You use a reaming tool to make a hole bigger and smoother. This gives the hole the exact size you need. The tool takes away a little bit of material. This helps parts fit together just right in many jobs, like in planes and cars. The sharp edges of a reamer make holes the right size and smooth. This is very important for precision machining. AFI Industrial Co., Ltd. helps you with expert services and modern machines.

Key Takeaways

- A reaming tool makes holes bigger and smoother. It helps parts fit together in machines and vehicles.

- Use a reamer after drilling to make the hole the right size. It also makes the surface of the hole look better.

- Pick the right reamer for your job. Use hand reamers for easy jobs. Use machine reamers for very accurate work.

- Start with a hole that is a little smaller than you need. This lets the reamer cut the hole to the right size.

- Keep your workspace clean before you start reaming. Remove any dirt or bits to help the tool work well.

- Check your reamer for damage before you use it. This helps you do good work and keeps your holes accurate.

- Use the right oil or grease to keep the reamer cool. This also helps make the hole smoother.

- Measure the hole when you finish to see if it is the right size. Change what you do next time if you need to.

Table of Contents

Reaming Tool Basics

What Is a Reaming Tool

A reaming tool is used to make holes more exact and smooth. You use a reamer after you drill a hole. It helps make the hole the right size and finish. Most reamers have sharp edges that cut away a little bit from inside the hole. Reamers can be made from different materials.

- Carbide reamers are good for hard materials and last longer in big jobs.

- High-speed steel reamers are used for many regular jobs.

- Carbide reamers also work better at fast speeds and can save money over time.

AFI Industrial Co., Ltd. gives expert machining services and uses new reaming tools to help you.

Purpose in Machining

A reamer helps you get a hole with a tight fit and a smooth inside. This is needed when parts must fit together just right, like in engines or machines. The main reasons for reaming are:

| Purpose | Description |

|---|---|

| Dimensional Accuracy | Reaming makes hole sizes more exact in machined parts. |

| Surface Quality | It makes the hole surface smoother and nicer. |

| Application in Industries | Used a lot for medium holes that need to be very exact. |

A reamer lets you control the hole size and makes the surface better than just drilling. You often use reaming in jobs where perfect fits are needed, like in cars or planes.

Reaming vs Drilling

You may wonder how reaming is different from drilling. Drilling makes a hole fast by taking out a lot of material. But the hole from a drill is not always the right size or smooth enough. Reaming is done after drilling to fix this.

| Process | Purpose | Characteristics |

|---|---|---|

| Drilling | Make holes | Fast, takes out more material |

| Reaming | Finish holes for smoothness and accuracy | Slow, takes out a little, makes holes round and exact |

- Reaming is a final step that makes the hole smoother and more exact.

- You use a reamer to make the inside of a hole better.

- Drilling is for making the first hole, but reaming makes it perfect.

Tip: If you want a hole that fits tightly and looks shiny and smooth, always use a reamer after you drill.

AFI Industrial Co., Ltd. uses both drilling and reaming to make sure their parts are high quality.

Types of Reaming Tools

Hand vs Machine Reamers

You will find two main types of reamers: hand reamers and machine reamers. Hand reamers work best for jobs where you need to finish a hole by hand. You use a tap wrench to turn them. These tools are great for light cutting and small adjustments. They help when you do not need very tight tolerances.

Machine reamers work with machines like drill presses or CNC machines. These reamers are stronger and more rigid. They can handle higher speeds and more force. Machine reamers give you better accuracy and a smoother finish. You should use them when you want tight tolerances and a clean cut.

Tip: Use hand reamers for simple jobs and machine reamers for high-precision work.

Here are some common reaming tools you might use:

- Chucking Reamer: Makes pre-drilled holes larger and smoother with tight tolerances.

- Hand Reamer: Good for light jobs, not for very precise holes.

- Shell Reamer: Works on large holes and lets you change cutting edges quickly.

- Ring Reamer: Best for high-speed work on big holes.

- Expansion Reamer: Lets you adjust the size to make up for tool wear.

- Tapered Reamer: Makes holes with a slight taper for special fits.

AFI Industrial Co., Ltd. supports both hand and machine reaming in their precision machining services.

Fixed vs Adjustable

You can choose between fixed and adjustable reamers. Fixed reamers have a set size. They give you high precision and are best for mass production. Adjustable reamers let you change the diameter within a certain range. This helps when you need to adjust for tool wear or different hole sizes.

| Feature | Adjustable Reamers | Fixed Reamers |

|---|---|---|

| Flexibility | Can change size for different needs | One set size only |

| Rigidity | Less rigid | More rigid |

| Precision | Slightly less precise | Very precise |

| Use | Good for rough jobs or when tools wear out quickly | Best for high-precision work |

| Maintenance | Can adjust for wear | Replace when worn |

Adjustable reamers work well for many materials, but fixed reamers are better for tough or hard materials. You should pick the type that matches your job needs.

Flute Styles

Flute style affects how chips leave the hole and how smooth the finish looks. The two main flute styles are right-hand spiral and left-hand spiral.

| Flute Style | Chip Removal Effect | Surface Finish Effect |

|---|---|---|

| Right-hand spiral | Lifts chips out of the hole, keeps hole clean | Makes a smoother finish |

| Left-hand spiral | Pushes chips down, not as good for chip removal | Gives a smooth cut, but can cause issues in blind holes |

Right-hand spiral flutes help you get a cleaner hole and a better finish. Left-hand spiral flutes work well for through holes but may not be the best for blind holes.

Note: The right flute style can make your job easier and improve the quality of your finished hole.

AFI Industrial Co., Ltd. offers a wide range of reaming tools with different flute styles. Their team can help you choose the best tool for your project, making sure you get the results you want.

How to Use a Reamer

Preparation Steps

Before you start the reaming process, you need to prepare the hole and your workspace. Good preparation helps you get the best results and keeps your tools in good shape.

Pre-Drilled Hole Size

You should always start with a pre-drilled hole that is slightly smaller than your final size. The reamer will remove a small amount of material to make the hole smooth and accurate. For most jobs, the pre-drilled hole should be about 90% to 94% of the final diameter. For example, if you want a 10 mm hole, drill it to about 9.9 mm first. This leaves enough material for the reamer to cut, but not too much.

Tip: Leave about 0.010″ to 0.015″ of material for larger holes and 0.003″ to 0.006″ for smaller holes. If you leave too little, the reamer may rub and wear out quickly. If you leave too much, the tool may not cut smoothly.

Deburring and Cleaning

After drilling, you must remove any burrs or sharp edges from the hole. Use a deburring tool or a file to clean up the edges. Make sure the hole is free from chips, dust, or oil. A clean hole helps the reamer cut smoothly and prevents scratches inside the hole.

- Remove all chips and debris from the work area.

- Wipe the hole with a clean cloth.

- Check for any leftover burrs or rough spots.

A clean and smooth starting hole is very important. The reaming tool cannot fix a hole that is already out of shape or has a rough surface. You need to start with a fair-quality hole to get the best results.

Tool Setup

Setting up your reamer and machine correctly is key to a successful reaming operation. Take your time with these steps to avoid mistakes.

Inspecting the Reamer

Check your reamer before you use it. Look for any signs of wear, chips, or dull edges. A sharp and straight reamer gives you a better finish and lasts longer. If you see any damage, replace or regrind the tool.

- Make sure the reamer is clean and free from oil or dirt.

- Check that the cutting edges are sharp.

- Inspect the shank for any bends or cracks.

You should also check the roundness and location of the starting hole. If the hole is not round or is off-center, the reamer will not fix it.

Securing the Tool

Secure the reamer in a high-quality chuck or holder. Make sure the tool is tight and does not slip. Keep the tool overhang as short as possible. This helps prevent flexing and keeps the reamer steady during the cut.

- Use a rigid setup to hold the workpiece.

- Make sure the machine spindle has no play.

- If possible, use a floating holder to reduce tool deflection.

Note: AFI Industrial Co., Ltd. uses advanced machines and strict quality control to make sure every reaming operation is set up for success.

Safety Tips

Safety is always important when you work with machining tools. Follow these tips to protect yourself and your workspace:

- Wear personal protective equipment (PPE) like safety glasses and gloves.

- Make sure the reamer is properly set up and secure before you start the machine.

- Keep your workspace clean and organized. Remove any loose tools or materials from the area.

- Follow your shop’s standard operating procedures for reaming operations.

- Never touch the reamer or workpiece while the machine is running.

Always stay alert and focused during the reaming process. A safe workspace helps you avoid accidents and keeps your tools in good condition.

AFI Industrial Co., Ltd. trains its team to follow strict safety and quality standards. Their experience ensures that every reaming a hole operation meets the highest level of precision and safety.

Step-by-Step Reaming Tool Guide

Machine Setup

Setting up your machine correctly is the first step to a successful reaming operation. You want to make sure everything is ready before you start. Follow these steps to prepare your machine for reaming:

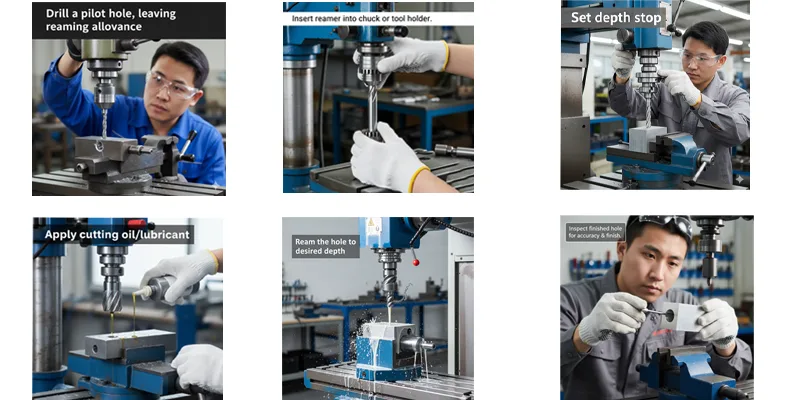

- Drill a hole that leaves enough material for the reamer to cut. This is called a ream allowance hole.

- Insert the reamer into the drill chuck or machine holder.

- If your machine does not have a rotational restriction device, install one. This keeps the reamer from spinning out of control.

- Touch the reamer to the top of the workpiece and set a depth stop. This helps you control how deep the reamer goes.

- Calculate the correct speed and feed for reaming. Run the reamer at about half the speed of the drill and use double the feed rate. This helps you get a smooth finish and prevents tool wear.

- Apply cutting oil or lubricant to both the reamer and the hole.

- Turn on the spindle and adjust the speed as needed.

- Lower the quill gently until the reamer is just above the workpiece.

- In one smooth motion, ream the hole to the desired depth.

- Turn off the spindle and carefully remove the reamer.

- Examine the finished hole for accuracy and surface quality.

Tip: Keep the tool overhang as short as possible. This gives you more stability and reduces the chance of tool deflection.

AFI Industrial Co., Ltd. uses advanced equipment and strict setup procedures to ensure fast turnaround and high-quality results.

Aligning the Reamer

Proper alignment of the reamer is very important. If the reamer is not lined up with the hole, you can get a bell-mouthed or tapered hole. This means the hole will not be straight or the right size.

- Check your machine for worn spindles or misaligned chucks. These can cause the reamer to wobble.

- Make sure the workpiece is held firmly and is not tilted.

- Use a floating reamer holder if your setup is not very rigid. This helps the reamer follow the hole and prevents distortion.

- Double-check the calibration of your machine before you start.

Note: Good alignment helps you avoid problems like chatter, squeaking, or uneven holes. Always take a moment to check your setup before reaming.

Lubrication

Lubrication plays a key role in reaming. It keeps the reamer cool, helps remove chips, and gives you a better surface finish. The type of lubricant you use depends on the material and the type of hole.

- For deep holes, use high-pressure coolant through the tool. This helps push chips out and keeps the reamer from getting too hot.

- When reaming stainless steel with carbide tools, use an emulsion coolant with 8–10% concentration. This gives you a smooth finish.

- For blind holes, oil-based cutting fluids or mist lubrication work well. They prevent chips from packing at the bottom of the hole.

- Minimal Quantity Lubrication (MQL) is a modern method that uses a small amount of oil right at the tool tip. This method is good for health and the environment.

If you do not use enough lubricant, you may see poor surface finish or even tool chipping. Always make sure you have a steady flow of the right fluid for your material.

Tip: Consistent lubrication helps your reaming tool last longer and keeps your holes accurate.

Reaming Technique

Feed and Speed

You need to set the right feed and speed for a successful reaming operation. If you run the machine too fast or too slow, you can damage the hole or the tool. Always remember that reaming works best at a slower speed but with a higher feed rate than drilling.

Here is a simple table to help you compare the recommended settings:

| Operation | Spindle Speed (RPM) | Feed Rate |

|---|---|---|

| Drilling | 100% | 100% |

| Reaming | 66% | 200%-300% |

You should run the reamer at about two-thirds the speed of your drill. Increase the feed rate to two or three times what you use for drilling. This helps the reamer cut smoothly and prevents rubbing. Always use steady pressure. If you use a machine, let it feed the tool. For hand reaming, use a tap wrench and turn the tool with even force.

To avoid chatter and get a smooth finish, try these techniques:

- Increase the feed rate to 200-300% higher than for drilling.

- Lower the spindle speed to about two-thirds of the drilling speed.

- Keep the tool rigid by minimizing overhang and securing the holder tightly.

- Choose the right flute style for your material.

- Use right-hand helical flutes for non-ferrous materials to lift chips out.

- Use left-hand helical flutes for pushing chips forward and reducing slack.

- Adjust spindle speed to avoid resonance and find a speed with minimal chatter.

Tip: If you hear squeaking or see vibration marks, adjust your speed or feed rate. A smooth, steady sound means you have the right settings.

Entry and Exit

How you start and finish the reaming process affects the quality of the hole. When you begin, align the reamer with the hole and start feeding gently. Do not force the tool. Let it center itself and cut evenly. If you push too hard at the start, you can damage the hole or break the tool.

As you reach the end of the hole, keep the feed steady. Do not stop or reverse the tool while it is still inside the hole. Always let the reamer exit the hole completely before turning off the machine or removing the tool. This prevents scratches and keeps the hole round and smooth.

Note: A careful entry and exit help you avoid bell-mouthed holes and rough finishes.

Inspection

After you finish reaming, you need to check the hole for size and surface quality. Inspection makes sure your work meets the required standards. You can use several tools to measure the hole. Each tool has its own strengths.

| Inspection Method | Description |

|---|---|

| Plug Gauges | Fastest way to ensure hole size; uses ‘go’ and ‘no-go’ gauges for tolerance limits. |

| Calipers | Common tool, but can have measurement inaccuracies of up to 0.002″ (0.05 mm). |

| Telescoping Bore Gauges | Effective for checking moderately tight tolerances; requires practice to use accurately. |

| Coordinate Measuring Machines (CMM) | Can check bores but may be less efficient than manual tools. |

Plug gauges give you a quick pass/fail check. Calipers are easy to use but may not be accurate enough for tight tolerances. Telescoping bore gauges work well if you have some experience. CMMs provide detailed measurements but take more time.

Always inspect the hole right after reaming. If you find any problems, you can fix them before moving to the next step.

AFI Industrial Co., Ltd. uses advanced inspection tools and strict quality checks. Their team ensures every hole meets your exact needs.

Achieving Precision Results

Consistent Pressure

When you use a reamer, you need to keep steady pressure. This helps the reamer stay centered in the hole. If you push too hard or too softly, the tool can move off track. Consistent pressure gives you a smooth surface and the right hole size. You also help the reamer last longer. If you change pressure often, you might get a rough finish or a hole that is not the right size. Keeping the pressure steady during reaming makes your work more accurate and helps your tools work better for a longer time.

Tip: Let the machine or your hand feed the reamer at a steady rate. Do not rush or stop in the middle of reaming a hole.

Tool Wear

You need to watch your reamer for signs of wear. A worn tool can ruin your work. Here are some signs that your reamer might need to be replaced or sharpened:

- Poor surface finish on the inside of the hole. Dull reamers can leave rough or uneven surfaces.

- You notice it takes more force to push the reamer through the hole.

- The reamer or the workpiece feels hotter than usual.

- The holes you make start to go out of size or shape.

If you see any of these signs, stop and check your tool. Using a worn reamer can lead to mistakes and wasted parts. You should inspect your reamer before each job. Clean it and look for chips or dull edges. Replace or sharpen the tool if you see damage. This keeps your reaming process smooth and your results accurate.

Lubrication Choice

Choosing the right lubricant is important for reaming. Lubrication helps the reamer cut smoothly and keeps it cool. It also helps remove chips from the hole. If you use the wrong lubricant, the tool can get too hot or wear out faster. For most metals, you can use cutting oil or a water-based coolant. For tough materials, you might need a special oil or a thicker coolant. Always apply enough lubricant to both the reamer and the hole before you start. This helps you get a better finish and makes your reamer last longer.

Note: Good lubrication is one of the best ways to protect your reamer and improve the quality of your work.

AFI Industrial Co., Ltd. uses high-quality lubricants and follows strict quality checks. Their team works to make sure every reaming job meets ISO 9001 and SGS standards for quality.

Measuring the Hole

After you finish reaming a hole, you need to check its size and shape. This makes sure your work matches what is needed. You use different tools to measure the diameter and roundness of the hole.

How to Measure Diameter

- Micrometer

A micrometer helps you measure the inside diameter. First, clean and check the micrometer. Put it gently into the hole. Turn the thimble until both sides touch the hole. Look at the scale to see the number. Measure in different places to make sure the size is the same. - Bore Gauge

A bore gauge shows the diameter on a dial or screen. Put the gauge inside the hole and let it expand until it fits tightly. Read the number on the display. Move the gauge to other spots to check if the hole is even everywhere.

Tip: Always measure in many places inside the hole. This helps you find spots that are too tight or too loose.

How to Measure Roundness

- Roundness Measuring Instrument

Put the workpiece with the hole on the spindle of the roundness measuring instrument. The probe moves along the edge while the spindle turns. The instrument records numbers at set times. You can look at the data to see how round the hole is. A lower roundness number means the hole is closer to a perfect circle. - Three-Point Method

Take three measurements at 120-degree spots around the hole. Compare the numbers. If they are close, the hole is round. If the numbers are different, the hole may not be the right shape.

Note: Checking roundness is important for parts that must fit together well. Even a small mistake can cause problems when putting things together.

Quality Assurance

You should always check your work after reaming a hole. Good measurement helps you avoid mistakes and wasting materials. AFI Industrial Co., Ltd. uses advanced inspection tools and strong quality checks. Their ISO 9001 and SGS certifications show they care about high standards. When you measure and check every hole, you know your parts will work well in real life.

Remember: Careful measurement is the last step in precision machining. It makes sure your hard work gives you good, reliable results.

Troubleshooting and Mistakes

Oversized Holes

Sometimes, the hole you make with a reamer is too big. This can happen for many reasons while you work. If the hole is too large, parts may not fit well. They might even fail when used. You need to stop this problem to keep your work correct.

Here is a table that shows why holes get too big and how to fix them:

| Cause of Oversized Holes | Possible Solutions |

|---|---|

| Misalignment | Adjust alignment |

| Incorrect feed/speed | Optimize feed/speed |

| Concentricity error | Check reamer setup |

| Damaged fit | Repair or replace |

| High cutting speed/feed | Reduce speed/feed |

| Unsuitable coolant | Use appropriate coolant |

Look for these problems:

- The hole and reamer are not lined up.

- The tool is damaged or worn out.

- The reamer has the wrong bevel lead.

- The speed or feed is too high.

- The coolant does not match the material.

To stop oversized holes, check your machine before you start. Make sure the reamer matches the hole. Use the right speed and feed for your job. Change old tools before you begin. Pick a coolant that works with your workpiece.

Tip: Careful setup and checking often help you avoid big holes and keep your parts the right size.

Poor Finish

If the inside of the hole is rough, it can cause trouble. Moving parts or seals may not work well. You want the surface smooth so parts fit and move easily. Bad finish comes from using the wrong tool, poor setup, or wrong feed rates.

Here is a table to help you find and fix poor finishes:

| Factors Contributing to Poor Surface Finish | Corrective Actions |

|---|---|

| Tool selection | Use the correct reamer type |

| Feed rates | Control feed rates |

| Machine setup | Ensure proper machine setup |

| Runout | Control runout |

You can make the finish better by:

- Choosing the right reamer for your material.

- Keeping the feed rate between 0.003 and 0.012 inches per turn.

- Making sure the machine holds the reamer steady.

- Using a floating holder to control runout if needed.

How you mount the tool matters a lot. If you drill and ream in the same setup, use a solid mount. This keeps the center straight and helps you get a smoother finish.

Note: A smooth finish lowers friction, helps seals work, and keeps dirt out of moving parts.

Tool Breakage

If your reamer breaks, your work stops and your part may get ruined. You need to know why this happens so you can stop it. Reamers break if you use the wrong tool, sharpen it badly, or use too much force.

Here is a table with reasons and fixes for tool breakage:

| Cause of Tool Breakage | Solution |

|---|---|

| Improper selection of tool materials | Select the right tool material for your workpiece |

| Incorrect geometric parameters | Adjust angles and blade shape for strength |

| Poor welding and sharpening quality | Use high-quality sharpening and welding |

| Excessive cutting force | Choose lower cutting amounts to reduce force and heat |

| Insufficient rigidity | Make the setup more rigid to stop vibration |

| Careless operation | Follow correct steps and avoid sudden loads on the tool |

Stop breakage by picking the right reamer material and shape. Make sure the tool is sharp and made well. Keep the setup strong and do not make sudden moves. Use the right force and speed for your material.

Always check your reamer before each job. Change it if you see chips, cracks, or dull edges. This keeps your work safe and correct.

Solutions

When you have trouble with reaming, there are ways to fix it. Each problem has a reason and a way to solve it. Here are some problems and what you can do about them:

1. Chatter and Squeaking

Chatter is a loud sound and leaves marks in the hole. Squeaking means the tool is rubbing, not cutting. You can fix these problems by:

- Lowering the spindle speed. This helps stop shaking.

- Making the feed rate higher. The reamer will cut better.

- Using a power feed if you can. This keeps the movement smooth.

- Checking if the reamer is sharp and has the right chamfer angle.

- Making sure the setup is tight. Loose parts can shake and cause noise.

Tip: If you hear chatter, stop and check your setup before you keep going.

2. Poor Surface Finish

A rough finish can make parts not fit well. You can make the finish better by:

- Regrinding the reamer so all chamfers are the same.

- Making the reamer margins smaller for soft materials.

- Adding a back taper to the reamer.

- Using spiral fluted reamers to help chips come out.

- Grinding a second lead angle behind the chamfer.

Here is a table to help you match problems and fixes:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Poor Finish | Unequal chamfers, wrong margins, spindle runout, chatter | Regrind chamfers, narrow margins, add back taper, lower speed, raise feed, use spiral flutes |

3. Tool Breakage

If your reamer breaks, you need to fix it fast. Tool breakage happens from too much force or bad alignment. You can stop this by:

- Reducing the amount of material left for the reamer to cut.

- Making sure the reamer and hole are lined up right.

- Using the right force. Do not push too hard.

- Checking the tool for damage before you use it.

| Problem | Possible Causes | Solutions |

|---|---|---|

| Tool Breakage | Too much force, bad alignment | Cut less, check alignment |

4. Preventive Measures

You can stop many problems by doing these things:

- Check your reamer before every job. Look for dull or chipped edges.

- Change the reamer if you see damage or if the finish gets worse.

- Keep your machine and tools clean.

- Use the right lubricant for your material.

- Always measure the hole after reaming to find mistakes early.

Remember: Checking often and having good habits help you get the best results when you use a reamer.

Best Practices

Maintenance

You want your reamer to last a long time and work well every time. Good maintenance helps you get the best results from your reaming jobs. Here are some simple steps you can follow:

- Clean your reamer after each use. This removes chips and debris that can damage the cutting edges.

- Inspect your reamer for wear or damage. Look for dull spots, chips, or cracks before you start a new job.

- Lubricate your reamer with the right oil. This keeps the tool moving smoothly and protects it from rust.

- Store your reamer in a dry place. Use a rust-inhibiting oil if you live in a humid area.

- Remove any build-up on the cutting edges with a fine-grit diamond honing tool. Be careful not to re-sharpen unless needed.

- Check the alignment and calibration of your reamer often. This helps you keep your holes accurate.

Tip: Regular maintenance saves you money and time. You avoid tool failure and get better results with every reaming operation.

Process Control

You need to control your process to get the same high-quality results every time. Good process control means you follow the same steps and check your work often. Here are some ways to keep your reaming process on track:

- Document each step of your reaming process. Write down the speeds, feeds, and lubricants you use.

- Use the same setup for each job. This helps you avoid mistakes and keeps your holes consistent.

- Monitor your reamer during use. If you notice more force is needed or the finish looks rough, stop and check the tool.

- Measure your holes after each reaming. Use plug gauges or bore gauges to make sure the size is correct.

- Keep your workspace clean and organized. This helps you find tools quickly and reduces the chance of errors.

| Step | Why It Matters |

|---|---|

| Document process | Ensures repeatable results |

| Monitor tool | Prevents tool failure |

| Measure holes | Confirms accuracy |

| Clean workspace | Reduces mistakes |

Note: When you control your process, you get reliable results and fewer surprises.

Continuous Improvement

You can always make your reaming process better. Continuous improvement means you look for small changes that help you work faster, safer, or with better quality. Here are some ideas:

- Review your results after each job. Ask yourself what went well and what could improve.

- Try new lubricants or cutting speeds to see if you get a smoother finish.

- Train yourself and your team on the latest reamer care and machining techniques.

- Replace old or worn reamers before they cause problems.

- Keep up with new tools and technology in the machining world.

If you want support with your precision machining needs, AFI Industrial Co., Ltd. offers expert help and reliable service. Their team can help you improve your process and get the best results from every reamer you use.

You have learned how to use a reamer for precision machining. First, pick the right tool for your job. Get your workspace ready before you begin. Use the reamer with care and check your work after. Always follow good steps to make holes smooth and the right size. If you need help or want great parts, AFI Industrial Co., Ltd. can help with your machining projects.

FAQ

You use a reaming tool to make a hole smoother and more accurate. It helps you get the exact size you need for parts to fit together well.

You should leave about 0.010″ to 0.015″ for large holes and 0.003″ to 0.006″ for small holes. This gives the reamer enough material to cut smoothly.

Yes, you can use a hand reamer with a tap wrench. Hand reaming works best for small jobs or when you do not need very tight tolerances.

Try lowering the spindle speed and increasing the feed rate. Make sure your setup is rigid. Check that the reamer is sharp and properly aligned.

Look for these signs:

- The hole surface looks rough.

- You need more force to cut.

- The reamer feels hot.

- The hole size is not correct.

You should use cutting oil or water-based coolant for most metals. For tough materials, use a special oil. Always apply enough lubricant to both the reamer and the hole.

Oversized holes can happen if the reamer is worn, the setup is not aligned, or the speed is too high. Check your tool, alignment, and machine settings before you start.