You use the heat treatment of aluminum to change how it acts. This helps you meet different needs. The most common types of heat treatment are annealing, homogenizing, solution heat treatment, natural aging, and artificial aging. These methods help you make aluminum stronger. They also enhance its ability to bend, increase hardness, and reduce internal stress.

Here are the types of aluminum heat treatment and how they work:

| Type of Treatment | Description |

|---|---|

| Annealing | Changes grain structure and lowers stress inside. |

| Homogenizing | Makes the structure even by heating close to melting. |

| Solution Heat Treatment | Mixes elements and maintains structure by cooling rapidly. |

| Natural Aging | Strengthens aluminum at room temperature over time. |

| Artificial Aging | Heats to a specific temperature to enhance strength. |

When you apply the heat treatment of aluminum, it becomes stronger. It also increases in hardness and improves its bending capabilities. These beneficial changes make aluminum valuable in many industries.

Key Takeaways

- Heat treatment changes how aluminum acts. It makes it stronger, harder, and more bendable.

- Some common heat treatment methods are annealing, homogenizing, solution heat treatment, natural aging, and artificial aging.

- Each method has its own job. Some make aluminum easier to shape. Others make it stronger.

- People use heat-treated aluminum in many industries. These include aerospace, automotive, and marine. It is popular because it is strong and light.

- It is important to control the temperature during heat treatment. This helps get the right results and keeps the metal safe from harm.

- Quality tests, like checking hardness and tensile strength, make sure the aluminum is good after treatment.

- Picking the right aluminum alloy and heat treatment is important. This helps your project work its best.

- Knowing the temper designation system helps you choose the right aluminum for your needs.

Table of Contents

Heat Treatment of Aluminum

Purpose

You use heat treatment to change how aluminum acts and get hardening aluminum. This helps you control its strength, hardness, and flexibility. Heating makes the grains inside the aluminum grow or shrink. It also changes how the elements mix in the alloy. This lets you get the right properties for your project.

Heat treatment is important because it matches aluminum’s properties to what you need. For example, you can make aluminum strong for airplane parts. You can also make it soft so it bends into shapes.

Here is a table that shows how different aluminum alloy series react to heat treatment:

| Alloy Series | Key Elements | Heat Treatment Effects |

|---|---|---|

| 2XXX | Cu (2.5–5.0%) | Forms Al2CuMg and CuAl2, which make it stronger and less stretchy. |

| 6XXX | Mg, Si | Makes Mg5Si6 and Mg2Si, which help stop rust and make it easier to shape. |

| 7XXX | Zn | Very strong alloys used in airplanes, like 7050, 7049, and 7075. |

Benefits of Heat Treatment

Heat treatment changes the tiny structure inside aluminum. You can control the size and shape of the grains. The elements inside spread out more evenly. These changes help the metal work better.

- Grains become even, so the metal gets stronger.

- Second phase particles spread out, so it bends and stretches more easily.

- Weak spots get smaller, so the metal lasts longer.

For example, T6 heat treatment makes grains smaller and the metal stronger. Tensile strength can go over 500 MPa, and it gets harder. T73 or RRA treatments help stop rust and keep good strength.

You can change the heat treatment to get the best results for your alloy. If you add more magnesium and use the right aging temperature, you can get strength over 340 MPa. This helps you make parts that are strong and light.

Industry Applications of Heat Treating Aluminum

Many industries use aluminum heat treatment to get the right properties. These aluminum common applications of heat treating include:

- The car industry, which uses 35% of all metal heat treatment. Car makers want parts that are light and strong for electric and hybrid cars.

- The airplane industry, which is growing fast and needs strong, safe materials.

- Metalworking, building, and energy companies use heat-treated aluminum for gears, axles, and other parts.

You pick aluminum heat treatment when you need parts that are strong, light, and tough. This makes it important in many jobs.

Types of Aluminum Heat Treatments

When you look at aluminum heat treatments, each method changes the metal in its own way. These processes help you get the right strength, flexibility, and hardness for your project. The table below shows how each type is different:

| Process | Purpose/Effect | Temperature Range | Key Characteristics |

|---|---|---|---|

| Annealing | Makes aluminum softer and easier to bend. | Specific temperature, slow cooling | Changes the inside structure, helps shape, stops cracks. |

| Homogenizing | Spreads alloying elements evenly in the metal. | 900°F to 1000°F | Removes uneven spots, makes shaping easier. |

| Solution Heat Treatment | Mixes alloying elements for a smooth structure. | 825°F to 980°F | Quick cooling keeps elements mixed, makes metal easier to bend. |

Annealing

Process

Annealing is one types of heat treating, it makes aluminum soft and easy to shape. You heat the metal to a set temperature and keep it there. Then you let it cool slowly. The temperature and time depend on the alloy type. For example:

| Aluminum Alloy Series | Temperature Range (°C) | Duration |

|---|---|---|

| 1xxx (Pure Aluminum) | 200-300 | 30 min – 2 hrs |

| 3xxx (Manganese) | 300-400 | 1-4 hrs |

| 5xxx (Magnesium) | 300-450 | 1-3 hrs |

| 6xxx (Mg-Si) | 350-500 | 1-5 hrs |

| 7xxx (Zinc) | 300-500 | 2-6 hrs |

Annealing changes the grains inside the metal. There are three steps:

- Recovery: Fewer grain problems.

- Recrystallization: New grains form with less stress.

- Grain Growth: Grains get bigger and stronger.

Recrystallization means new grains form inside the metal. These grains have little stress and few problems at their edges.

Applications

Annealing helps you bend or shape aluminum without breaking it. It works well for sheets, wires, and tubes. You use it after cold working to make the metal less stressed and easier to use. Annealing stops parts from cracking or breaking when you shape them.

- Makes metal easier to bend or stretch.

- Removes stress inside, so parts last longer.

- Lowers the chance of cracks when forming.

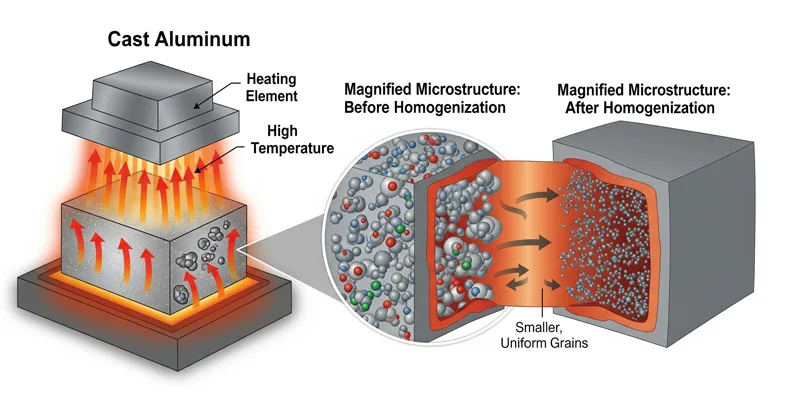

Homogenizing

Process

Homogenizing makes cast aluminum more even inside. You heat the metal to a high temperature, usually between 900°F and 1000°F (about 480°C to 540°C), and keep it there for hours. For example, Al5083 alloy is heated at 500°C for 3 hours.

Atoms move and spread out during this process. This fixes uneven spots from casting. The metal cools slowly after heating.

- Homogenizing removes uneven elements and phases.

- Atoms spread out evenly, fixing the inside structure.

- The metal gets a smoother inside with smaller grains.

Applications

Homogenizing is mostly for cast aluminum products. It helps the metal work better and makes it stronger. You use it before rolling, squeezing, or shaping.

- Makes shaping and working easier.

- Makes metal stronger and steadier.

- Gets castings ready for more steps.

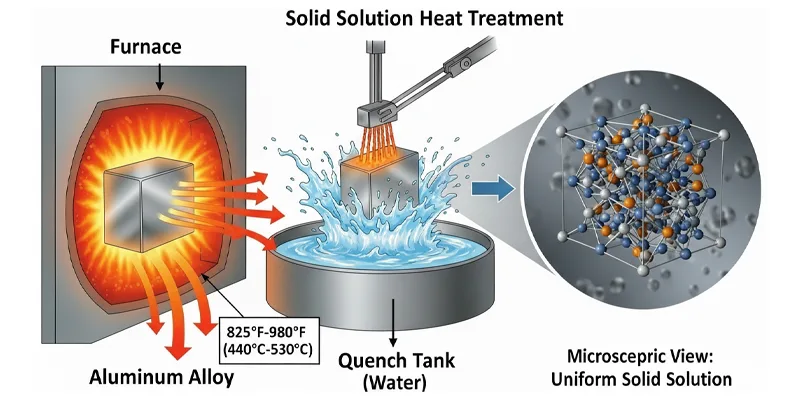

Solution Heat Treatment Process

Process

Solution heat treatment mixes alloying elements into aluminum. You heat the metal to a certain temperature, usually between 825°F and 980°F (about 440°C to 530°C), and hold it there. Then you cool it quickly, often in water. This fast cooling keeps the elements mixed.

This process makes the metal easier to bend and gets it ready for more strengthening.

| Property | Before Treatment | After Treatment | Improvement |

|---|---|---|---|

| Ultimate Tensile Strength | N/A | 650 MPa | Big increase |

| Maximum Elongation | N/A | 13.2% | Good increase |

| Hardness (HV) | N/A | 190.4 HV | Higher |

Applications

You use solution heat treatment process for strong aluminum alloys, like those in planes and cars. This process gives you a good mix of strength and flexibility. After this, you can use aging to make the metal even stronger.

- Gets alloys ready for age hardening.

- Makes metal stronger and harder.

- Used for airplane parts, car frames, and tough pieces.

Picking the right heat treatment lets you match aluminum’s properties to your needs. Each method gives you control over strength, bending, and steadiness.

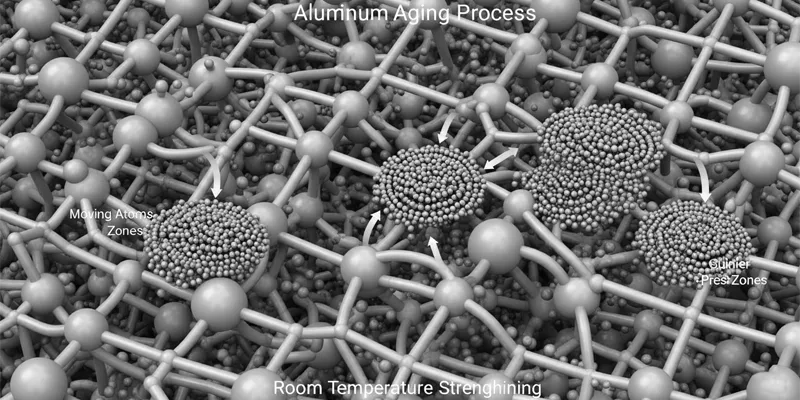

Natural Aging

Process

Natural aging makes aluminum alloys stronger at room temperature. After solution heat treatment, you let the metal sit. You do not add heat. Atoms inside move slowly. They form tiny clusters called Guinier-Preston zones. These clusters make the metal harder and stronger over time.

- Natural aging is also called low-temperature aging.

- You do not need special tools for aging process.

- The process happens by itself after heat treating.

Natural aging works best for some alloys. How fast and how much the metal hardens depends on the alloy type. Here is a table that shows how long different alloys take to age at room temperature:

| Alloy | Aging Time at Room Temperature | Notes |

|---|---|---|

| 2024 | Rapid aging within 1 day | Hardening almost done after 4 days. Used in T4, T3, T36 tempers. |

| 6061 | Good aging in 4 days | Often used in T4 temper; keeps aging slowly for months. |

| 7075/79 | Strong aging in several days | Keeps getting harder for years; rarely used in W temper. |

Natural aging gives you an easy way to make metal stronger. The process uses extra spaces in the metal. These spaces help clusters form.

Applications

You use natural aging to make metal stronger without extra heating. This method is good for parts that do not need to be made quickly. You often see natural aging in:

- Aircraft parts that need both strength and flexibility.

- Car panels and frames made from 2024 or 6061 alloys.

- Structural pieces that can get stronger over time before use.

Natural aging is common in the T4 temper. You let the metal get harder at room temperature after solution heat treatment. You pick this method when you want slow, steady strength.

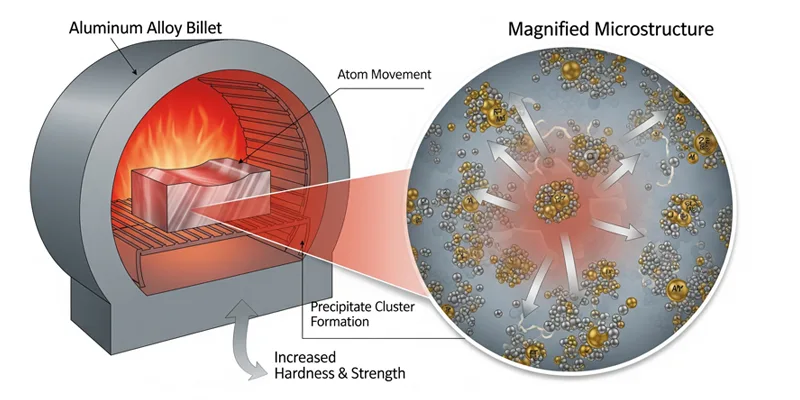

Artificial Aging

Process

Artificial aging is also called precipitation hardening or age hardening. It uses heat to make the metal harden faster. After solution heat treatment, you put the aluminum in an oven. The oven is set to a temperature higher than room temperature but much lower than melting. The heat helps atoms move and form strong particles inside.

Here are the main things you control in artificial aging:

| Process Variable | Description |

|---|---|

| Aging Temperature | The temperature for aging, usually between 95°-205°C. |

| Aging Time | How long the aluminum stays at the aging temperature. |

| Chemical Composition | The alloying elements in the aluminum, which affect how fast it hardens. |

You can change the temperature and time to control the final properties. Lower temperatures and longer times usually give higher strength. Higher temperatures and shorter times make the process faster but may lower strength.

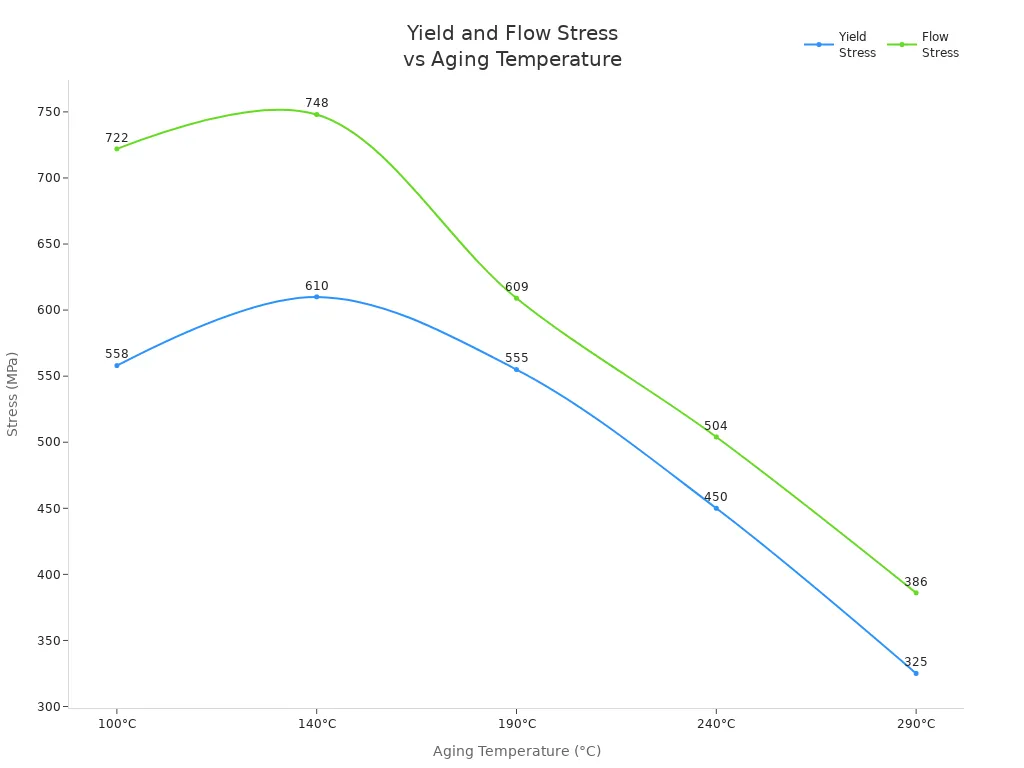

The chart below shows how yield and flow stress change at different aging temperatures:

Artificial aging uses equilibrium vacancies. These help the metal harden faster than natural aging. You get a big increase in strength in a short time.

Applications

You use artificial aging when you need strong parts quickly. This method is common in industries that need high performance and fast production. You often see artificial aging in:

- Aerospace parts like wings and landing gear.

- Automotive wheels, frames, and suspension parts.

- Marine hardware and defense equipment.

Artificial aging is an important step for many high-strength alloys. You use it after solution heat treatment to get the best mix of strength and toughness. This method lets you control the metal’s final properties. It is great for tough jobs.

Aluminum Heat Treatment Processes

Temperature Control

You need to control temperature carefully when you work with aluminum, it’s the key steps of the heat treating process. The right temperature helps you get the best results from the heat treating process. If you use the wrong temperature, you can make the metal too soft or even melt it.

“I can’t emphasize too much the criticality of temperatures in this heat treating process. If you’re not careful, the castings can get soft on you, or in the worst case, they melt.”

You should follow these best practices for temperature control:

- Keep the temperature steady during solution heat treatment, usually around 525°C.

- Quench the aluminum quickly in water or a special liquid to lock in the structure.

- Control how fast you put the metal into the quench. A rate between 0.15 m/s and 3 m/s helps prevent bending or warping.

- Heat the metal slowly at first. This stops big temperature changes that can cause cracks or distortion.

You also need to check your equipment often. Here is a simple checklist:

- Check the heat treat furnace for even temperature every three months and after any repairs.

- Use certified thermocouples and test your temperature system every week.

- Follow SAE standards to keep the heat even in your furnace.

Equipment

You use special equipment for heat treating aluminum. The main tool is the heat treat furnace. This furnace lets you set and hold the right temperature for each step. You also need quenching tanks filled with water or polymer solutions. These tanks help you cool the metal quickly after heating.

Some other important tools include:

- Thermocouples: These measure the temperature inside the furnace.

- Timers: These help you keep track of how long you heat or cool the metal.

- Racks and baskets: These hold the aluminum parts in place during the heat treatment process.

You must keep your equipment clean and in good shape. Dirty or broken tools can ruin your results. Always check your furnace and quenching tanks before you start.

Quality Assurance

You want to make sure your aluminum meets the right standards after heat treating. Quality assurance helps you check if the metal has the strength and hardness you need.

You can use these common tests:

- Mechanical Testing: You pull or bend a sample to see how strong it is.

- Hardness Testing: You use a Rockwell ‘B’ tester to measure how hard the metal is.

- Conductivity Measurements: You use an eddy-current meter to check how well the metal carries electricity. This test shows if the heat treatment worked as planned.

Tip: Always test a few samples from each batch. This helps you catch problems early and keep your products safe.

If you follow these steps, you can trust your aluminum parts to perform well in their final use.

Types of Aluminum Alloys

Heat-Treatable Alloys

You use heat-treatable aluminum alloys when you need high strength and durability. These alloys contain elements like copper, magnesium, silicon, or zinc. You can make them stronger by using heat treatment processes such as solution heat treatment and artificial aging. This makes them perfect for jobs where you need the metal to handle heavy loads or resist dents.

Here is a table that shows the main differences between heat-treatable and non-heat-treatable alloys:

| Type of Alloy | Composition Details | Strengthening Method |

|---|---|---|

| Non-Heat-Treatable Alloys | Alloying with elements like manganese, silicon, and magnesium (1xxx, 3xxx, 4xxx, 5xxx series) | Strength is increased through cold working or strain hardening, with final stabilization treatments. |

| Heat-Treatable Alloys | Alloying with elements such as copper, magnesium, silicon, and zinc (2xxx, 6xxx, 7xxx series) | Strength is enhanced through thermal treatments, quenching, and artificial aging processes. |

You often see heat-treatable aluminum alloys in airplanes, cars, and bikes. These alloys can reach very high strength after you heat treat them. For example, you might use the 6xxx series for car panels because you can make them strong and thin at the same time.

Tip: If you need a part that must stay strong under stress, choose a heat-treatable alloy.

Non-Heat-Treatable Alloys

Non-heat-treatable aluminum alloys work best when you need good formability and corrosion resistance. You cannot make them stronger by heat treating. Instead, you increase their strength by cold working, which means you bend or roll the metal to make it harder.

You find these alloys in the 1xxx, 3xxx, 4xxx, and 5xxx series. They are great for making cans, kitchen foil, and marine parts. These alloys do not reach the same strength as heat-treatable types, but they resist rust and are easy to shape.

- Non-heat-treatable alloys are best for parts that do not need high strength.

- You can use them for products that need to last in wet or salty places.

- These alloys usually have a yield strength below 300 MPa, so you should not use them for airplane frames or other high-stress jobs.

Temper Designation System

You use the temper designation system to show how aluminum alloys have been processed. This system uses letters and numbers to tell you about the treatment and the properties of the metal. Even if two alloys have the same composition, their temper codes can make them act very differently.

Here is a table with the most common temper codes:

| Temper Code | Description |

|---|---|

| -F | as fabricated |

| -O | annealed |

| -H | strain hardened |

| -T | thermally treated |

The temper code affects how strong, hard, or flexible your aluminum alloy will be. For example:

- H-Series: You get strain-hardened alloys, which means you made them stronger by working the metal without heat.

- T-Series: You get heat-treated alloys, which means you used heat to make them stronger and tougher.

Note: The temper designation helps you pick the right aluminum alloy for your job. It tells you if the metal will bend, stretch, or hold up under pressure.

You should always check the temper code before you choose an alloy. This helps you make sure the metal will work well in your project. The right temper can change the strength, hardness, and even how long your part will last.

Applications of Aluminum Heat Treatment

Aerospace

Aluminum heat treatment is very important in making airplane parts. When you use alloys like 2024 and 7075, the parts get strong and stay light. These alloys help build wings, fuselages, and landing gear. The parts can handle lots of stress and tough weather.

Solution treatment and precipitation hardening make these alloys stronger and harder. This helps airplane parts last longer and resist damage, even in harsh places.

Here is a table that shows how alloys help in aerospace:

| Alloy | Application | Performance Improvement |

|---|---|---|

| 2024 | Aircraft wings and repairs | High tensile strength and stress resistance |

| 7075 | Fuselages and gears | High fatigue resistance in extreme conditions |

These processes help parts meet strict safety rules. Picking the right heat treatment keeps airplanes safe, reliable, and efficient.

Automotive

Heat treating aluminum is common in making car parts. When you heat treat aluminum, the parts get stronger and last longer. Solution treatment and precipitation hardening help parts keep their shape under heavy loads. This makes cars safer and more dependable.

- Suspension parts get stronger and bend better. They handle bumps and turns.

- Annealed parts take more stress and strain. This helps them last longer.

- Heat-treated parts wear out slower. Your car works better for more years.

Heat treating also makes cars lighter. Lighter cars use less fuel and drive better. You do not lose safety or strength.

You use these methods for wheels, frames, and engine parts. Picking the right process gives you strong, tough, and high-performing parts.

Marine

Aluminum heat treatment helps protect boats and marine gear from the sea. The 6351 alloy is good at resisting rust in saltwater. When you heat treat this alloy, it gets stronger and fights rust better.

- Heat-treated marine parts last longer in salt and wet places.

- You use these alloys for boat hulls, decks, and underwater fittings.

- The right treatment keeps your gear strong and safe in changing sea conditions.

Studies show heat treatment changes how aluminum acts in the ocean. You get better strength and more protection from rust.

Choosing heat-treated aluminum for marine use keeps boats and equipment safe and reliable for many years.

Defense

Aluminum heat treatment is important in defense. Heating aluminum makes it stronger and tougher. This helps military parts last longer. Defense systems need materials that can handle stress. They must resist damage and work for a long time. You use different heat treatments to get these results.

| Heat Treatment Method | Purpose | Benefits |

|---|---|---|

| Preheating/Homogenizing | Reduces chemical segregation, improves workability | Enhances material characteristics |

| Annealing | Softens strain-hardened structures | Stabilizes properties |

| Solution Heat Treatment | Mixes alloying elements evenly | Improves mechanical properties |

| Precipitation Heat Treatment | Hardens through controlled precipitation | Increases structural integrity |

These methods help make many defense parts. Some examples are:

- Electronic boxes that protect equipment

- Radar and communication systems with strong cases

- Cooling systems for electronics

- Vehicle and armor parts

- Fluid systems for fuel or coolant

Heat treating aluminum for defense gives three main benefits:

- Cast aluminum parts get stronger.

- The metal’s structure gets better.

- Tensile strength goes up so parts hold heavy loads.

Heat-treated aluminum lets you build lighter and stronger military gear. These parts work well in tough places.

Consumer Products

Heat-treated aluminum is used in many everyday products. This process makes items strong, light, and durable. Electronics, sports gear, and kitchen tools often use heat-treated aluminum.

Here is a table that shows how industries use heat-treated aluminum and the benefits:

| Industry | Application Areas | Performance Benefits |

|---|---|---|

| Automotive | Engine parts, structural elements, body panels | Reduced vehicle weight, better fuel efficiency |

| Aerospace | Aircraft structures, landing gear, fuselage frames | High strength-to-weight ratio, corrosion resistance |

| Construction | Facades, roofing, window frames | Durability, corrosion resistance, good looks |

You see heat-treated aluminum in:

- Laptops and phones with strong, light cases

- Bikes and sports gear that are tough and easy to carry

- Cookware and kitchen tools that do not bend and last long

Choosing products made with heat-treated aluminum means they last longer and work better.

Heat treating aluminum helps make many products safer and lighter. This process makes things more reliable for everyone.

You now know about the main aluminum heat treatments. These include annealing, homogenizing, solution heat treatment, natural aging, and artificial aging. Each process lets you change how strong, hard, or flexible the metal is. You pick the best method for your project and alloy. The temper code helps you choose the right metal for your needs.

| Metric | Value |

|---|---|

| Market size (2024) | USD 0.55 Billion |

| Projected market size (2033) | USD 0.75 Billion |

| CAGR (2026-2033) | 3.9% |

- Aerospace, automotive, and packaging need better heat treatments.

- New furnace technology helps make heat treating faster.

- The Midwest and Southeast U.S. are growing the most in this market.

FAQ

You use heat treatment to change how aluminum acts. This process lets you make the metal stronger, harder, or more flexible. You can match the metal’s properties to your project needs.

You cannot heat treat every aluminum alloy. Only heat-treatable alloys, like the 2xxx, 6xxx, and 7xxx series, respond well. Non-heat-treatable alloys get stronger through cold working instead.

You check your alloy type and the final properties you want. The temper code helps you pick the right process. You can also ask your supplier for advice.

Yes, heat treatment can change corrosion resistance. Some treatments, like T73, improve it. Others may lower it. Always check the alloy and temper for the best results.

You use tests like hardness checks, tensile strength tests, and conductivity measurements. These tests show if your aluminum has the right strength and hardness.

You can often repeat heat treatment steps, like solution treating and aging, if you follow the right process. Always check your alloy’s limits before trying again.

Quenching locks the alloying elements in place. Fast cooling helps you get the best strength and hardness. Slow cooling can lower the metal’s performance.

Tip: Always follow the recommended quenching speed for your alloy.