You need good Chinese manufacturing companies for metal stamping jobs. The list has 50 trusted makers. AFI Industrial Co., Ltd is one of these leading manufacturing companies. They know a lot about stamping and steel parts. Certifications and years of work help you pick partners who provide steady quality. These Chinese companies support big industries. They work with cars, electronics, planes, and medical tools. See what they do and who they help:

| Specialty | Industries Served |

|---|---|

| Automotive | Automotive, electronics, medical, aerospace |

| Steel Parts | Automotive, aerospace, electronics consumers |

You can use these profiles and tips to find the best supplier for your project. It makes your work of sourcing from China with confidence.

Key Takeaways

- Pick trusted metal stamping companies in China for good quality and service.

- Look for certifications like ISO 9001 and IATF 16949 to make sure they meet quality rules.

- Choose suppliers who have worked in your industry for better results.

- Check what a company can do, like their machines, and how much they can make.

- Find out how long it takes to get your metal parts so they arrive on time.

- Ask for samples before you order a lot to check the quality.

- Make strong connections with suppliers for better communication and service.

- Learn about different areas in China, like Guangdong for skilled workers and Jiangsu for technology.

Table of Contents

Top Chinese Manufacturing Companies

Metal Stamping Parts Manufacturers

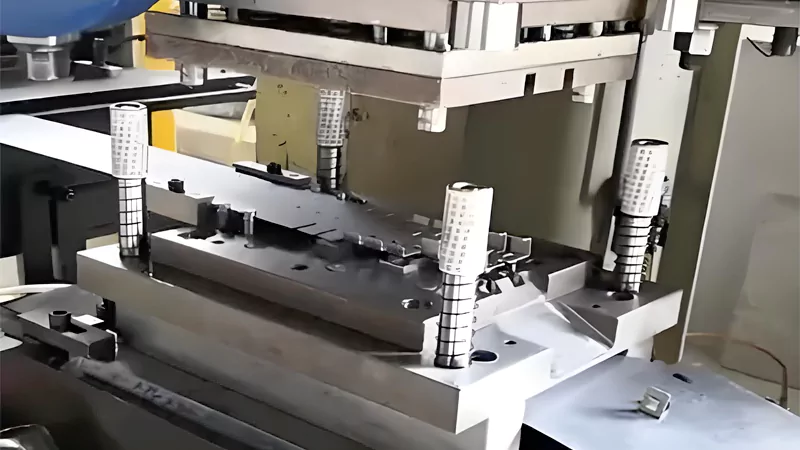

You need partners you can trust for metal stamping in China. Many Chinese manufacturing companies do advanced stamping for cars, electronics, planes, and medical tools. These companies use fast presses and special dies. They strictly enforce quality control and monitoring. You can trust their skills and certificates.

Here are some top metal stamping parts makers:

- AFI Industrial Co., Ltd (Shenzhen)

AFI Industrial Co., Ltd is a top Chinese manufacturing company. They do metal stamping, deep drawing, and progressive die stamping. The company has ISO 9001 and IATF 16949 certificates. AFI works with cars, electronics, and consumer goods. - Heju Precision Electronic Co., Ltd (Dongguan)

Heju Precision is great at high-precision metal stamping. They use new stamping machines and robots. Heju is one of “China’s Top 100 Stamping Companies.” They work with electronics, cars, and medical devices. - SEYI Machinery (China) Co., Ltd (Suzhou)

SEYI Machinery makes new stamping solutions. Their SDE Series won the “Metal Forming Industry Ringier Innovation Awards.” SEYI helps car, appliance, and electronics makers. - Dongguan Xinhongyuan Metal Products Co., Ltd

Xinhongyuan does custom metal stamping and progressive die stamping. They have ISO 9001 quality and work fast. The company makes parts for cars, home appliances, and machines. - Ningbo Zhenhai Xinxie Machinery Co., Ltd

Xinxie Machinery does precision stamping and metal forming. They give steady quality for cars and electronics.

🏆 Industry Recognition:

- Heju Precision: “China’s Top 100 Stamping Companies”

- SEYI Machinery SDE Series: “Metal Forming Industry Ringier Innovation Awards”

These Chinese manufacturing companies care about quality and new ideas. They want customers to be happy. Their metal stamping skills help you get exact parts and make many pieces fast.

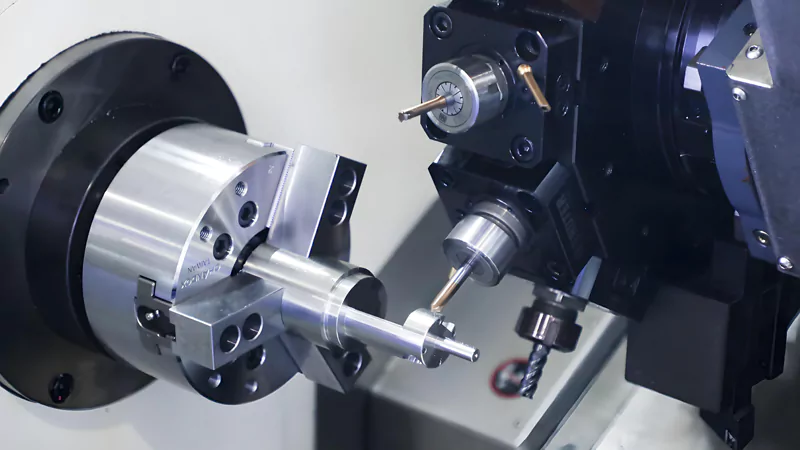

CNC Machining Specialists

CNC machining is very important for making metal parts. Many Chinese manufacturing companies buy new CNC machines and hire skilled workers. You get hard parts made with high accuracy.

Top CNC machining specialists are:

- Shenzhen Yixin Precision Metal & Plastic Ltd

Yixin Precision does CNC milling, turning, and EDM. They have ISO 9001 quality and make fast samples. The company works with electronics, cars, and planes. - Kunshan JST Industry Co., Ltd

JST Industry does CNC machining for metal and plastic. They have experience with cars, robots, and medical devices. - Dongguan PTJ Hardware Products Co., Ltd

PTJ Hardware does CNC machining, turning, and milling. They make exact parts from many materials. PTJ helps electronics, medical, and industrial companies. - Ningbo OEM Industry Manufacturer Ltd

OEM Industry Manufacturer does CNC machining and assembly. Their ISO 9001 process is good for cars and electronics. - Suzhou Wisdom International Co., Ltd

Wisdom International does CNC machining, fast samples, and small batches. They help with planes, medical, and electronics.

These Chinese manufacturing companies help you make custom parts with hard shapes. Their CNC machining helps you design and build products fast.

Sheet Metal Fabricators

Sheet metal fabrication lets you make boxes, brackets, and custom parts. Top china manufacturing companies use laser cutting, bending, welding, and finishing. They make strong sheet metal parts.

Many sheet metal fabricators work with clients from other countries. They have important certificates:

| Fabricator Name | Certifications |

|---|---|

| China ISO Certified Professional Sheet Metal Companies | ISO 9001:2015 |

| Rizhao Borhaf Metal Products Co., Ltd | ISO 9001, IATF 16949 |

You can trust these companies for steady quality. They follow world rules. They help with cars, electronics, and consumer goods.

Other top sheet metal fabricators are:

- Foshan Nanhai Huitai Technology Machine Co., Ltd

Huitai Technology does sheet metal work, laser cutting, and assembly. They have ISO 9001 quality and deliver fast. - Shanghai Metal Corporation

Shanghai Metal does sheet metal work, stamping, and welding. They have experience with big projects and many industries. - Guangzhou Dajin Precision Sheet Metal Co., Ltd

Dajin Precision makes custom sheet metal parts for electronics, telecom, and medical devices.

Chinese manufacturing companies in sheet metal work care about accuracy, speed, and service. Their skills help you finish hard projects.

Contract Manufacturing Leaders

You want a partner who helps with every step. Contract manufacturing leaders in China give full support. They help from design to delivery. These companies handle big orders and hard projects. They use advanced metal stamping and stamping technology. This meets strict industry rules. You get lots of parts, steady quality, and fast delivery.

AFI Industrial Co., Ltd is a contract manufacturing leader. This company does metal stamping, stamping, CNC machining, and assembly. You can trust their ISO 9001 and IATF 16949 certifications. AFI Industrial Co., Ltd works with cars, electronics, and medical tools. Their team helps with design, testing, and making many parts. You get help at every step.

Other top contract manufacturing leaders are:

- Foxconn Technology Group (Shenzhen): Foxconn does big metal stamping and stamping for electronics and consumer goods. Their factories use robots and digital tracking.

- BYD Precision Manufacture Co., Ltd (Shenzhen): BYD does stamping, metal stamping, and assembly for cars and electronics. Their supply chain handles raw materials and finished products.

- Great Wall Precision Industrial Co., Ltd (Jiangsu): Great Wall does stamping, metal stamping, and contract assembly. They focus on quality checks and quick work.

- Shanghai Electric Group Co., Ltd (Shanghai): Shanghai Electric does stamping, metal stamping, and system integration for energy and industry.

You can see how contract manufacturing leaders and smaller makers are different in the table below:

| Manufacturer Size | Production Capacity | Technological Capabilities | Supply Chain Complexity |

|---|---|---|---|

| Larger Manufacturers | Make lots of parts | Use advanced technology | Have complex supply chains |

| Smaller Manufacturers | Make fewer parts | Make special products | Have simple supply chains |

Contract manufacturing leaders use advanced stamping and metal stamping. You get better speed, lower costs, and fewer delays. These companies buy new machines and digital systems. You get help from their experience and strong supply chains.

💡 Tip: Pick a contract manufacturer with strong metal stamping and stamping skills. Check for certifications and good work in your industry.

Regional Highlights

China is number one in metal stamping and stamping. You find top makers in several regions. Each region has special strengths.

| Region | Key Factors Contributing to Success |

|---|---|

| Guangdong | Government help, metalworking clusters |

| Jiangsu | New technology and digital fabrication |

Guangdong is known for government help and metalworking clusters. Many stamping and metal stamping factories are in Shenzhen and Dongguan. These cities have skilled workers and buyers from around the world.

Jiangsu is good at technology and digital fabrication. Companies here use smart machines for stamping and metal stamping. You get exact parts and fast delivery.

Shanghai and nearby areas also matter a lot. Many contract manufacturers do stamping and metal stamping for cars, electronics, and consumer goods.

- China makes over half of the world’s steel.

- The country makes more than half of the global aluminum.

- China is the biggest maker of solar panels, which helps its factories.

You benefit from this size and skill. When you pick a supplier in these regions, you get the newest stamping and metal stamping technology. You also get strong supply chains and quick shipping.

🚀 Note: Regional leaders like Guangdong and Jiangsu help you get great results for your stamping and metal stamping projects.

Metal Stamping in China

Applications

Metal stamping helps make exact parts for many industries. This process shapes metal sheets into accurate pieces. You see metal stamping used in cars, electronics, planes, and medical tools. AFI Industrial Co., Ltd gives stamped parts for cars and electronics. Stamping makes brackets, connectors, enclosures, and custom metal stamping parts. Many factories in China do custom metal stamping for special designs. Stamping is fast and makes lots of parts quickly. You find stamping in consumer goods, home appliances, and machines. Stamping is good when you need parts that fit well and have steady quality.

Advantages

You get many benefits when you buy metal stamping parts from China. China is a leader in stamping because it has new technology and skilled workers. The metal stamping market is growing fast. The table below shows how big the market is:

| Year | Revenue (USD Million) | CAGR (2024-2030) |

|---|---|---|

| 2023 | 42,479.1 | N/A |

| 2030 | 62,804.9 | 5.7% |

China is a good choice for metal stamping because it saves money. Labor costs are lower, and materials are of good quality. You trust Chinese suppliers for steady quality and dependability. Many companies, like AFI Industrial Co., Ltd, follow strict quality rules. You benefit from new technology and smart ideas. Factories buy the best machines for stamping and custom metal stamping. You get parts fast and can ask for custom metal stamping for special needs.

The table below shows the main benefits of getting metal stamping parts from China:

| Advantage | Description |

|---|---|

| Cost-Effective Manufacturing | Lower labor costs and good materials help you save money. |

| Quality and Reliability | Strong quality checks give you good parts and steady results. |

| Advanced Technology and Innovation | New machines and smart ideas make production better and faster. |

| Customization and Flexibility | You can get many kinds of parts made just for you, and get them quickly. |

| Sustainable Practices | Factories care about the environment by recycling and saving energy. |

China lets you order custom metal stamping in small or large amounts. You get quick delivery and help with new products. You also benefit from green practices. Many factories recycle and use energy-saving machines for stamping. China’s metal stamping industry keeps growing. You have many suppliers and smart solutions for your projects.

💡 Tip: Pick a supplier with lots of experience and strong certificates for metal stamping. You get better parts and good value for a long time.

Top Manufacturing Companies – Rankings and Profiles

Evaluation Criteria

When you want to find the best manufacturing companies in China, you need a simple way to compare them. You should look at their experience, certifications, whether they can make custom parts, how they check quality, and if they follow industry rules. These things help you pick a partner who gives you reliable metal stamping and stamping parts.

Here is a table that lists the main things to check and some examples:

| Criteria | Example Supplier |

|---|---|

| Experience | Dongguan Jiacai Hardware (17 years) |

| Certifications | Shenzhen Yaopeng Metal (ISO compliance) |

| Customization | Zhongshan Yishang Metal (OEM/ODM) |

| Quality Verification | Xiamen MX Machining (100% on-time delivery) |

| Industry Standards | Shenzhen Tuofa (Fortune 500 collaborations) |

You should also look for certifications. The most common ones are ISO 9001, ISO 14001, and CE Certification. These show a company meets world rules for quality, safety, and the environment.

| Certification | Description |

|---|---|

| ISO 9001 | Quality management system for meeting customer and regulatory needs |

| ISO 14001 | Environmental management and compliance |

| CE Certification | Health and safety requirements for the European market |

🏅 Tip: Always ask to see certifications and check if the company has worked in your industry.

Company Strengths

You want to know what makes the top manufacturing companies special. The best companies can do precision machining, make new designs fast, add surface treatments, and meet tight tolerances. They also deliver parts quickly, so your projects stay on track.

- Precision machining makes exact parts.

- Rapid prototyping helps with new ideas.

- Surface treatments make parts last longer.

- Tight tolerances mean better quality.

- Fast lead times mean you get parts quickly.

These skills are important for aerospace, automotive, electronics, and medical devices. Companies like AFI Industrial Co., Ltd are very good at metal stamping and stamping. They use advanced machines and check quality carefully. You can trust them to give you the parts you need.

The best manufacturing companies care about quality control and making customers happy. They know that steady quality and on-time delivery help you do well. When you pick a supplier with these skills, you get reliable metal stamping parts for your business.

China Contract Manufacturing – Sourcing Guide

Selection Factors

When you look for Chinese contract manufacturing partners, you should think about a few important things. These things help you find contract manufacturing companies that give you good metal stamping and stamping parts. The table below shows what to check before you pick a supplier:

| Factor | Description |

|---|---|

| Factory Presence | Go to the factory or have someone check it. This helps you see if they follow your rules and keep up quality. |

| Evaluation of Samples | Ask for samples to see if the manufacturer can make what you need before you buy a lot. |

| Building Rapport | Try to make a good relationship with your supplier. In China, strong connections help you get better service. |

| Working with Sourcing Agent | Use a sourcing agent to help talk, make deals, and check quality. |

| Capacity | Make sure the manufacturer can handle your order size and grow with you if needed. |

| Equipment and Technology | Check if the factory uses new machines and technology for custom manufacturing. |

| OEM Contract | Sign a clear contract to protect your designs, ideas, and business. |

💡 Tip: Always ask for samples and try to visit the factory if you can. This helps you avoid problems and makes sure you get the right contract manufacturing services.

Supplier Evaluation

You want to work with contract manufacturing companies you can trust. Use these steps to check if a supplier is reliable when you buy from China:

- Check the company’s business license and registration.

- Visit the factory or have someone else check it for you.

- See how well they talk with you and how fast they answer.

- Ask for product samples, especially for metal stamping or stamping parts.

- Set up quality checks during production to find problems early.

- Read reviews and feedback from other buyers who used their contract manufacturing services.

AFI Industrial Co., Ltd. is a good example because they let you check their factory and show clear samples. They use advanced stamping equipment and have a strong record in metal stamping. You can trust their team to help you from start to finish.

When you follow these steps, you lower your risks and find contract manufacturing companies that deliver on time and meet your needs. Good suppliers help your business grow and keep your customers happy.

🚀 Note: Reliable contract manufacturing companies buy new technology and want long partnerships. Pick a partner who supports your goals and can change with your needs.

Industry Applications

Automotive

Cars and trucks need strong metal parts. Metal stamping shapes brackets, chassis parts, and connectors. Companies like AFI Industrial Co., Ltd make these for big car brands. They use advanced presses to make many parts fast. The parts fit well and last a long time. These companies follow strict quality rules. You can trust the safety of every part. Fast delivery and lower costs help you stay ahead in the car market.

Electronics

Electronics need small and exact metal parts. Stamping makes connectors, shields, and frames for devices. These include smartphones, computers, and home appliances. You want thin but strong parts. Chinese companies use high-speed presses and check quality carefully. They can make custom designs for new products. You get parts that help your devices work better and last longer. Many Chinese companies work with big electronics brands. They can handle large orders and tight deadlines.

⚡ Tip: Pick a supplier with experience in electronics. They know how important accuracy is. This helps you avoid expensive mistakes.

Aerospace

Aerospace needs the best metal parts. These parts must be light and strong. They must handle tough conditions. Chinese suppliers use advanced stamping for planes and satellites. They test every part to meet world rules.

Here are the main needs for aerospace metal parts in China:

| Requirement | Description |

|---|---|

| Material Properties | Check thermal, optical, mechanical, chemical, and electrical properties of materials. |

| Fabrication Methods | Follow design and safety rules for engines and parts in aerospace. |

| Quality Control Standards | Test parts to make sure they work well and are safe. |

Look for these features in your aerospace supplier: High strength-to-weight ratio for safer aircraft. Good corrosion resistance for harsh places. Durability for long use and fewer repairs. Can work under high heat, pressure, and stress.

Suppliers like Yijin have ISO 9001:2015 certification. They keep strict quality checks during production. They deliver high-precision parts fast, which is important for aerospace. You can trust these companies to help you meet world standards and keep things safe.

Medical

You need good metal parts for medical devices. Chinese companies know the strict rules in this field. They use advanced metal stamping and stamping for surgical tools and hospital machines. Companies like AFI Industrial Co., Ltd care about safety and accuracy. You can trust their work on medical projects.

Chinese metal parts producers follow steps to meet medical device rules:

- They check suppliers very carefully. They look at quality systems and how things are made.

- They build strong partnerships. Long-term teamwork helps keep quality steady.

- They watch and check their work all the time. Regular checks help them follow the rules and lower risks.

- They buy new machines. Precision machining and automation make better parts.

- They keep good records. Detailed notes help with audits and risk checks.

You get benefits from this careful way of working. Factories use clean rooms and special inspection tools. They test each batch to meet world standards. You get safe parts for tough medical jobs.

✅ Tip: Always ask for certificates and full records when you buy medical parts. This helps you follow world rules and avoid delays.

Chinese suppliers also make prototypes fast and can change production quickly. You can order small test batches or big orders for full use. Their skill in metal stamping and stamping gives you good results every time.

How to Choose Metal Stamping Parts Manufacturers

Capabilities

When you pick metal stamping parts manufacturers, check what they can do first. The best company should help you from start to finish. You want a partner who can do easy and hard stamping jobs. Look for factories with new stamping machines and skilled workers. These companies should make custom stamping parts, including samples and big orders.

Some important things to look for are:

- Experience with many metal stamping jobs

- Strong quality checks

- New stamping machines and tools

- Can make custom parts and samples

- Can make lots of parts for big orders

- Fast shipping and good delivery

- Good prices

- Friendly customer service

AFI Industrial Co., Ltd is a good choice because they do all these things. They help with both regular and special stamping needs. Their team helps you fix problems and make your product better.

💡 Tip: Always ask about their stamping machines and if they can make more parts when your business grows.

Certifications

Certifications show that metal stamping parts manufacturers follow strict rules for quality. You should always check for ISO 9001 and IATF 16949 certificates. These are the most important for metal stamping. They show the company meets world rules for quality and safety.

Most buyers around the world trust companies with these certificates. When you see these, you know the company checks every step of stamping. This lowers your risk and helps you get good metal stamping parts.

| Certification | What It Means |

|---|---|

| ISO 9001 | Quality management for stamping |

| IATF 16949 | Automotive quality for metal stamping |

✅ Note: About 75% of buyers pick metal stamping parts manufacturers with these certificates.

Experience

Experience is very important in metal stamping. Companies with many years in stamping know how to fix hard problems. They have worked on many projects and can handle special jobs. For example, AFI Industrial Co., Ltd has made metal stamping parts for cars, electronics, and medical tools for a long time.

Supro is good at hard stamping jobs and always does a steady job. Tenral Metal has almost twenty years of experience in precision metal stamping and custom work. Xinhongyuan is a leader in car stamping by using skill and new ideas.

When you pick a company with lots of experience, you get better parts and fewer mistakes. These companies know how to meet tight rules and deliver on time. You can trust them to keep your stamping project going well.

🚀 Tip: Ask for examples of old stamping jobs. This helps you see if the company can do what you need.

Communication

You need clear and quick communication with metal stamping parts manufacturers. Good communication helps you stop mistakes and delays. Find a supplier who answers fast and explains each step. A company like AFI Industrial Co., Ltd gives updates and listens to your needs. They use easy words and show drawings, samples, and test results. This makes your project easier to handle.

Test a supplier’s communication by sending questions before you order. See how fast they reply and if their answers are clear. Good communication builds trust and helps fix problems early. If a company uses email and instant messaging, you get help faster. You also want a supplier who can talk about design or production changes. This helps you get the right metal stamping parts for your business.

💬 Tip: Always ask for one main contact person. This makes it easier to fix problems and get updates on your order.

Lead Times

Lead times are very important in metal stamping and stamping. You want your parts on time so your project stays on track. The best suppliers give a clear timeline for each step. They tell you how long it takes to make samples, start production, and ship your order.

Some companies use new machines and automation to work faster. This helps you get parts quickly, even for big orders. If a supplier has a strong supply chain, you get steady delivery with fewer delays. Always ask for a detailed schedule before you order. This helps you plan your project and avoid surprises.

You can compare lead times by asking for sample timelines from different suppliers. Pick a company that meets your deadlines and can handle rush orders if needed.

⏱️ Note: Fast lead times help you launch products sooner and keep your customers happy.

Pricing

Pricing for metal stamping and stamping parts can change for many reasons. You should know what affects the cost before you pick a supplier. Companies like AFI Industrial Co., Ltd set prices by looking at the design, order size, and how hard the job is. If you need special dies or complex shapes, the price may be higher.

Metal stamping die manufacturers often work with automotive and aerospace. These industries need high-quality parts, which can change the price. Some suppliers use new machines and automation to lower labor costs. Others use older tools to save money, but this can affect quality.

Here is a table that shows what affects pricing for metal stamping:

| Factor | Description |

|---|---|

| Automation | The more automated the process, the lower the labor cost and the better the price. |

| Design Optimization | Skilled engineers can make designs more efficient, saving you money in production. |

| Equipment Modernity | New machines give better results but may cost more at first. |

You should also look at these points when you compare prices:

- Modern machines and dies improve quality and performance.

- Automation lowers manpower and can cut your costs.

- Good engineers can make your design better for long-term savings.

Always ask for a full quote that lists all costs, including tooling, samples, and shipping. This helps you avoid hidden fees and compare offers from different suppliers. Pick a company that gives you fair prices and steady quality for your metal stamping needs.

💡 Tip: Do not pick the cheapest option without checking quality and service. The best value comes from a balance of price, quality, and support.

Regional Overview

Shenzhen

Shenzhen is a global center for making metal parts. Many top suppliers are here, like AFI Industrial Co., Ltd. The city leads in metal stamping because it has new technology and skilled workers. If you buy from Shenzhen, you get many good things:

| Advantage | Description |

|---|---|

| Precision Manufacturing | Good sheet metal parts match exact needs and make products better. |

| Cost Efficiency | Quality parts help you waste less and save money. |

| Enhanced Production Speed | Top suppliers work fast, so you get parts quickly. |

| Sustainability | Good parts help factories work better and protect the environment. |

Shenzhen suppliers check quality carefully and ship fast. Most factories use new machines and robots. This helps you get exact metal stamping parts for cars, electronics, and medical tools. Shenzhen likes new ideas and working quickly, so it is a great place for your projects.

Dongguan

Dongguan is special for making metal parts. You can pick from many ways to make things. This helps you choose what is best for your project. Dongguan has many material suppliers and skilled makers. They care about quality and making things right, which makes Dongguan different.

You can use many methods in Dongguan:

- Precision CNC machining for detailed parts

- Additive manufacturing for quick samples

- Traditional die casting for lots of parts

This means you always find what you need. Dongguan’s network helps with small and big orders. You get good stamping and metal stamping for cars, planes, and electronics. The city is known for quality and being flexible, so it is smart to buy metal parts here.

Jiangsu

Jiangsu is another big place for making metal parts. You get help from strong factories and new buildings. Many factories buy new machines and hire skilled workers. This area is known for using new technology and digital tools. You find suppliers who make very exact stamping parts for hard jobs.

Jiangsu’s factories often work on big projects. They finish work quickly and keep quality steady. You can expect careful checks and new ways to make things. Many companies work with big car, electronics, and medical brands. If you choose Jiangsu suppliers, you get partners who help you finish work on time and meet high standards.

Foshan

Foshan is a big place for making metal parts in southern China. There are many factories here that do metal stamping and stamping. These companies use new machines and skilled workers to make good parts. You can buy brackets, enclosures, and custom pieces for many uses. These include appliances, lighting, and building projects.

Foshan suppliers often work with buyers from other countries. They know world rules and can meet your quality needs. Many factories have ISO 9001 certificates. You get help from their export experience and their skill with small or large orders.

If you need parts fast, Foshan companies can help you. They use quick production lines and let you order different amounts. You get on-time delivery and good help after you buy. Some top companies in Foshan also help with design and surface finishing.

💡 Tip: Ask Foshan suppliers if they have worked in your industry. This helps you get the right parts for your job.

Guangzhou

Guangzhou gives you many choices for metal parts. There are lots of factories here that do stamping and metal stamping. The city has a strong supply chain for materials and shipping. This means you get steady work and fast shipping.

You can work with Guangzhou suppliers for cars, electronics, and consumer goods. These companies buy new machines and check quality carefully. You get parts that meet strict rules. Many factories in Guangzhou also help with assembly and packing. This makes it easier to manage your orders.

Guangzhou is close to big ports, so you save time and money on shipping. You can visit factories and see how they work. This gives you more control and helps you build good partnerships.

- Main benefits of Guangzhou suppliers:

- Good shipping network

- Careful quality checks

- Easy order changes

Shanghai

Shanghai is a top place for high-quality manufacturing in China. You find many top suppliers here, like AFI Industrial Co., Ltd. They do precision metal stamping and stamping. These companies use the newest machines and follow world rules. You get parts with tight sizes and smooth finishes.

Shanghai suppliers work on hard jobs in aerospace, medical, and cars. They focus on new ideas and always try to get better. You get help from their tech team and their skill with tough projects. Many factories in Shanghai also do fast samples and engineering help.

If you need a partner for big or special orders, Shanghai is a good pick. You get skilled engineers and strong project teams. The city’s business style makes it easy to talk and work with suppliers.

🚀 Note: Pick Shanghai suppliers when you need new machines and strict quality checks for your metal parts.

Related Services

Warehousing

You need a safe place to keep your metal parts before shipping. Many top suppliers in China have warehousing services. These services help keep your products safe and ready to send out. AFI Industrial Co., Ltd has modern storage with climate control and security. You can keep metal stamping parts and finished stamping products there until you need them. This helps you manage your stock and avoid waiting.

Warehousing in China gives you these benefits:

- Lower storage costs than in other countries

- Easy access to ports and airports for shipping

- Real-time tracking of your inventory

- Flexible space for small or big orders

You can ask your supplier to keep your goods until you want to ship them. This makes your supply chain work better and helps you plan.

Fulfillment

Fulfillment services help you get products to customers fast. Chinese metal parts producers often pick, pack, and ship orders for you. You do not have to do these steps yourself. Companies like AFI Industrial Co., Ltd pack metal stamping parts carefully and get them ready to send. They use strong boxes to protect your stamping products during shipping.

Key features of fulfillment services are:

- Order processing and tracking

- Custom packaging and labels

- Fast help with urgent orders

- Handling returns

You save time and make fewer mistakes with fulfillment services. Your customers get their orders faster, and you can focus on your business.

Logistics

Logistics connects your products from the factory to your door. Chinese metal parts producers offer many logistics services for buyers in other countries. You can choose end-to-end logistics, which covers everything from storage to delivery. Many suppliers set up shipping, handle export papers, and check quality before shipping.

Here are common logistics solutions you can get:

- End-to-end logistics and export help

- Shipping by sea, air, or land

- Quality checks before shipping

- Import/export help for easy customs

You can also get help with finding metal products and checking if suppliers follow rules. Some companies find the cheapest way to ship their goods. This helps you save money and avoid delays.

🚚 Tip: Ask your supplier if they have real-time tracking and quality checks during shipping. This helps you feel safe and fix problems fast.

A good logistics partner makes sure your metal stamping and stamping parts arrive safely and on time. You get better results when you work with experienced companies like AFI Industrial Co., Ltd.

Consulting

Sometimes you need help when buying metal parts from China. Consulting services help you make good choices and avoid mistakes. Many top suppliers, like AFI Industrial Co., Ltd, give consulting to help you with your project.

Consulting teams know a lot about the metal stamping industry. They help you pick the right materials, designs, and ways to make parts. You get advice on stamping methods that match your needs. If you want to make your product better or save money, a consultant can help you find the best way.

Here are some ways consulting services help your business:

- Project Planning: Consultants help you set goals and plan your project. You learn how to organize your metal stamping work for success.

- Supplier Selection: Experts help you find good stamping partners. They check certificates, quality systems, and past jobs.

- Process Optimization: You get tips to make your stamping process faster and better. This can save you time and money.

- Quality Control: Consultants show you how to check quality at every step. You learn to find problems early and keep your parts good.

- Regulatory Guidance: If you sell in other countries, you must follow the rules. Consulting teams explain these rules and help you follow them.

💡 Tip: Always ask your consultant for a clear plan. This helps you see your progress and reach your goals.

You can also use consulting services to train your team. Many companies have workshops on metal stamping and stamping technology. Your staff learns new skills and keeps up with new trends.

A good consultant listens to what you need. They answer your questions and give honest advice. You get help with drawings, cost checks, and schedules. If you have a problem, your consultant finds a quick answer.

The table below shows what you get from a consulting service:

| Service Area | What You Get |

|---|---|

| Technical Advice | Help with designs and materials |

| Supplier Audits | Checks on factory quality |

| Cost Analysis | Ways to save money |

| Training | Staff workshops and skill updates |

When you work with a trusted company like AFI Industrial Co., Ltd, you get years of experience. Their consulting team helps you avoid risks and get the most from your metal stamping project. You make better choices and grow your business with confidence.

You can count on many metal stamping companies in China, like AFI Industrial Co., Ltd, to give you good results. Use simple ways to pick the best supplier for what you need. Start by talking to your favorite companies, asking for prices, and ordering some samples. Keep checking your suppliers often to do well for a long time. Pay attention to these important things:

| Factor | Description |

|---|---|

| Quality | Look at how the supplier checks and controls quality. |

| Capacity | Make sure the supplier can handle your order size and deliver on time. |

| Risks | Watch out for problems with delivery, the market, or following rules. |

| Costs | Check prices and make sure the company is strong with money for your stamping jobs. |

Working well with your metal stamping partners helps your business get bigger.

FAQ

Look for ISO 9001 and IATF 16949 certificates. These mean the company follows strict quality rules. Many trusted Chinese suppliers, like AFI Industrial Co., Ltd, have these certificates.

Contact the supplier and ask for a sample. Most companies give samples before big orders. This lets you check if the quality and fit are right.

Metal stamping parts are used in cars, electronics, planes, medical, and consumer goods. Chinese makers help many big brands in these areas.

Check their certificates and visit the factory if you can. Ask for references and read customer reviews. Also, check their business license to be sure.

Lead times depend on order size and how hard the job is. Samples usually come in 7–10 days. Big orders take about 2–4 weeks.

Yes, many Chinese makers take small orders. You can ask for custom designs and test samples before making more.

Most suppliers take wire transfers, PayPal, and letters of credit. Always check payment rules before you order.

Suppliers often help with shipping from start to finish. You can pick sea, air, or express shipping. Tracking and customs help are also offered for buyers in other countries.