When you compare aluminum 6061 vs aluminum 6063 , you notice they act differently. 6061 is chosen because it is strong and light, making it a popular option. It is also easy to weld. On the other hand, 6063 is excellent for shaping and has a good surface quality, which makes it useful for creating intricate designs.

| Property | AA6061 (Aluminum) | AA6063 |

|---|---|---|

| Hardness | Higher | Lower |

Choosing the right alloy, whether it’s aluminum 6061 vs aluminum 6063, helps your project perform well and prevents you from making costly mistakes.

Key Takeaways

- 6061 aluminum is stronger and tougher. It works well for heavy jobs. 6063 aluminum is easier to shape. It has a smoother finish. This makes it good for decoration. Pick 6061 if you need strength. Use it for cars and planes. Pick 6063 if looks are important. Use it for window frames and furniture. Both alloys fight rust well. 6063 is better outside because it is smooth. Think about how easy it is to machine. 6063 is easier to work with. This saves time on hard designs. You can weld both alloys. 6061 gives stronger welds. Always pick the right alloy for your project. This gives you the best results.

Table of Contents

Overview

6061 vs 6063

When you look at 6061 vs 6063, you see clear differences in how each aluminum alloy performs and where you should use them. Both alloys belong to the 6000 series, but they serve different needs. You need to know these differences to pick the right material for your project.

- 6061 vs 6063 aluminum shows that 6061 gives you higher strength and toughness. You often find it in parts that need to handle heavy loads or stress.

- 6063 aluminum stands out for its smooth finish and better ability to form into shapes. You see it in places where appearance and corrosion resistance matter most.

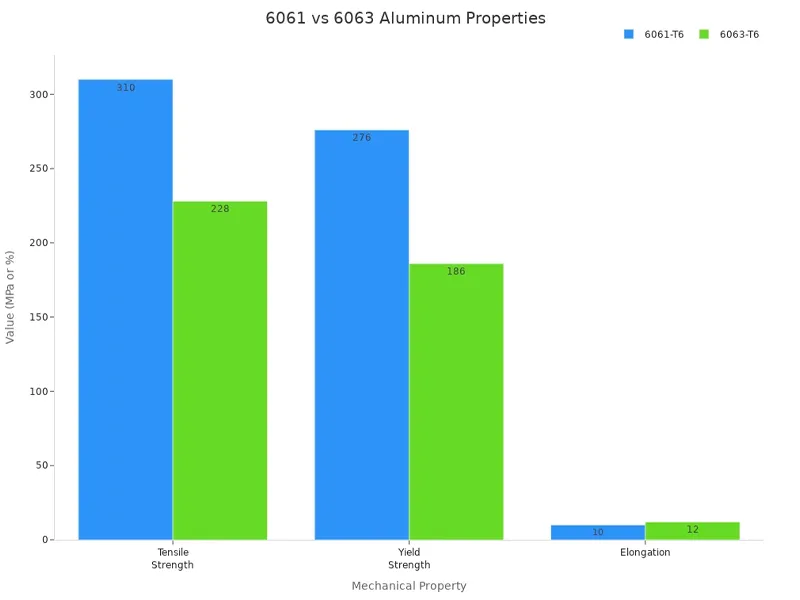

Here is a quick comparison table to help you see the main mechanical differences:

| Property | 6061-T6 | 6063-T6 |

|---|---|---|

| Tensile Strength (MPa) | 310 | 228 |

| Yield Strength (MPa) | 276 | 186 |

| Elongation (%) | 10 | 12 |

You can see that 6061 vs 6063 aluminum gives you a choice between strength and flexibility. 6061 aluminum works best when you need strong, durable parts. You find it in automotive frames, aerospace parts, and heavy machinery. 6063 aluminum is better for projects where you want a smooth look and easy shaping, like window frames, doors, and furniture.

Choosing between 6061 vs 6063 aluminum matters because the right alloy helps your project last longer and perform better. If you pick the wrong one, you might face problems like weak parts or poor appearance.

To sum up, 6061 vs 6063 aluminum is not just about numbers. You need to match the alloy to your needs. If you want strength, go with 6061. If you want a nice finish and easy forming, 6063 is your best choice.

6061 Aluminum

Mechanical Properties

Strength

6061 aluminum is known for being very strong. This alloy is tough and works well for hard jobs. The T6 temper can reach at least 42,000 psi for ultimate tensile strength. Its yield strength is at least 35,000 psi. These numbers show why 6061 is picked for heavy loads or stress.

| Temper | Ultimate Tensile Strength (psi) | Yield Strength (psi) |

|---|---|---|

| 6061-0 | ≤ 18,000 | ≤ 8,000 |

| 6061-T4 | ≥ 30,000 | ≥ 16,000 |

| 6061-T6 | ≥ 42,000 | ≥ 35,000 |

6061 aluminum is great for projects that need strength and durability.

Fatigue

6061 aluminum has medium fatigue resistance. This means it works for parts that get used over and over. It does not last as long as some alloys like 7075. How you use it can change how long it lasts. For most uses, its fatigue resistance is good enough.

Hardness

6061 is pretty hard compared to other aluminum types. The Brinell hardness for 6061-T6 is about 95. The Rockwell B value is around 60. The Vickers value is close to 107. These numbers mean 6061 resists dents and scratches better than many other kinds.

| Property | Value |

|---|---|

| Hardness (Brinell) | 95 |

| Hardness (Rockwell B) | 60 |

| Hardness (Vickers) | 107 |

Elongation

6061 aluminum is both strong and flexible. In the T6 temper, it can stretch about 10% before breaking. You can bend or shape 6061 without it snapping suddenly.

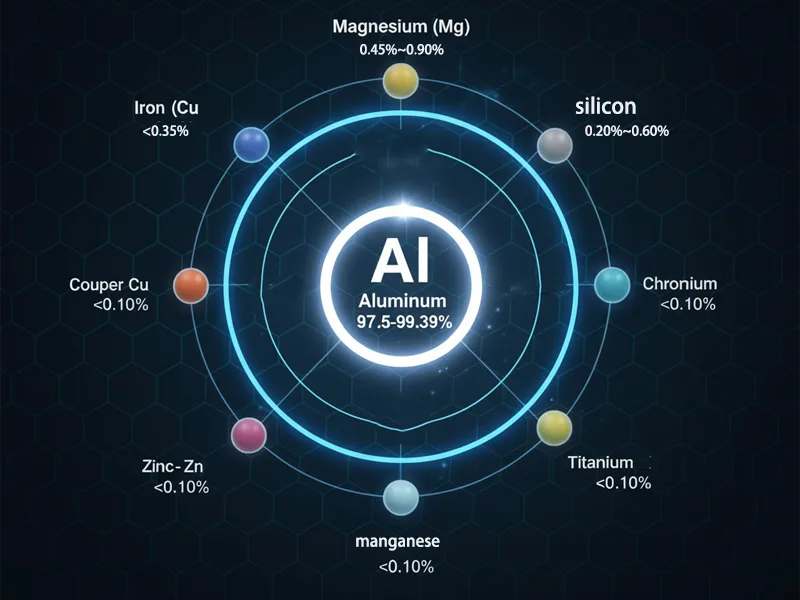

Chemical Composition

6061 aluminum is made from a mix of elements. It has mostly aluminum. It also has magnesium, silicon, iron, copper, chromium, zinc, titanium, and manganese. This mix helps make it strong, resistant to corrosion, and easy to work with.

| Element | Minimum (% by weight) | Maximum (% by weight) |

|---|---|---|

| Aluminum (Al) | 95.85 | 98.56 |

| Magnesium | 0.80 | 1.20 |

| Silicon | 0.40 | 0.80 |

| Iron | 0 | 0.70 |

| Copper | 0.15 | 0.40 |

| Chromium | 0.04 | 0.35 |

| Zinc | 0 | 0.25 |

| Titanium | 0 | 0.15 |

| Manganese | 0 | 0.15 |

| Others | 0 | 0.15 total |

This chemical mix gives 6061 its strength and corrosion resistance.

Uses

6061 aluminum is used in many industries. Its strength, corrosion resistance, and easy machining make it popular. You can find 6061 in truck frames, rail coaches, military bridges, and shipbuilding. It is also used in aerospace parts, towers, pylons, marine fittings, camera lenses, yachts, motorcycles, bicycle frames, fishing reels, and scuba tanks.

- Common uses for 6061 aluminum:

- Heavy duty structural applications

- Automobile manufacturing

- Marine fittings

- Scuba tanks

- Electrical fittings

- Archery equipment

Tip: If you want high strength aluminum extrusions, 6061 aluminum is a smart pick for your project.

6063 Aluminum

Mechanical Properties

Strength

6063 aluminum is not as strong as 6061. It has a tensile strength of about 228 MPa. Its yield strength is 186 MPa in the T6 temper. 6063 is good for things that do not need to hold heavy weight. People use 6063 when strength is not the most important thing. You can use it for frames, rails, and parts that look nice.

Fatigue

6063 aluminum works well for light jobs that move or bend. It does not last as long as stronger alloys if used a lot. If you make window frames or trim, 6063 will last a long time. Do not use 6063 for parts that shake or vibrate all the time.

Hardness

6063 aluminum is softer than 6061. The Brinell hardness for 6063-T6 is about 73. This means you can cut or shape it more easily. It dents more than harder types, but it is still good for many uses.

| Property | Value |

|---|---|

| Hardness (Brinell) | 73 |

| Hardness (Rockwell B) | 40 |

| Hardness (Vickers) | 80 |

Elongation

6063 aluminum can stretch more before it breaks. In the T6 temper, it can stretch about 12%. This makes it easy to bend into shapes. You can curve it for special designs. Many people use this performance characteristics of aluminum 6063 for parts that need to look smooth and round.

Chemical Composition

6063 aluminum is mostly aluminum with magnesium and silicon. This mix helps it resist rust and makes it easy to shape. Here is a table that shows what is in 6063 aluminum:

| Element | Minimum (% by weight) | Maximum (% by weight) |

|---|---|---|

| Aluminum | 97.5 | 99.39 |

| Magnesium | 0.45 | 0.90 |

| Silicon | 0.20 | 0.60 |

| Iron | 0 | 0.35 |

| Copper | 0 | 0.10 |

| Manganese | 0 | 0.10 |

| Chromium | 0 | 0.10 |

| Zinc | 0 | 0.10 |

| Titanium | 0 | 0.10 |

| Others | 0 | 0.15 total |

This mix gives 6063 aluminum a smooth surface and helps it resist rust.

Uses

6063 aluminum is often used for making shapes. You see it in window frames, door frames, and curtain walls. Builders like 6063 for trim and railings that look nice. You can also find it in furniture, racks, and sign frames. If you want a clean look, 6063 is a great choice.

- Common uses for 6063 aluminum:

- Window and door frames

- Architectural extrusions

- Decorative trim

- Furniture and display racks

- Sign frames

- Railings and balustrades

Use 6063 aluminum when you want a smooth look and easy shaping. This alloy lets you make creative designs. If you need custom shapes, 6063 will help you get them.

Tip: Pick 6063 aluminum for projects where looks and shape are more important than strength. You will get a nice finish and it is easy to work with every time.

Comparison

Mechanical Properties

Before you pick between aluminum 6061 and 6063 aluminum alloys, you should look at their mechanical properties. Both are part of the 6000 series, but they are not the same. Aluminum 6061 is strong and light, so it works well for building things that need to hold weight. 6063 bends more easily and has a smoother finish, which is good for buildings and decorations.

| Property | 6061-T6 | 6063-T6 |

|---|---|---|

| Tensile Strength (MPa) | 310 | 228 |

| Yield Strength (MPa) | 276 | 186 |

| Elongation (%) | 10 | 12 |

| Hardness (Brinell) | 95 | 73 |

6061 is best when you need strong parts that last. It can handle heavy loads. 6063 is easier to shape and bend, so you can make smooth and round designs. If you want strength, use 6061. If you want flexibility and a nice look, 6063 is better.

Pick 6061 for tough jobs. Pick 6063 for creative shapes and smooth looks.

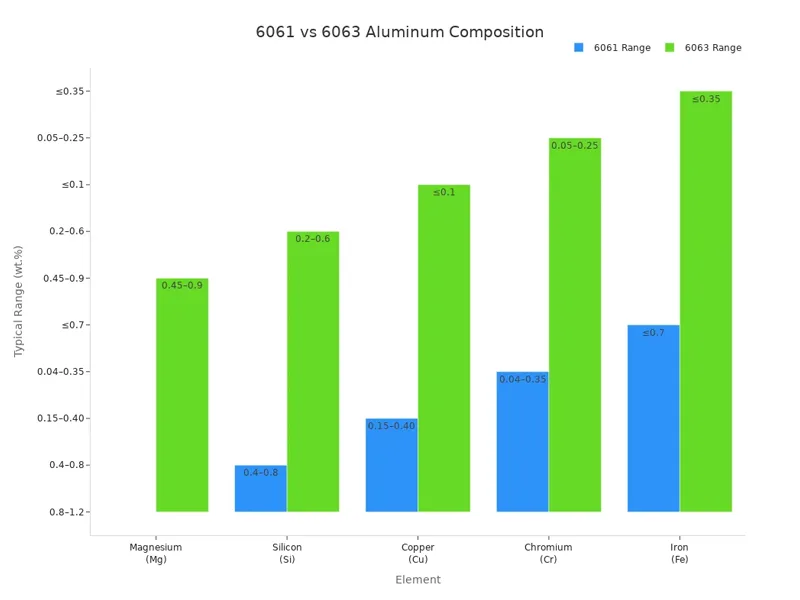

Chemical Composition

What is inside each aluminum alloy changes how it works. 6061 and 6063 have different amounts of magnesium, silicon, copper, and iron. These elements make each alloy act differently.

| Element | 6061 Typical Range (wt.%) | 6063 Typical Range (wt.%) |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Magnesium | 0.8 – 1.2 | 0.45 – 0.9 |

| Silicon | 0.4 – 0.8 | 0.2 – 0.6 |

| Copper | 0.15 – 0.40 | ≤ 0.1 |

| Chromium | 0.04 – 0.35 | 0.05 – 0.25 |

| Iron | ≤ 0.7 | ≤ 0.35 |

6061 has more magnesium and copper. This makes it stronger and better for hard jobs. 6063 has less copper and iron, so it is smoother and resists rust well. Both have silicon, which helps stop rust and makes casting easier.

- Magnesium makes the alloy stronger but harder to shape.

- Silicon helps with strength and stops rust.

- Copper adds strength but can make it less bendy.

- Chromium and manganese help with strength and rust resistance.

- Iron changes how easy it is to machine and how it resists rust.

Both alloys resist rust well, especially after anodizing. 6063 is great in wet places because of its silicon. You can use 6063 where there is a lot of moisture and not worry about rust.

Application Suitability

You need to pick the right aluminum alloy for your job. 6061 and 6063 are used for different things. 6061 is used when you need strength. 6063 is used for projects that need a smooth finish.

| 6061 Aluminum Alloy | 6063 Aluminum Alloy |

|---|---|

| Building products (structural) | Window and door frames |

| Truck components | Balustrading |

| Aircraft parts | Outdoor furniture |

| Automotive parts | Electrical and electronics |

| Bicycle frames | Piping |

| Railroad cars | Storage tanks |

| Heavy-duty structures | Extreme sports equipment |

- Use 6061 for building frames, truck parts, and aircraft.

- Use 6063 for windows, doors, furniture, and trim.

- 6061 gives you strong parts for hard jobs.

- 6063 lets you make smooth, stylish shapes for things people see.

If you want strength and parts that last, pick 6061. If you want a nice look and easy shaping, choose 6063.

Pros and Cons Summary:

- 6061 Pros:

- High strength-to-weight ratio

- Good machinability

- Great corrosion resistance

- Best for structural applications

- 6061 Cons:

- Harder to form into complex shapes

- Surface finish not as smooth as 6063

- 6063 Pros:

- Excellent surface finish

- Easy to extrude and shape

- Great corrosion resistance

- Ideal for architectural aluminum and decorative uses

- 6063 Cons:

- Lower strength than 6061

- Not suitable for heavy-duty structural applications

Think about what your project needs before you choose. If you want strength and parts that last, 6061 is best. If you want a smooth look and easy forming, 6063 will help you reach your design goals.

Selection

Factors

When you pick between 6061 and 6063 aluminum, you should think about a few key things. These things can change how your project works and how much money you spend.

Strength

Strength is very important to check first. 6061 aluminum is stronger than 6063. Use 6061 if your project needs to hold a lot of weight or handle stress. 6063 is not as strong, so it is better for lighter jobs or when looks are more important than strength.

Machinability

Machinability means how easy it is to cut or shape the metal. 6063 aluminum is easier to machine than 6061. You can make smooth shapes with less work. 6061 is harder to machine and can make sticky chips. If you need to make many small parts, 6063 can save you time.

Weldability

Both 6061 and 6063 aluminum are good for welding. You can join them together without much trouble. 6061 is picked when you need strong welds. 6063 is also good for welding, but it is best for projects that do not need to be very strong.

Surface Finish

Surface finish is important if you want your project to look nice. 6063 aluminum gives a smoother and shinier finish. You see this in window frames and trim. 6061 does not look as smooth, so it is not used as much when looks matter.

Cost

Cost is another thing to think about. 6061 aluminum usually costs more because it is stronger. 6063 aluminum costs less, so it is better for big projects that do not need a lot of strength.

Here is a table to help you compare these things:

| Factor | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

| Strength | Higher strength | Lower strength |

| Formability | Good formability | Superior formability |

| Workability | Excellent workability | Good workability |

| Aesthetic | Less suitable for finishes | Superior finishing options |

| Cost | Higher | Lower |

| Machinability | Tougher, sticky chips | Easier to machine |

| Weldability | Excellent, high strength | Excellent, versatile |

Tip: Always pick the alloy that fits your project best. Think about strength, looks, and cost before you choose.

Mistakes

People sometimes make mistakes when picking between 6061 and 6063 aluminum. You can avoid problems if you know what to look for.

- Not knowing the special properties of each alloy, like strength and rust resistance.

- Only thinking about strength and forgetting other needs.

- Not thinking about how important looks are for some projects.

If you pick 6061 just because it is strong, you might miss the smooth finish and easy shaping of 6063. If you use 6063 for a heavy job, your project might not last long.

Note: Always check what your project really needs. Do not just pick the strongest or cheapest one.

Case Studies

When you pick between 6061 and 6063 aluminum, your choice changes how your project works and lasts. You can see these choices in real-life examples. Let’s see how different industries use these alloys.

Automotive Applications

6061 aluminum is used in many car parts. Car makers use it for frames, wheels, and engine blocks. 6061 is strong and easy to weld. This helps cars stay safe and light. Cars use less fuel because the metal is strong but not heavy. 6061 also resists rust, so car parts last longer. Even in bad weather, these parts do not break down fast.

Tip: For a strong and safe car frame, use 6061 aluminum. It gives you safety and lasts a long time.

Aerospace Projects

6061 aluminum is found in airplane wings, panels, and support beams. Engineers need materials that can handle stress. 6061 gives strength and resists rust. It also welds well, which keeps planes safe. The metal is light, so planes use less fuel.

Note: In airplanes, every pound is important. 6061 aluminum helps save weight and keeps strength.

Architectural and Decorative Uses

6063 aluminum is great for buildings and design. You see it in window frames, door trims, and railings. Builders like 6063 because it is easy to shape. It gives a smooth and shiny finish. This makes buildings look modern and nice. 6063 is also used in furniture and display racks. The metal bends into cool shapes without breaking.

If you want your project to look nice and feel smooth, 6063 aluminum is a good pick.

Quick Comparison Table

Here is a table that shows how each alloy helps:

| Alloy | Key Properties | Applications |

|---|---|---|

| 6061 | High strength, weldability, corrosion resistance | Structural components in automotive |

| 6063 | Excellent extrudability, aesthetic finish | Architectural trims and aesthetic uses |

Lessons Learned

Picking the right alloy saves time and money. Use 6061 for tough jobs and you get strong parts. Use 6063 for design work and you get smooth finishes. Match the alloy to your needs to avoid mistakes.

Remember: Always check what your project needs. The right aluminum alloy helps you build safer, better, and nicer products. 🏆

You have learned the main ways 6061 and 6063 aluminum are different. Look at the table below for a fast summary:

| Property | 6061 aluminum | 6063 aluminum |

|---|---|---|

| Strength | Higher | Moderate |

| Hardness | Greater | Softer |

| Best Use | Structural, heavy-duty | Architectural, decorative |

Pick 6061 aluminum if you need strong parts for cars or machines. Use 6063 aluminum when you want frames or furniture that look nice. Always choose the aluminum that fits what your project needs. If you want to know more, read guides about aluminum or ask a metals expert for help.

FAQ

6061 aluminum gives you higher strength. 6063 aluminum offers a smoother finish and better formability. You should pick 6061 for heavy-duty parts. Choose 6063 for decorative or architectural projects.

Yes, you can weld both alloys. 6061 gives you stronger welds. 6063 welds easily and looks better after welding. Always use the right filler material for best results.

Both alloys resist corrosion well. 6063 aluminum works best for outdoor frames and trim because it forms a smoother, more attractive surface. 6061 also resists rust and works well for structural outdoor parts.

6063 aluminum is easier to machine and shape. You can create complex designs with less effort. 6061 is harder and may produce sticky chips, but you can still machine it with the right tools.

Yes, you can anodize both alloys. 6063 gives you a brighter, smoother finish after anodizing. 6061 also anodizes well, but the finish may not look as shiny.

6063 aluminum usually costs less than 6061. You save money on large projects that do not need high strength. 6061 costs more because it is stronger and used for heavy-duty parts.

- 6061: Car frames, bike parts, aircraft, heavy machinery.

- 6063: Window frames, doors, railings, furniture, decorative trim.

Tip: Always match the alloy to your project’s needs for best results.