gets shaped by stretching, not pushing. You get strong and smooth products. The sizes are very close to what you want. Drawing aluminum works best for round or straight shapes. People use it to make containers, pots, and tubes.

Extruded Aluminum Overview

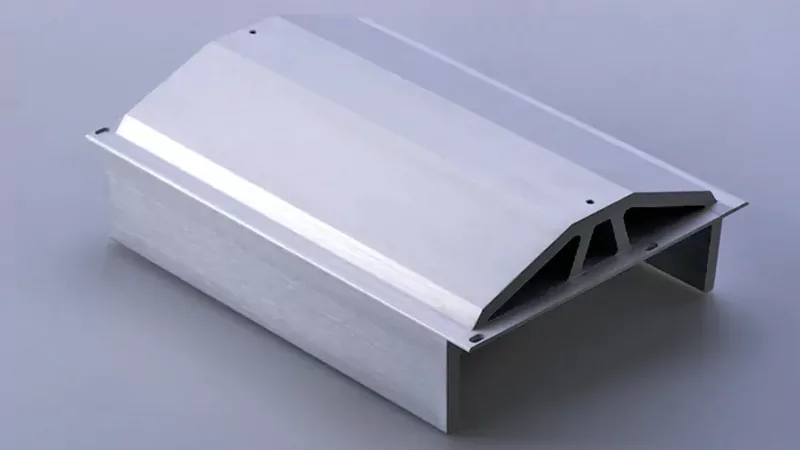

Extruded aluminum is good for tricky shapes. It is also fast for making lots of items. The process pushes hot aluminum through a die. Here are the steps for making extruded aluminum:

- Heat the aluminum billet to about 800-925°F.

- Put lubricant on the billet and ram.

- Move the billet to the cradle.

- Use a ram to push the billet into the container.

- Press the billet against the die.

- Squeeze the soft metal through the die opening.

- Watch the exit temperature.

- Cool and guide the extruded aluminum down the run-out table.

- Cut the extrusion to the needed length.

- Stretch the aluminum to make it stronger.

- Heat-treat the extruded aluminum if needed.

Extruded aluminum can be many shapes. It can be tubes, window frames, doors, brackets, and railings. You can use hot extrusion with heated metal. You can use cold extrusion at room temperature. Most extruded aluminum uses hot extrusion. This helps the metal flow and shape better.

Key Differences

There are big differences between drawing aluminum and extruded aluminum. Drawing aluminum uses lower temperatures. It works best for simple, straight shapes. Extruded aluminum uses higher temperatures. It can make more complex shapes. Drawing aluminum gives you exact sizes and smooth finishes. Extruded aluminum gives you more shape choices and faster work. Drawing aluminum costs more because it needs special tools. Extruded aluminum usually costs less. It fits more types of products. Pick drawing aluminum for simple, strong things like cans or tubes. Pick extruded aluminum for parts with tricky shapes, like window frames or railings.

Tip: Use drawing aluminum for simple, exact parts. Use extruded aluminum for tricky shapes and bigger amounts.

Drawing Aluminum Process

Strength and Tolerances

When you choose drawn aluminum, you get strong parts with tight tolerances. This process stretches the metal, which makes it tougher. You can use drawn aluminum for projects that need exact sizes and reliable strength.

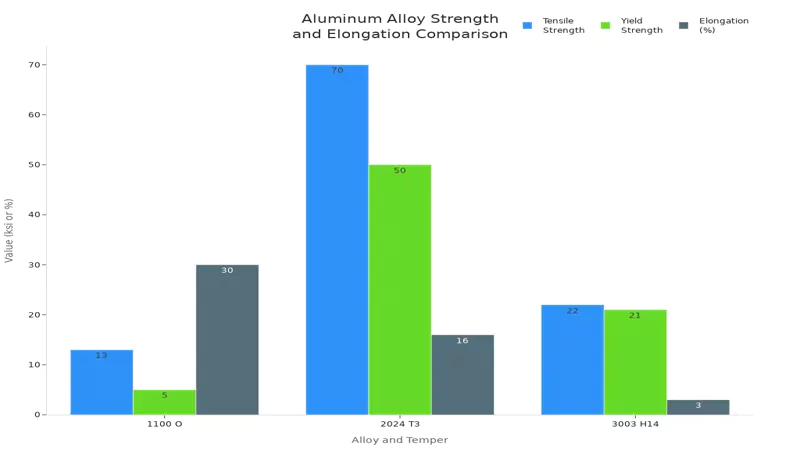

Drawn aluminum stands out because it offers better strength than many other forming methods. You can see the difference in the table below. It shows the strength and flexibility of common drawn aluminum alloys.

| Alloy | Temper | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) |

|---|---|---|---|---|

| 1100 | O | 13 | 5 | 30 |

| 2024 | T3 | 70 | 50 | 16 |

| 3003 | H14 | 22 | 21 | 3 |

You can see that drawn aluminum can reach high tensile and yield strengths, especially with alloys like 2024 in T3 temper. This means you get parts that can handle more force before breaking. The elongation numbers show how much the metal can stretch before it snaps. If you need flexible parts, you might pick an alloy with higher elongation.

You can trust drawn aluminum to keep its shape. The process gives you parts with close measurements. You often see tolerances as tight as ±0.002 inches. This helps you when you need parts that fit together perfectly. Drawn aluminum works well for tubes, rods, and wires that must match exact sizes.

If you compare drawn aluminum to other metals, you notice that materials like stainless steel and tool steel can hold even tighter tolerances. These metals have high dimensional stability. Drawn aluminum is more malleable, so it fits projects where you need good strength but can accept slightly looser tolerances.

You should pick drawn aluminum when you want a balance of strength and precision. You get parts that last longer and perform better. You also get a smooth surface finish, which helps if you need parts that look good or slide easily.

Tip: Use drawn aluminum for parts that need to be strong, exact, and smooth. You get reliable results every time.

Drawn Aluminum Limitations

When you choose drawn aluminum for your project, you get many benefits. However, you also need to know about the limits of this process. Understanding these limits helps you decide if drawn aluminum fits your needs or if you should look at other options.

1. Shape Restrictions

Drawn aluminum works best for simple shapes. You can make tubes, rods, and wires with this method. If you want complex or detailed shapes, drawn aluminum may not work. The process pulls the metal through a die, so you cannot create sharp corners or deep grooves. You also cannot make hollow shapes with changing diameters. If your design needs special features, you might need to pick another method.

2. Size Limits

You can only make certain sizes with drawn aluminum. The process works well for small to medium parts. If you need very large pieces, drawn aluminum may not be the right choice. The equipment has limits on how much metal you can draw at once. You also need to think about the length. Very long parts can bend or break during drawing.

3. Cost Factors

Drawn aluminum often costs more than other forming methods. You need special dies and tools for each size and shape. If you want to change your design, you must pay for new tools. This makes drawn aluminum less cost-effective for small runs or custom parts. If you need many different shapes, the costs can add up quickly.

4. Production Speed

You may notice that drawn aluminum takes more time to produce than extruded aluminum. The process moves slowly to keep the metal strong and smooth. If you need a large number of parts fast, drawn aluminum might slow down your project.

5. Material Choices

Not all aluminum alloys work well for drawing. Some alloys crack or break when you try to draw them. You must pick alloys that can stretch without losing strength. This limits your choices if you need special properties in your metal.

Note: Always check if your design and material match the limits of drawn aluminum before you start production.

| Limitation | Impact on Your Project |

|---|---|

| Shape restrictions | Limits to simple, straight designs |

| Size limits | Best for small to medium parts |

| Higher costs | More expensive for custom or small runs |

| Slower production | Not ideal for high-volume needs |

| Alloy restrictions | Fewer material options |

You should weigh these limits against the strengths of drawn aluminum. If your project needs simple, strong, and precise parts, drawn aluminum still offers great value. If you need complex shapes, fast production, or lower costs, you may want to explore other forming methods.

Extruded Aluminum Process

How Extrusion Works

You make extruded aluminum by pushing hot metal through a die. First, you heat an aluminum billet until it gets soft. Then, you push this billet through a shaped hole called a die. The metal changes shape as it moves through the die. This way, you get long pieces with the same shape all the way through. You can make simple bars or more detailed shapes. The process is fast and gives you strong, light parts.

Extruded Aluminum Types

You see many kinds of extruded aluminum in building and car making. People like extruded aluminum because it is light, strong, and does not rust easily. It also saves money when you need many shapes for different jobs.

Here are some usual types of extruded aluminum:

- Angles

- Square tubes

- Round tubes

- T-profiles

- U-profiles

- Z-shapes

- Channels

Extruded aluminum tubes are used in window frames, railings, and car parts. These tubes are easy to cut and connect. You can also use them for supports and pipes. In buildings, you find extruded aluminum in skylights and covers. In cars, it is used in cross members and frames.

Tip: Pick extruded aluminum tubes if you want strong, light, and rust-proof parts for buildings or cars.

Surface Finish and Speed

Extruded aluminum has a normal surface finish. Drawn aluminum is usually smoother and shinier. You can see the difference in this table:

| Property | Extruded Seamless Tube | Drawn Seamless Tube |

|---|---|---|

| Surface Finish | Standard | Superior |

If you want a better finish, you can polish or anodize extruded aluminum. These steps make your parts look and feel nicer.

Extruded aluminum is made quickly. This helps you get lots of parts fast. Here is a table that shows how fast you can make them:

| Speed Range (m/min) | Description |

|---|---|

| 5 – 60 | General extrusion speeds for various profiles |

| Up to 100 | Speeds for high-capacity lines with easy alloys |

You can make many parts in a short time with extruded aluminum. This makes it good for big jobs or when you need lots of pieces.

Note: Extruded aluminum gives you fast work, many shape choices, and saves money. It is great for projects where you need quick and flexible designs.

Extruded Aluminum Limitations

When you choose extruded aluminum, you get many benefits. You also need to know about the limits of this process. Understanding these limits helps you decide if extrusion fits your project.

1. Tolerance Limits

Extruded aluminum does not always give you tight tolerances. You may see small changes in size from one part to another. If your project needs exact measurements, you might need extra machining after extrusion. Most extruded profiles have tolerances around ±0.010 inches. Drawn aluminum can reach tighter tolerances.

2. Surface Finish

You get a standard surface finish with extruded aluminum. The finish may show lines or marks from the die. If you want a smooth or shiny look, you must polish or anodize the parts. This adds time and cost to your project.

3. Shape Restrictions

Extrusion lets you make many shapes, but not every design works. Very thin walls or sharp corners can cause problems. The metal may not fill the die completely. You may need to change your design to fit the process.

4. Strength

Extruded aluminum is strong, but not as strong as drawn aluminum. The metal flows through the die, which can leave weak spots. If you need parts that handle high stress, you should check the alloy and temper. Some extruded shapes may bend or twist more easily.

5. Cost for Small Runs

Extrusion saves money when you make many parts. If you only need a few pieces, the cost of making a custom die can be high. You pay for the die even if you make a small batch. This makes extrusion less cost-effective for short runs.

6. Alloy Choices

Not every aluminum alloy works well for extrusion. Some alloys do not flow easily through the die. You must pick alloys that shape well and keep good strength. This limits your choices if you need special properties.

Tip: Always check your design and alloy before you start extrusion. Talk to your supplier about what works best.

Here is a table to help you see the main limits of extruded aluminum:

| Limitation | What You Need to Know |

|---|---|

| Tolerance limits | Not as exact as drawn aluminum |

| Surface finish | Needs extra work for smooth look |

| Shape restrictions | Thin walls and sharp corners are hard |

| Strength | May not match drawn aluminum |

| Cost for small runs | Die cost is high for few pieces |

| Alloy choices | Fewer options than other methods |

You should weigh these limits against the benefits of extrusion. If you need fast production, flexible shapes, and lower costs for big jobs, extrusion works well. If you need exact sizes, smooth surfaces, or special alloys, you may want to look at other forming methods.

Note: Knowing the limits of extruded aluminum helps you make better choices for your project. Always match the process to your needs.

Drawn vs. Extruded Aluminum

Shape Flexibility

You might wonder how each process handles different shapes. Here are some things to think about:

- Drawn aluminum uses plastic deformation. This means the metal is pulled through a die. The parts can bend and flex well. You get good elasticity and flexibility. This is great for things that need to spring back or bend.

- Extruded aluminum uses heat and pressure. The metal is pushed through a shaped opening. You can make complex and detailed shapes. You can create channels, angles, and custom profiles. These shapes do not flex as much as drawn aluminum. This process is about making detailed shapes, not flexible ones.

Tip: Pick drawn aluminum if you need parts that bend or flex. Choose extruded aluminum for detailed or custom shapes.

Mechanical Properties

You should check the strength and hardness of each type. Drawn aluminum is often stronger. The metal stretches during the process. This makes the grain structure tighter and stronger. Extruded aluminum is strong too, but not always as much as drawn aluminum.

Here is a table to help you compare:

| Property | Value |

|---|---|

| Tensile Strength | T6 30,000 psi minimum |

| Rockwell Hardness | E scale of E50 |

| Yield Strength | T6 = 25,000 psi minimum |

Drawn aluminum usually has higher tensile and yield strength. The parts resist breaking and bending. The hardness is higher, so the parts last longer. Extruded aluminum can be strong, but you may need special alloys or tempers to match drawn aluminum.

Note: If you need high strength and hardness, drawn aluminum is often better.

Cost Comparison

You want to keep your project on budget. The cost difference between drawn and extruded aluminum matters.

- Drawn aluminum costs more for each part. You pay for special dies and slower production. It is best for projects that need high precision or small amounts.

- Extruded aluminum saves money when you make many parts. The process is faster and uses less expensive tools. You get lower costs for big runs or complex shapes.

If you need a few exact parts, drawn aluminum gives the best results, but costs more. If you need many parts or custom shapes, extruded aluminum helps you save money.

Tip: For big or complex projects, pick extruded aluminum to save money. For small, precise jobs, drawn aluminum is worth the extra cost.

Production Volume

When you plan your project, you need to think about how many parts you want to make. Production volume affects your choice between drawn aluminum and extruded aluminum.

Drawn Aluminum works best for small to medium runs. You get high precision and strong parts, but the process moves slowly. Each new size or shape needs a special die. This makes setup costs higher. If you only need a few parts or want to test a design, drawn aluminum can be expensive. You pay more for each piece when you make fewer parts.

Extruded Aluminum fits large production runs. The process moves quickly once you set up the die. You can make thousands of parts in a short time. The cost per part drops as you make more pieces. Extrusion is the better choice if you need many parts with the same shape. You save money and get your parts faster.

Here is a table to help you compare:

| Process | Best For | Setup Cost | Speed | Cost Per Part (High Volume) |

|---|---|---|---|---|

| Drawn Aluminum | Small/Medium Runs | High | Slow | High |

| Extruded Aluminum | Large/High-Volume Runs | Medium | Fast | Low |

Tip: If you need a lot of parts, pick extruded aluminum. If you need only a few, drawn aluminum gives you better precision but costs more.

You should match your production volume to the right process. This helps you control costs and meet your project deadlines. Always ask your supplier about the best choice for your order size.

Applications

Drawn Aluminum Uses

Drawn aluminum is used in many fields. It gives you parts that are strong and exact. In airplanes, it is found in the body, wings, and support parts. Aluminum is about 80% of a plane’s weight. Special alloys make it strong and stop rust. These features help meet tough safety rules.

Aviation uses drawn aluminum for its very high strength. It is good when you need tough parts that do not break easily. You see it in the outer skin, inside frames, and heat parts of planes. The strength-to-weight ratio helps make planes lighter. This saves fuel and cuts costs.

Some common uses for drawn aluminum are:

- Panels and skins for airplane bodies and wings

- Support frames inside planes

- Heat exchangers and shields for heat

- Seamless tubes for fuel and hydraulic lines

- Cans for food and drinks

- Medical syringes and special tubes

Seamless tubes are picked when you need lines that do not leak. These tubes are used in planes, hospitals, and factories. Drawn aluminum also helps lower costs while meeting hard standards.

Tip: Pick drawn aluminum if you need exact shapes, strong parts, and smooth surfaces for tough jobs.

Extruded Aluminum Uses

Extruded aluminum lets you make many shapes and sizes. It is used most in building and construction. Its strength and light weight make it great for window and door frames in big buildings. You also see it in walls and outside covers that add style and support.

You can use extruded aluminum for:

- Window and door frames in houses and offices

- Walls and covers on buildings

- Handrails, balconies, and safety rails

- Roof covers and hanging ceilings

- Pipes and guide rails for plumbing

- Furniture, stairs, and lights inside

- Rails and panels for sheds or trailers

- Art pieces and custom shapes

Extruded aluminum works well inside and outside. You can finish it in many ways to fit your project. Seamless tubes made by extrusion are used for pipes and supports. These tubes do not rust and last a long time.

Note: Use extruded aluminum if you want many shapes, fast work, and to save money on big projects.

Choosing the Right Process

Decision Factors

You want to pick the best aluminum forming method for your project. You need to look at a few key factors. Each factor helps you decide if drawing or extrusion fits your needs.

Here are the main decision factors:

| Factor | Drawing Aluminum | Extruded Aluminum |

|---|---|---|

| Precision | Very high | Good, but less exact |

| Shape Complexity | Simple, straight shapes | Complex, custom shapes |

| Strength | Higher | Good, varies by alloy |

| Surface Finish | Smooth, shiny | Standard, can improve |

| Cost | Higher for small runs | Lower for big batches |

| Speed | Slower | Faster |

| Volume | Small to medium | Medium to large |

| Alloy Choices | Limited | More options |

You should match your project needs to these factors. If you want exact sizes and strong parts, drawing aluminum works best. If you need many shapes or want to save money, extrusion is the better choice.

Tip: Write down your top priorities before you choose. This helps you see which process matches your goals.

Use this checklist to guide your decision:

- Do you need very tight tolerances?

- Is your part a simple tube, rod, or wire?

- Do you want a smooth, shiny finish?

- Will you make only a few parts?

- Do you need high strength for safety or stress?

- Is your design complex or custom?

- Do you need many parts quickly?

- Is cost a big concern for your project?

- Do you need special alloys or finishes?

If you answer “yes” to the first five questions, drawing aluminum may suit your needs. If you answer “yes” to the last four, extruded aluminum could be the better fit.

Project Questions

You need to ask yourself some questions before you decide. These questions help you match your project to the right process.

Ask yourself:

- What shape do you need?

Simple tubes and rods work well with drawing. Complex profiles fit extrusion. - How exact do your measurements need to be?

Drawing gives you tighter tolerances. Extrusion works for most jobs but may need extra machining. - How many parts do you need?

Drawing suits small batches. Extrusion is best for large runs. - What is your budget?

Drawing costs more for each part. Extrusion saves money when you make many pieces. - How fast do you need your parts?

Drawing takes longer. Extrusion is faster. - What surface finish do you want?

Drawing gives a smooth finish. Extrusion can be polished or anodized. - Do you need special alloys?

Some alloys work better with one process than the other.

Note: Talk to your supplier or engineer if you feel unsure. They can help you match your needs to the right process.

Emoji Checklist:

- ✅ Need exact size? Choose drawing.

- ✅ Want tricky shapes? Choose extrusion.

- ✅ Need lots of parts fast? Choose extrusion.

- ✅ Want smooth finish? Choose drawing.

You make the best choice when you match your answers to the strengths of each process. This helps you get strong, reliable, and cost-effective aluminum parts for your project.

Cost and Availability

Material Costs

You want to know how much each process costs. Material costs can change based on the type of aluminum, the shape you need, and how many parts you order. Drawn aluminum usually costs more per part. You pay for special dies and slower production. Extruded aluminum often costs less, especially when you order large batches. The process uses less expensive tooling and moves faster.

You see price changes when you pick different alloys. Some alloys cost more because they are harder to shape or need extra steps. If you choose a common alloy, you save money. Custom shapes or rare alloys raise the price. You should ask your supplier for a quote before you start. This helps you plan your budget.

Tip: If you want to save money, pick standard alloys and simple shapes. Order more parts at once to lower your cost per piece.

Lead Times

You need to think about how long it takes to get your parts. Lead time means the time from placing your order to receiving your finished aluminum parts. Drawn aluminum often takes longer to produce than extruded aluminum. You wait for special tooling, slow forming, and careful inspection.

Here is a table that shows average lead times for custom orders:

| Type of Aluminum Processing | Average Lead Time |

|---|---|

| Drawn seamless aluminum tubing | 50-60 weeks |

| Structural extrusions in 7xx & 2xx alloys | 25-30 weeks |

| Drawn porthole tubing | 12-14 weeks |

You see that drawn seamless tubing can take up to a year. Structural extrusions need about half that time. Drawn porthole tubing is much faster. You should plan ahead if you need drawn aluminum. Extruded aluminum helps you get parts sooner, especially for big projects.

When you order, you also need to think about these steps:

- Tooling lead time: Time to make the dies and tools.

- Aluminum extrusion lead time: Time to shape and cool the metal.

- Fabrication lead time: Time to cut, finish, and inspect your parts.

Note: Always ask your supplier about lead times before you order. This helps you avoid delays and keeps your project on track.

Customization

You may want custom shapes, sizes, or finishes for your project. Both drawing and extrusion let you customize your aluminum parts. Drawing works best for simple shapes like tubes and rods. You get tight tolerances and smooth finishes. Extrusion gives you more options for complex profiles, channels, and angles.

If you need a special design, extrusion is usually faster and less expensive. You pay for a custom die, but you get more shape choices. Drawing needs special tooling for each size, which raises costs and lead times. You can also ask for custom finishes, such as anodizing or painting. These steps add cost but help your parts look and perform better.

Tip: Choose extrusion for custom shapes and fast delivery. Pick drawing for exact sizes and smooth surfaces.

You should match your customization needs to the strengths of each process. This helps you get the right parts without spending too much or waiting too long.

Summary Table

You want to see the main differences between drawn aluminum and extruded aluminum at a glance. The table below helps you compare the most important features. You can use this summary to match your project needs to the right process.

| Metric | Drawn Aluminum | Extruded Aluminum |

|---|---|---|

| Process | You pull aluminum through a die. The metal stretches and changes shape. This gives you strong and smooth parts. | You heat aluminum and push it through a die. The metal flows into many shapes. You get fast results and flexible designs. |

| Applications | You use drawn aluminum for pots, cans, tubes, and round items. These parts need tight tolerances and smooth finishes. | You use extruded aluminum for brackets, tubing, doors, window frames, and railings. These parts can have complex shapes and custom profiles. |

| Cost | You pay more for drawn aluminum. The process takes longer and needs special tools. This suits small batches or parts that need high precision. | You save money with extruded aluminum. The process moves quickly and uses less expensive tooling. This works best for large runs and custom shapes. |

| Product Types | You get simple designs with drawn aluminum. Tubes, rods, and wires are common. The process limits you to straight or round shapes. | You get a wide variety of shapes with extruded aluminum. You can make channels, angles, and detailed profiles. The process lets you create almost any shape you need. |

Tip: Use this table to check which process fits your project. If you need exact sizes and strong parts, drawn aluminum works best. If you want many shapes and lower costs, extruded aluminum is the better choice.

Key Points to Remember

- Drawn aluminum gives you strong, smooth, and precise parts. You use it for simple shapes and small batches.

- Extruded aluminum offers flexible designs, fast production, and lower costs. You use it for complex shapes and large orders.

You should think about your project’s needs before you choose. Ask yourself what shape you want, how many parts you need, and how much you want to spend. The right choice helps you get the best results.

✅ Need tight tolerances and smooth finish? Choose drawn aluminum.

✅ Want complex shapes and fast delivery? Choose extruded aluminum.

You can always talk to your supplier or engineer if you feel unsure. They can help you match your needs to the right process. Use this summary table as your quick guide for making smart decisions about aluminum forming.

Pick drawing aluminum if you want parts that are simple and strong. It is also good when you need exact sizes. Extruded aluminum is better for tricky shapes or when you need many parts fast. It also helps if you want to save money. Think about what your project needs for price, wait time, and quality. New tools like AI and nano-coatings make both ways better. Remember, extrusion can affect the environment, so choose smart and green ways. If you are not sure, ask a supplier or engineer for help. Look at what your project needs and pick the best way for your design.

Tip: Make sure your alloy and process match your goals for strength, precision, and being eco-friendly.

FAQ

Drawn aluminum is shaped by pulling it through a die. Extruded aluminum is made by pushing hot metal through a die. Drawn aluminum gives you closer measurements. Extruded aluminum can make more detailed shapes.

Drawn aluminum has a smoother surface. Stretching makes it shiny and even. Extruded aluminum may need polishing or anodizing to look better.

Extrusion works for most custom shapes. Drawing is best for simple tubes, rods, and wires. Extrusion gives you more choices for special profiles.

Tip: Pick extrusion if you want creative shapes.

Extrusion saves money when you order many parts. It is faster and uses cheaper tools. Drawing costs more for each part, especially for small batches.

Ask your supplier about which alloy to use. Some alloys are better for drawing. Others work well for extrusion. Pick an alloy that fits your strength and corrosion needs.

| Process | Alloy Choices |

|---|---|

| Drawing | Limited |

| Extrusion | More options |

Drawn aluminum is usually stronger. Stretching makes the grain tighter. Extruded aluminum is strong too, but you may need special alloys or tempers to match the strength.

Drawn aluminum takes longer, especially for custom sizes. Extruded aluminum arrives faster, especially for standard shapes. Always check with your supplier about lead times.

Note: Plan ahead so you do not have delays.