You can shape metal using the hydroforming process. This method employs high-pressure hydraulic fluid to push the metal into a die, allowing for the creation of complex shapes without the need to heat the metal. As a result, the metal retains its strength. Many industries utilize the hydroforming process to produce precise parts.

| Industry | Application Description |

|---|---|

| Automotive | The hydroforming process is essential for creating complex shapes for car parts. |

| Aerospace | It is crucial for manufacturing parts with exact shapes and smooth surfaces. |

| Healthcare | The hydroforming process is used to form medical equipment parts with very smooth finishes. |

| Defense | It is excellent for producing important parts with high quality and accuracy. |

Key Takeaways

- Hydroforming shapes metal with high-pressure hydraulic fluid. This lets people make complex designs without heating the metal.

- The process keeps the metal strong. This makes it good for cars, planes, and healthcare tools.

- Hydroforming saves money for small or medium production runs. It needs fewer tools and dies than older methods.

- The process makes parts with very smooth surfaces. This means less extra work is needed to finish them.

- Hydroforming is great for making parts that are light and strong. This is very important for cars and airplanes.

- Picking the right metal, like aluminum or stainless steel, is important for hydroforming. Ductile metals work best for this process.

- Hydroforming works best for parts with tricky shapes and smooth surfaces. Many people choose it over stamping for these reasons.

- Knowing what hydroforming cannot do, like certain design limits and metal types, helps people get good results.

Table of Contents

Hydroforming Process

What Is Hydroforming

Hydroforming is a way to shape metal using fluid power. You put a metal blank on a shaped tool. A soft diaphragm filled with hydraulic fluid pushes on the metal. The pressure makes the metal take the shape of the die. The hydroforming process works at room temperature. This keeps the metal strong and not brittle.

Hydroforming uses Pascal’s Law. When you press on a trapped fluid, the force spreads everywhere. This even pressure helps make smooth and complex shapes. It does not hurt the metal. People use this process for car parts, bike frames, and kitchen sinks.

How It Works

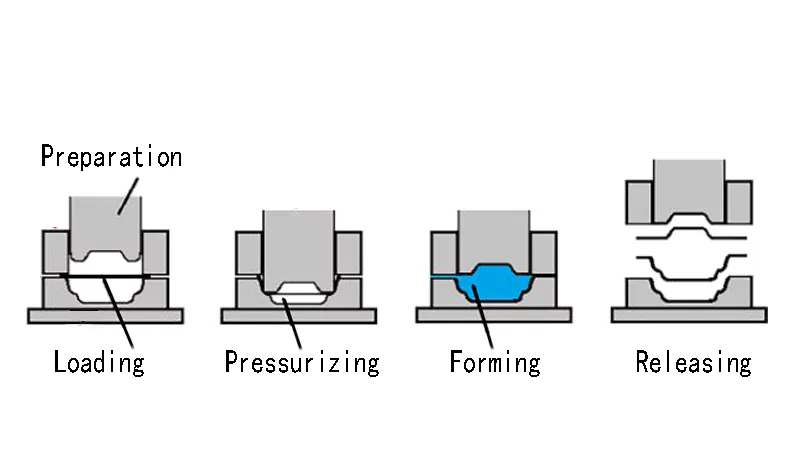

You follow steps when you use the hydroforming process:

- Tooling Setup: First, you set up the tooling. The upper chamber holds the pressurized fluid. There is a rubber diaphragm and a wear pad. The lower part is the die. The die gives the metal its final shape.

- Placement of Metal Blank: Next, you put the metal blank in the chamber. You make sure it is secure. Then you close the chamber.

- Pressurizing: You fill the chamber with hydraulic fluid. You increase the pressure. The diaphragm presses the metal into the die. This step shapes the metal how you want.

- Depressurization and Removal: After shaping, you release the pressure. You open the chamber. You take out the new part.

Tip: Using a flexible diaphragm or bladder helps press the metal smoothly. This method is good for making shallow, complex parts like car panels. The diaphragm also keeps the metal strong.

You might want to know how hydroforming is different from other ways to shape metal. Here is a table to show the differences:

| Feature | Hydroforming | Deep Draw Stamping |

|---|---|---|

| Tooling Costs | Lower tooling costs, simpler dies | Higher tooling costs, complex dies |

| Material Flexibility | Adapts to different thicknesses easily | Material-specific tooling required |

| Surface Quality | Superior surface finish, fewer imperfections | Potential for surface imperfections |

| Production Volume | Ideal for low to medium volumes | Better for high volume production |

| Part Complexity | Excels at complex shapes | Limited by tooling complexity |

Hydroforming uses liquid pressure to shape metal. This lets you make more complex shapes and use materials better. Metal stamping uses mechanical pressure. It can make more waste.

| Hydroforming | Metal Stamping | |

|---|---|---|

| Technology Principle | Uses liquid pressure to deform materials, allowing for complex shapes | Relies on mechanical pressure for rapid forming |

| Material Utilization | Superior material utilization with reduced waste | Lower material utilization with more scrap produced |

The hydroforming process helps you make hollow parts that are strong. You can make parts that are light and tough. This makes hydroforming a smart choice for many industries.

Types

Hydroforming has two main ways to shape metal. These are sheet hydroforming and tube hydroforming. Each way helps make different parts for many jobs. You can look at the table to see the main types and their smaller groups:

| Category | Subcategories |

|---|---|

| Tube | Electro Hydraulic, High Pressure THF, Hot Gas Tube Hydroforming, Hybrid Hydroforming, Impulsive, Low Pressure THF, Tube Expansion, Warm Hydroforming, With Counterpunch |

| Sheet | Cavity: Double Blank, Electro Hydraulic, Hot Gas Hydroforming, Impulsive Hydroforming, Moveable die/Counterpunch, Multi-stage, Warm Hydroforming; Punch: Hot Gas Hydroforming, Hybrid Double Blank, Hybrid Single Blank, Impulsive Hydroforming, Multi-stage, Warm Hydroforming |

Sheet Hydroforming

Sheet hydroforming shapes flat metal sheets into tricky forms. This method is good for making car doors, hoods, and panels. You start with a flat sheet. You press it into a die with high-pressure fluid. The metal copies the die’s shape. It does not tear or wrinkle.

Note: Sheet hydroforming lets you make smooth, detailed shapes from flat sheets. The parts look nice and fit just right.

Here are some ways people use sheet hydroforming:

- Automotive: You can make light and strong parts like chassis and body panels. These parts meet tough standards.

- Industrial: You can make strong machine parts. These parts must be tough and exact.

You can compare sheet hydroforming and tube hydroforming in this table:

| Feature | Sheet Hydroforming | Tube Hydroforming |

|---|---|---|

| Material Used | Flat metal sheets | Metal tubes |

| Shape of Final Product | Complex shapes from flat sheets | Various shapes and sizes of tubes |

| Industries Served | General manufacturing | Primarily automotive |

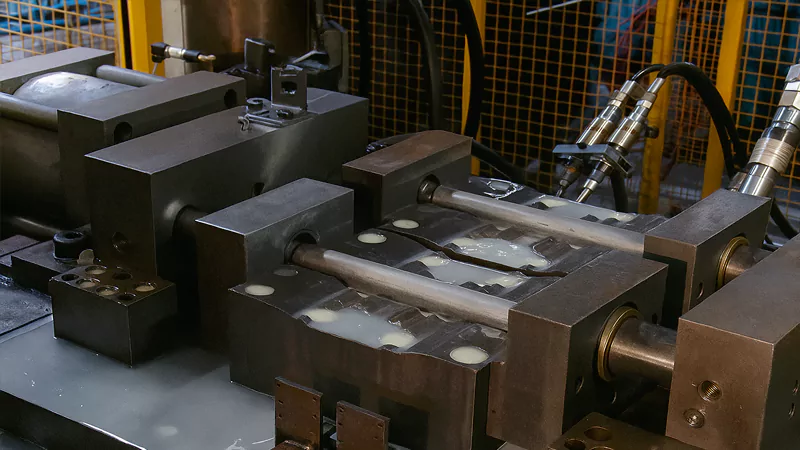

Tube Hydroforming

Tube hydroforming shapes hollow metal tubes into strong, light parts. You use this way to make bike frames, car engine cradles, and exhausts. You put a metal tube in a die. Then you fill it with high-pressure fluid. The pressure makes the tube match the die’s shape.

Tube hydroforming gives you many good things:

- You can make tricky shapes with high accuracy.

- You use less material and make less waste, so you save money.

- You make parts stronger by cold forming.

- You get parts with no seams, so they are stronger.

- You can make tubes that are both strong and light.

- You get parts with the same size every time.

🚗 Tube hydroforming is used a lot in cars. You can make strong, light frames and parts. These help cars work better and use less gas.

The hydroforming process, with sheets or tubes, lets you make parts that are tricky and strong. You can pick the best type for the shape and strength you want.

Steps

Preparation

Before you start the hydroforming process, you need to get everything ready. Good preparation helps you make strong and accurate parts.

Tooling

You begin by setting up the right tools. The die gives your metal its final shape. You must check that the die is clean and free from damage. You also need to make sure the press and all parts are working well. If you use a flexible diaphragm or bladder, you should inspect it for any wear or cracks. This step helps you avoid problems during forming.

Metal Setup

Next, you prepare the metal you want to shape. If you use a tube, you must cut it to the correct length. Sometimes, you bend the tube first to match the shape you want. This step makes sure the tube fits perfectly inside the die. Here are some key actions you take during metal setup:

- Cut the raw tube to the right length.

- Bend the tube with a tube bender if needed.

- Check that the tube or sheet fits snugly in the die.

Tip: Careful metal setup helps you get the best results from the hydroforming process.

Loading

Now you load the metal into the die. You place the tube or sheet in the lower die and make sure it sits in the right spot. For tubes, you use an axial feed. This means you push both ends of the tube at the same time, using special controls to keep the movement even. You also set the pressure load for the tube’s surface. The way you load the metal matters a lot. If you follow the right loading path, you get a better part at the end.

- Place the metal blank or tube in the die.

- Use axial feed to push both ends of the tube evenly.

- Set the pressure load for the tube’s surface.

- Make sure the metal is secure and ready for the next step.

Pressurizing

After loading, you start the pressurizing step. You fill the chamber with hydraulic fluid and increase the pressure. The pressure pushes the metal into the die, shaping it. In most cases, you use high pressure between 5,000 and 10,000 PSI (34 to 69 MPa). For some parts, you may need even higher pressure, sometimes over 25,000 PSI (172 MPa). You control the pressure carefully to avoid damaging the metal.

- Fill the chamber with hydraulic fluid.

- Increase the pressure to the needed level.

- Watch the pressure closely to keep the metal safe.

- Use higher pressure for tougher or more complex shapes.

⚡ High pressure is the key to shaping metal in the hydroforming process. It lets you create strong and detailed parts without heating the metal.

Forming

The forming step is where you see the real magic of hydroforming. You use high-pressure hydraulic fluid to push the metal into the die. This step shapes the metal into the exact form you want. The process happens inside a hydroforming press.

- You place the metal blank or tube into the press.

- The press closes, and hydraulic fluid fills the chamber.

- The fluid pressure rises quickly, forcing the metal to stretch and fit the die.

This method lets you create complex shapes with great accuracy. The high-pressure fluid spreads evenly, so the metal flows smoothly into every part of the die. You get parts with uniform thickness and very few defects.

Tip: Using a single rigid die helps you avoid mistakes. It keeps the shape precise and the surface smooth.

You also keep the metal strong during forming. The pressure does not thin the metal too much. This is important for parts that need to be both light and tough, like those in cars and airplanes. The process also helps you avoid weak spots or stress points. You get a part that is strong all over.

Here is what makes the forming step so effective:

- High-pressure fluid shapes the metal exactly as needed.

- The die controls the final shape and size.

- You get even wall thickness, which means no weak areas.

- The process reduces material waste and keeps the part strong.

The forming step is the heart of hydroforming. You turn a simple metal blank into a finished part with the right shape and strength.

Releasing

After you finish forming, you need to release the pressure and remove the part. You lower the hydraulic pressure slowly. This step keeps the part from getting damaged. Once the pressure drops, you open the press.

- Open the chamber carefully.

- Take out the shaped metal part.

- Check the part for any signs of damage or defects.

You must handle the part gently. The metal may still have some stress from forming. Careful removal helps you keep the part in perfect shape.

Note: Always inspect the part right after releasing. Early checks help you catch any problems before moving to the next step.

Finishing

The last step is finishing. You make sure the part meets all your needs. This step can include trimming, cleaning, and checking the part’s size.

- Trim off any extra metal left from forming.

- Smooth out rough edges or surfaces.

- Clean the part to remove oil or debris.

- Measure the part to make sure it matches the design.

Sometimes, you may need to add holes or other features. You can do this with extra tools or machines. Finishing makes the part ready for use or for the next step in making a product.

🛠️ Good finishing gives you a part that looks great and works well. It also helps the part last longer in its final job.

By following these steps, you can shape metal parts that are strong, accurate, and ready for many uses.

Materials

When you choose a metal for the hydroforming process, you want to pick one that bends and stretches without breaking. Some metals work better than others. You can see the most common choices below.

Common Metals

Aluminum

Aluminum is a top pick for hydroforming. You can shape it into many forms because it is soft and flexible. This metal is also light, so you can use it to make car parts, bike frames, and even airplane pieces. Aluminum does not rust easily, so your parts last longer.

Stainless Steel

Stainless steel is another popular choice. You can use it when you need strong and sturdy parts. This metal resists rust and keeps its shape well. Many car makers use stainless steel for exhaust systems and other parts that need to handle heat and stress. In hydroforming, stainless steel works well because it can stretch without cracking.

Tip: Ductile metals like aluminum and stainless steel are often used in hydroforming because you can shape them into lightweight and sturdy parts with fluid pressure.

Brass

Brass is a metal that looks gold and feels smooth. You can shape brass into detailed parts. Many people use brass for musical instruments, plumbing parts, and decorative items. Brass bends well and keeps a nice finish after forming.

Titanium

Titanium is strong and very light. You can use it for parts that need to be tough but not heavy. Many aerospace and medical companies use titanium. It does not rust and can handle high temperatures. Hydroforming helps you shape titanium into complex forms that would be hard to make with other methods.

| Metal | Key Properties | Common Uses |

|---|---|---|

| Aluminum | Lightweight, flexible | Car panels, bike frames |

| Stainless Steel | Strong, rust-resistant | Exhausts, kitchen sinks |

| Brass | Decorative, easy to shape | Instruments, fittings |

| Titanium | Tough, light, heat-proof | Aircraft, medical implants |

Selection Factors

When you pick a metal for hydroforming, you need to think about how it will act during the process. Some metals spring back after you shape them. Others might crack if you push them too far. You want to make sure you get the same results every time.

- Springback: Some metals try to return to their old shape after forming. You need to plan for this so your parts stay the right size.

- Material Fractures: If a metal is too hard or brittle, it can crack during forming. You should choose metals that can stretch without breaking.

- Repeatability: You want to use metals that give you the same shape and quality every time you run the hydroforming process.

🛠️ Always test your metal before starting a big project. This helps you avoid mistakes and get the best results.

By understanding the properties of each metal and the factors that affect forming, you can choose the best material for your next hydroforming project.

Benefits

Complex Shapes

Hydroforming lets you make shapes that are hard to do with other ways. It uses high-pressure fluid to push metal into a mold. You do not need many old-style tools. You can make curves and details in just one step. Car makers use this to get exact shapes for frames and panels. Other industries use it when they need special shapes, like in planes and medical tools.

- Hydroforming uses strong fluid pressure to shape metal into molds. This helps you make detailed designs.

- You do not need as many tools, so making new shapes is easier.

- This way is good for jobs that need special curves or details.

- You can get smooth surfaces and sharp corners in one step.

Note: Hydroforming can make harder shapes than stamping. But it might take more time and cost more for big batches.

Strength

Hydroforming makes parts that are not just tricky but also strong. The process makes the metal tougher. This means parts can take more force before bending or breaking. You also get parts that are light but still stiff and tough. The fluid pressure makes the edges and curves even stronger. This helps parts last longer and work better.

| Benefit Description | Strength Comparison |

|---|---|

| Hydroformed parts are stronger and stiffer than normal ones. | Higher than conventional |

| You get lighter, tougher, and stiffer parts for better use. | Higher than conventional |

| The process makes the tube’s edges stronger. | Higher than conventional |

Tip: Stronger parts mean you can use less metal. This saves weight but keeps the part good.

Cost

Hydroforming can help you save money, mostly for small or medium batches. The tools cost much less than for metal stamping. You need fewer dies and can finish parts in fewer steps. This means you spend less on machines and workers. You also get smooth finishes, so you do not need to clean or polish as much.

| Aspect | Hydroforming | Metal Stamping |

|---|---|---|

| Tooling Cost | Up to 50% less | Higher tooling costs |

| Number of Dies | Fewer dies needed | More dies needed |

| Production Cycle | One cycle | Many cycles |

| Complexity of Shapes | Can make tricky shapes | Not as good for tricky shapes |

| Finishing Requirements | Smooth finish, fewer steps | Often needs extra steps |

💡 If you want to make tricky parts without spending too much, hydroforming is a smart pick.

Surface Quality

When you use hydroforming, you get metal parts with great surface quality. The process uses high-pressure fluid to push the metal against a smooth die. This stops scratches and marks that can happen with other ways. You do not need to polish the parts much after forming. The surface looks clean and even right away.

Hydroforming gives you many surface quality benefits:

- Uniformity: The wall thickness is the same everywhere. The pressure spreads out evenly, so you do not get thin spots or bulges. This makes your parts strong and dependable.

- Precision: You get very accurate shapes. The metal fits the die perfectly, so every part matches your design. You do not have to fix mistakes or change the shape later.

- Complex Geometry: You can make shapes with curves, corners, and details that are hard to do with stamping or pressing. The surface stays smooth, even on tough designs.

Tip: If you want parts with sharp edges or deep curves, hydroforming helps you get a smooth finish without extra work.

You can compare hydroforming to other ways of shaping metal. Stamping and pressing often leave marks or rough spots. You may need to sand or polish those parts before using them. Hydroforming cuts down on these problems. The fluid pressure does not scratch the metal. The die keeps the surface safe during forming.

Surface quality is important in many industries. Car makers want panels that look perfect. Aerospace companies need parts with no cracks or weak spots. Medical equipment must have smooth surfaces for safety and hygiene. Hydroforming helps you meet these needs.

Here is a table that shows how hydroforming improves surface quality compared to traditional methods:

| Feature | Hydroforming | Traditional Stamping |

|---|---|---|

| Surface Finish | Smooth, uniform | May need polishing |

| Wall Thickness | Consistent | Can vary |

| Detail Accuracy | High | Lower |

| Defect Rate | Low | Higher |

You also save time and money. You do not spend hours fixing rough surfaces. You get parts that are ready to use or paint. The process works well for both simple and complex shapes.

If you want to make metal parts that look good and last long, hydroforming is a smart choice. You get smooth surfaces, strong walls, and precise shapes every time. This helps your products stand out and work better.

Suitability

When to Use

You should use the hydroforming process when you need metal parts with tricky shapes, smooth surfaces, or strong and light designs. This method is best for parts that must be tough but not heavy. Car makers use hydroforming a lot. They make exhaust modules, axle and transmission parts, body frames, and engine subframes with it. These parts are usually made from steel or aluminum tubes. Hydroforming can make these parts about 30% lighter than old ways. Using fewer parts in one build makes the product stronger and stiffer.

You can also use hydroforming for bike frames, kitchen sinks, and some airplane parts. If you want a part with curves, bends, or hollow spots, this process works better than stamping or welding. You save material and get a part that looks and works better.

Tip: Pick hydroforming if you want fewer welds, less weight, and stronger finished parts.

Here is a table to help you see if hydroforming is right for your project:

| Best Use Cases | Why Choose Hydroforming? |

|---|---|

| Automotive frames and exhaust | Lighter, stronger, fewer welds |

| Bicycle frames | Complex shapes, smooth surfaces |

| Aerospace brackets | High strength, low weight |

| Kitchen sinks | Deep draws, seamless finish |

Limitations

Hydroforming does not work for every job. You need to know what it cannot do before you start. Some shapes and metals can be hard to form. Here are the main problems you might see:

- Design Tolerances: Tight rules can cost more and make checking quality harder.

- Tight Corners: Sharp corners are hard to make. The metal might break if it cannot move into these spots.

- Flat Surfaces: Keeping flat areas flat is tough. The metal might bend or warp during forming.

- Materials: Some metals, like 17-4 PH stainless steel and some titanium, are hard to form. You may need another way for these.

- Lubrication: You must use the right oil. Bad lubrication can ruin the part.

- Tool Design: Tricky shapes may need more tools. This adds time and cost.

Note: Always test your design and metal before making lots of parts. This helps you avoid big mistakes.

You should also know that hydroforming is best for medium-sized batches. If you need millions of parts, stamping may be faster and cheaper. If your part has sharp corners or big flat areas, you may need to change your design or pick another process.

Hydroforming gives you many good things, but you must make sure it fits your needs. Think about your part’s shape, size, and metal before you choose this method.

You can use the hydroforming process to shape metal into hard forms. This process uses high-pressure hydraulic fluid to push the metal. You get parts that are strong and light. The surfaces are smooth, and you do not waste much metal. Many industries pick hydroforming because it is fast and saves money. It also makes parts very exact.

| Benefit | Description |

|---|---|

| Fewer Welds | Parts are stronger and air moves better. |

| Remarkable Precision | Material feeding is controlled very closely. |

| Waste Reduction | Less material is used by joining sections together. |

| Enhanced Surface Quality | Surfaces are smooth and have no defects. |

If you want lighter parts or tricky shapes, you should try hydroforming for your next project.

FAQ

Hydroforming lets you make tricky shapes with fewer tools. It uses strong fluid pressure to shape metal. You get smooth surfaces and strong parts. You also waste less metal.

Yes, you can use hydroforming for small or medium batches. You save money because you do not need many dies.

You can make curves, bends, and hollow shapes. Hydroforming helps you create deep shapes, sharp corners, and smooth surfaces.

No, it does not work with every metal. You get the best results with ductile metals like aluminum, stainless steel, brass, and titanium. Hard or brittle metals might crack.

Hydroformed parts are very strong and stiff. The process keeps the metal tough. You get light parts that last a long time.

Yes, hydroforming is safer for the environment than many other ways. You use less material and make less waste. You often do not need extra finishing steps.

You need special hydroforming presses for this process. These machines use high-pressure hydraulic fluid to shape metal. Regular stamping presses will not work.

Tip: Always check your machine’s pressure limits before you start a new project.